Indentation mechanism for automatic paperboard compression of corrugated cases

A corrugated box and indentation technology, which is applied in the field of indentation mechanism for automatic compression of corrugated cardboard, can solve problems such as low efficiency, unsafety, and inability to adjust indentation, and achieve high efficiency and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

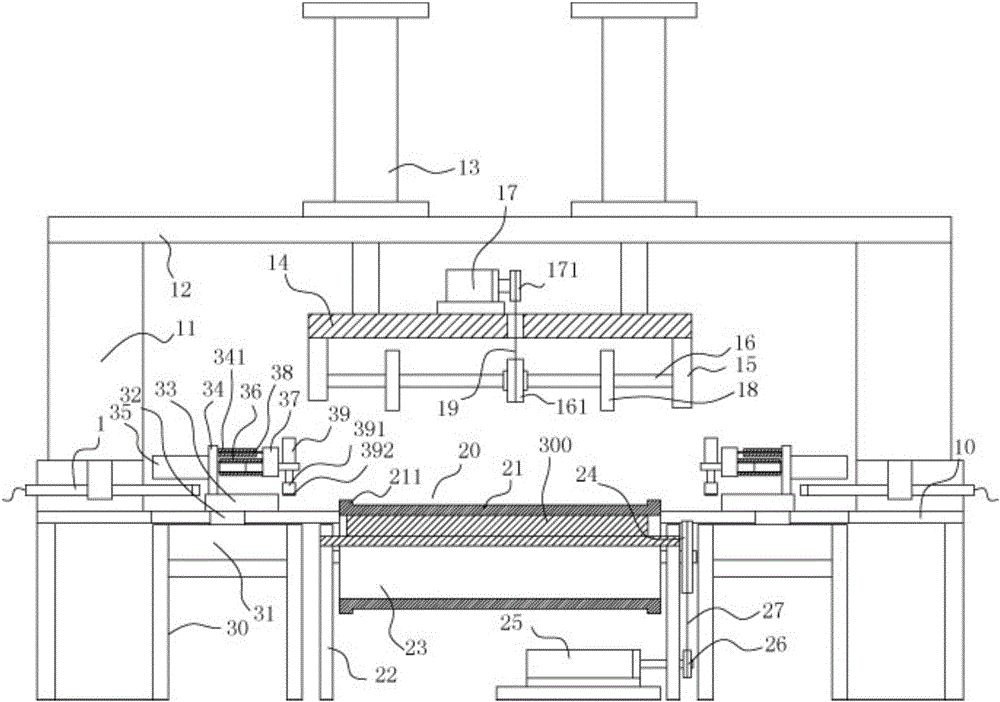

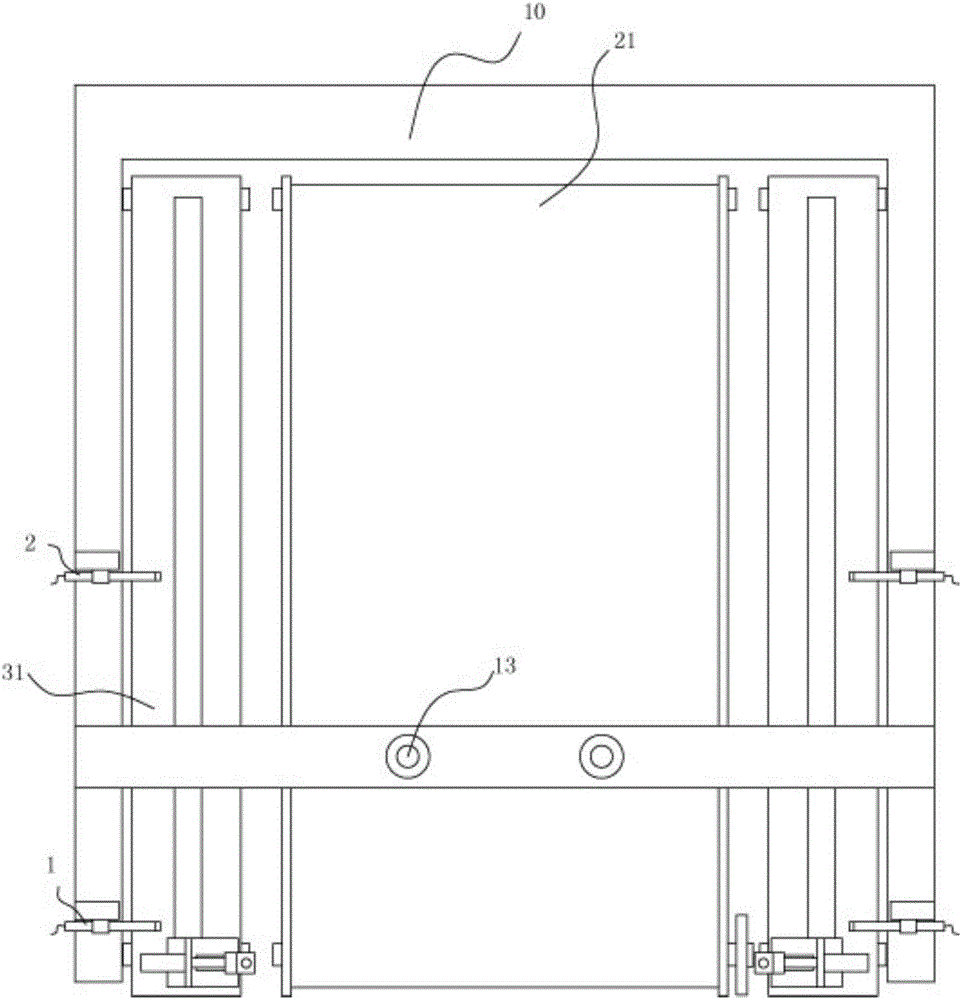

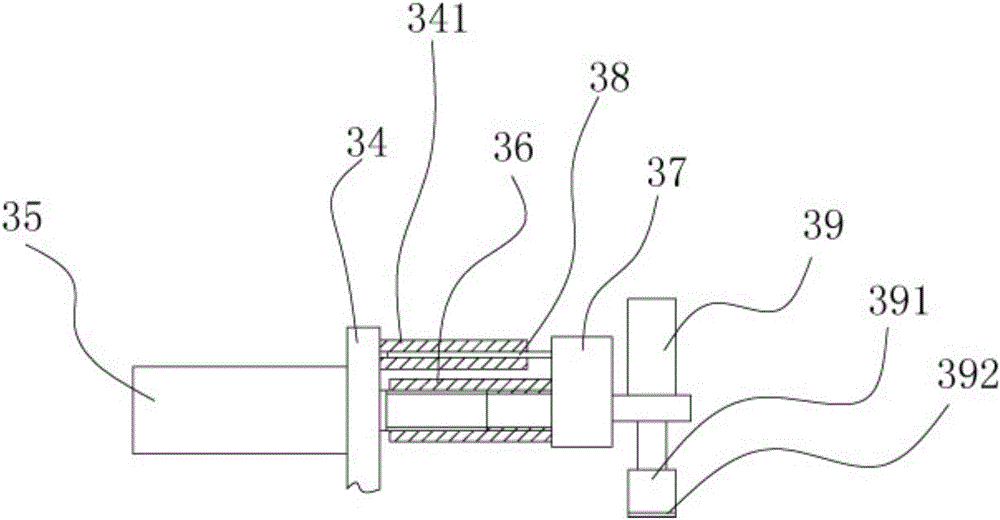

[0017] Example: see Figures 1 to 3 As shown, a creasing mechanism for automatic compression of corrugated cartons includes a U-shaped frame 10, a conveyor belt device 20 and two mobile frames 30 are provided in the U-shaped frame 10, and the two mobile frames 30 are positioned at On both sides of the conveyor belt device 20, a first proximity switch 1 and a second proximity switch 2 are fixed on the top plates on the left and right sides of the U-shaped frame 10, the first proximity switch 1 is at the front of the U-shaped frame 10, the second Two proximity switches 2 are in the middle part of the U-shaped frame 10, the left and right sides of the U-shaped frame 10 between the first proximity switch 1 and the second proximity switch 2 are fixed with a vertical support plate 11, and the upper support plate 12 is fixed on On the two vertical support plates 11, two downward pressure cylinders 13 are fixed on the upper support plate 12, and the push rods of the downward pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com