Patents

Literature

53results about How to "No manual fixation required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

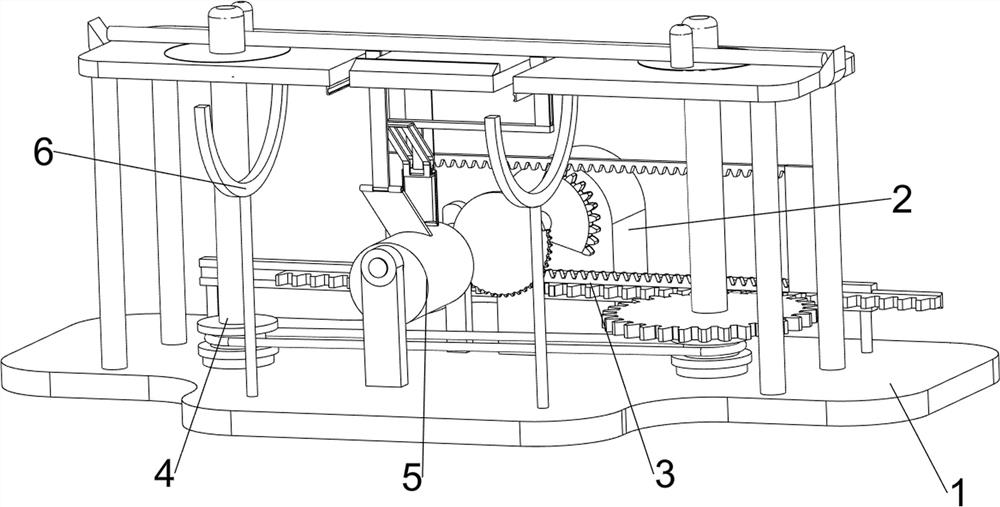

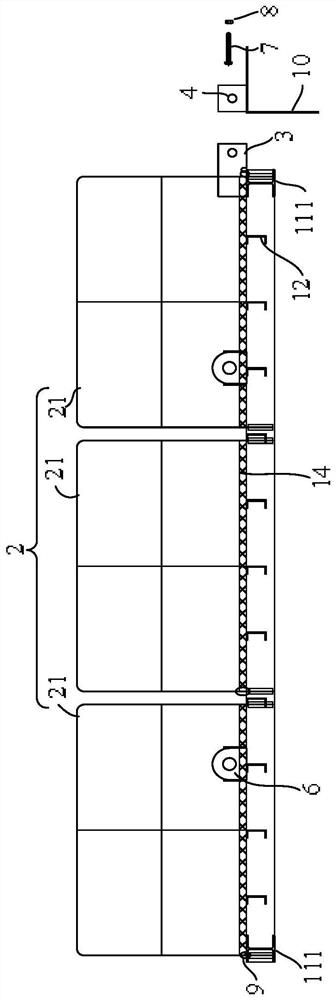

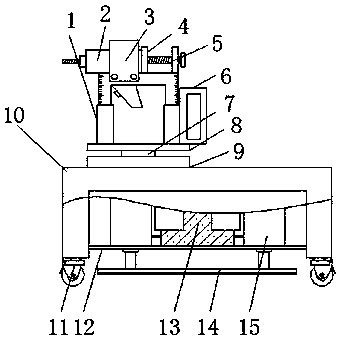

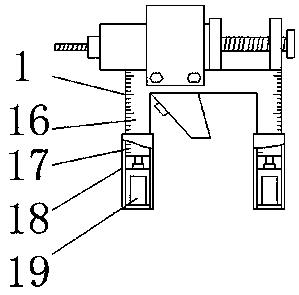

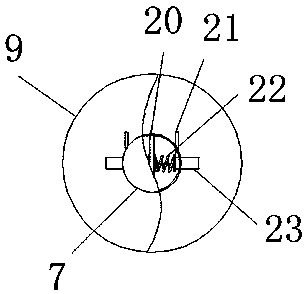

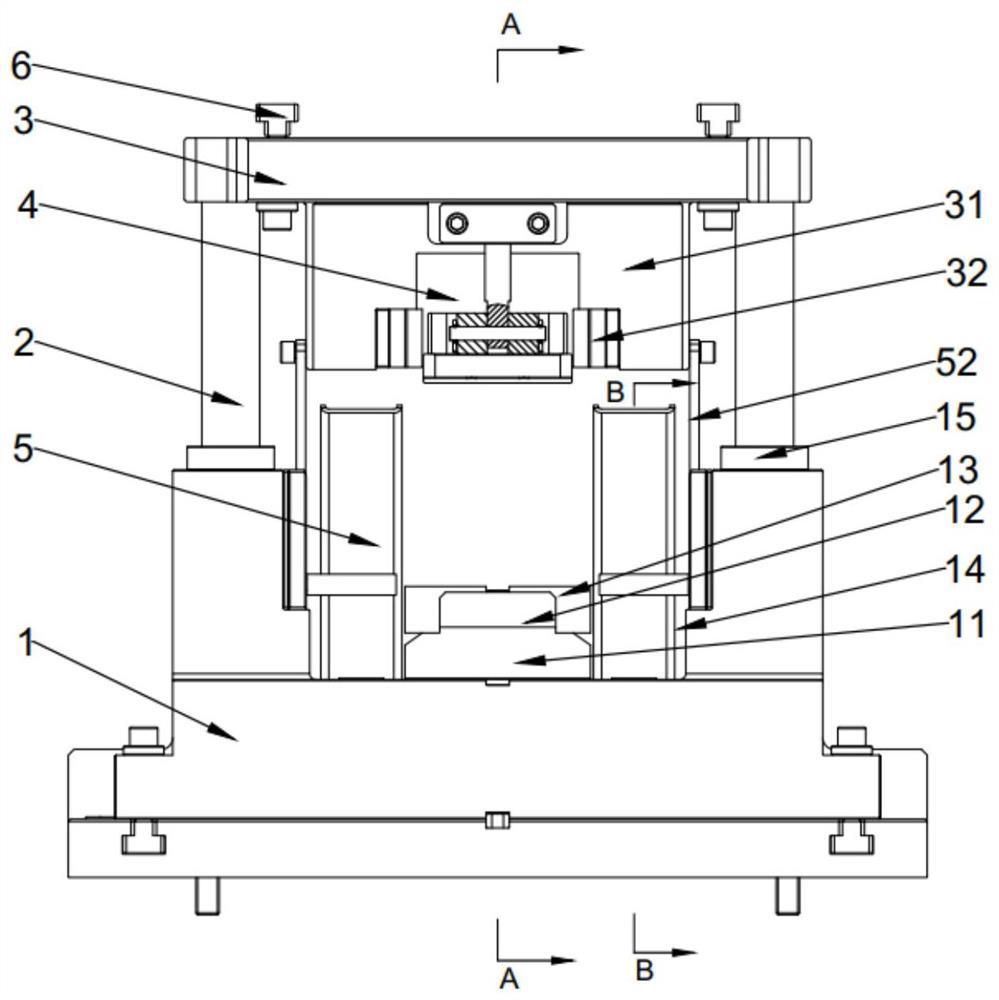

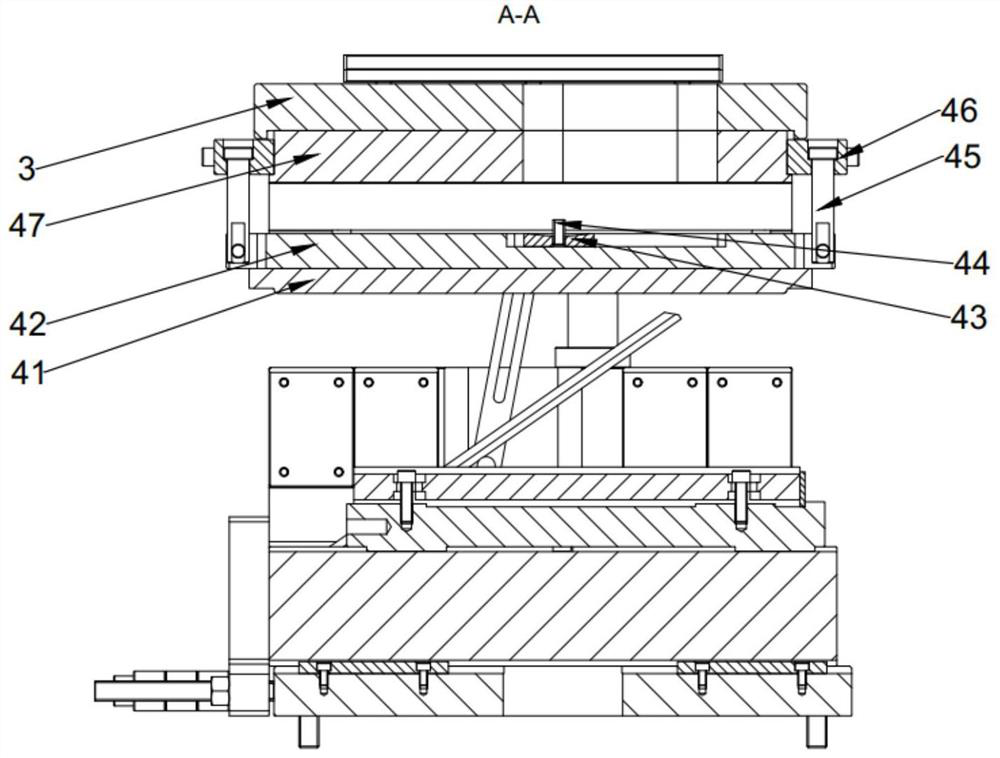

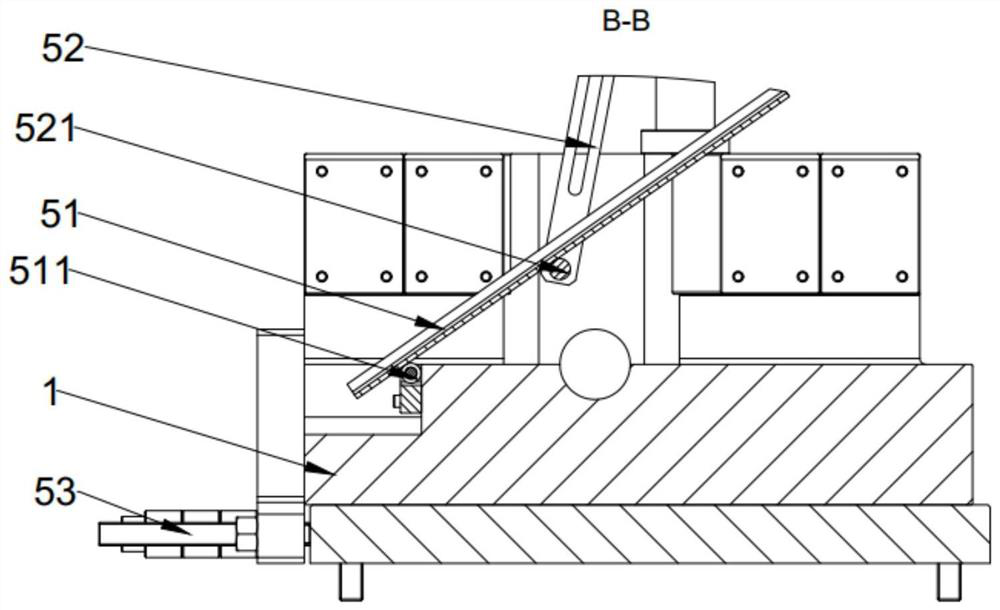

Indentation mechanism for automatic paperboard compression of corrugated cases

InactiveCN104999700AMeet depth requirementsImprove efficiencyPaper-makingBox making operationsPaperboardEngineering

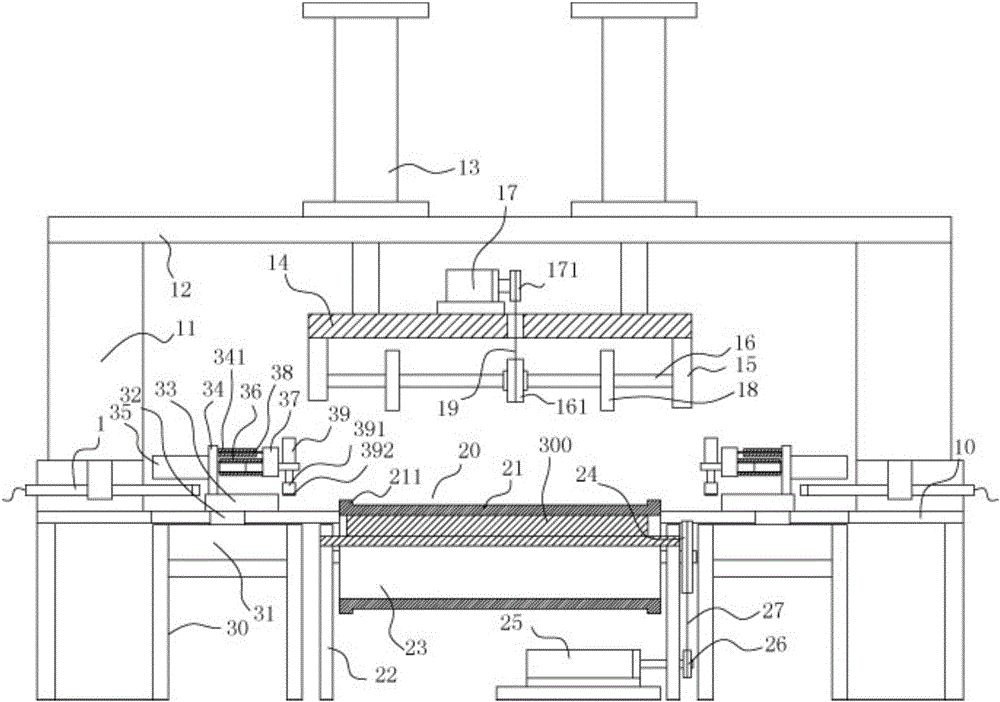

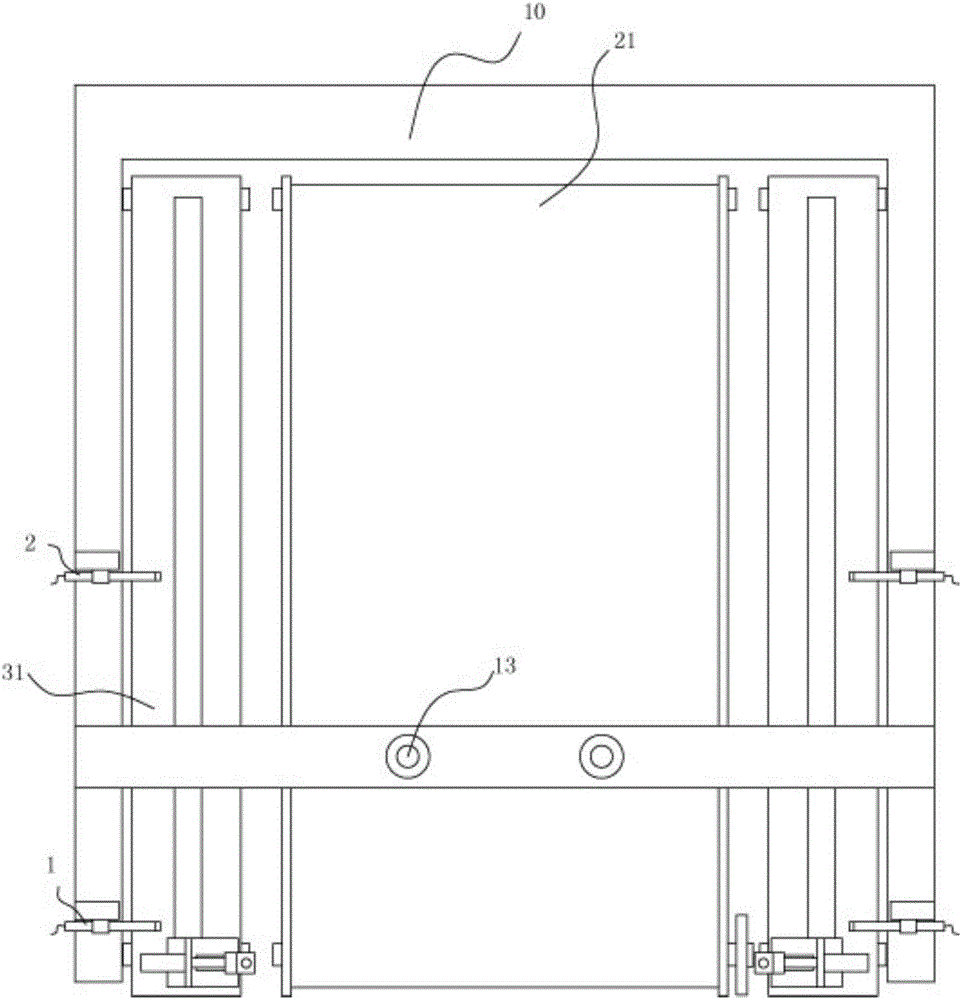

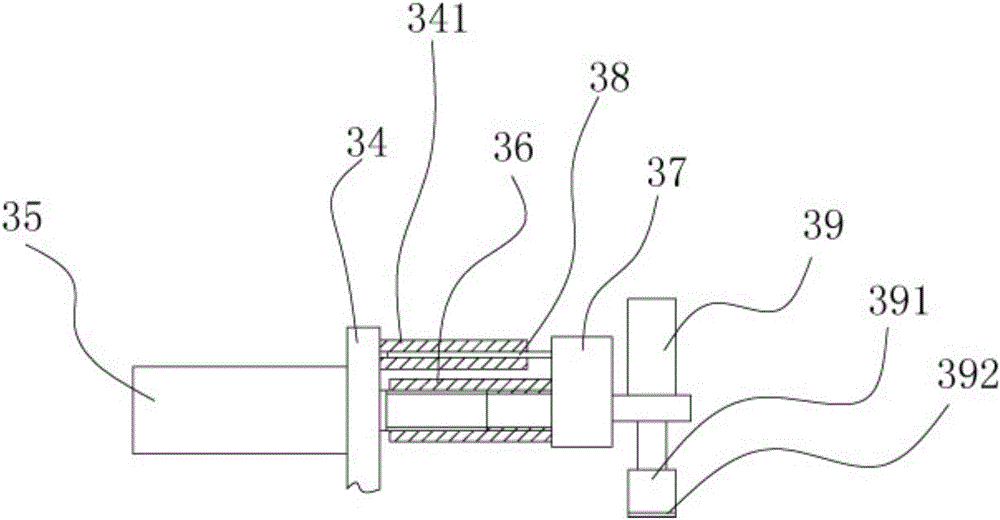

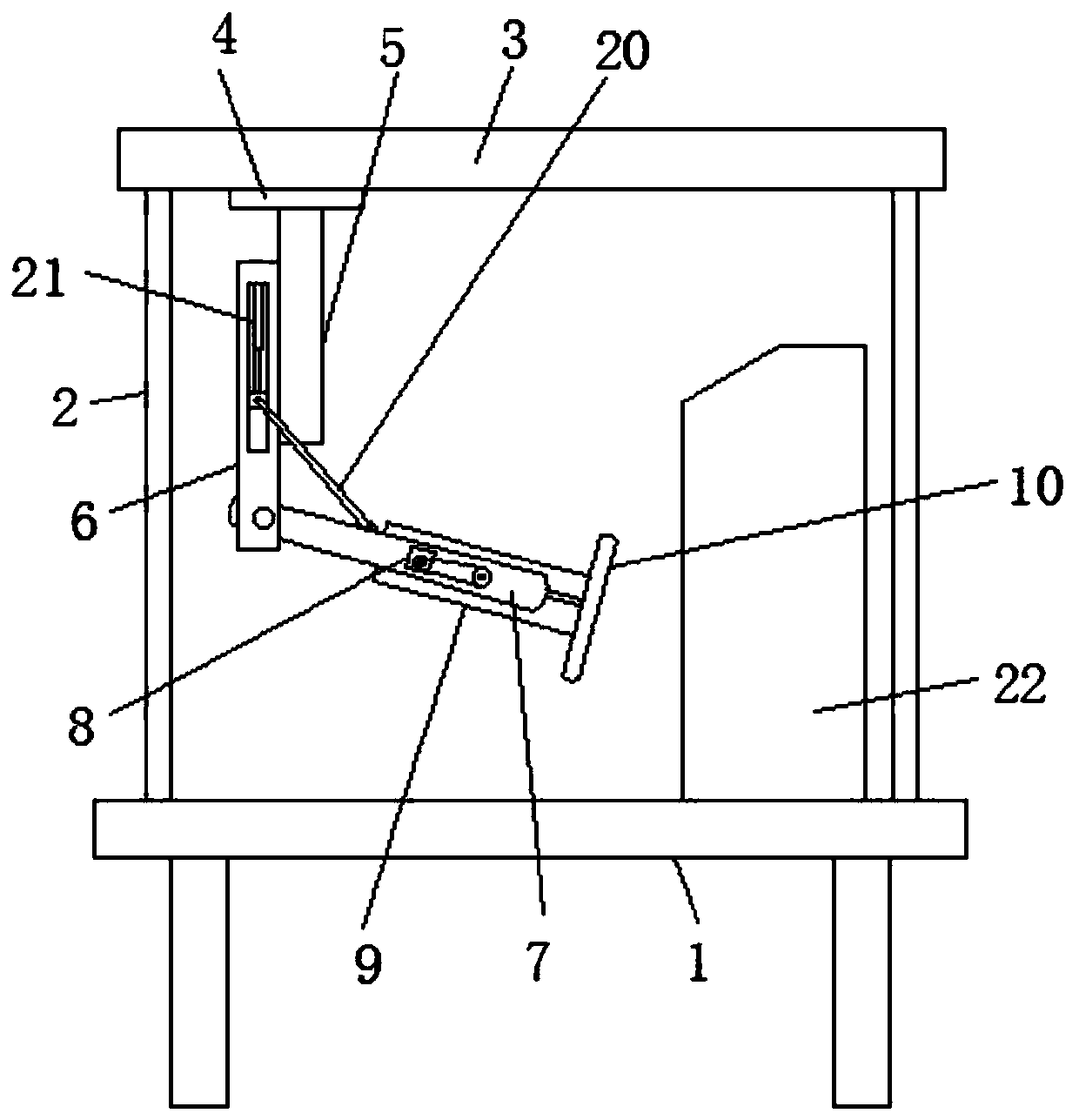

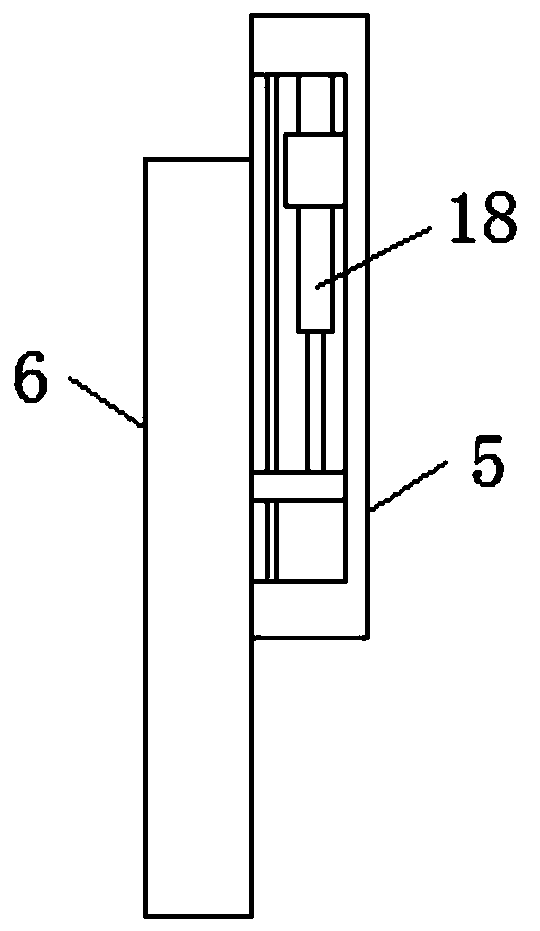

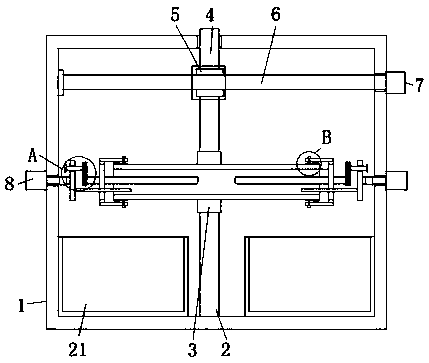

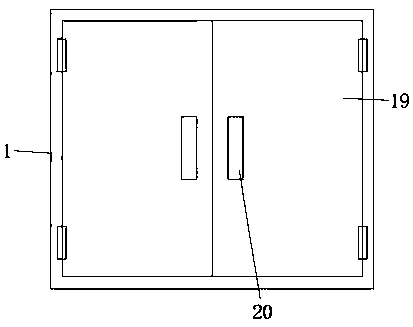

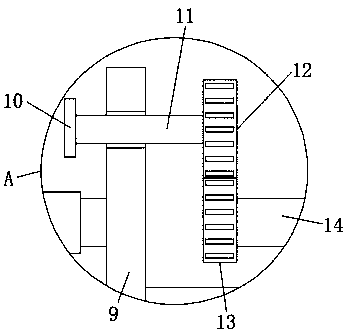

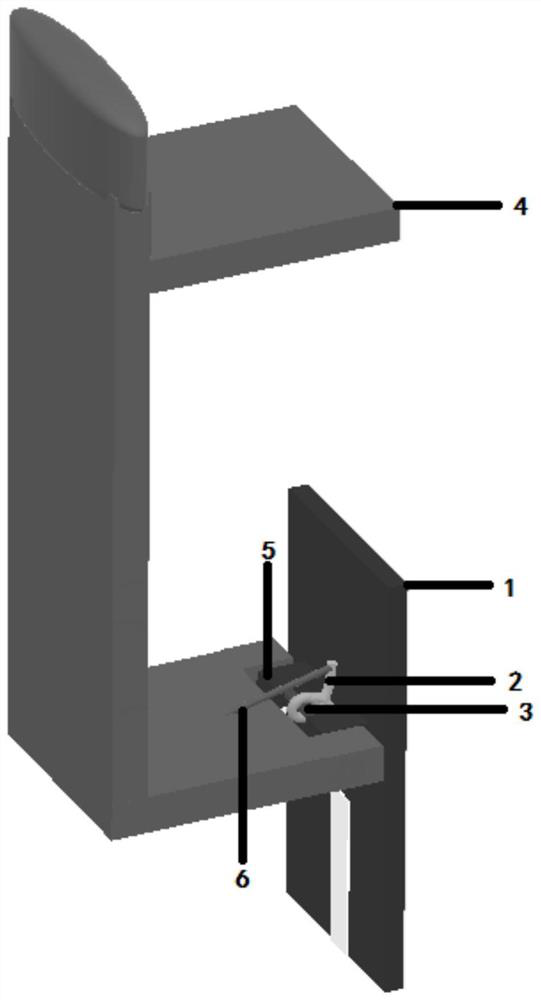

The invention discloses an indentation mechanism for automatic paperboard compression of corrugated cases. The indentation mechanism comprises a U-shaped machine frame. A conveyor belt device and two mobile racks are arranged in the U-shaped machine frame, and the two mobile racks are located on the two sides of the conveyor belt device. A first proximity switch and a second proximity switch are fixed to top plates on the left and right sides of the U-shaped machine frame respectively. Vertical supporting plates are fixed to the left and right sides of the portion, between the first proximity switch and the second proximity switch, of the U-shaped machine frame. An upper supporting plate is fixed to the two vertical supporting plates. Two downward-pressing air cylinders are fixed to the upper supporting plate. Push rods of the downward-pressing air cylinders penetrate through the upper supporting plate vertically and downwards and are fixedly provided with a driving plate. Two connection plates are fixed to the bottom face of the driving plate. The two ends of a rotary rod are hinged to the connection plates. An indentation driving motor is fixed to the driving plate. An indentation driving wheel is fixed to an output shaft of the indentation driving motor. The indentation mechanism can automatically fix paperboards on a conveyor belt and can also automatically release the paperboards. Meanwhile, indentation rollers can be adjusted vertically.

