A kind of intelligent self-regulating temperature material and preparation method thereof

A self-adjusting and intelligent technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of inability to realize intelligent self-regulation and high cost of materials, and achieve large latent heat of phase change, low cost, and adsorption phase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Intelligent temperature-regulating phase-change energy storage composite material

[0031] The intelligent temperature-regulating phase-change energy storage composite material includes stearate and glass pumice, stearic acid is loaded in the pores of glass pumice, and the stearate is methyl stearate and ethyl stearate.

Embodiment 2

[0032] Example 2 Intelligent temperature-regulating phase-change energy storage composite material

[0033] There are stearate and glass pumice in the intelligent temperature-regulating phase change energy storage composite material, stearic acid is loaded in the pores of glass pumice, the stearate is methyl stearate, ethyl stearate, Wherein the mass ratio of methyl stearate: ethyl stearate is 1:1, and the mass ratio of stearate to glass pumice is 1:3-10.

Embodiment 3

[0034] Example 3 Intelligent temperature-regulating phase-change energy storage composite material

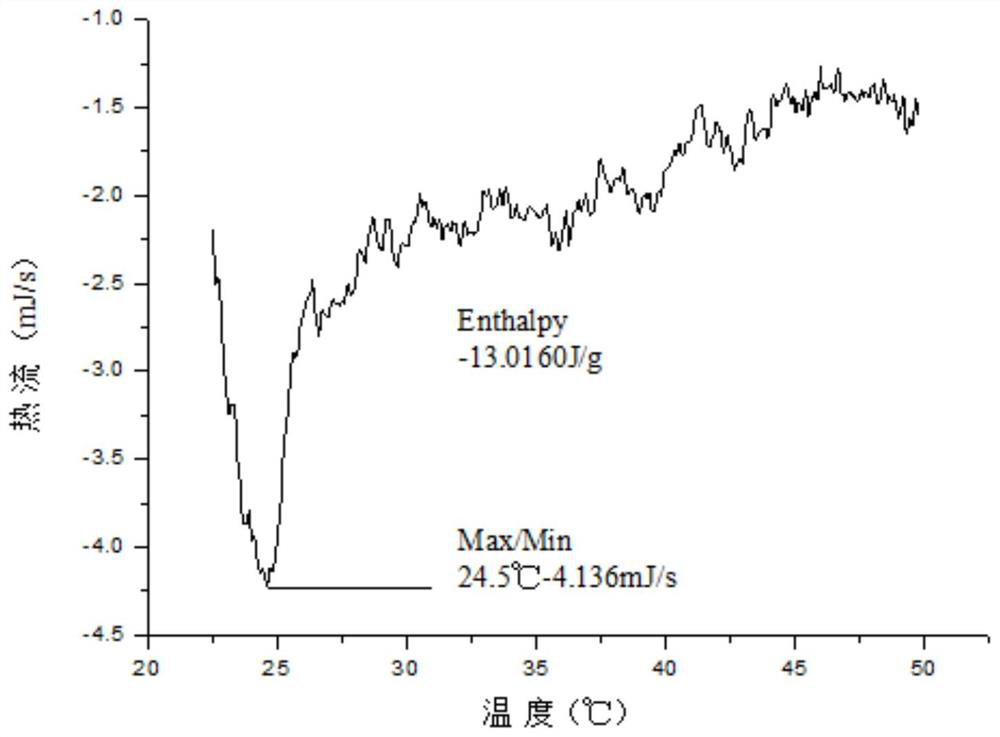

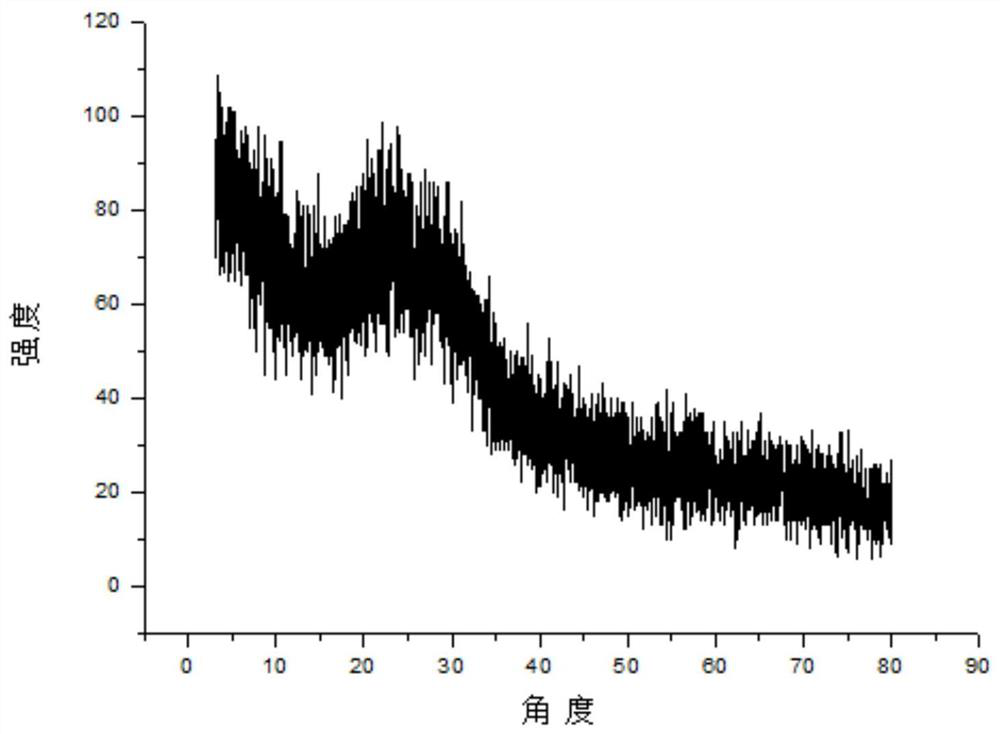

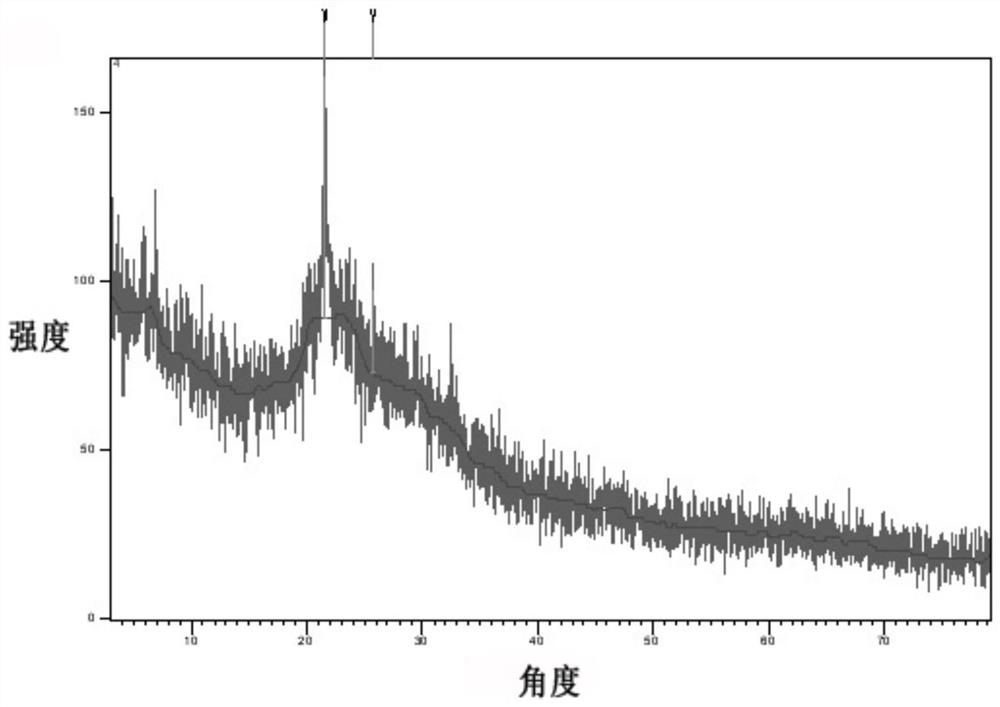

[0035] There are stearate and glass pumice in the intelligent temperature-regulating phase change energy storage composite material, stearic acid is loaded in the pores of glass pumice, the stearate is methyl stearate, ethyl stearate, Wherein the mass ratio of methyl stearate: ethyl stearate is 1:1, and the mass ratio of stearate and glass pumice is 1:4. figure 1 It is shown that the phase transition temperature point of the material is 24.5°C, and the phase transition enthalpy is -13.0160 / g. figure 2 , image 3 XRD characterization proves that the carrier has no change before and after, and the supported phase change material is an amorphous compound. Figure 4 , Figure 5 In the infrared spectrum of glass pumice, it is located at 1000cm -1 The absorption is typical Si-O bond stretching vibration absorption, 3400cm -1 O-H stretching vibration for glass pumice adsorbing w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com