Bagasse-based water retaining agent and preparation method thereof

A technology of water-retaining agent and bagasse, which is applied in the direction of chemical instruments and methods, sewage/sludge fertilizer, fertilizer made from biological waste, etc. It can solve the problems of unfavorable ecological environment, sustainable development of plant planting, failure to improve soil function, and difficulty in degradation, etc. Problems, achieve the effect of improving grafting reaction efficiency, improving water retention effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

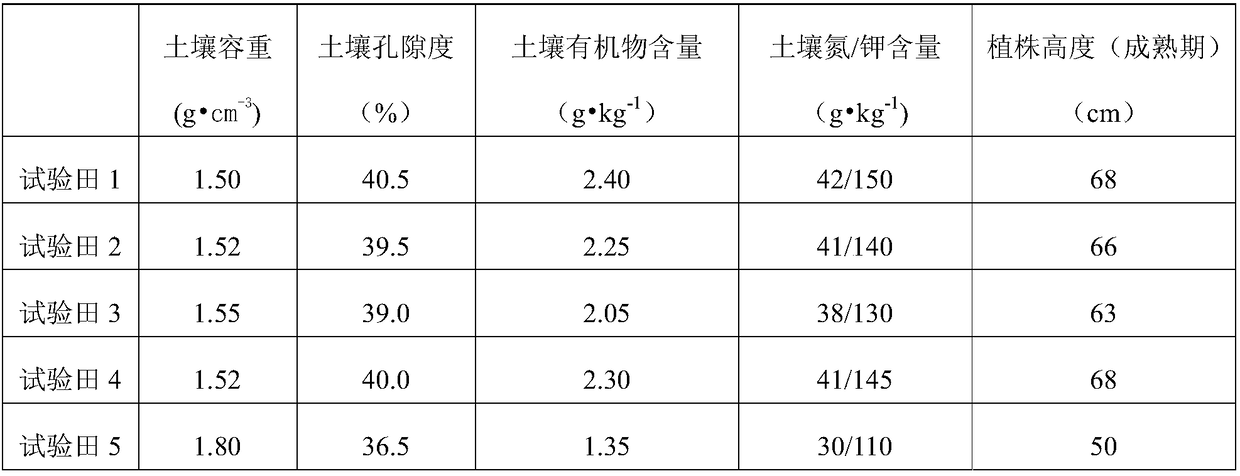

Examples

Embodiment 1

[0039] A bagasse-based water-retaining agent comprises the following components in parts by weight:

[0040] 80 parts of bagasse, 20 parts of waste silk, 15 parts of bagasse biochar, 5 parts of bentonite, 15 parts of sludge, 60 parts of potassium acrylate, 2 parts of crosslinking agent, 1 part of initiator, and 3 parts of polymerization agent.

[0041] The sludge is farm sludge. The crosslinking agent is glycerol. The initiators are hydrogen peroxide and potassium persulfate. The polymerization agent is ammonia water.

[0042] A preparation method of bagasse-based water-retaining agent, comprising the following steps:

[0043] S1. Preprocessing

[0044] 1) Weigh bagasse, crush and pass through a 100-mesh sieve to obtain bagasse powder; add 0.7% H to the bagasse powder 2 o 2 and 4% NaOH mixture, the H 2 o 2 The liquid-to-solid ratio of the mixed solution of NaOH and bagasse is 30:1; stir and react at 85°C for 3-5 hours, then suction filter and dry; then add 31ml / LCH 3 ...

Embodiment 2

[0054] A bagasse-based water-retaining agent comprises the following components in parts by weight:

[0055] 60 parts of bagasse, 20 parts of waste silk, 20 parts of bagasse biochar, 10 parts of bentonite, 10 parts of sludge, 50 parts of potassium acrylate, 1.5 parts of crosslinking agent, 1.5 parts of initiator, and 2 parts of polymerization agent.

[0056] The sludge is farm sludge. The crosslinking agent is glycerol. The initiators are hydrogen peroxide and potassium persulfate.

[0057] The preparation method is the same as in Example 1.

Embodiment 3

[0059] A bagasse-based water-retaining agent comprises the following components in parts by weight:

[0060] 100 parts of bagasse, 10 parts of waste silk, 10 parts of bagasse biochar, 10 parts of bentonite, 20 parts of sludge, 60 parts of potassium acrylate, 3 parts of crosslinking agent, 1 part of initiator, 3 parts of polymerization agent.

[0061] The sludge is chemical plant sludge. The crosslinking agent is glycerol. The initiators are hydrogen peroxide and potassium persulfate.

[0062] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com