Owner:浙江骏驰纸制品有限公司

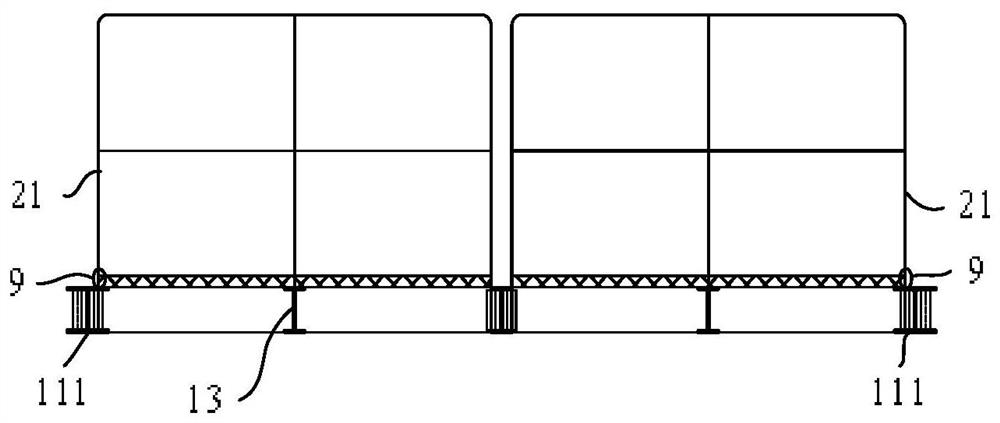

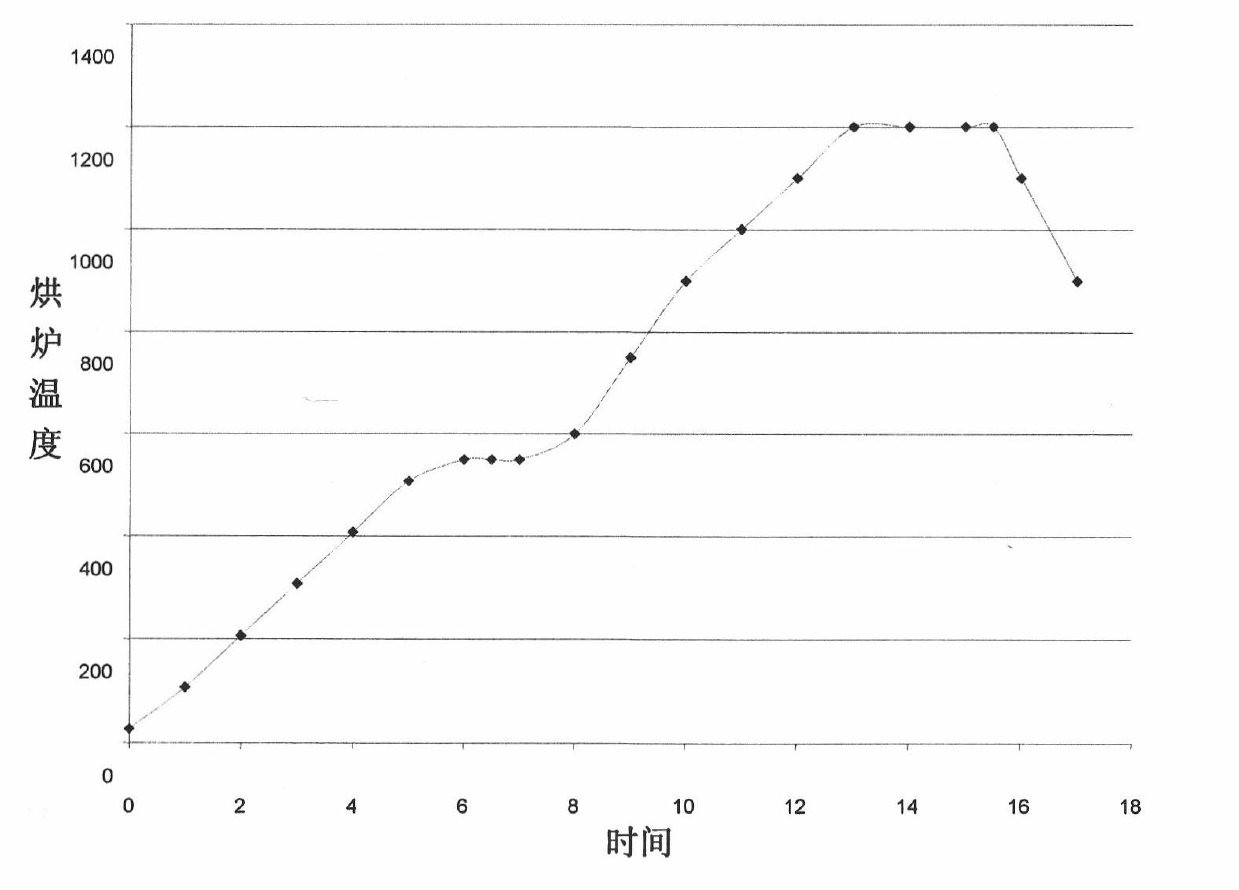

Biochemical ceramic as well as preparation method and application thereof

InactiveCN101475362AAvoid washing awayNo manual fixation requiredTreatment using aerobic processesSustainable biological treatmentEutrophicationFiltration

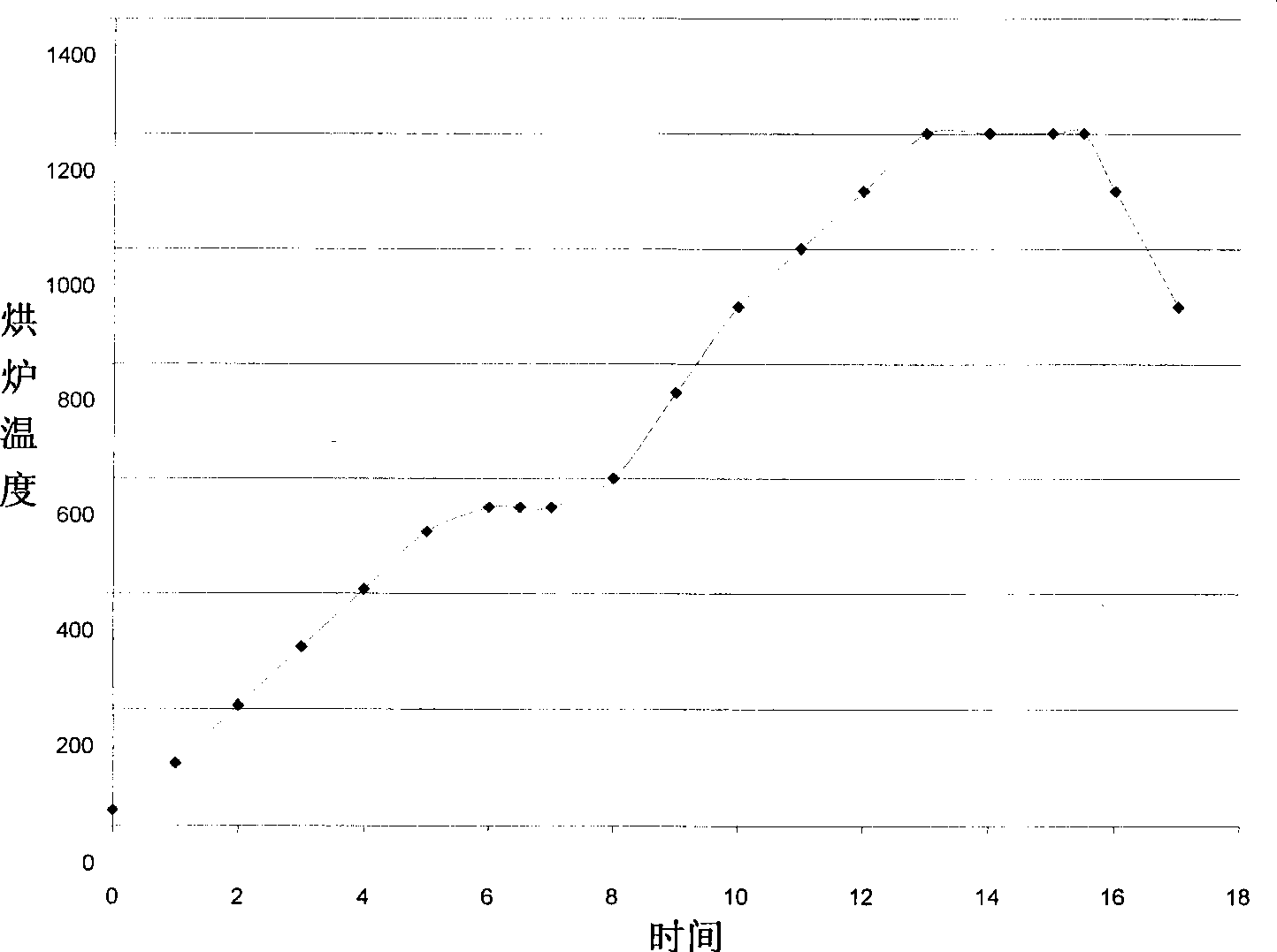

The invention relates to biochemical ceramic and a preparation method and application thereof. The biochemical ceramic adopts wastewater sludge as a main raw material and is prepared through the supplementary materials of calcium carbonate or gypsum, clay, dehydrate calcium hydroxide, liquid wax, iron dust or brown iron oxide via anoxic burning. The biochemical ceramic can be used as a biological medium of a granular sludge bed in a biological filter or a trickling filter or during the anaerobic treatment, and can also be used for reducing the water body eutrophication or build a filtration dam to reduce the pollution caused by the wastewater. The retractable biochemical ceramic can automatically fix bacteria so as to prevent the biomass from being flushed away without artificial fixation, and can immobilize the heavy metal elements in the sludge and release no heavy metal elements in the application process. The biochemical ceramic can be used for preparing cogs with different shapes and sizes; therefore, the biochemical ceramic has a wider application prospect.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

