Biochemical ceramic as well as preparation method and application thereof

A ceramic and biochemical technology, applied in the direction of ceramic products, chemical instruments and methods, applications, etc., can solve the problems of no decolorization, loss of carbon source, lack of microbial carbon source in ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A biochemical ceramic is fired from the following raw materials, and the amount of each component is part by weight:

[0009] 30-40 parts of sludge, 8-15 parts of calcium carbonate or gypsum, 12-42 parts of clay, 0-10 parts of wood chips, 2-4 parts of calcium hydroxide dihydrate, 0-10 parts of kaolin, 1-15 parts of liquid wax , 0-10 parts of iron powder or iron oxide powder, 0-5 parts of activated carbon, 0-10 parts of coal powder. The above-mentioned sludge is the surplus sludge of the sewage treatment plant.

[0010] The preparation method of the biochemical ceramics of the present invention has the following steps:

[0011] (1) Mix various raw materials according to the above-mentioned biochemical ceramic formula, prepare them into mud or granular mud, use a template to make and shape, and dry into a blank;

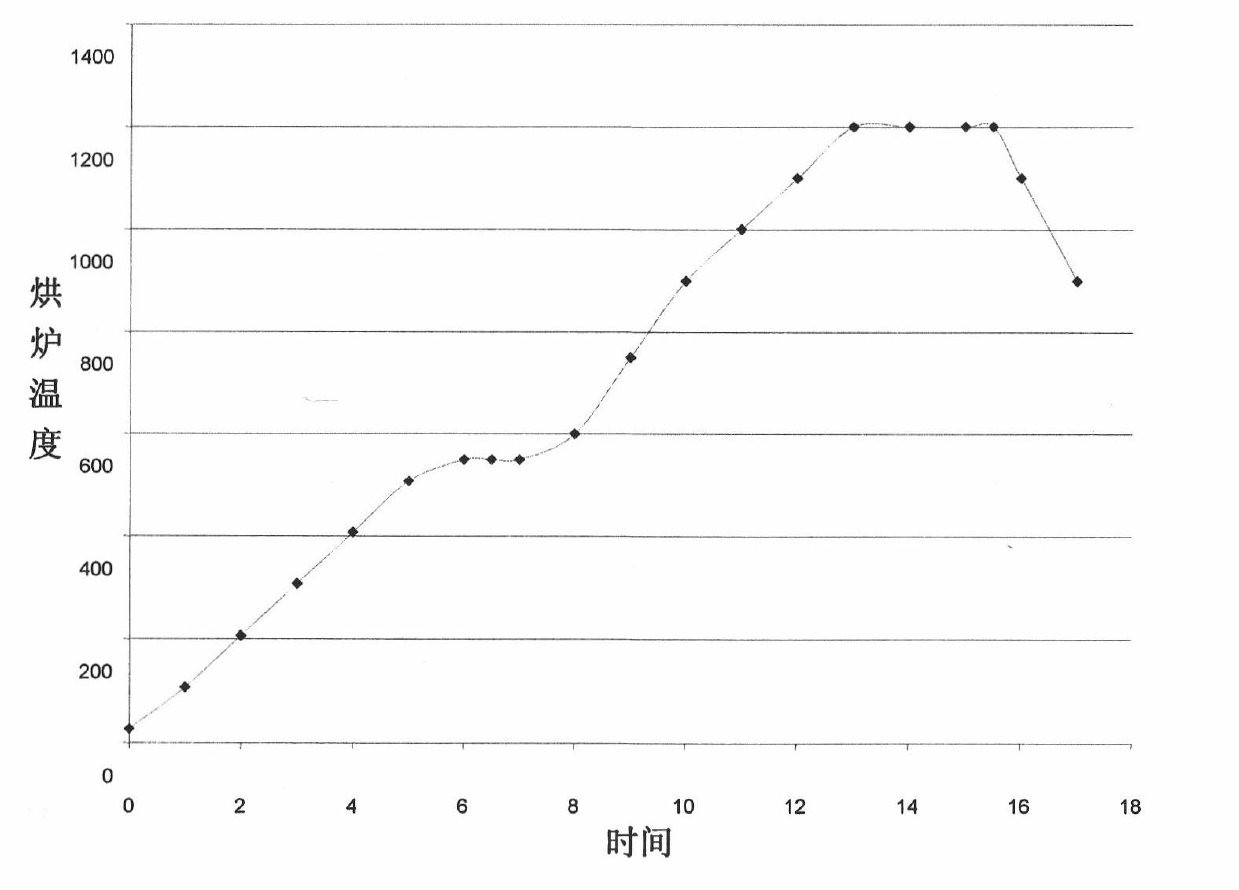

[0012] (2) Place the blank obtained in step (1) in a high-temperature oven for firing. The heating rate of the oven temperature is not more than 100°C per hour. When t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com