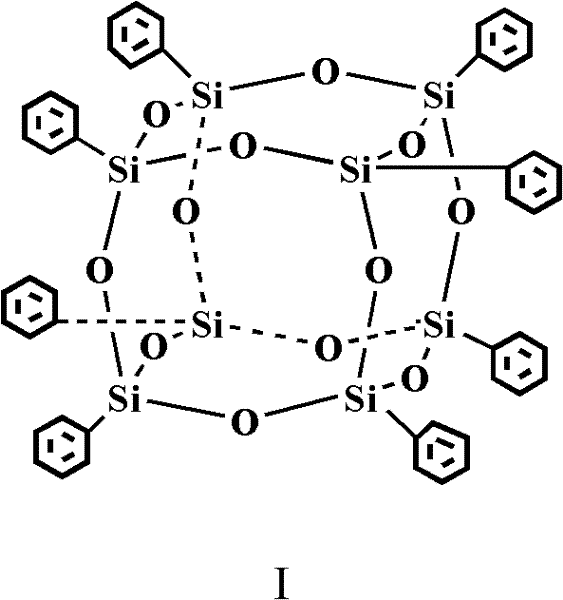

Preparation method of cage poly (phenylsilsequioxane)

A technology of polysilsesquioxane and phenyltrialkoxysilane, which is applied in the field of organic-inorganic hybrid materials, can solve the problems of complex structure of raw material monomers and low product yield, and achieve industrial scale production, The effect of high reuse rate and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

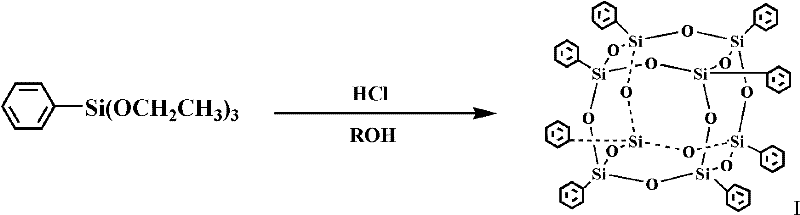

Method used

Image

Examples

Embodiment 1

[0030] Add 200.0mL ethanol and 20.0mL phenyltriethoxysilane monomer into a 500.0mL three-necked round-bottom flask, stir and mix evenly, add 15.0mL hydrochloric acid (36.0wt%) dropwise to the above mixed solution within 40min, and keep stirring Speed, control the reaction temperature at 55 ° C, hydrolysis polycondensation 72h. After the reaction was completed, it was lowered to room temperature, and the reaction mother liquor was removed by filtration to obtain a white powdery solid. The obtained solid was washed with methanol, recrystallized from dichloromethane, and vacuum-dried to obtain 6.88 g of a solid product with a yield of 64.3%.

[0031] Structural characterization data: FTIR, 1110cm -1 (νSi-O-Si), 1135cm -1 (νSi-C), 3094cm -1 , 3073cm -1 and2924cm -1 (νC-H), 1595cm -1 and 1491cm -1 (νC=C); 1 H-NMR, δ=7.802-7.399, (CDCl 3 ); 13 C-NMR, 135.89ppm, 130.14ppm and 128.53ppm (CDCl 3 ); 29 Si-NMR, -78.47ppm (CDCl 3 ).

Embodiment 2

[0033] Add 240.0 mL of methanol and 9.0 mL of concentrated hydrochloric acid (28.0 wt %) into a 500.0 mL three-necked round-bottom flask, and stir to mix evenly. Under mechanical stirring, 25.0 mL of phenyltrimethoxysilane monomer was added dropwise into the mixed solution within 30 minutes, the reaction temperature was controlled at 35° C., and hydrolysis and polycondensation were allowed to stand for 76 hours. After the reaction was completed, it was lowered to room temperature, and the reaction mother liquor was removed by filtration to obtain a white powdery solid. The obtained solid was washed with methanol, recrystallized with dichloromethane, and vacuum-dried to obtain 9.42 g of a solid product with a yield of 70.4%.

Embodiment 3

[0035] Add 280.0 mL of isopropanol and 20.0 mL of concentrated hydrochloric acid (30.0 wt %) into a 500.0 mL three-neck round bottom flask, and stir to mix evenly. Under mechanical stirring, 30.0 mL of phenyltriethoxysilane monomer was added dropwise into the mixed solution within 35 minutes, the reaction temperature was controlled at 50° C., the stirring speed was constant, and hydrolysis and polycondensation were carried out for 82 hours. After the reaction was completed, it was lowered to room temperature, and the reaction mother liquor was removed by filtration to obtain a white powdery solid. The solid obtained by washing with ethanol was recrystallized with a mixed solvent of dichloromethane and acetone (3:1 volume ratio), and vacuum-dried to 15.09 g solid product, yield 72.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com