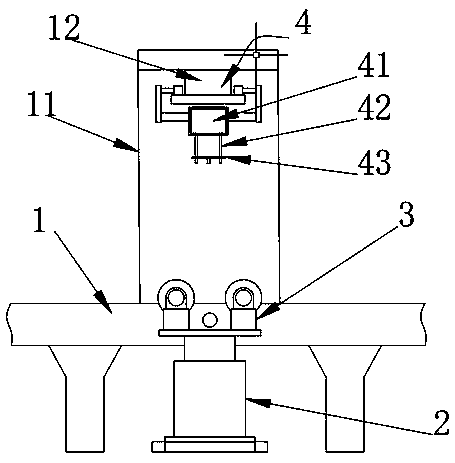

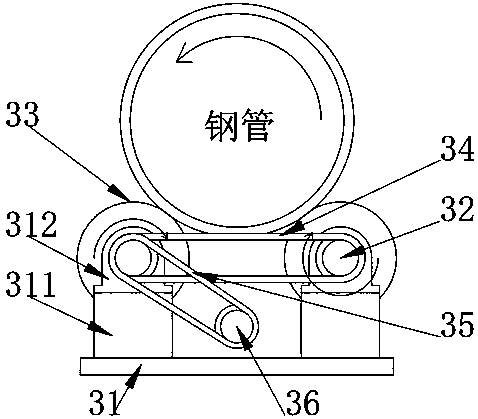

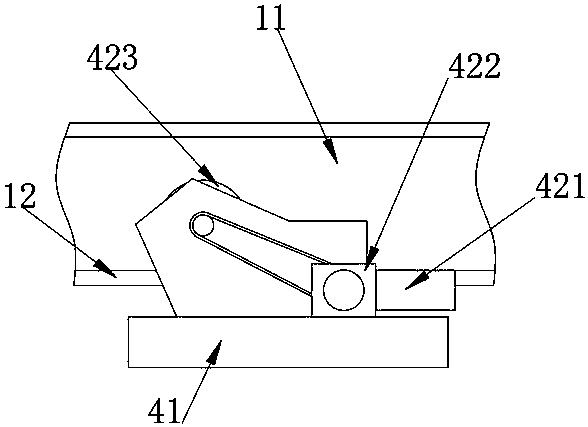

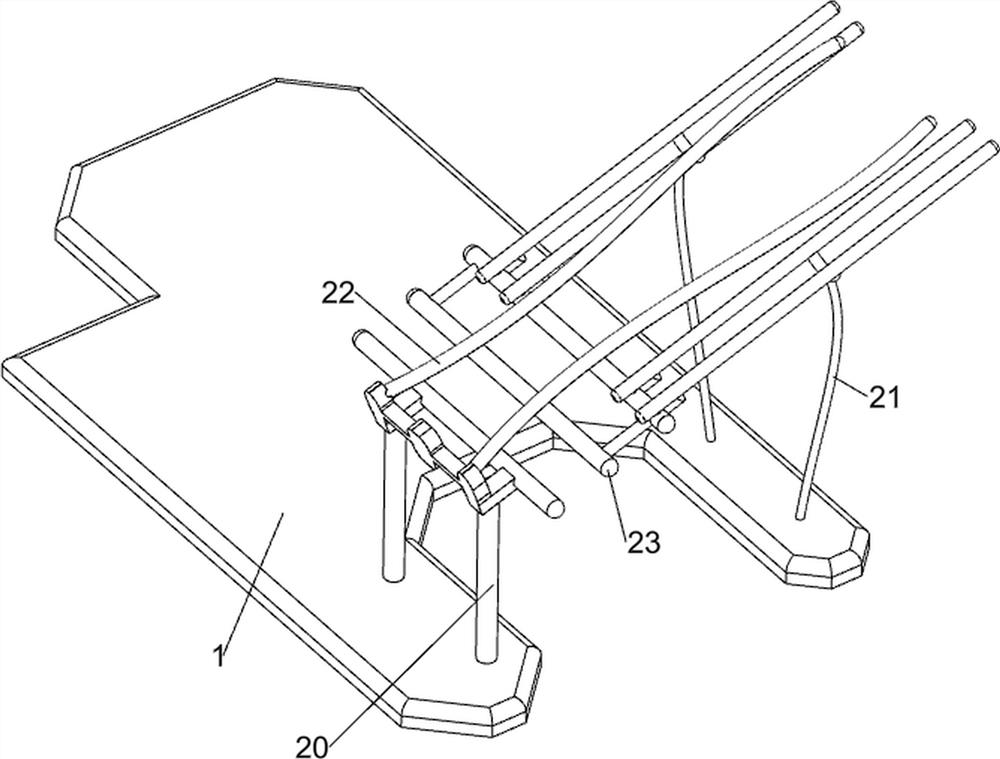

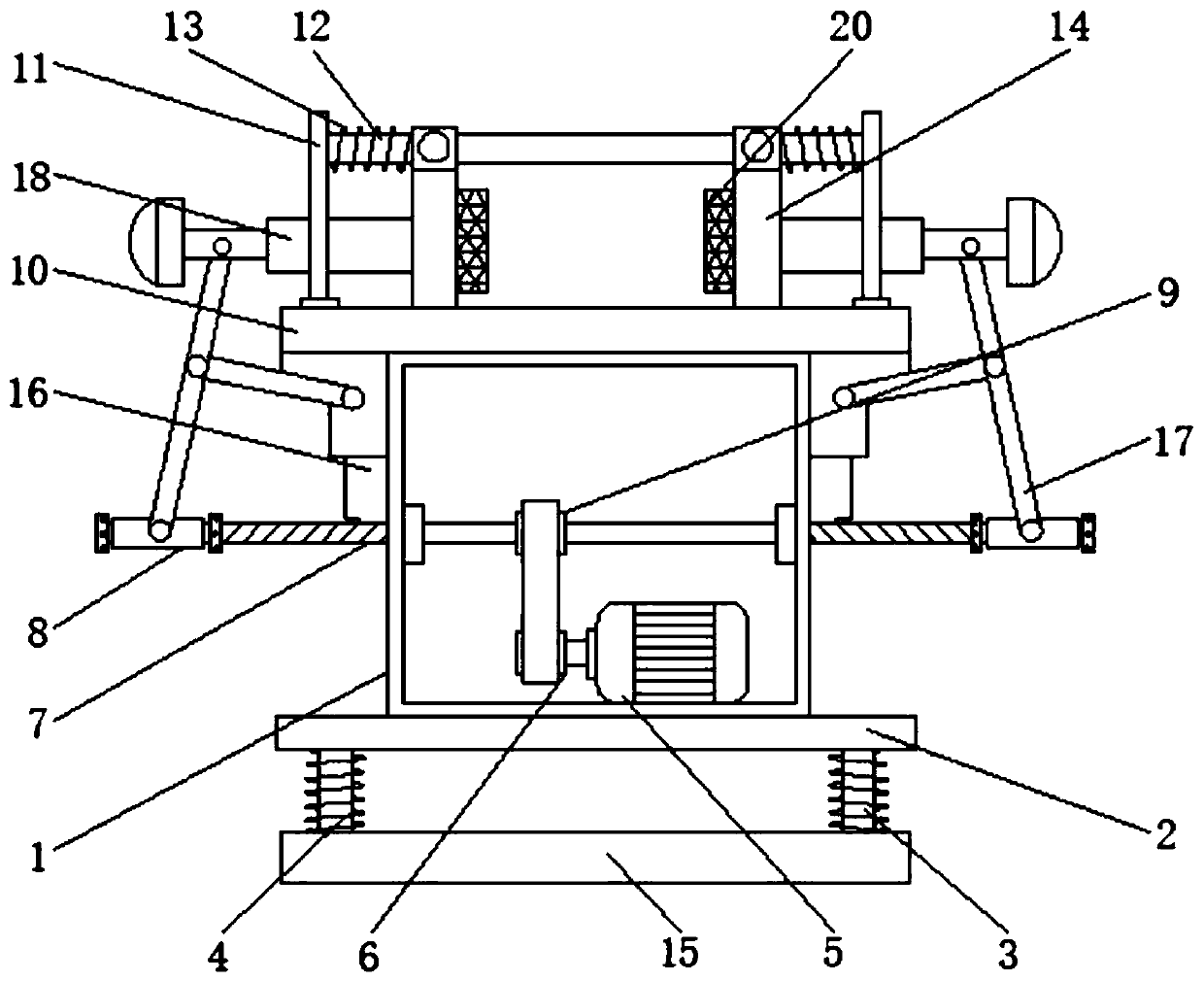

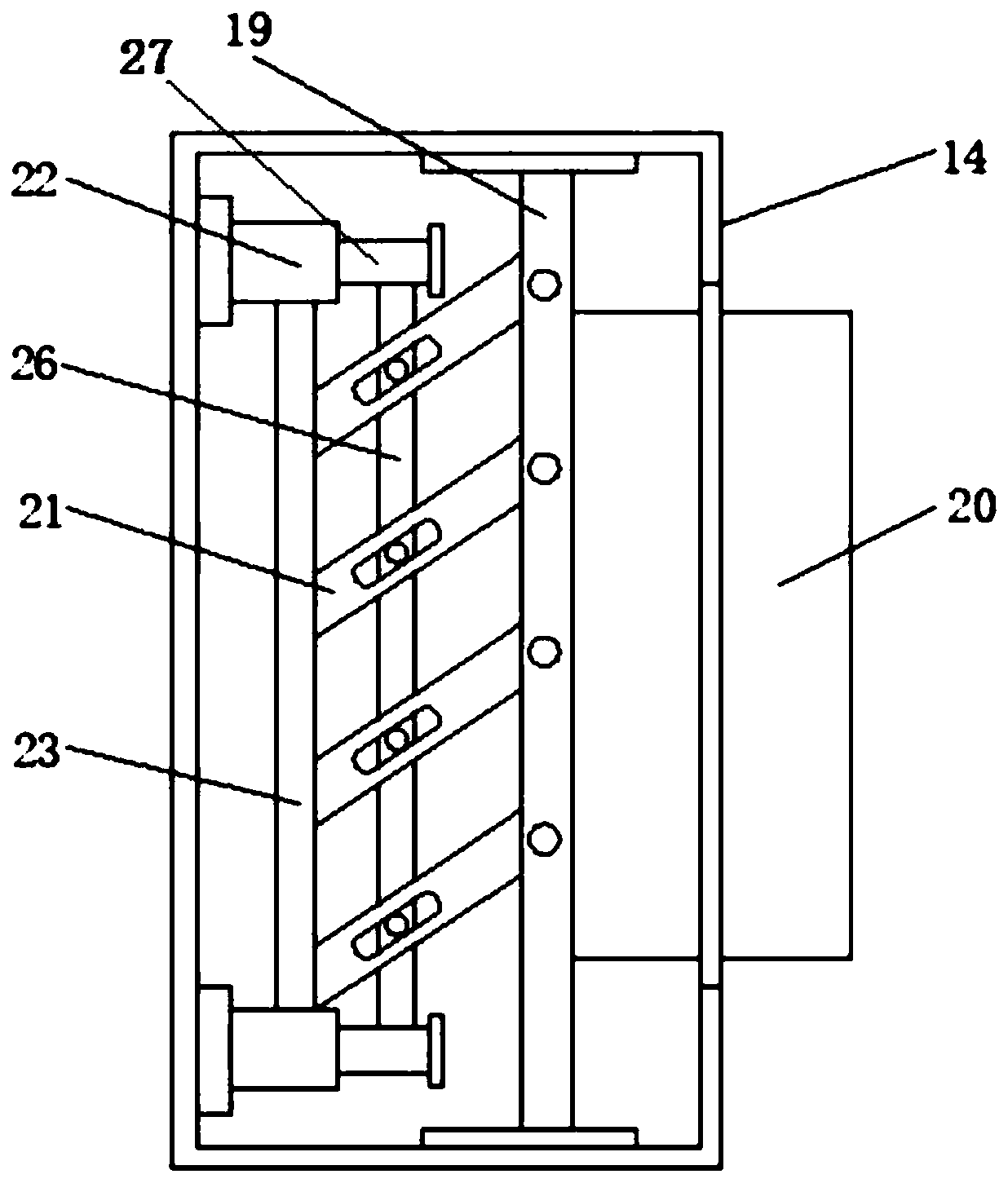

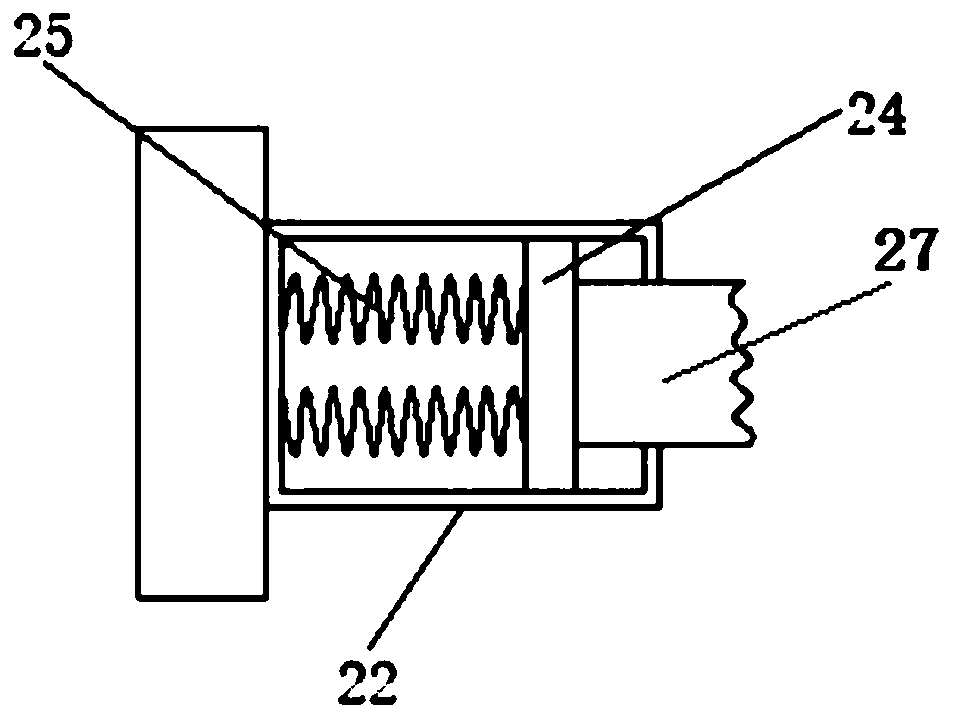

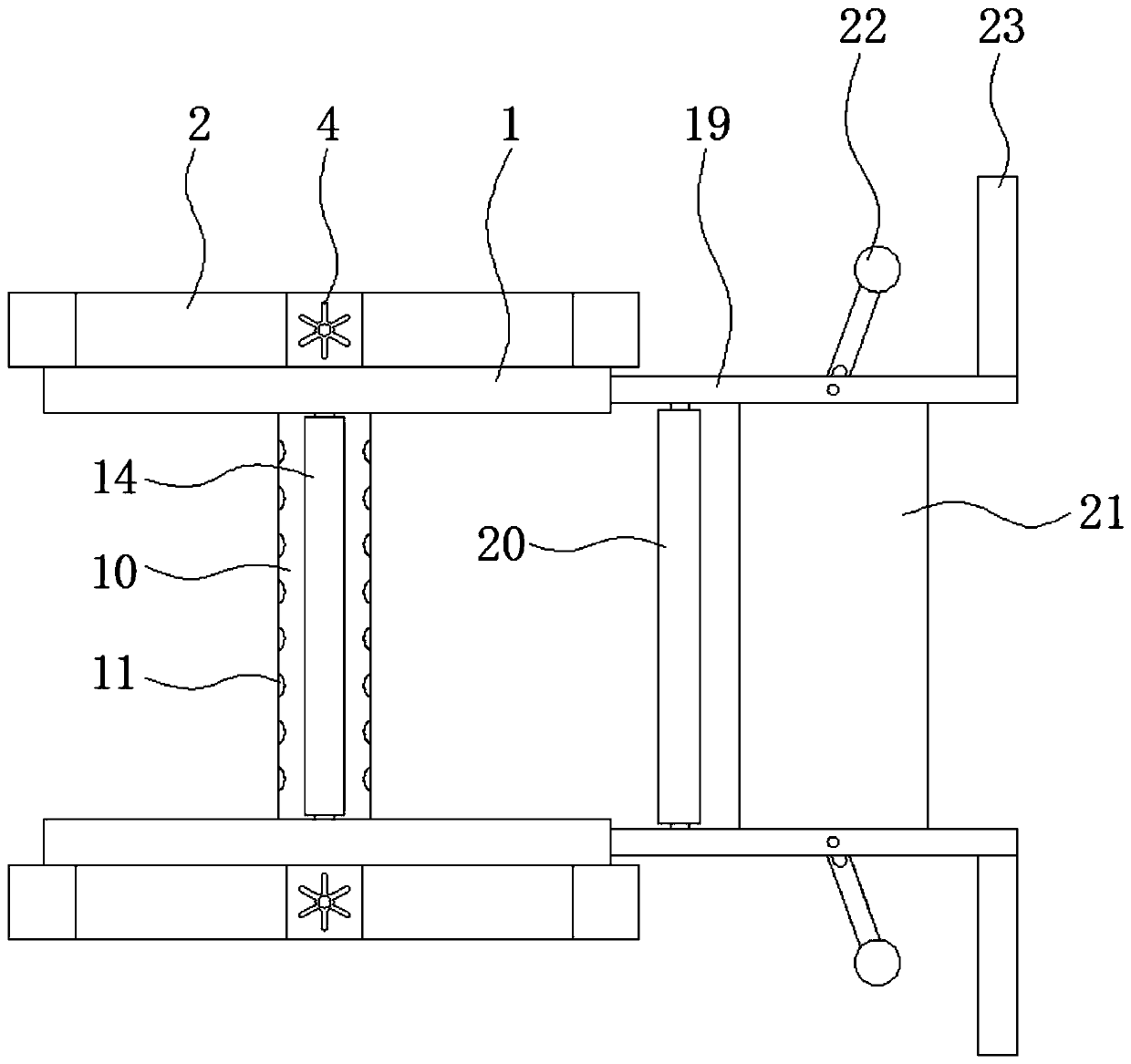

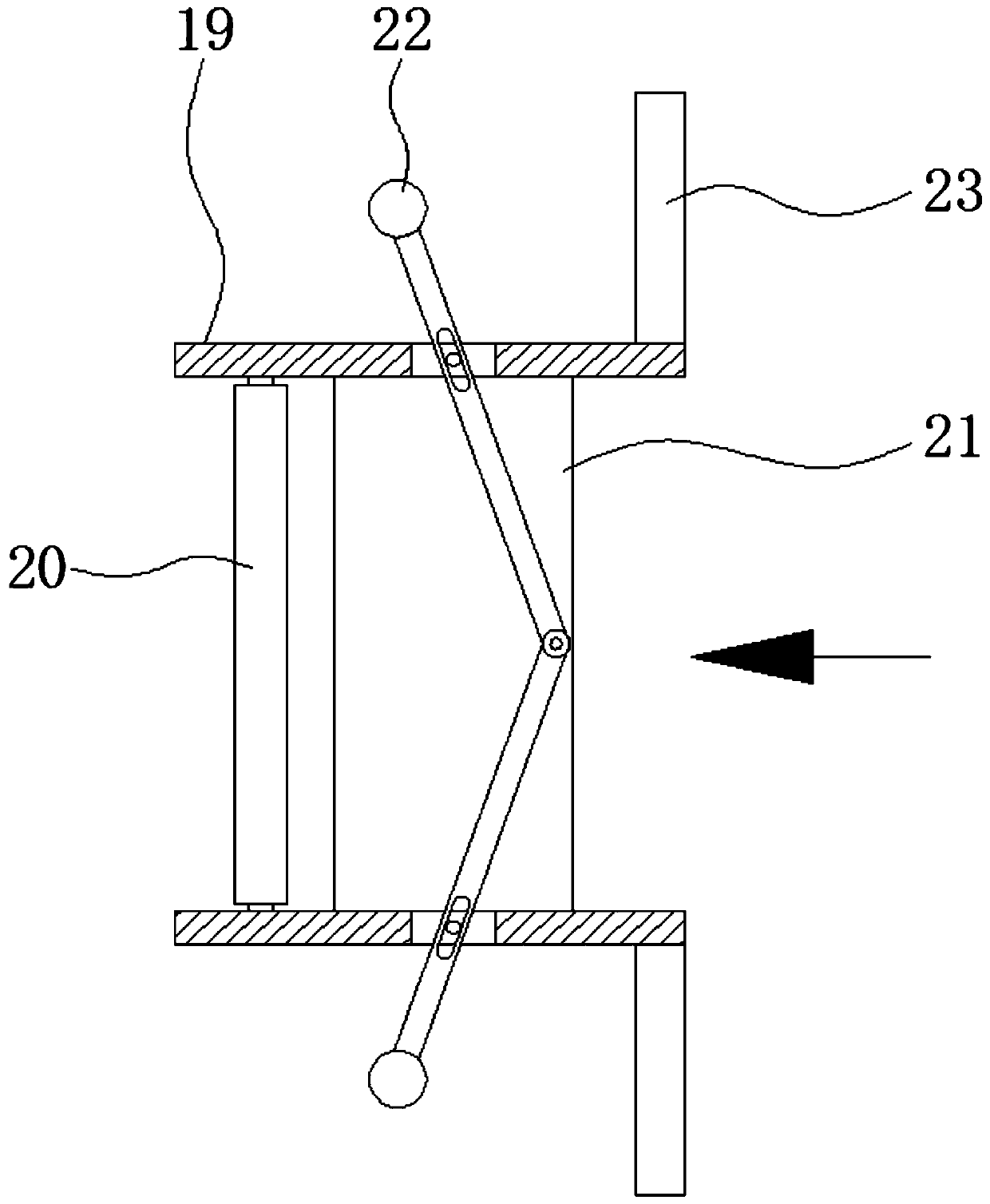

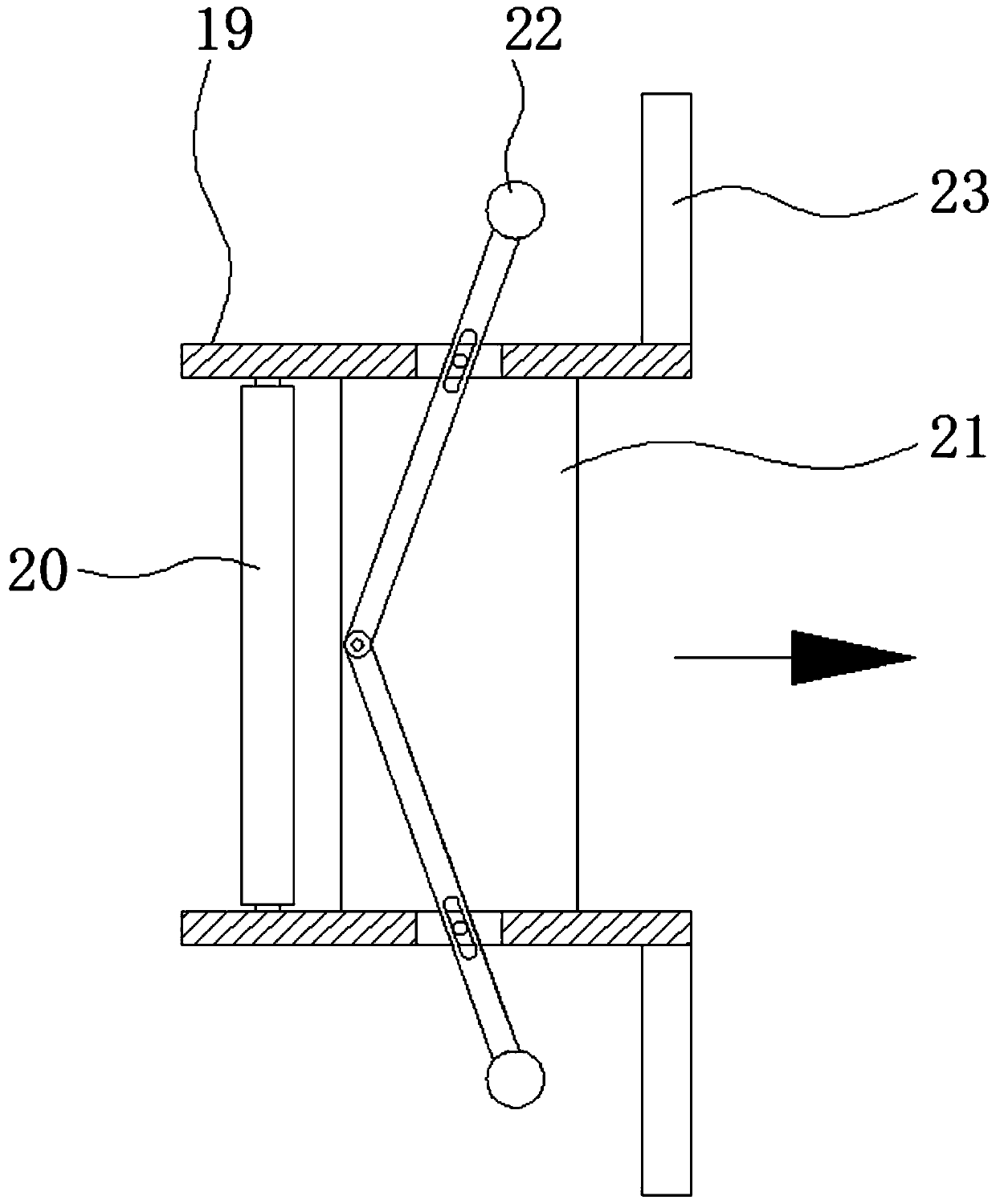

Lifting type multifunctional steel pipe spraying equipment

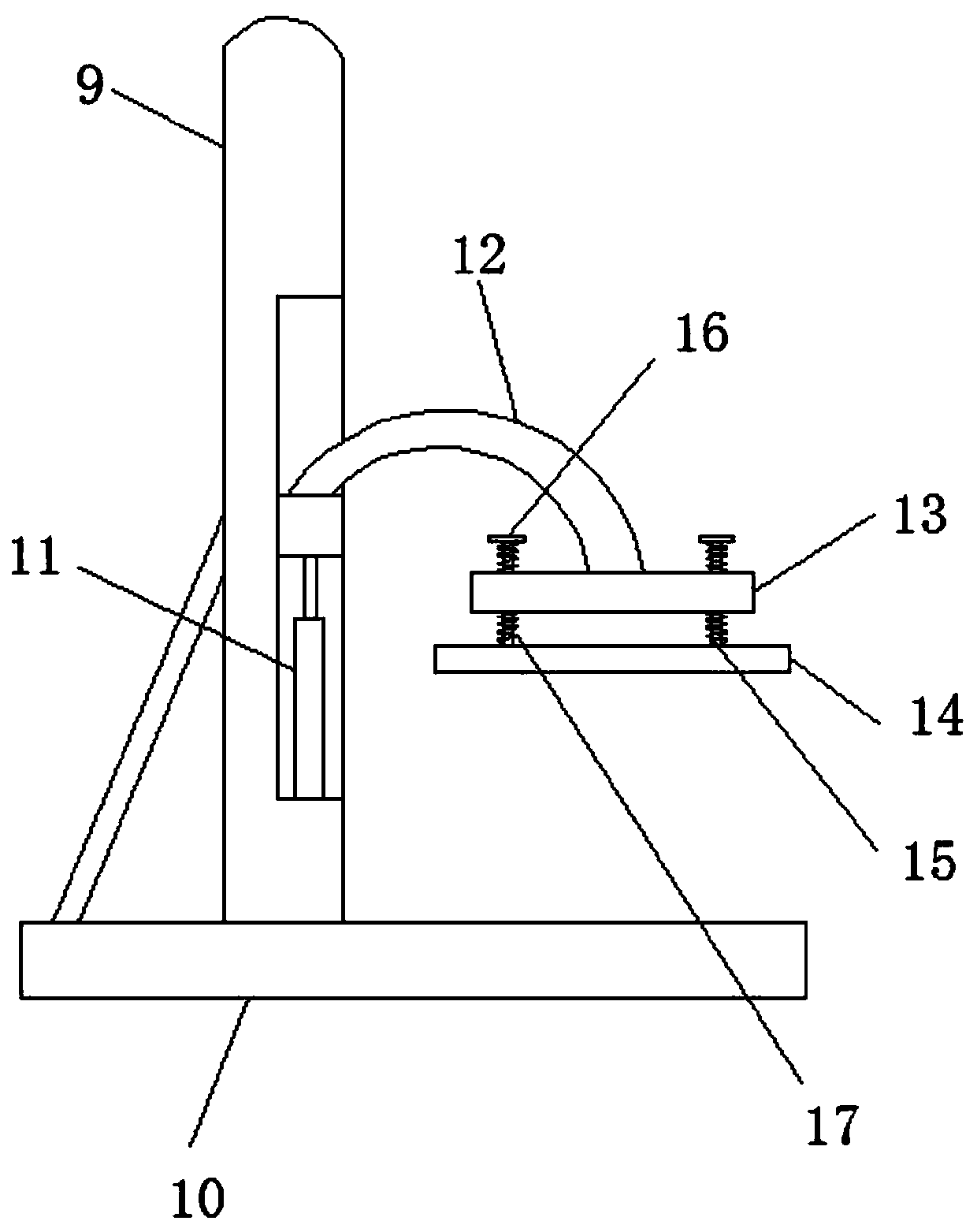

InactiveCN109701790APrecise positioningSpray evenlySpraying apparatusArchitectural engineeringPortal frame

The invention belongs to the technical field of steel pipe spraying machining, and particularly relates to lifting type multifunctional steel pipe spraying equipment. The lifting type multifunctionalsteel pipe spraying equipment comprises a rack, a lifting assembly, a lifting roller set and a spraying assembly. The lifting assembly is mounted on the supporting face and located on the inner side of the rack. The lifting roller set is mounted at the output end of the lifting assembly. A portal frame is fixed to the rack, and a guide rail is welded to the bottom of the portal frame. The liftingroller set is arranged, and a steel pipe can be lifted and rotated through the lifting roller set; the device structure is simple, the steel pipe can be located conveniently, and the equipment can adapt to steel pipes of different types; the steel pipe can be rotated while being lifted; uniform spraying can be conveniently carried out on the steel pipe, and meanwhile the spraying speed is greatlyincreased; and the problems that in existing equipment, consumed time is long, the stability of manual steel pipe fixing is poor, the labor intensity is large, and the work efficiency is low are solved.

Owner:甘肃三色科技涂装工程有限公司

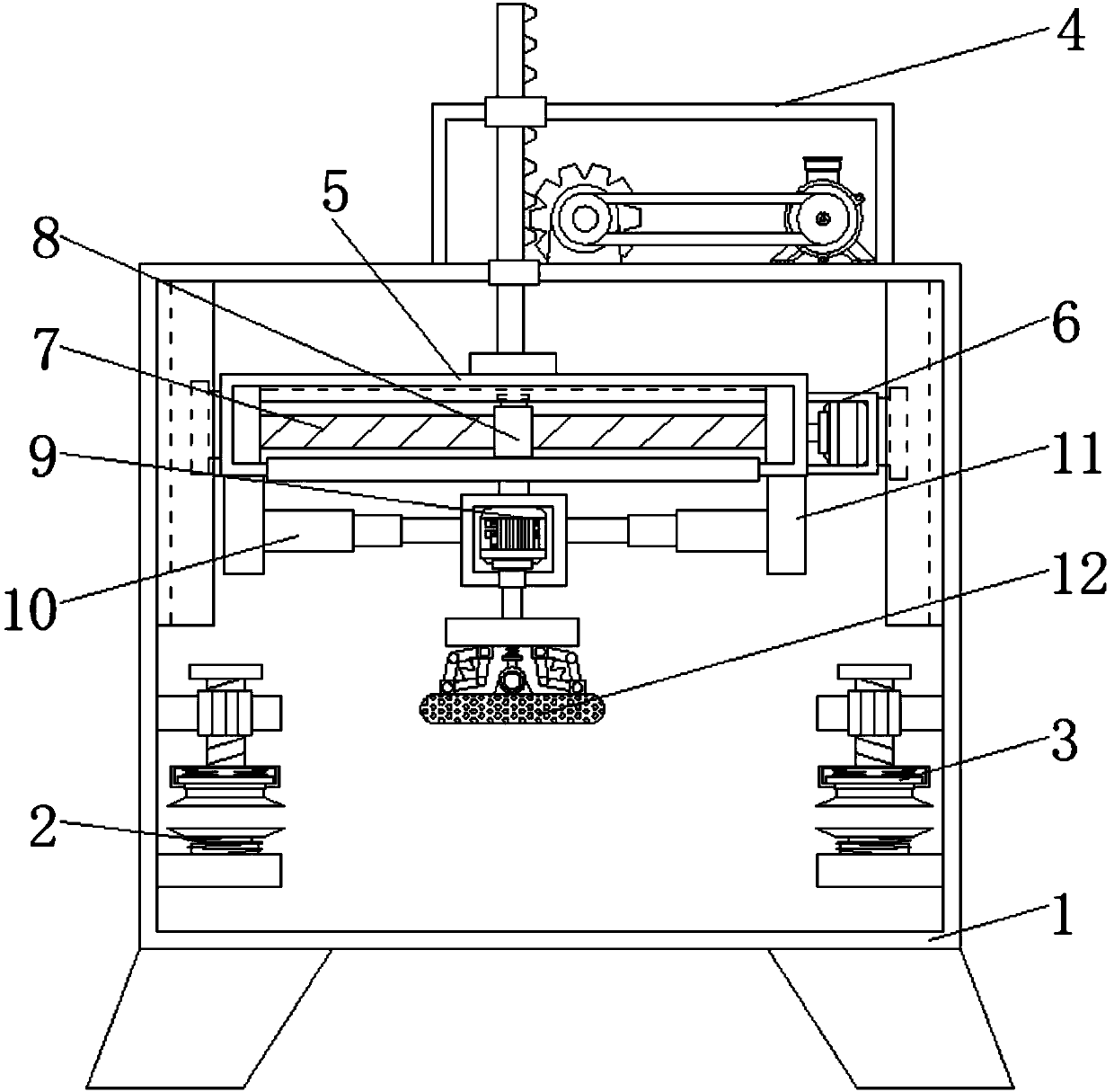

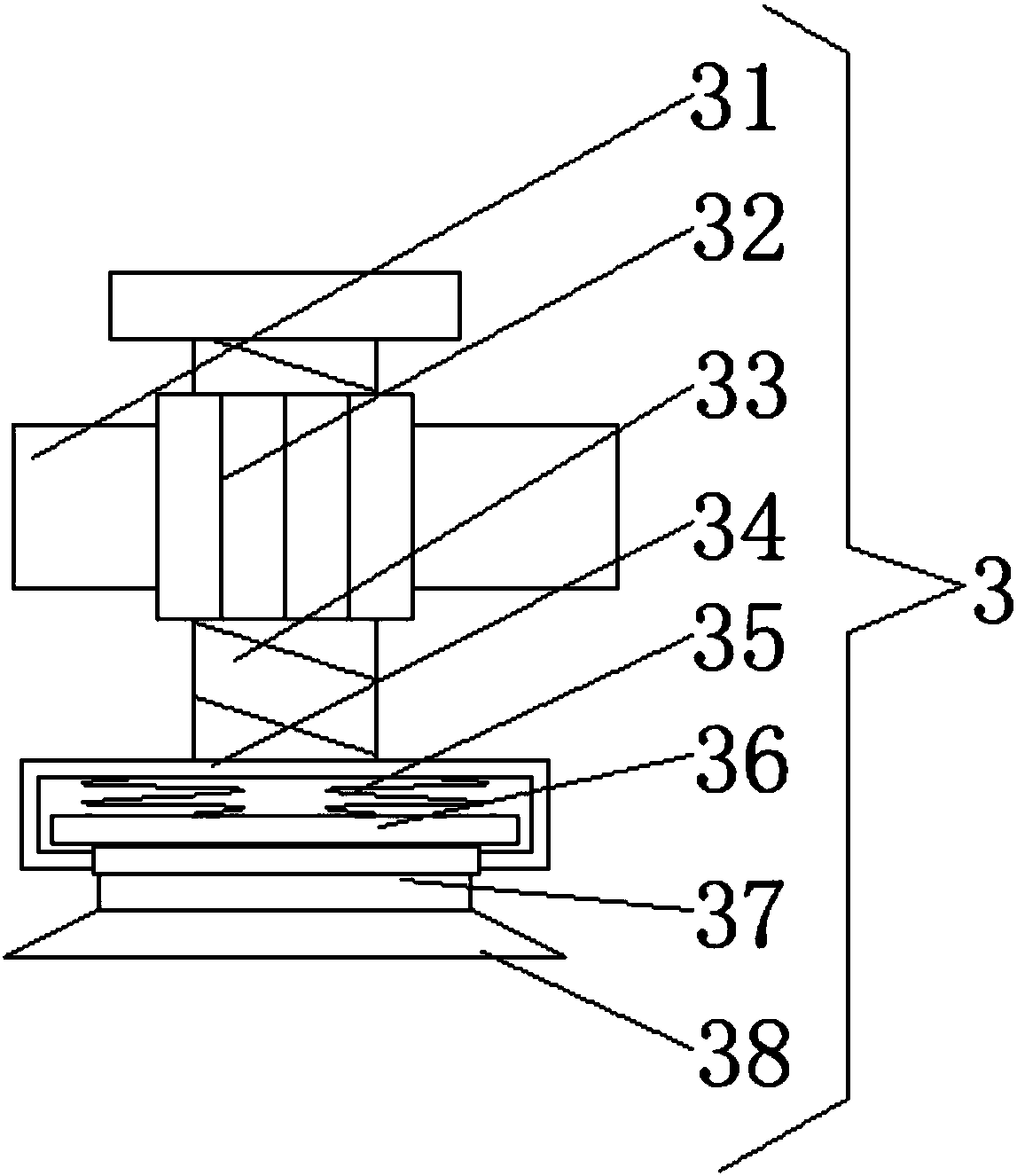

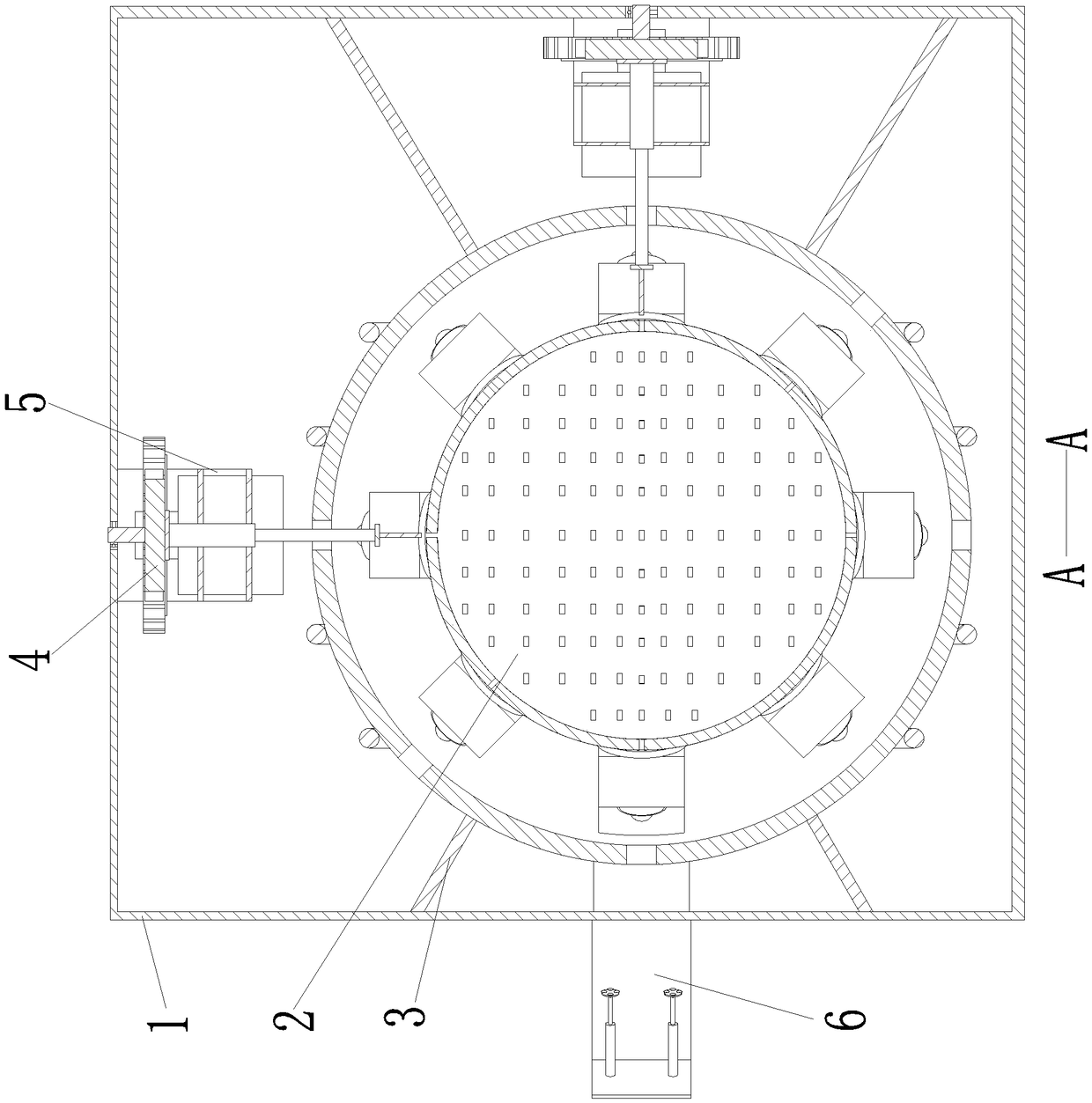

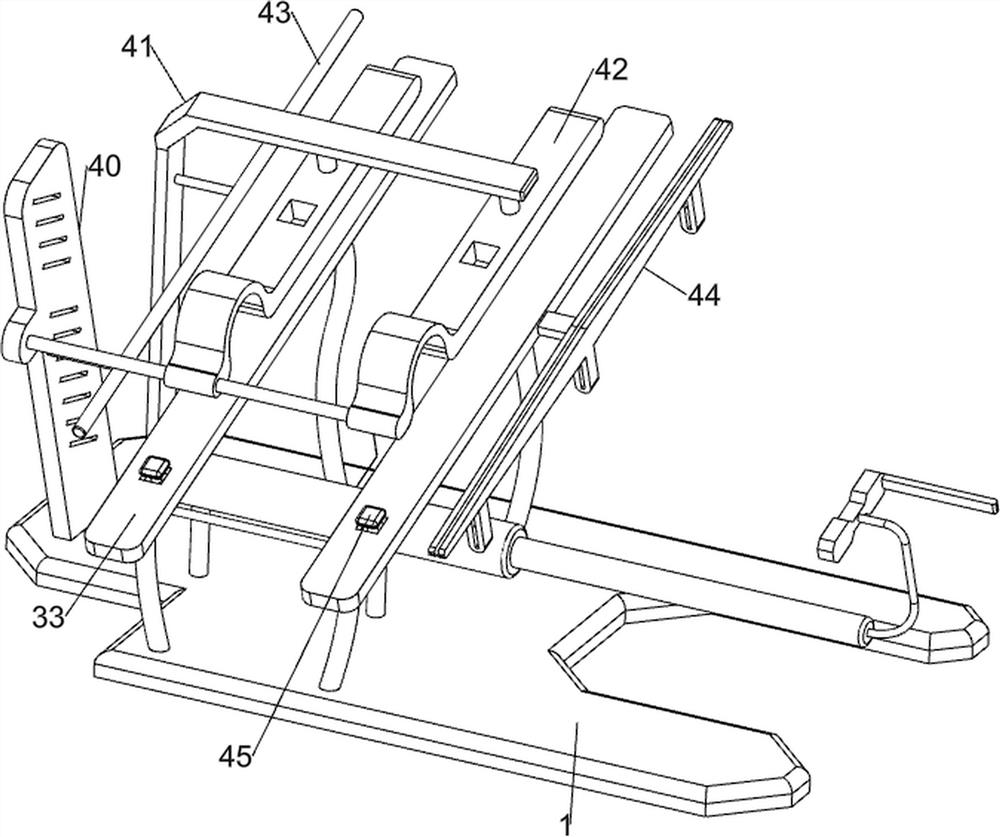

Stable polishing device for bamboo products

PendingCN107553239ATo achieve the purpose of clamping and fixingGuaranteed grinding effectGrinding drivesGrinding work supportsEngineeringMobile device

The invention discloses a stabilizing grinding device for bamboo products, which comprises an outer frame, fixing devices are fixedly connected to both sides of the inner wall of the outer frame, and a moving device is fixedly connected to the top of the outer frame, and the bottom of the moving device penetrates the outer frame. frame and extend to the inside of the outer frame, one end of the mobile device inside the mobile device is fixedly connected to the mobile frame, the right side of the mobile frame is fixedly connected to the first motor, and one end of the output shaft of the first motor passes through the mobile frame and extends to The inside of the moving frame, the invention relates to the technical field of bamboo products related equipment. The stable grinding device for bamboo products achieves the purpose of clamping and fixing bamboo products without manual fixing, reduces the burden on workers, ensures the effect of grinding bamboo products, is convenient to adapt to bamboo products of different sizes, improves the practicability of the device, and is convenient The grinding process ensures the quality of the grinding, improves the stability of the device, and is convenient for taking out and placing bamboo products.

Owner:安吉县安信信息有限公司

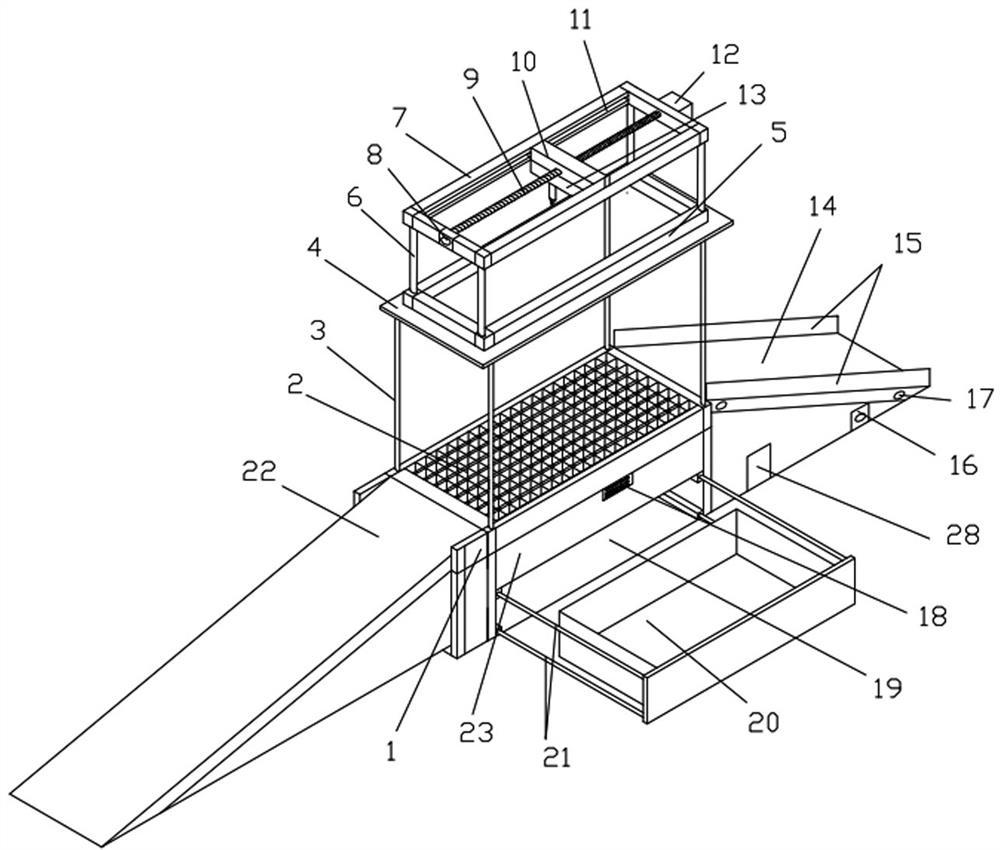

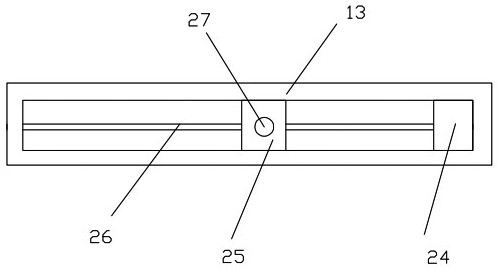

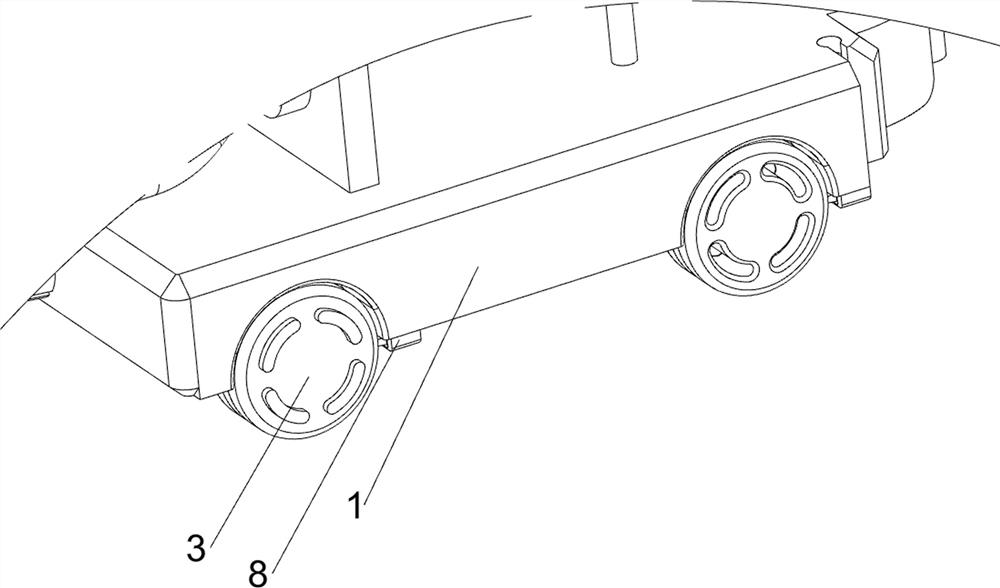

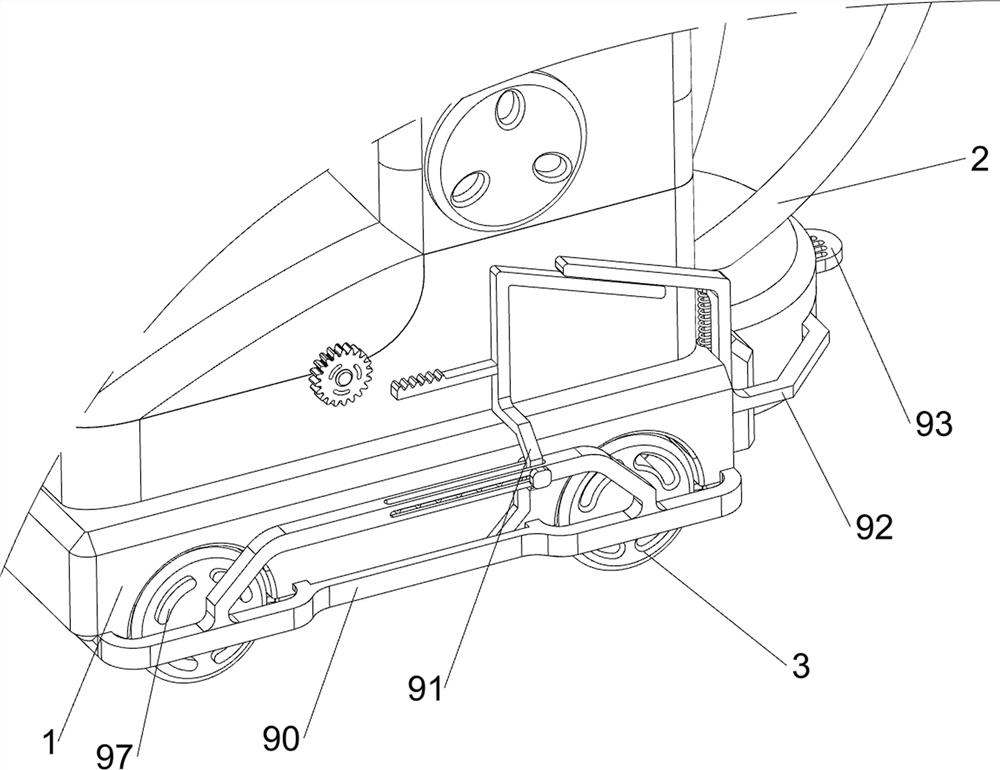

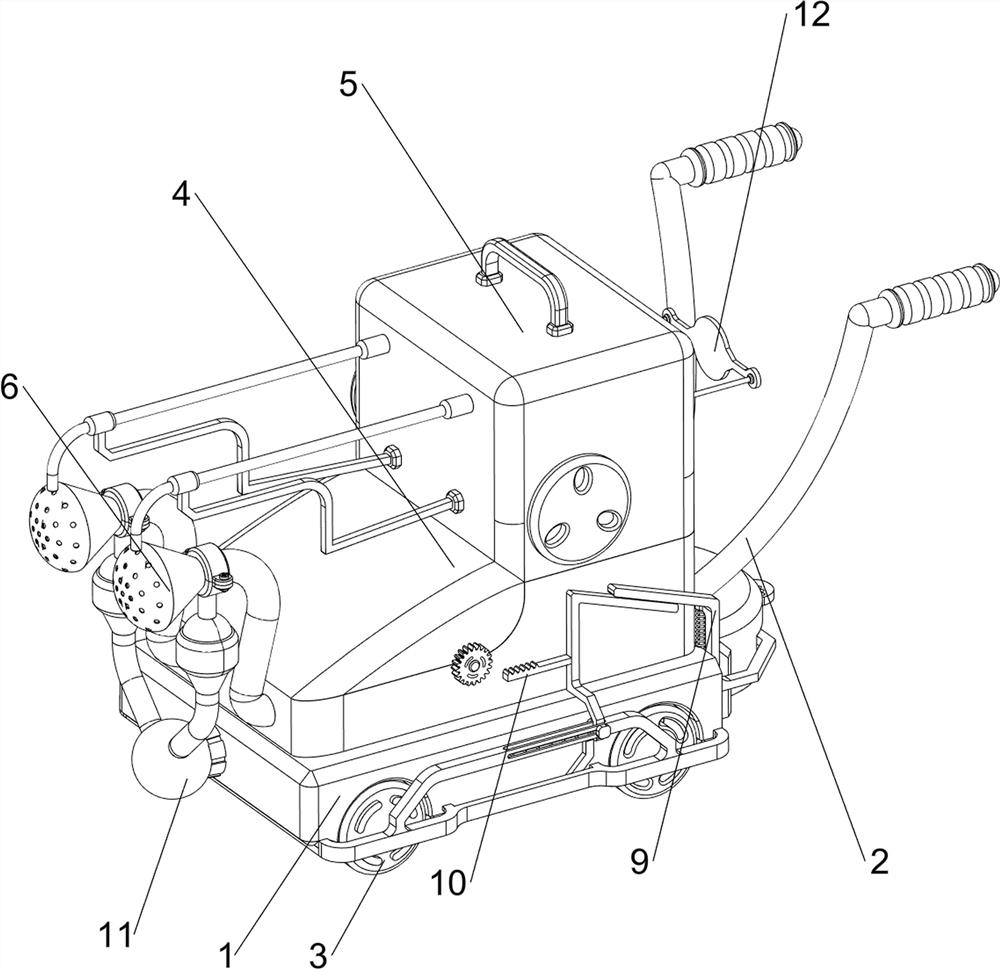

Automatic boxing equipment for biological capsule production

ActiveCN112478296AReduce labor costsEasy to take outIndividual articlesBiological glueProcess engineering

The invention relates to boxing equipment, in particular to automatic boxing equipment for biological capsule production. The automatic boxing equipment for biological capsule production can limit medicine boxes, and achieve automatic boxing and automatic discharging. The automatic boxing equipment for biological capsule production comprises a base, a placing mechanism and a pushing mechanism, wherein the placing mechanism is arranged on one side of the base, and the base is provided with the pushing mechanism. Through the cooperation of the placing mechanism and the pushing mechanism, capsules can be automatically boxed and can be automatically conveyed, and therefore the labor cost can be saved; through the cooperation of a limiting assembly and a downward pressing assembly, the boxes can be automatically moved forwards, and people can conveniently take out the boxes; and meanwhile, the medicine boxes can be limited, and therefore the medicine boxes do not need to be manually fixed.

Owner:中芝堂药业(山东)有限公司

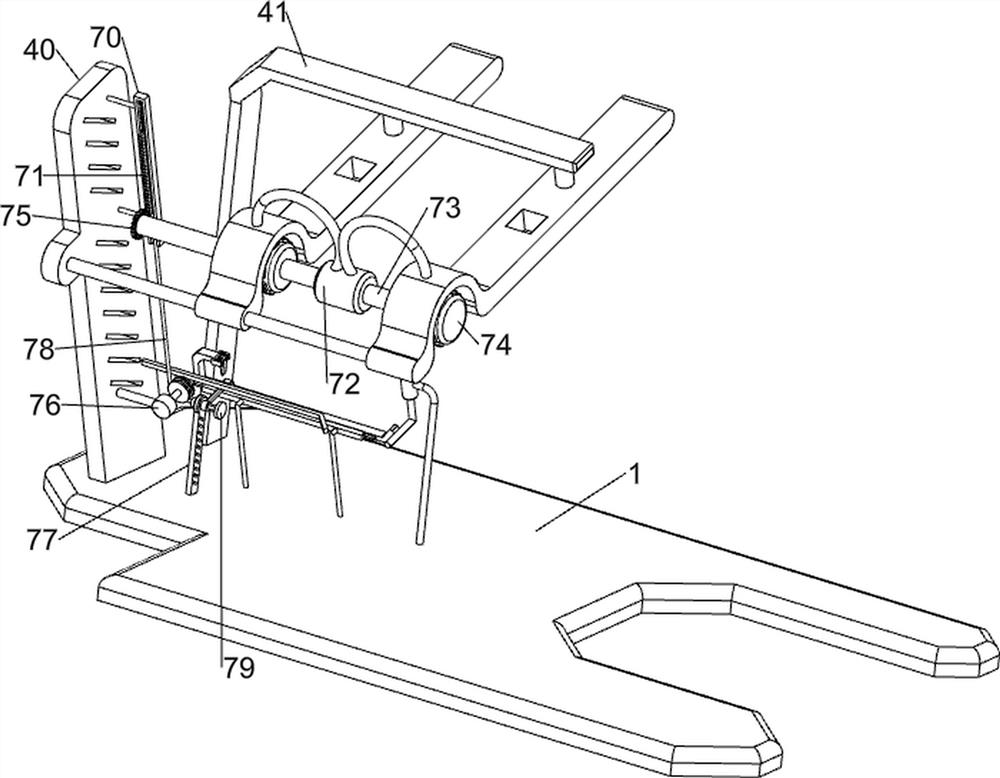

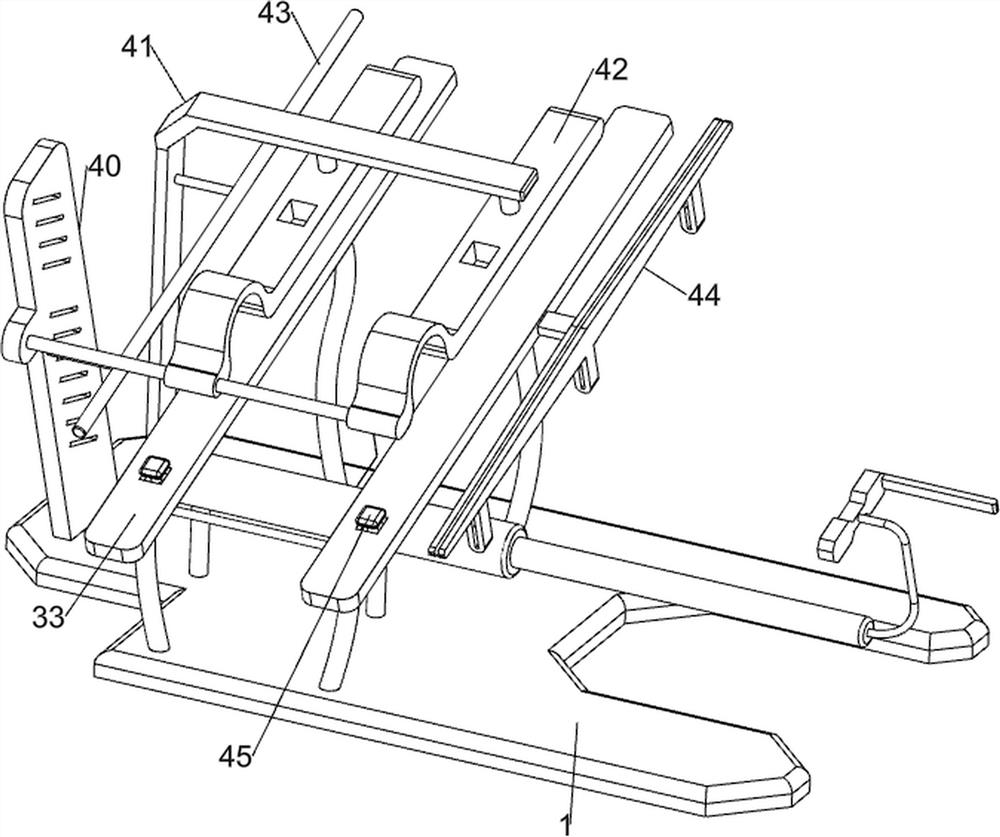

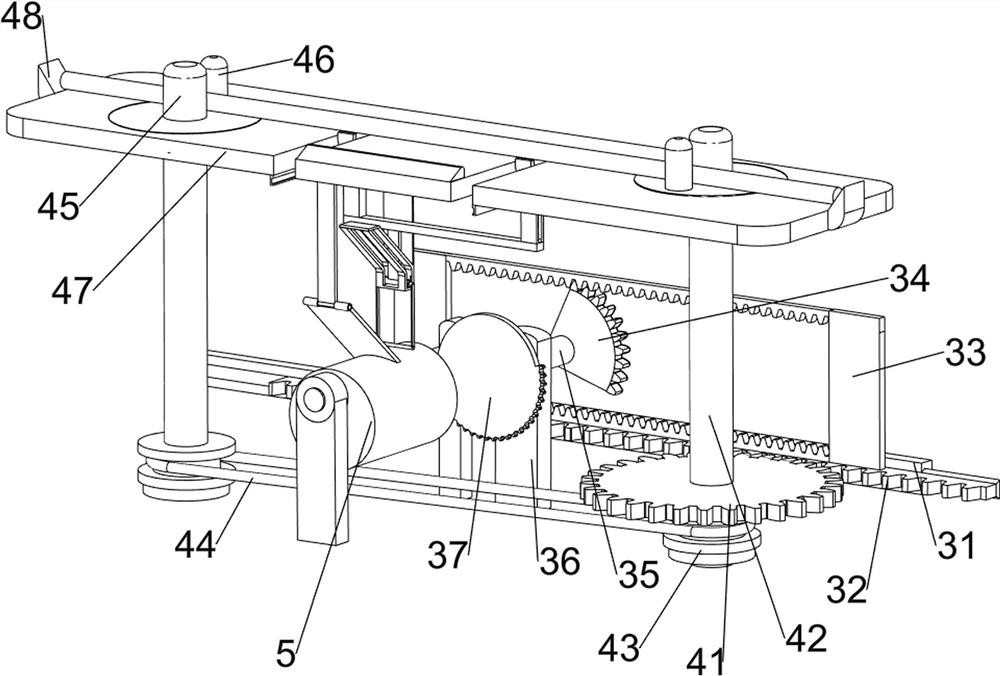

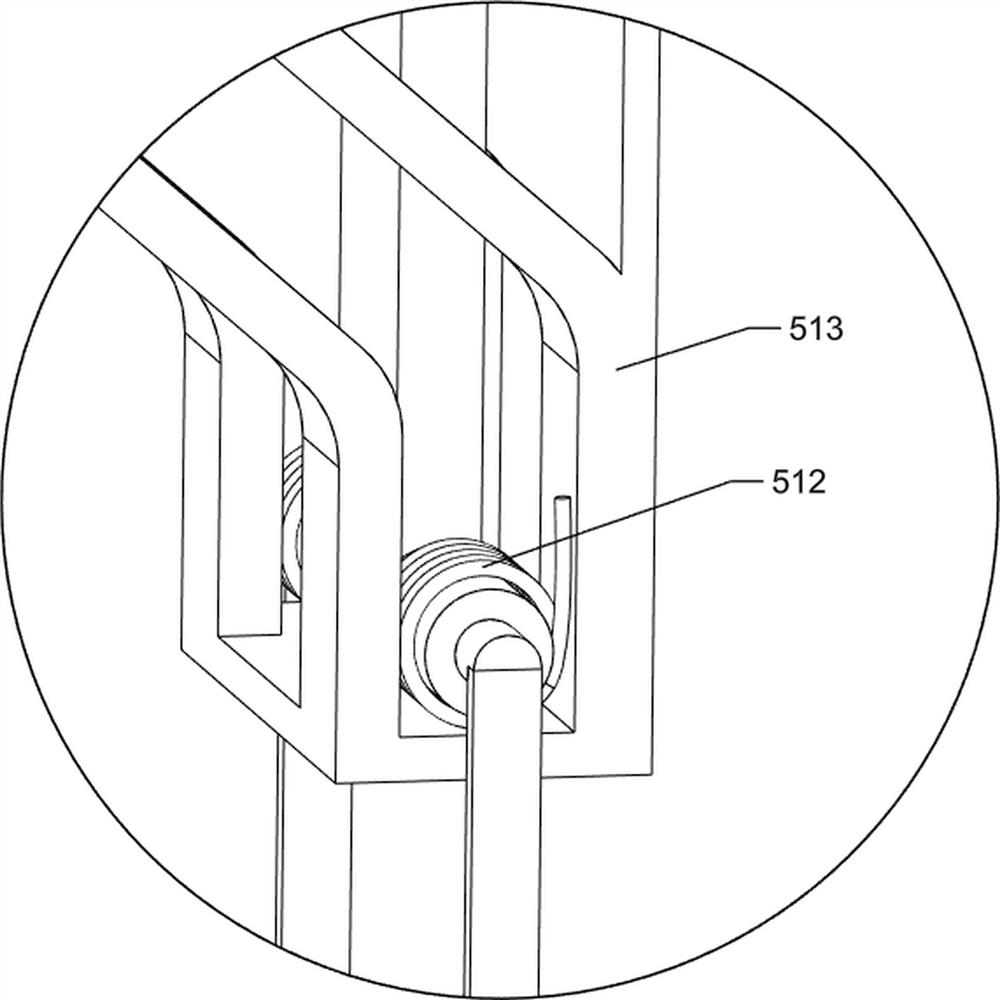

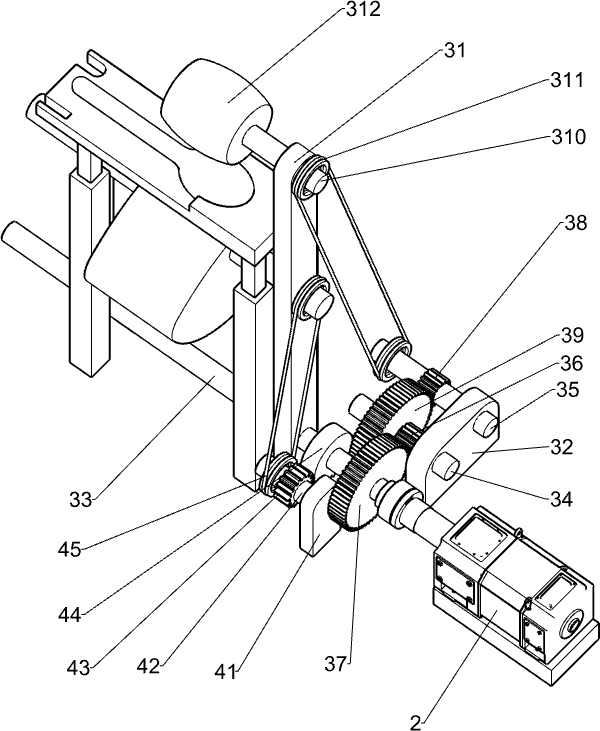

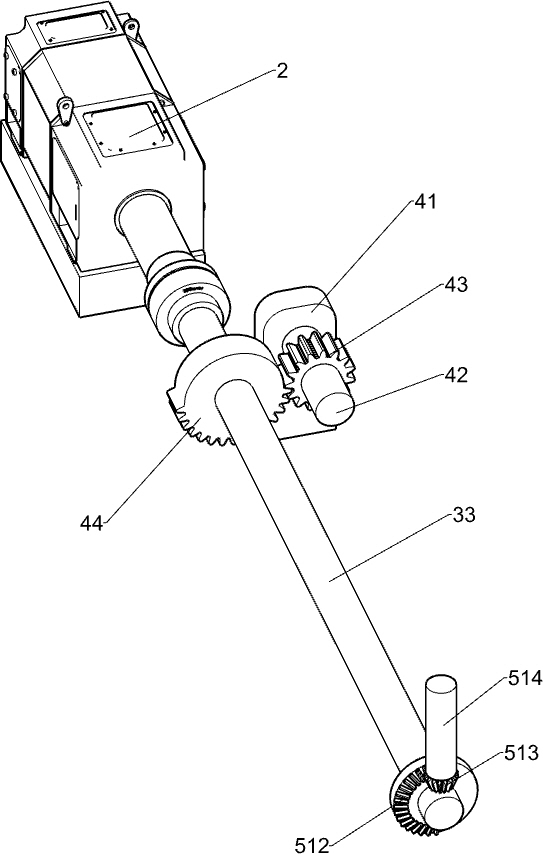

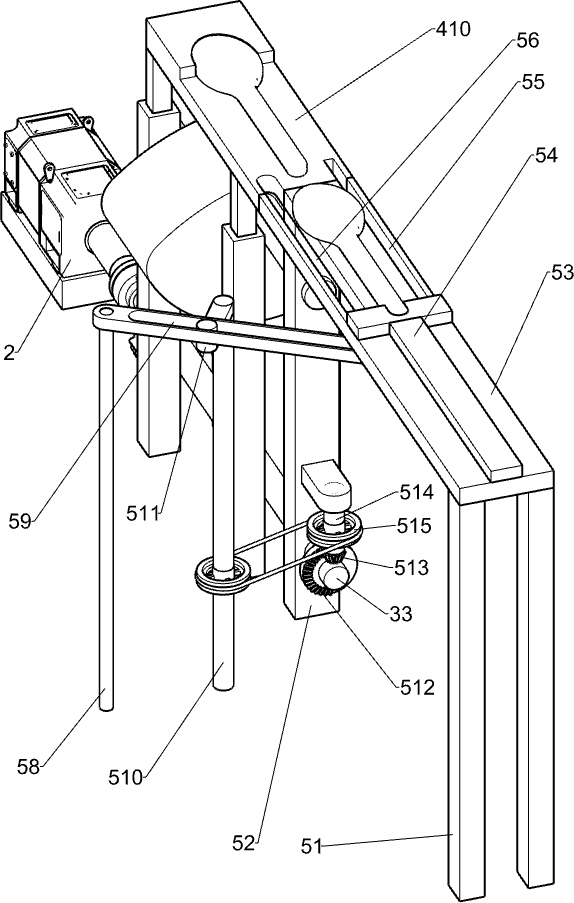

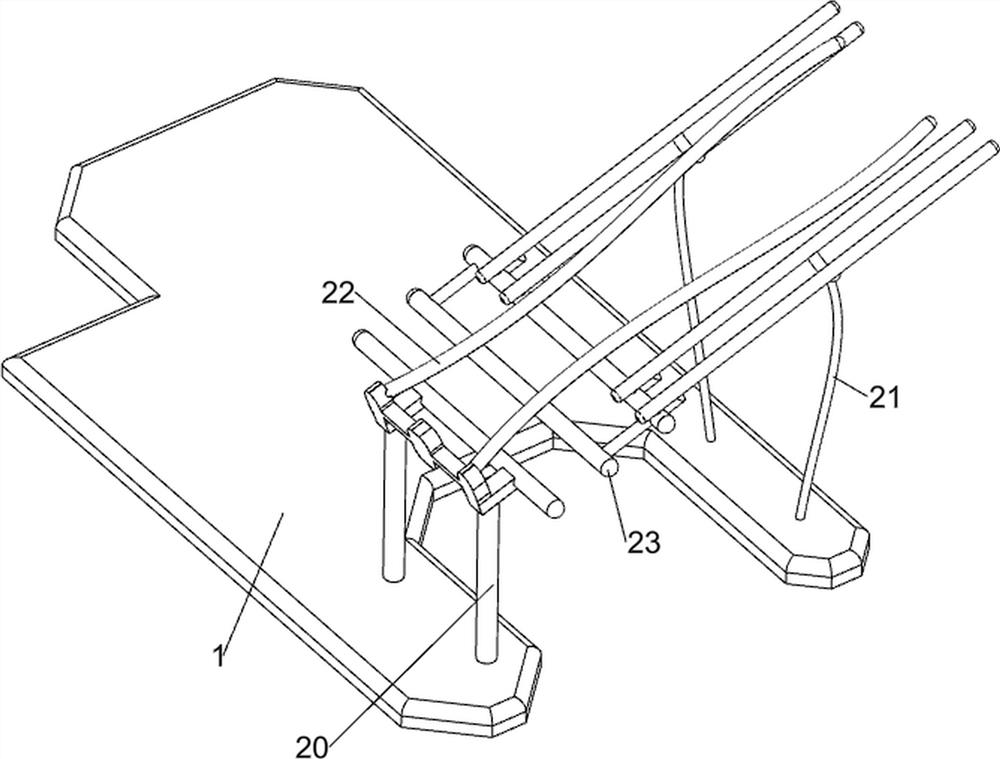

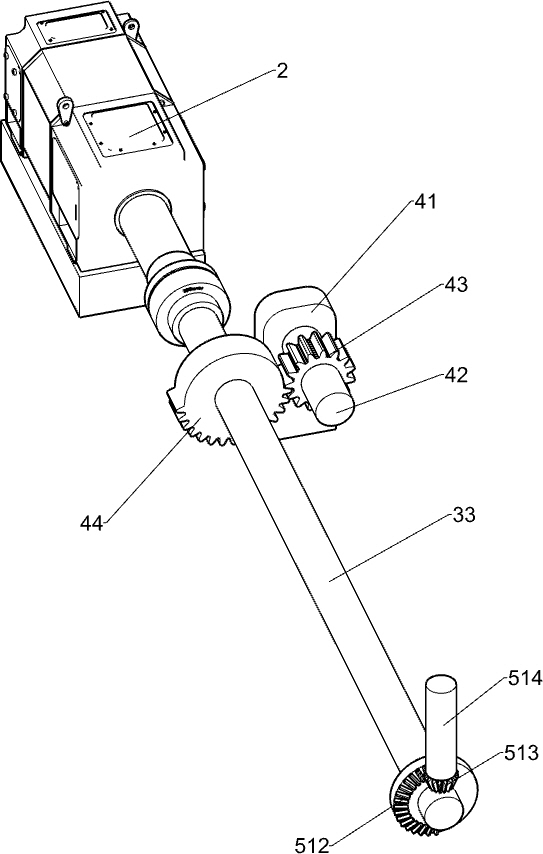

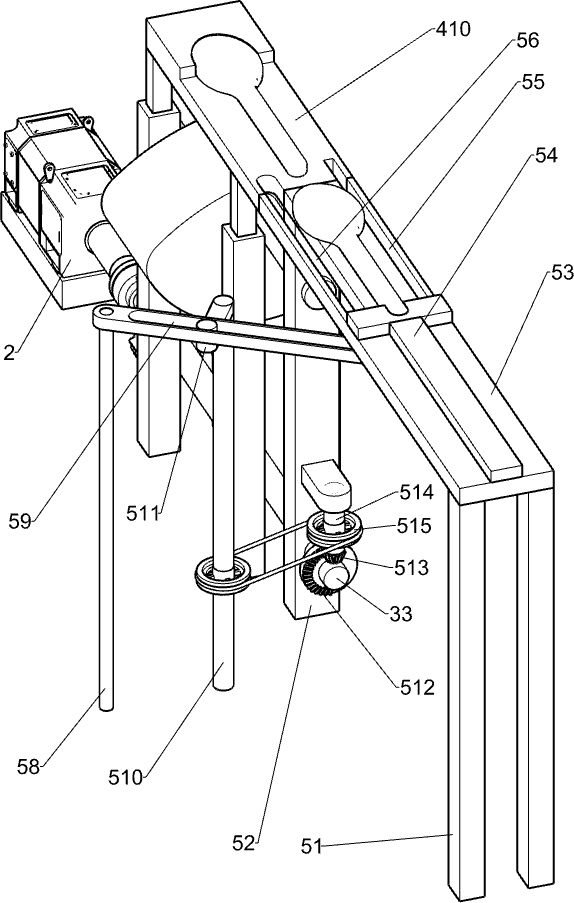

Full-automatic steel bar twisting device

The invention relates to a twisting device, in particular to a full-automatic steel bar twisting device. The full-automatic steel bar twisting device is small in size, light and convenient to transport and capable of achieving automatic bending and discharging during operation. The full-automatic steel bar twisting device comprises a base, a gear motor, a transmission mechanism and a twisting mechanism, and one side of the top of the base is connected with the gear motor, Through cooperation of the gear motor, the transmission mechanism and the twisting mechanism, after people manually place steel bars on a twisting table, the steel bars are automatically bent through the transmission mechanism and the twisting mechanism, the steel bars do not need to be manually fixed in the bending process, and time and labor are saved. After the steel bars are successfully bent, the bent steel bars can be pushed forwards through a pushing mechanism, and a collecting mechanism can facilitate people to collect the bent steel bars.

Owner:康建霞

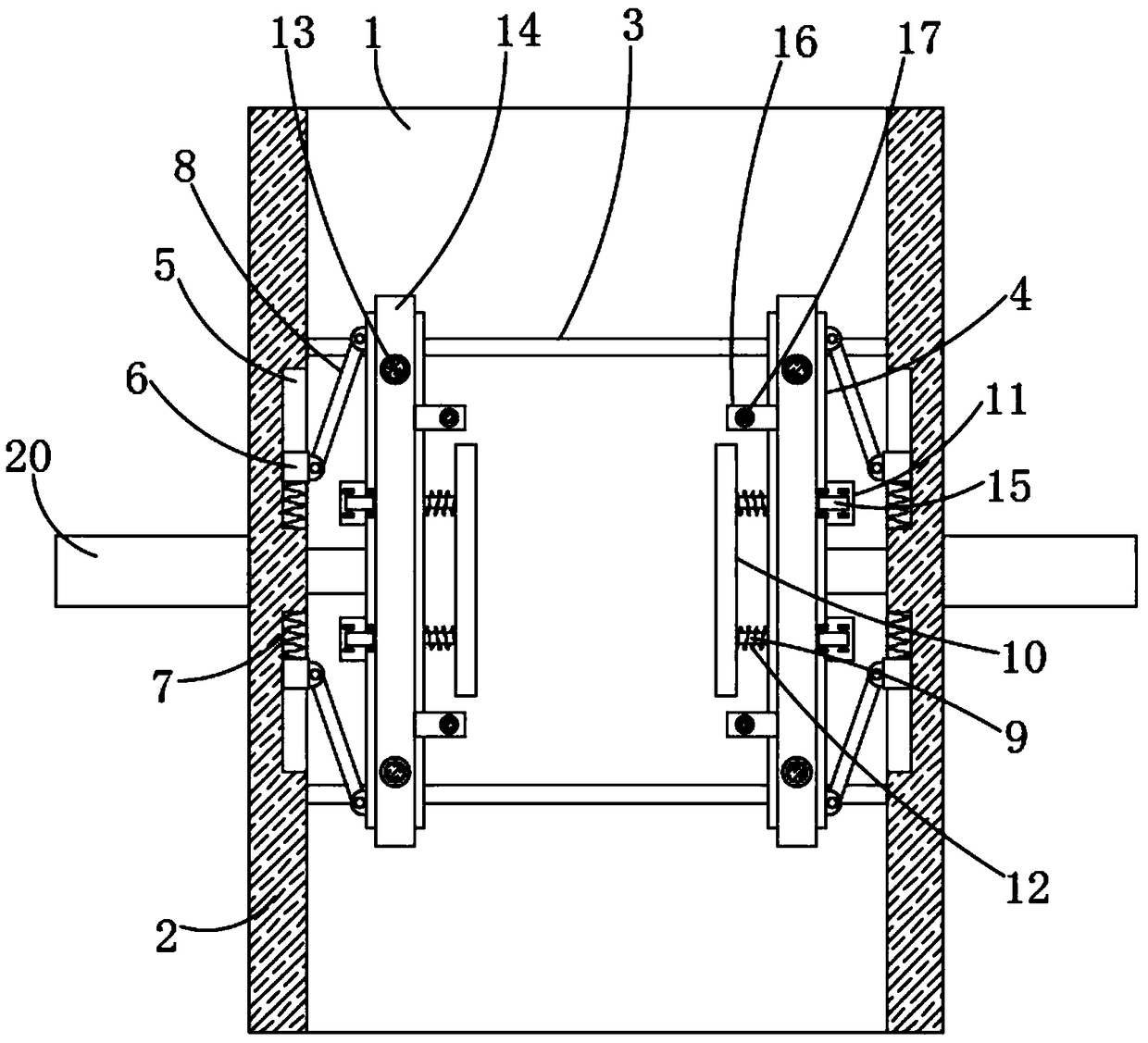

Plate engraving machine fixing device

InactiveCN109177622AGuaranteed stabilityNovel structureModel makingEngravingEngineeringMechanical engineering

The invention belongs to the field of plate machining, and particularly discloses a plate engraving machine fixing device. The plate engraving machine fixing device comprises a workbench, side platesare symmetrically and fixedly connected to the two sides, in the length direction of the workbench, of the top side of the workbench, and sliding grooves are symmetrically formed in the portions, located between the two side plates, of the top side of the workbench; movable plates are symmetrically and slidably installed between the two sliding grooves, and driving mechanisms are connected to thesides, far away from each other, of the two movable plates; and clamping grooves are symmetrically formed in the sides, close to each other and located between the two sliding grooves, of the two sideplates, clamping blocks are slidably installed in the clamping grooves, and first springs are installed on the sides, close to each other, of the two clamping blocks in the two clamping grooves. According to the plate engraving machine fixing device, through the structural design of the movable plates, the clamping grooves, the clamping blocks, the first springs, supporting rods, connecting rods,clamping plates, connecting blocks, second springs, fixing rods and pushing rod motors, the top side edge of a plate can be extruded and fixed while the side wall of the plate is extruded and fixed.

Owner:黄雨辰

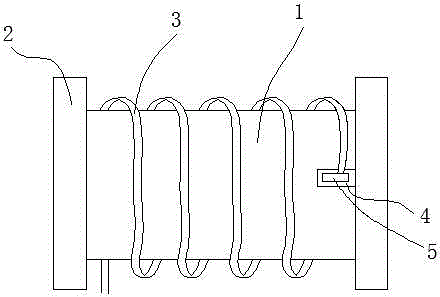

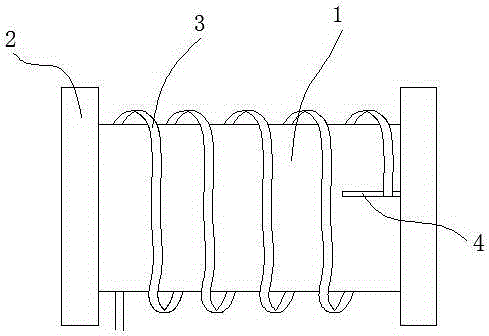

Steel wire rope winding device

The invention discloses a steel wire rope winding device. The steel wire rope winding device comprises a rope winding device body (1); limiting bosses (2) are arranged at the two ends of the rope winding device body (1); a steel wire rope (3) is wound on the rope winding device body (1); the rope winding device body (1) is further provided with a groove (4) in which a clamp (5) is fixed; and one end of the steel wire rope (3) is fixed through the clamp (5). According to the steel wire rope winding device, before winding, firstly, one end of the steel wire rope is clamped through the clamp, then, direct winding is performed, manual fixing is not needed, and operation is easy and convenient.

Owner:JIANGYIN HUASHUO MACHINERY MFG

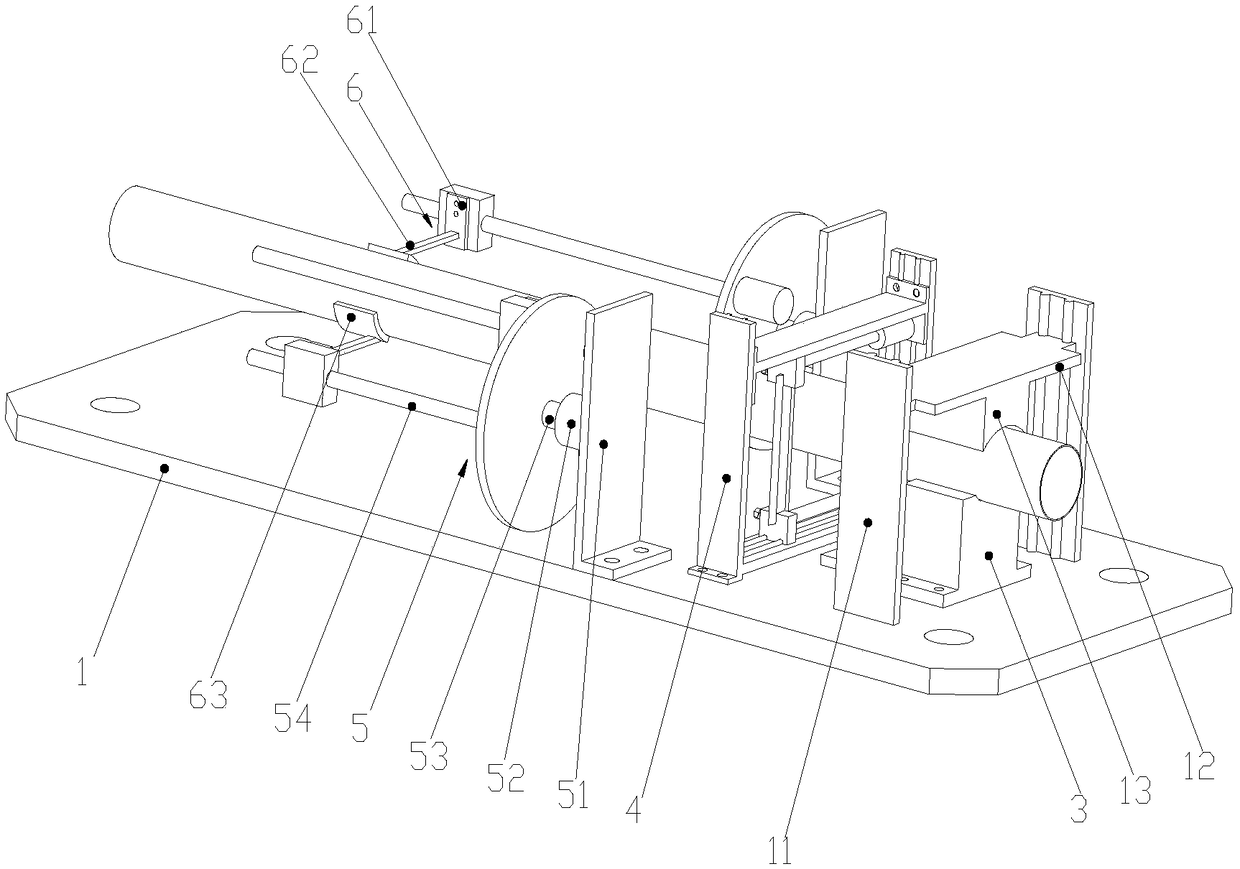

Wooden shovel forming machine

ActiveCN111805630ARealize automatic cuttingNo manual fixation requiredProfiling/shaping machinesMolding machineElectric machinery

The invention relates to a forming machine, in particular to a wooden shovel forming machine. The invention aims to provide the wooden shovel forming machine capable of fixing a wooden shovel automatically, taking the wooden shovel automatically and reducing manual operations. The wooden shovel forming machine comprises a base, wherein a motor is arranged on the side part of the base, a cutting mechanism is arranged on the side part of the base on the side, close to the motor, the motor is connected to the cutting mechanism, an ejecting mechanism is mounted on the side part of the base on theside, close to the cutting mechanism, and the ejecting mechanism is connected to the cutting mechanism. By means of the cutting mechanism, the wooden shovel is cut automatically, and meanwhile, underthe action of the ejecting mechanism, the wooden shovel is not fixed manually; by means of a pushing mechanism, the wooden shovel is moved to a working plate automatically and it is not needed to place the to-be-cut wooden shovel to the working plate repeatedly manually; by means of an unloading mechanism, the to-be-cut wooden shovels are placed in a centralized manner, so that it is convenient topush out the wooden shovels by a push rod, and a work needs not to take the wooden shovels repeatedly.

Owner:阳炽贵

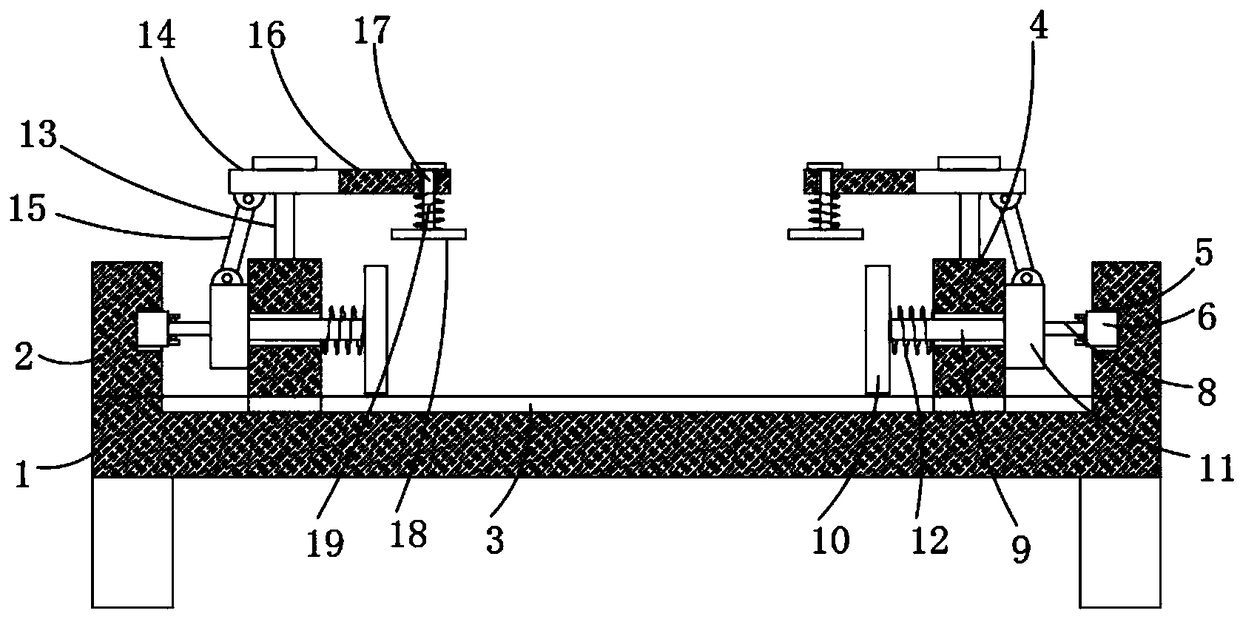

Fixing device for part machining

PendingCN111496678ANo manual fixation requiredLabor savingGrinding work supportsElectric machineScrew thread

The invention discloses a fixing device for part machining. The fixing device comprises a base, a control box and an operation table which are sequentially arranged from bottom to top; the two sides of the top of the operation table are each slidably connected with a movable plate; a motor is arranged in the control box, a power output shaft of the motor is in transmission connection with a lead screw, the two ends of the lead screw penetrate through the two side walls of the control box correspondingly to stretch out of the control box, and the two ends of the lead screw are provided with a right-hand thread and a left-hand thread and are in threaded connection with threaded plates; the threaded plates are each connected with a push rod through a T-shaped connecting rod, and the push rodsare arranged on the outer sides of the two movable plates; the motor drives the lead screw to rotate through belt transmission, thus the two threaded plates move in the mode of getting away from eachother, and through transmission of the T-shaped connecting rods, the two push rods are driven to move oppositely; thus the two movable plates are driven to move oppositely, parts between the two movable plates are clamped in a contact mode, the parts are automatically clamped, manual fixing is not needed, the parts are fixed stably, the parts with various sizes can be fixed, and the practicability is high.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

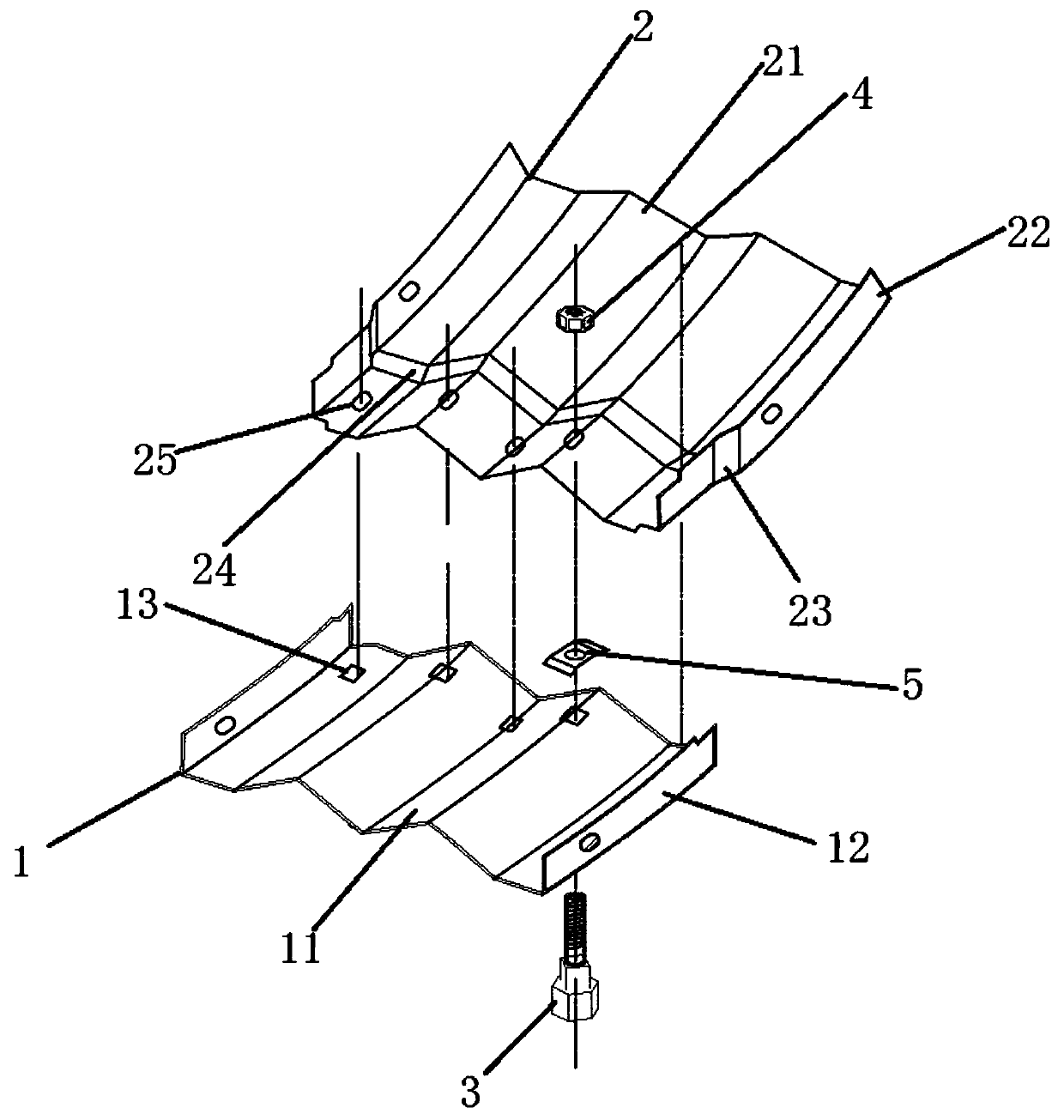

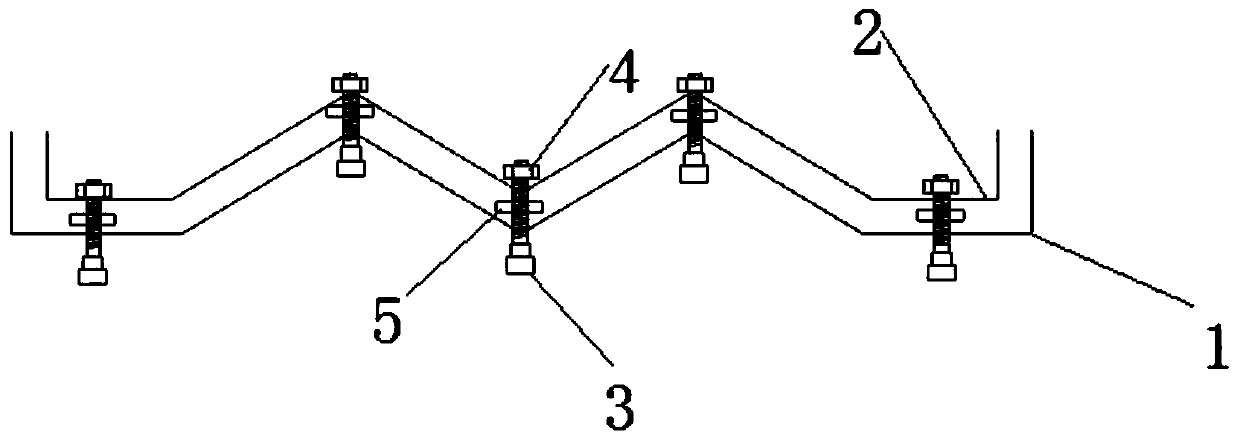

Connecting structure for internal assembling of corrugated plates and connecting method of connecting structure

PendingCN110453793ANarrow back sectionOptimize connection formGround-workUnderground chambersEngineeringBuilding construction

The invention discloses a connecting structure for internal assembling of corrugated plates and a connecting method of the connecting structure. The connecting structure comprises the first corrugatedplate, the second corrugated plate, square neck bolts, nuts and a bolt anti-retreat clamp springs, wherein the junctions of the first corrugated plate and the second corrugated plate are in lapping joint and are fixedly connected through the square neck bolts, the bolt anti-retreat clamp springs and the nuts. According to the connecting structure for internal assembling of the corrugated plates and the connecting method of the connecting structure, the inner sides of the corrugated plates can be connected, the specific connecting form is optimized, the outer sides of the corrugated plates completely do not need to be manually fixed, the outer sides of the corrugated pipes do not need a connecting operation space, the connecting structure and the connecting method adapt to the working condition that during mounting in a closed space, personnel cannot enter the outer side, and great convenience is provided for construction

Owner:HENGSHUI LINENG NEW MATERIAL ENG

Digital printing shearing machine

InactiveCN112238478ARealize shear processingNo manual fixation requiredMetal working apparatusTextile printerEngineering

The invention relates to the technical field of digital printing, in particular to a digital printing shearing machine. The digital printing shearing machine comprises a bottom supporting device, a paper conveying device, an extrusion discharging component, extrusion fixing components, a lifting cutting component, connecting limiting components, a lifting power device, an auxiliary transmission device and a width adjusting device, the right end of the bottom supporting device is slidably connected with the extrusion discharging component, the two extrusion fixing components are arranged, the two extrusion fixing components are both connected with the bottom supporting device, the bottom supporting device is slidably connected with the lifting cutting component, the two connecting limitingcomponents are arranged, the two connecting limiting components are both fixedly connected to the position above the bottom supporting device, and the two connecting limiting components are both in sliding connection with the lifting cutting component. The digital printing shearing machine can achieve automatic fixing of the printing paper, manual fixing is not needed, and large-scale shearing machining of the printing paper can be achieved.

Owner:白和平

Detection tool for left front wall outer side plate assembly

InactiveCN110954040AFacilitate multi-faceted detectionMeet the needs of multi-directional detectionMeasurement devicesEngineeringStructural engineering

The invention discloses a detection tool for a left front wall outer side plate assembly and belongs to the technical field of part detection. The detection tool comprises a transverse plate, a supporting column is mounted at the top of the transverse plate; a top plate is mounted at the top of the supporting column; a detection assembly is mounted at the top of the transverse plate; a movable block is mounted at the bottom of the top plate in a sliding manner; a vertical plate is installed at the bottom of the movable block, a vertically-arranged lifting plate is installed on the vertical plate in a sliding mode, two symmetrically-arranged swing rods are hinged to the bottom of the lifting plate, a positioning plate is rotatably installed on the opposite sides of the two swing rods, a bottom plate is installed at one end of the positioning plate, and an arc-shaped rod is installed on the positioning plate in a sliding mode; when the left front wall outer side plate is positioned and clamped, damage to the left front wall outer side plate is avoided through elastic clamping, the positioning effect is good, height, angle, horizontal position and turnover adjustment can be conductedon the left front wall outer side plate when positioning and clamping are achieved, and the requirement for multi-directional detection is met.

Owner:湖北炫彩汽车零部件科技有限公司

Steel wire rope winder

The invention discloses a steel wire rope winder which comprises a rope winder body (1). Limiting bosses (2) are arranged at the two ends of the rope winder body (1). A steel wire rope (3) is wound around the rope winder body (1). The rope winder body (1) is further provided with a groove (4). The width of the groove (4) is 1-2 mm smaller than the diameter of the steel wire rope (3). Before the steel wire rope is wound, one end of the steel wire rope is inserted in the groove, the groove can clamp the steel wire rope as the width of the groove is slightly smaller than the diameter of the steel wire rope, then the steel wire rope can be directly wound without being fixed manually, and operation is easy and convenient.

Owner:JIANGYIN HUASHUO MACHINERY MFG

Acrylic carving machine capable of automatically fixing materials

The invention discloses an acrylic carving machine capable of automatically fixing materials. The acrylic carving machine comprises a carving machine body, an acrylic plate support frame is mounted at the top of the carving machine body, first hydraulic cylinders are mounted at four corners of the acrylic plate support frame, a connecting plate is mounted at the tops of the first hydraulic cylinders, and a material pressing plate is mounted at the top of the connecting plate; and electric extendable rods are mounted at the four corners of the top of the material pressing plate correspondingly, a top frame is mounted at the tops of the electric extendable rods, sliding grooves are formed in the two sides of the interior of the top frame correspondingly, and first sliding blocks are connected into the sliding grooves. The carving machine is high in functionality, capable of achieving automatic feeding and automatic discharging, free of manual carrying, high in efficiency and high in speed, capable of rapidly fixing an acrylic plate, improving the stability performance during carving, free of manual fixing, capable of saving the time for disassembling and assembling a fixing clamp, and capable of recycling chippings generated during carving, and people can conveniently operate and use the carving machine.

Owner:李兆灿

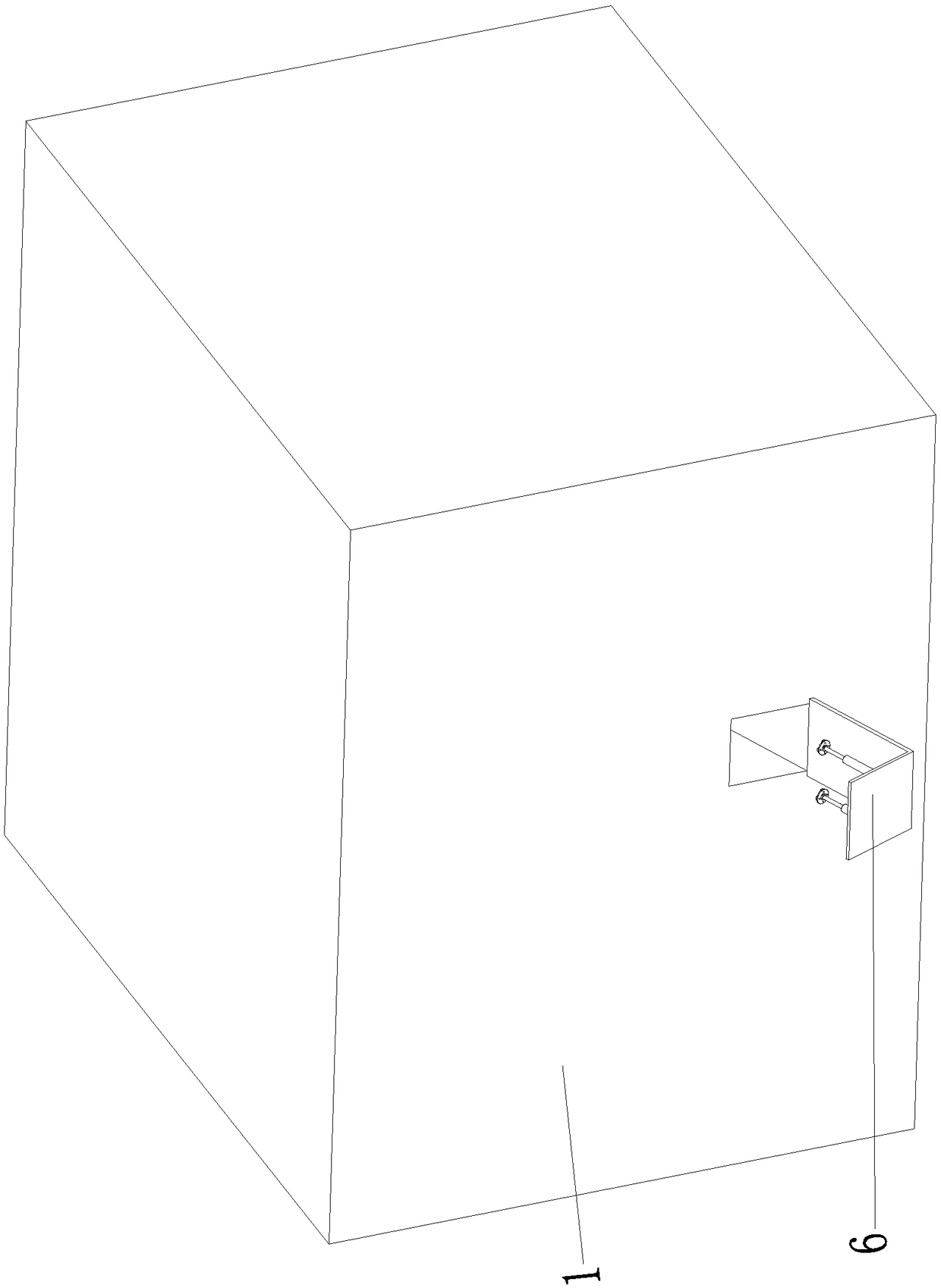

Intelligent Chinese medicine storage cabinet with constant temperature

The invention relates to an intelligent Chinese medicine storage cabinet with constant temperature, comprising a box body, a spherical medicine box mechanism, a spherical fixing plate, medicine box rotating mechanisms, a rotating fixing plate and a pick-and-place mechanism. A spherical medicine box mechanism is installed inside the box body through a spherical fixing plate, two medicine box rotating mechanism are arranged on that inn wall of the box body through a rotating fixing plate. The pick-and-place mechanism is arranged on that box body, a medicine taking groove is arranged on the box body. The invention solves the problem that the volume of the traditional medicine cabinet is large, As that medicine cabinet is arrange relatively high, when adding or changing drugs, the staff need to stand on a ladder or a platform to operate, the speed is slow and the hidden danger exist, the labor intensity of the staff is large, the work efficiency is low, the automation degree is low, and the like, and the functions of automatically storing and storing the drugs and constant temperature dehumidification can be realized. The invention relates to a medicine cabinet, which comprises a medicine cabinet, a medicine cabinet, a medicine cabinet, a medicine cabinet and a medicine cabinet.

Owner:THE FIRST AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

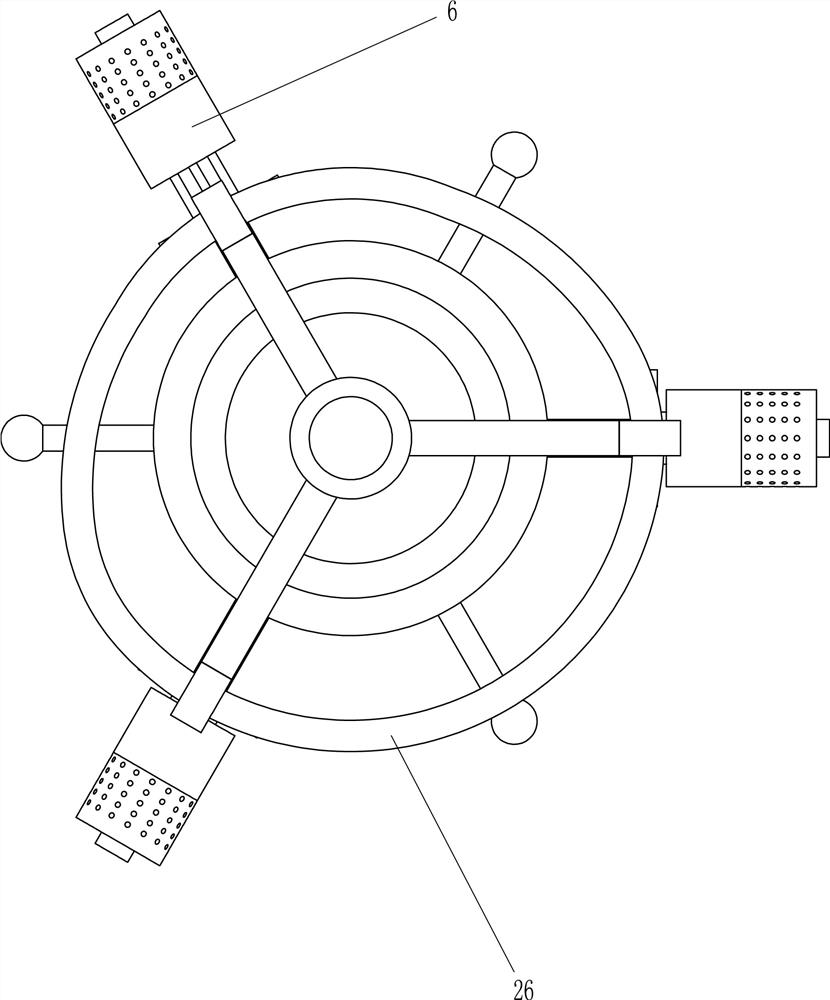

Wet-type spraying dust falling device for tunnel blasting

PendingCN114856682AFlexible dust removal workNo manual fixation requiredUsing liquid separation agentDust removalClassical mechanicsStructural engineering

Owner:曾诚

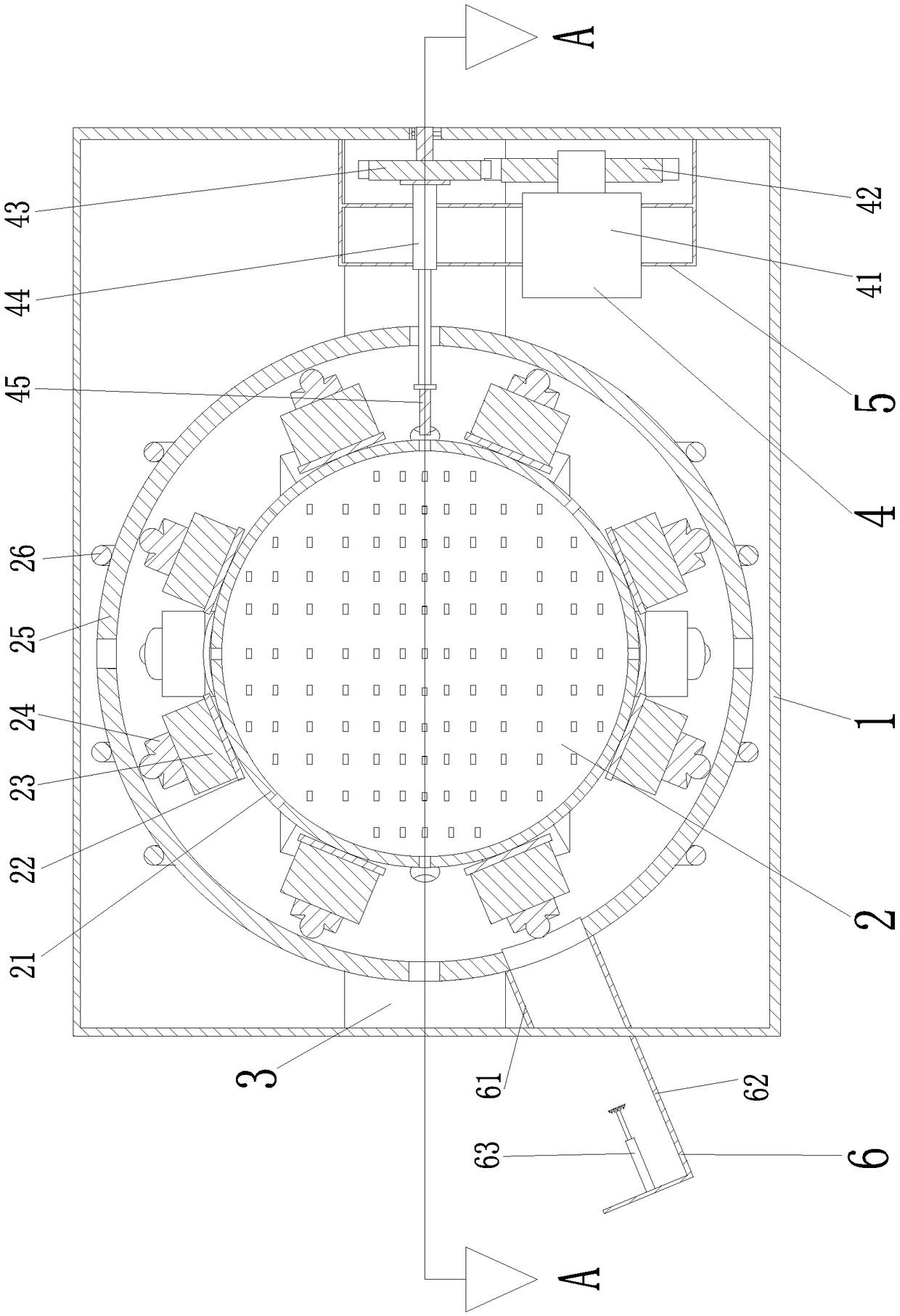

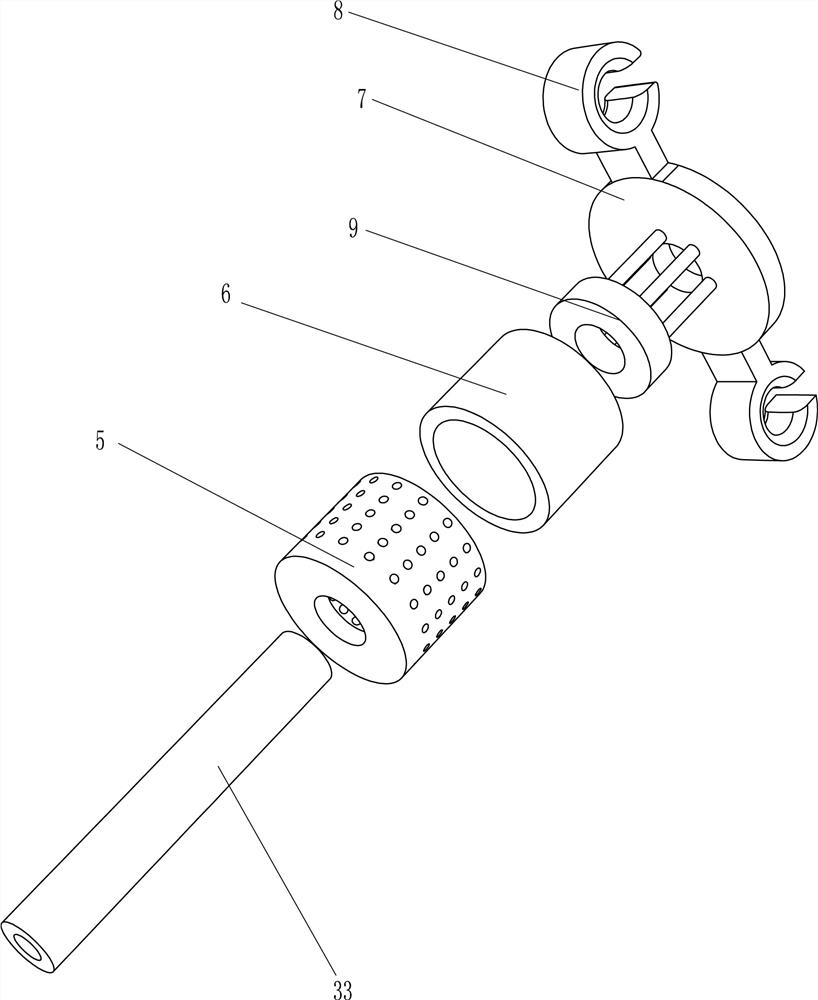

A kind of polishing equipment for the outer wall of the packer rubber cylinder

ActiveCN108908079BEasy to polishImprove polishing effectPolishing machinesSealing/packingPolishingElectric machinery

The invention discloses polishing equipment for a rubber barrel outer wall of a packer. The polishing equipment comprises a polishing equipment main body, wherein a supporting rod is fixed at the middle position of the polishing equipment main body; a first fixed block is mounted at the top of the supporting rod; an opening is formed in the middle position of the top of the polishing equipment main body; a thread sleeve is connected with the inner part of the opening through a thread; the lower end of the thread sleeve extends into the polishing equipment main body; a second fixed block is mounted; a worm wheel sleeves an external thread of the thread sleeve; a worm rod is engaged with the worm wheel; one end of the worm rod extends to the outer part of the polishing equipment main body and is connected with an output shaft of a first driving motor; second driving motors are mounted at middle positions of two sides of the polishing equipment main body through locking bolts; the outputshaft of each second driving motor extends into the polishing equipment main body and is fixedly provided with a rotating plate; each rotating plate is provided with a through hole; a rotating columnis movably arranged in each through hole. The polishing equipment disclosed by the invention is reasonable in structure, ingenious in design, simple to operate, convenient to use and suitable for popularization.

Owner:QINGDAO UNIV OF SCI & TECH

Device for laterally pulling air conditioning unit into cabin

PendingCN113978657AImprove construction efficiencyAvoid high fallWaterborne vesselsEngineeringStructural engineering

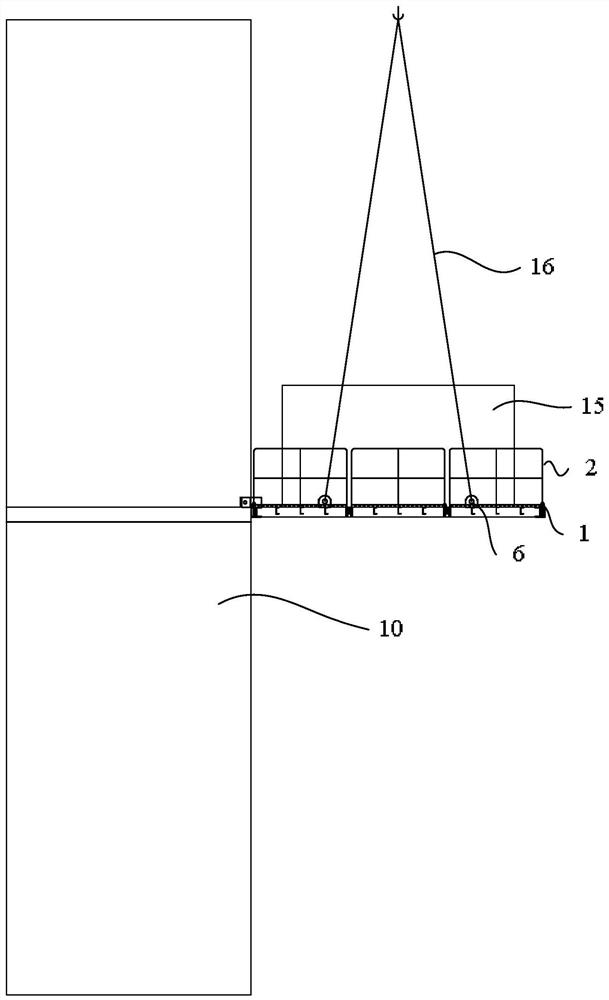

The invention relates to the technical field of cruise ship air conditioning station construction, in particular to a device for laterally pulling an air conditioning unit into a cabin, the device is applied to a cruise ship and comprises a supporting component and a protection component detachably connected with the supporting component, and the protection component defines a hollow containing space on the supporting component to place to-be-hoisted objects; the supporting component is provided with a first connecting component, a ship side plate of the cruise ship is provided with a second connecting component, and the first connecting component is detachably connected with the second connecting component. By means of the device for laterally pulling the combined air conditioning unit into the cabin, the operation of laterally pulling the combined air conditioning unit into the cabin is achieved, the risk that the combined air conditioning unit is prone to touching an interference object in the direct lifting process is avoided, the device is safer and more reliable, and the construction efficiency is improved. In addition, due to the arrangement of the protection component, the risk of high falling in the hoisting process is avoided. In addition, through the two connecting components, the device is connected to a ship side plate, and the combined air conditioning unit is convenient to carry.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

Biochemical ceramic as well as preparation method and application thereof

InactiveCN101475362BAvoid washing awayNo manual fixation requiredTreatment using aerobic processesSustainable biological treatmentEutrophicationFiltration

The invention relates to biochemical ceramic and a preparation method and application thereof. The biochemical ceramic adopts wastewater sludge as a main raw material and is prepared through the supplementary materials of calcium carbonate or gypsum, clay, dehydrate calcium hydroxide, liquid wax, iron dust or brown iron oxide via anoxic burning. The biochemical ceramic can be used as a biologicalmedium of a granular sludge bed in a biological filter or a trickling filter or during the anaerobic treatment, and can also be used for reducing the water body eutrophication or build a filtration dam to reduce the pollution caused by the wastewater. The retractable biochemical ceramic can automatically fix bacteria so as to prevent the biomass from being flushed away without artificial fixation, and can immobilize the heavy metal elements in the sludge and release no heavy metal elements in the application process. The biochemical ceramic can be used for preparing cogs with different shapesand sizes; therefore, the biochemical ceramic has a wider application prospect.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

A rubber glove inspection device

ActiveCN111855087BEasy to checkNo manual fixation requiredFluid-tightness measurement using fluid/vacuumPolymer scienceHand parts

The invention relates to an inspection device, in particular to a rubber glove inspection device. The technical problem of the present invention is to provide a rubber glove inspection device that can automatically fix rubber gloves, reduce manual operations, and avoid manual hand soreness. The technical solution of the present invention is: a rubber glove inspection device, including: a base, a rotating mechanism is arranged on the base; an air blowing mechanism, the parts of the rotating mechanism and the base are provided with an air blowing mechanism; a support column, which is installed on the base side. The invention drives the rubber gloves to rotate through the rotating mechanism, which facilitates the inspection of the rubber gloves and completes the inspection work of the rubber gloves. Through the air blowing mechanism, the wind generated by the air jet can be blown into the rubber gloves to inspect the rubber gloves without Manually aim the jet at the rubber glove, through the adsorption cylinder, piston and compression cylinder, the rubber glove can be adsorbed on the adsorption cylinder, without manually fixing the rubber glove.

Owner:南京润京乳胶制品有限公司

A hand-held electric drill drilling auxiliary electric drill stand

ActiveCN110355405BNo need to moveAchieve fixationWork benchesPortable drilling machinesStructural engineeringElectrical and Electronics engineering

The invention discloses a handheld electric drill punching auxiliary electric drill frame. The device comprises a mounting frame, a mounting seat and a movable frame, wherein a guide rail is arrangedon the movable frame; the mounting seat is slidably arranged on the guide rail; a turntable arranged at the bottom of the mounting frame is rotatably arranged on the mounting seat through a rotating shaft; the mounting frame consists of a movable frame and a shaping frame; one end of the movable frame is installed on movable rods of second electric push rods installed in the shaping frame; a bottom box is installed on the bottom surface of the movable frame; a storage battery and first electric push rods are installed in the bottom box; and a movable rod installed on the output end of each first electric push rod penetrates through the bottom of the bottom box and extends to a supporting plate. According to the device, the mounting frame is designed to be telescopic; drilling height can bechanged at any time; scale marks are arranged on the mounting frame, so that specific drilling height is changed according to the change of the scale marks; and reading is convenient.

Owner:BENGBU COLLEGE

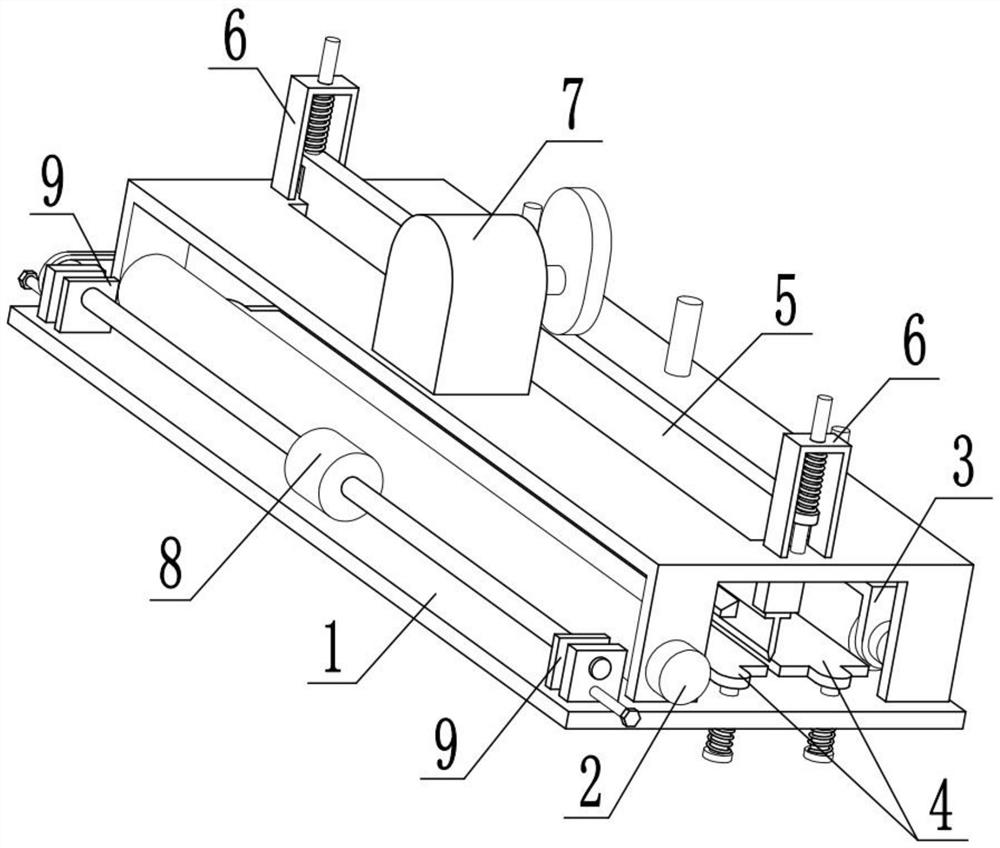

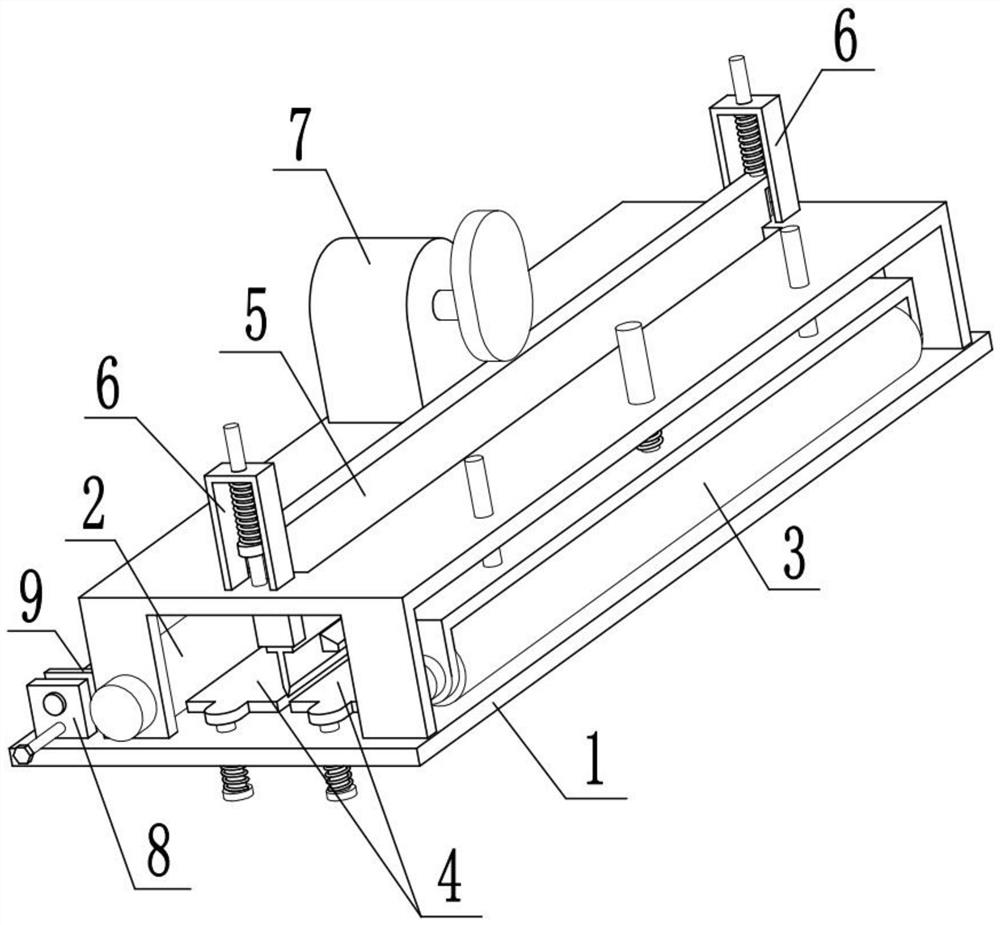

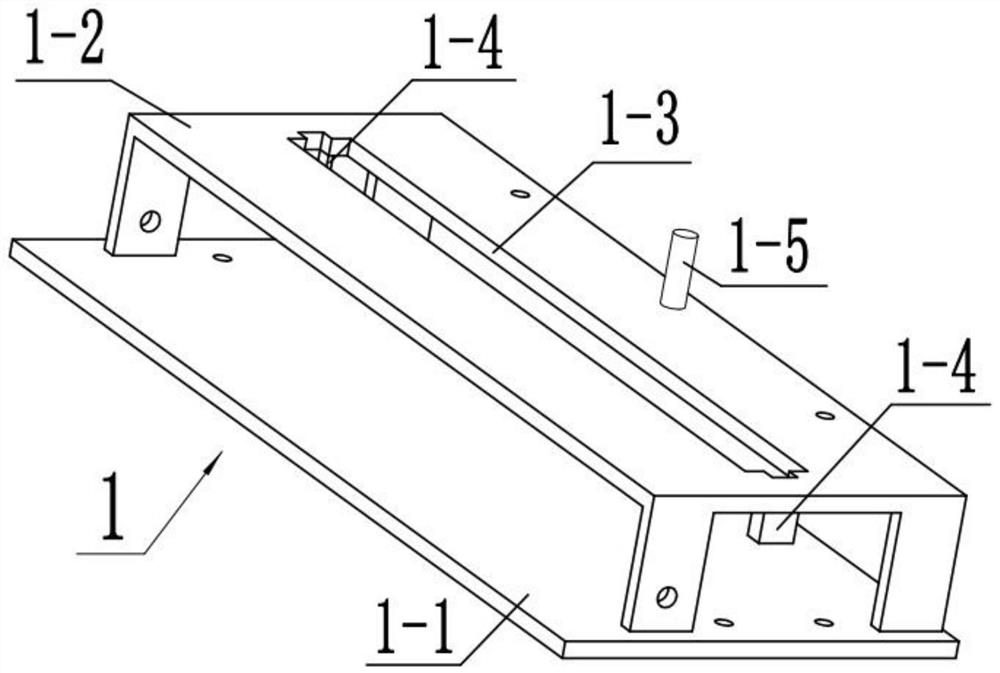

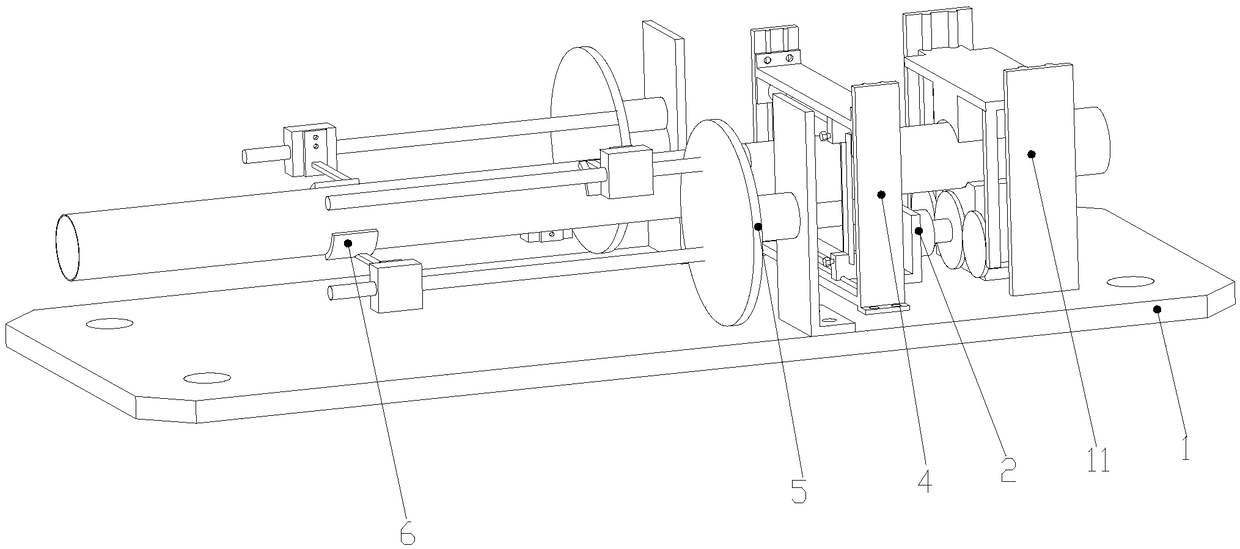

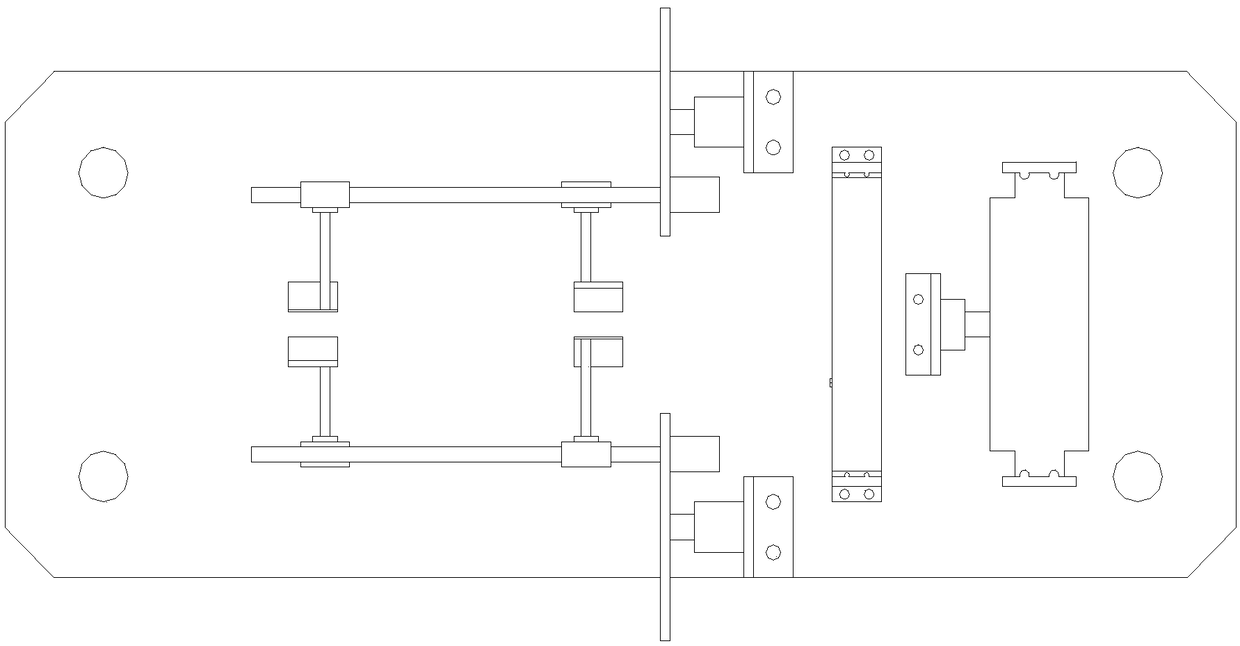

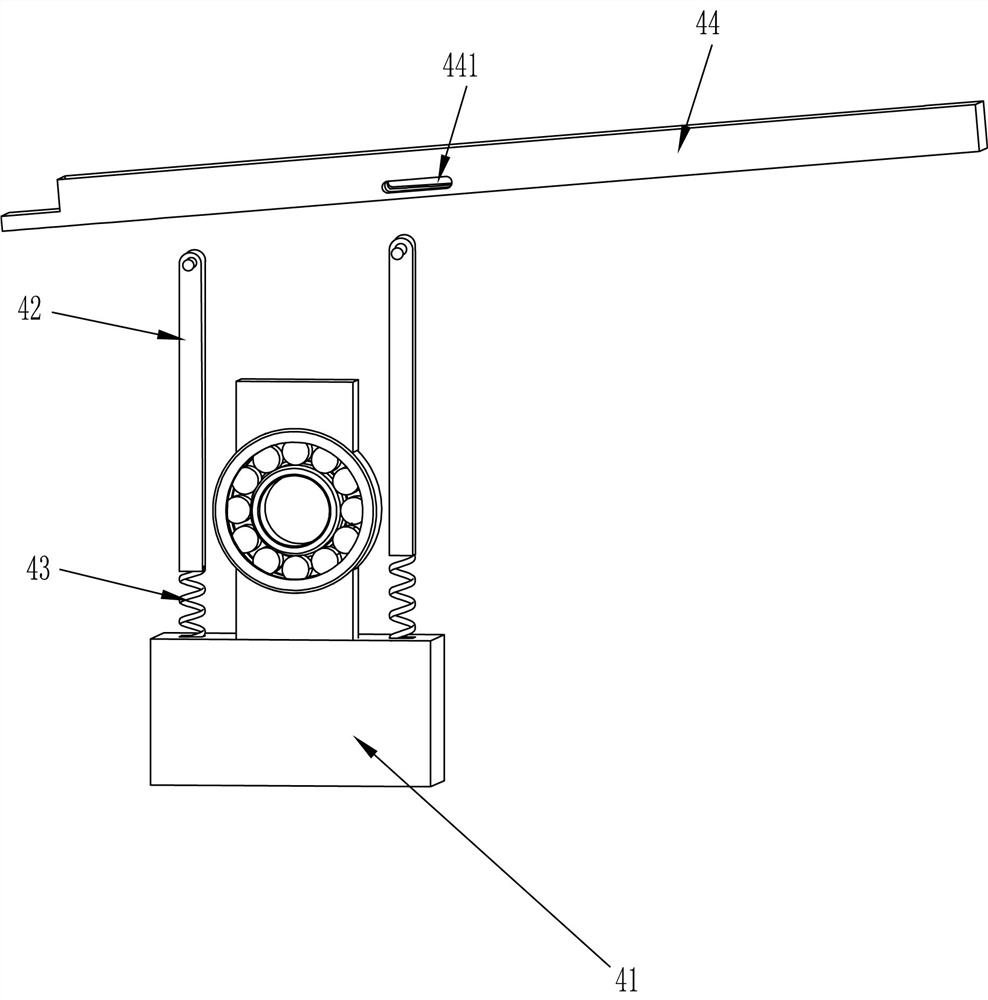

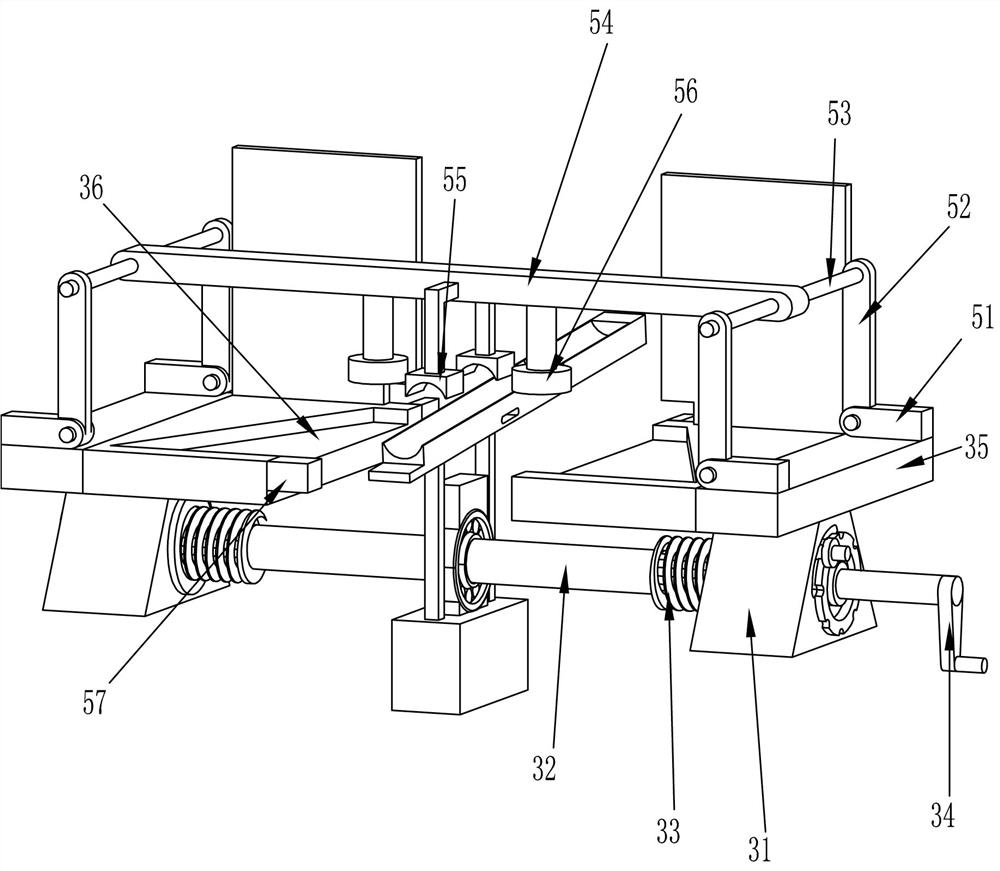

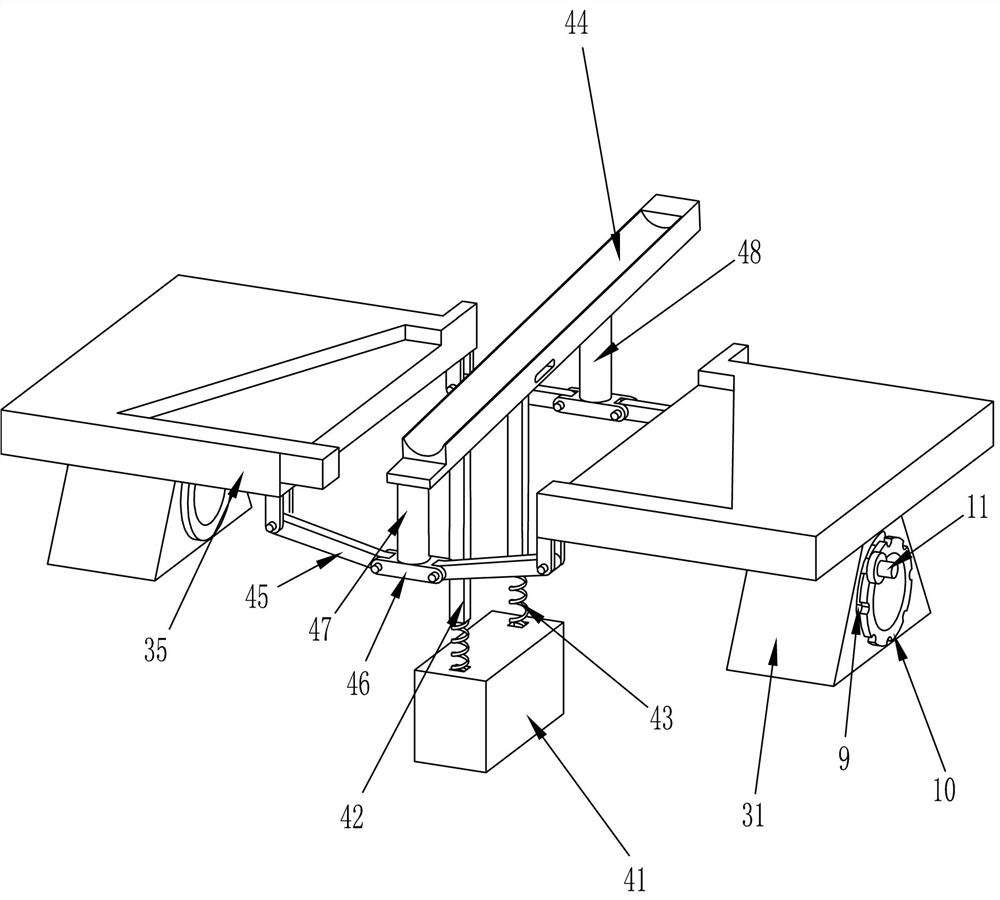

Automatic feeding cutting device of frequency converter heat dissipating pipe

ActiveCN109227166ANo manual fixation requiredIncrease productivityMetal working apparatusPositioning apparatusFrequency changer

The invention discloses an automatic feeding cutting device of a frequency converter heat dissipating pipe. The device comprises a base, supporting frames are arranged on the base, a first supportingplatform is arranged between the supporting frames, a second supporting platform is arranged on the first supporting platform, a transmission rack is arranged at the lower end of the second supportingplatform, a driving unit is fixedly installed on the base, a placing platform is fixedly installed on the base, a cutting unit is fixedly installed on the base, a feeding unit is arranged on the upper end of the base, and a tight clamping unit is fixedly installed on the feeding unit. The feeding unit is started to tightly clamp the heat dissipating pipe, a rolling bead lead screw is driven to feed the heat dissipating pipe, when the feeding of the heat dissipating pipe is completed, the driving unit allows the second platform to tightly clamp the heat dissipating pipe placed on the placing platform, the cutting unit is started to cut the heat dissipating pipe, after the cutting of the first section of the heat dissipating pipe is completed, the heat dissipating pipe is expanded through the driving unit, a second rotary motor is started again to feed the heat dissipating pipe, and the next section of cutting of the heat dissipating pipe is conducted.

Owner:CHAOHU JINHUI AUTOMATIC CONTROL EQUIP

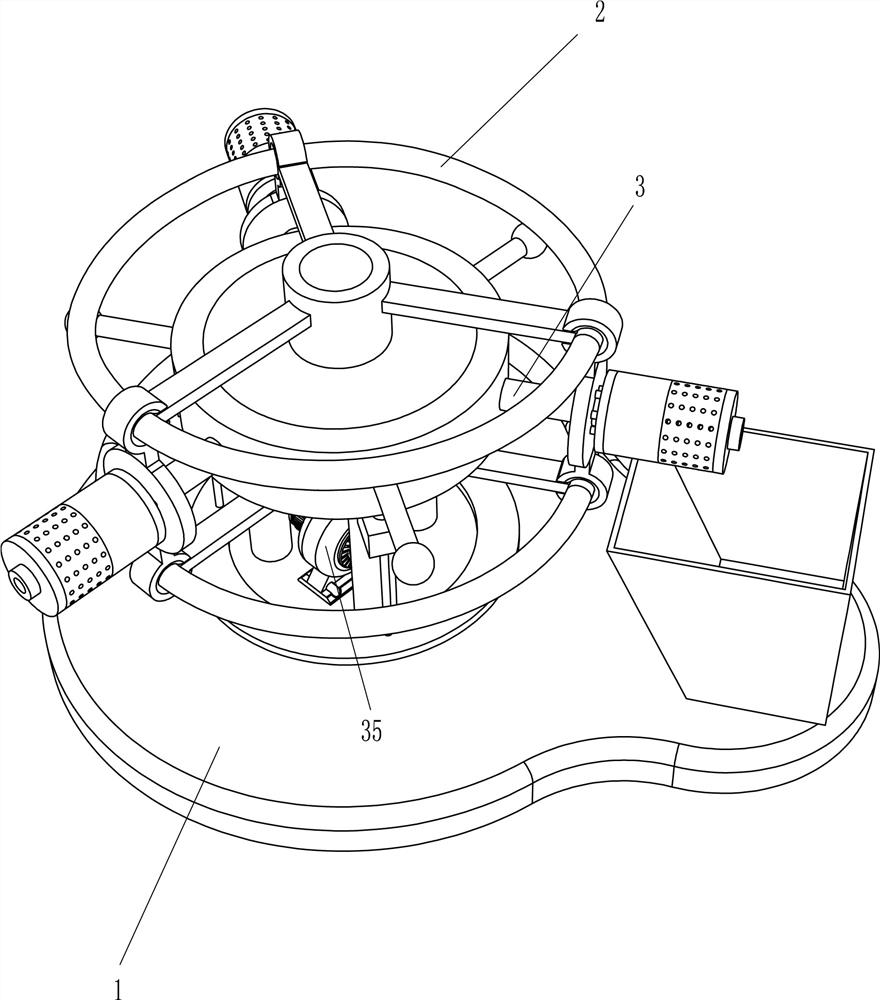

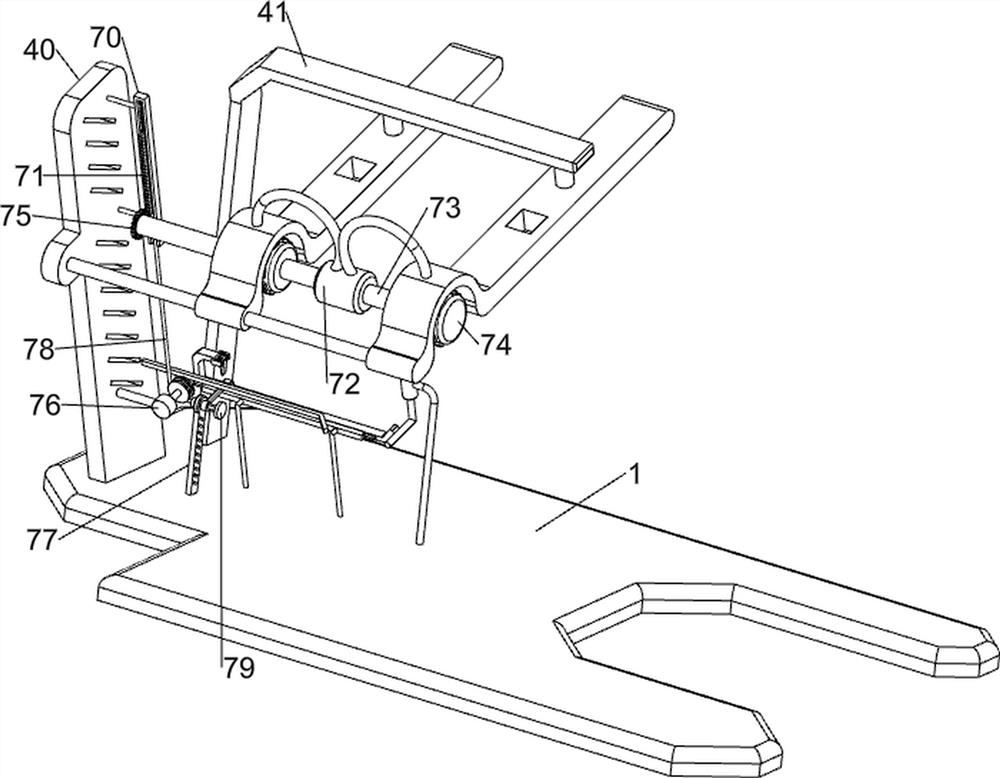

Fixing device for stirring blade welding

ActiveCN111922581ARealize automatic movementNo manual fixation requiredWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeWelding process

The invention relates to a welding device, in particular to a fixing device for stirring blade welding. The fixing device for stirring blade welding does not need to be operated by multiple persons, improves the welding efficiency and protects workers against damage. According to the technical scheme, the fixing device for stirring blade welding comprises a base and an ejection mechanism; the sidepart of the base is provided with a fixing seat, and clamping mechanisms are arranged inside and at the top of the fixing seat; and the ejection mechanism is arranged in the fixing seat. According tothe fixing device for stirring blade welding, by means of the clamping mechanisms, blades can automatically move towards the inner side, meanwhile, a steel pipe and the blades are pressed through a pressing mechanism, and manual blade fixing is not needed; by means of the ejection mechanism, a small supporting block and a large supporting block, an arc-shaped containing plate can automatically incline forwards, so that the welded stirring blades automatically slide down; and the rotating shaft can be fixed through an arc-shaped clamping groove, a chuck and a bayonet lock, and the rotating shaft is prevented from deflecting to drive the blades to move in the welding process.

Owner:淮北扬帆有色冶金科技有限公司

A kind of automatic cartoning equipment for biocapsule production

ActiveCN112478296BReduce labor costsEasy to take outIndividual articlesBiochemical engineeringProcess engineering

The invention relates to a cartoning device, in particular to an automatic cartoning device for the production of biological capsules. The technical problem is: to provide an automatic cartoning device for the production of biological capsules that can limit the medicine box, automatically pack and automatically discharge. Provided is such an automatic cartoning device for biocapsule production, which includes a base and a placing mechanism, one side of the base is provided with a placing mechanism; and a pushing mechanism is provided on the base. Through the cooperation between the placing mechanism and the pushing mechanism, the capsules can be automatically loaded into the box, and the capsules can be automatically transferred, which can save labor costs. It is easy for people to take out, and at the same time, the medicine box can be limited, so that there is no need to manually fix the medicine box.

Owner:中芝堂药业(山东)有限公司

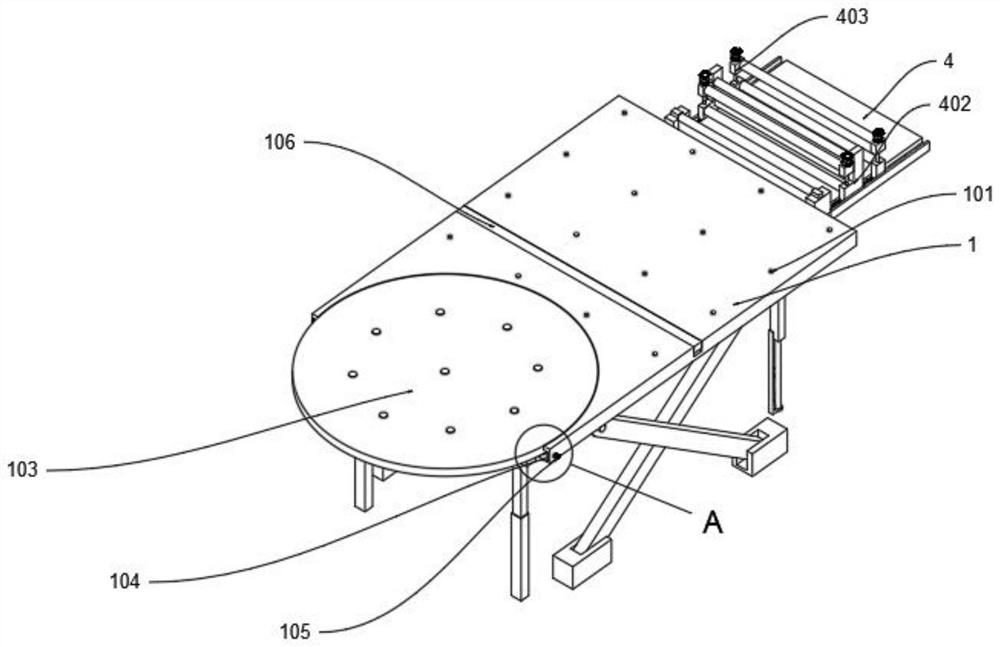

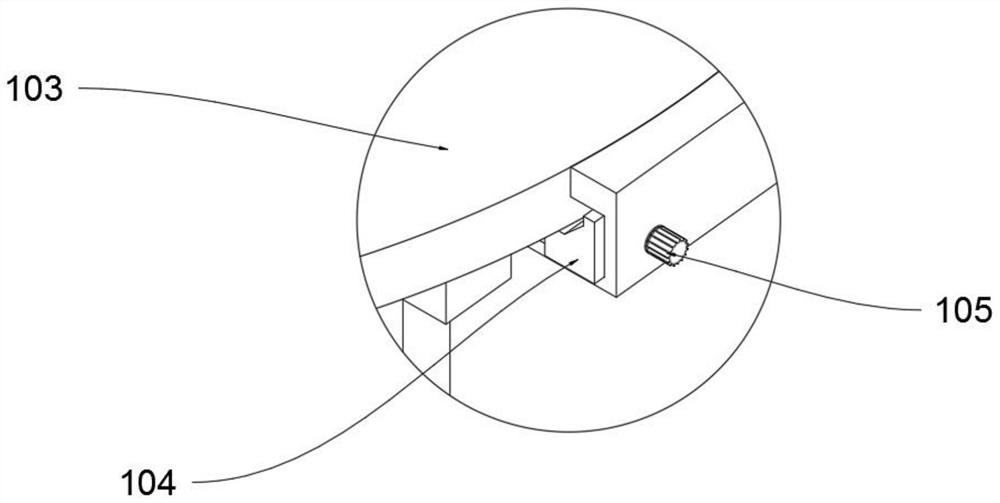

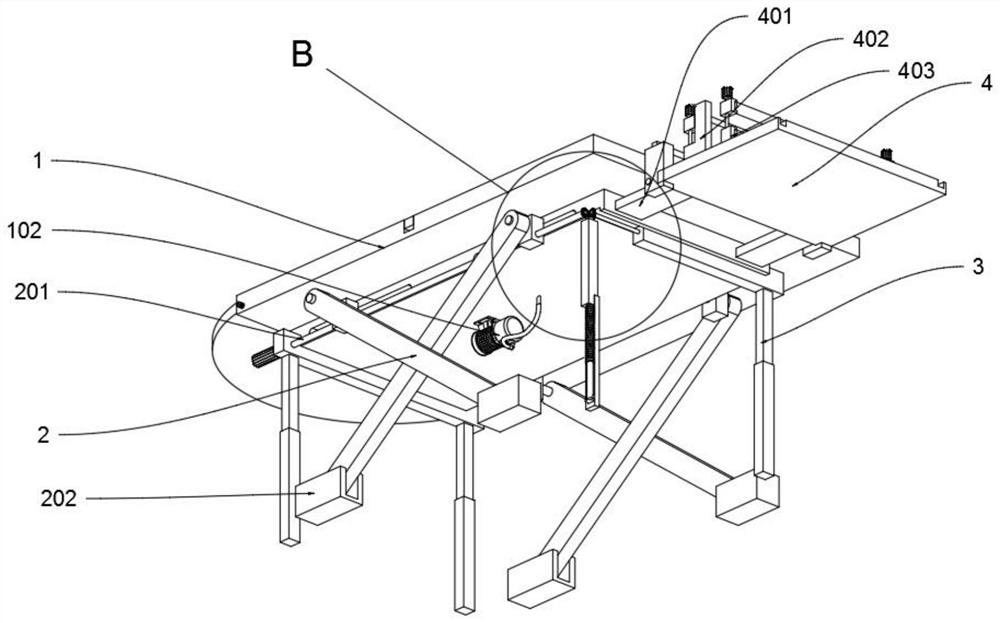

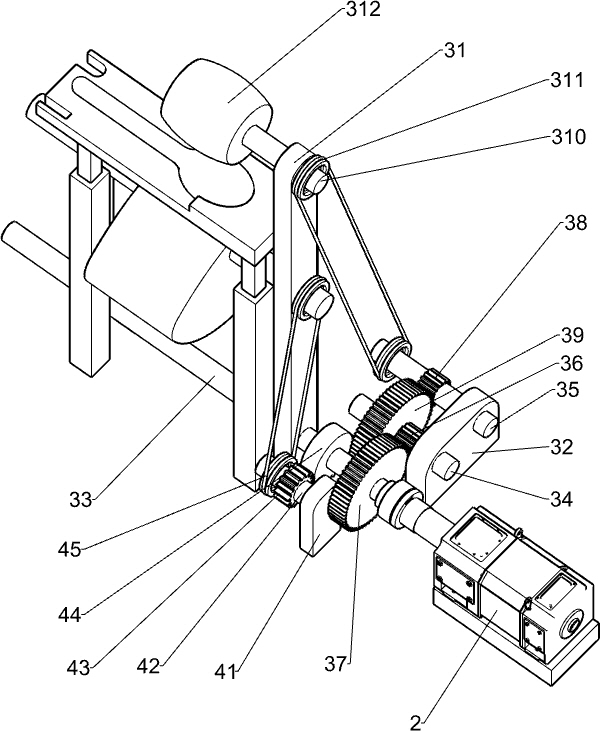

A rotary cutting table for clothing design

Owner:JILIN INST OF PHYSICAL EDUCATION

A wooden shovel forming machine

ActiveCN111805630BRealize automatic cuttingNo manual fixation requiredProfiling/shaping machinesMolding machineElectric machinery

The invention relates to a forming machine, in particular to a wooden shovel forming machine. Technical problem: Provide a wooden shovel forming machine that can automatically fix the wooden shovel, automatically take the wooden shovel, and reduce manual operations. The technical solution of the present invention is: a wooden shovel forming machine, including: a base, a motor is provided on the side of the base, a cutting mechanism is provided on the side of the base near the motor, the motor is connected with the cutting mechanism, and the side near the cutting mechanism The side of the base is equipped with a material jacking mechanism, and the material jacking mechanism is connected with the cutting mechanism. The invention realizes the automatic cutting of the wooden shovel through the cutting mechanism. At the same time, under the action of the ejecting mechanism, it is not necessary to manually fix the wooden shovel, and the wooden shovel can be automatically moved to the working board through the pushing mechanism, without manual work. The cutting wooden shovel is placed on the working board, and the wooden shovel to be cut is placed centrally through the unloading mechanism, so that the wooden shovel can be pushed out by the push rod, and the manual does not need to take the wooden shovel repeatedly.

Owner:阳炽贵

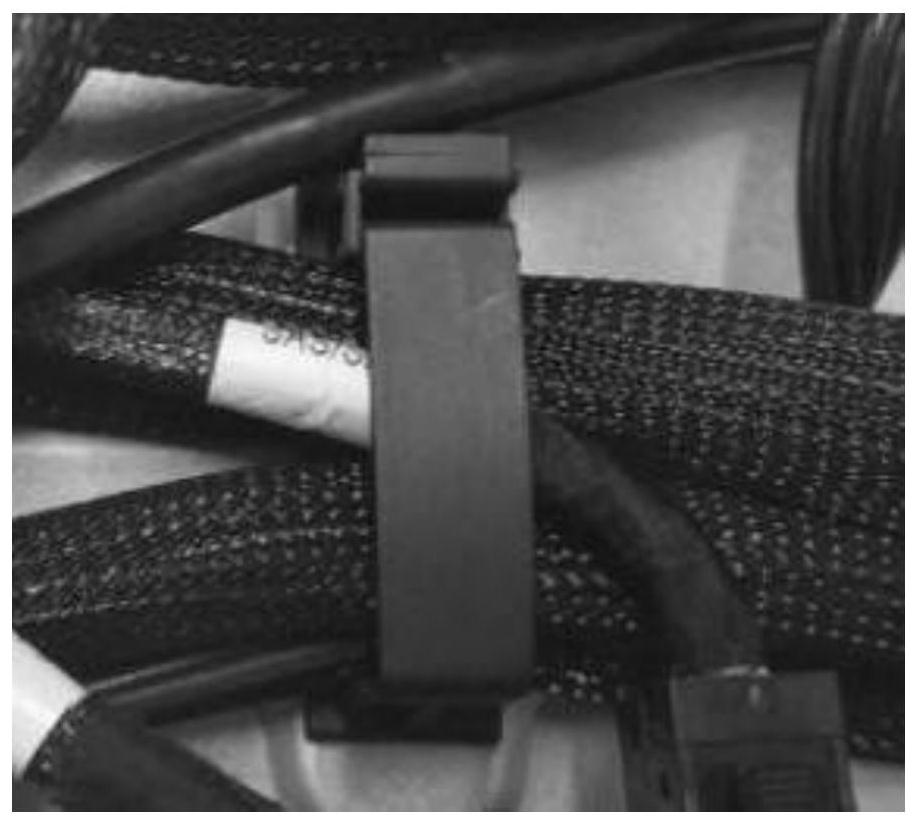

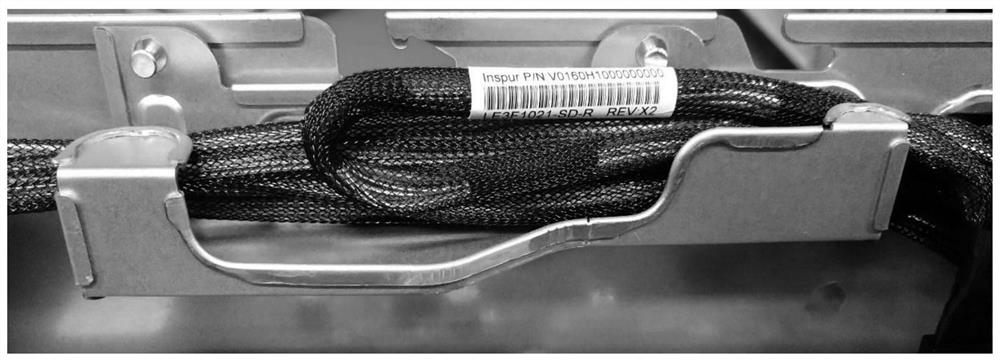

A wire management device

ActiveCN109659878BConvenient and flexible useEasy to placeElectrical apparatusTorsion springIndustrial engineering

The invention discloses a wire management device, comprising: a fixed piece, a torsion spring, a torsion spring support rod and a wire clamping part, wherein: one side of the fixing piece has a mounting protrusion, and the mounting protrusion is provided with a through hole; the wire clamping part The end part has a concave part that fits with the installation protrusion, and the two opposite side walls of the concave part are provided with holes; one end of the torsion spring is against the fixed piece, the other end is against the fixed piece, and the extension rod at the other end is connected to the clip The inner walls of the line components are fixedly connected; the torsion spring is set on the torsion spring support rod, the torsion spring support rod passes through the through hole, and the two ends of the torsion spring support rod are installed in the holes respectively. The cable management device uses the torsion force of the torsion spring to fix the cable, which is convenient and flexible to use, avoids the problem of loose buckle after repeated use, and saves space.

Owner:INSPUR BUSINESS MACHINE CO LTD

Strip coiling device with grabbing position, coiling position and unloading position arranged on rotating disc

The invention provides a strip coiling device with a grabbing position, a coiling position and an unloading position arranged on a rotating disc, and relates to the technical field of strip coiling. The strip coiling device with the grabbing position, the coiling position and the unloading position arranged on the rotating disc comprises a baffle, wherein a supporting frame is fixedly mounted on the outer side of the bottom of the baffle, a threaded rod is rotationally connected to the inside of the supporting frame, a rotary knob is fixedly mounted at the top end of the threaded rod, and theperiphery of the threaded rod meshes with a first threaded sleeve. According to the strip coiling device with the grabbing position, the coiling position and the unloading position arranged on the rotating disc, the stability is improved when a strip is placed, the occurrence of safety accidents is avoided, a winding roller and the strip head of the strip can be automatically adsorbed, the manualfixation is not needed, the time and the labor are saved, in the coiling process, a roller formed by coiling the strip can be extruded continuously, the tightness of coiling is guaranteed, the coilingamount is improved, the strip can be flattened, and the longitudinal fold of the strip is avoided.

Owner:平邑经发科技服务有限公司

Single-trimming universal die

PendingCN113976715AReduce processing costsImprove processing efficiencyStripping-off devicesStructural engineeringMachine tool

The invention relates to a single-trimming universal die. The die comprises a lower die plate, an upper die plate, a material pressing device and a material returning device, the upper die plate can be installed on the lower die plate in a manner of sliding up and down relative to the lower die plate, a lower knife rest is installed in the middle of the lower die plate, and a lower knife is installed on the lower knife rest; an upper knife rest is mounted at the bottom of the upper die plate, and upper knives are mounted on two sides of the upper knife rest; the material pressing device is located on the lower side of the upper knife rest, the material pressing device penetrates through the upper knife rest and is installed at the bottom of the upper die plate in an up-down sliding mode, and the material pressing device is connected to a machine tool fixing frame through a pressing cylinder; and the material returning device is movably connected to the lower die plate and the upper die plate respectively. Steel plates of different structures and sizes can be machined, both single-edge cutting and double-edge cutting can be achieved, multiple machining procedures can be achieved, machining cost is saved, and machining efficiency is improved. The steel plates are automatically fixed through the material pressing device, manual fixing is not needed, and the production efficiency is improved. Through the material returning device, waste materials can be automatically returned, and the labor cost is saved.

Owner:东风汽车底盘系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com