Full-automatic steel bar twisting device

A fully automatic, torsion-type technology, applied in the field of torsion-type equipment, can solve the problems of large volume and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

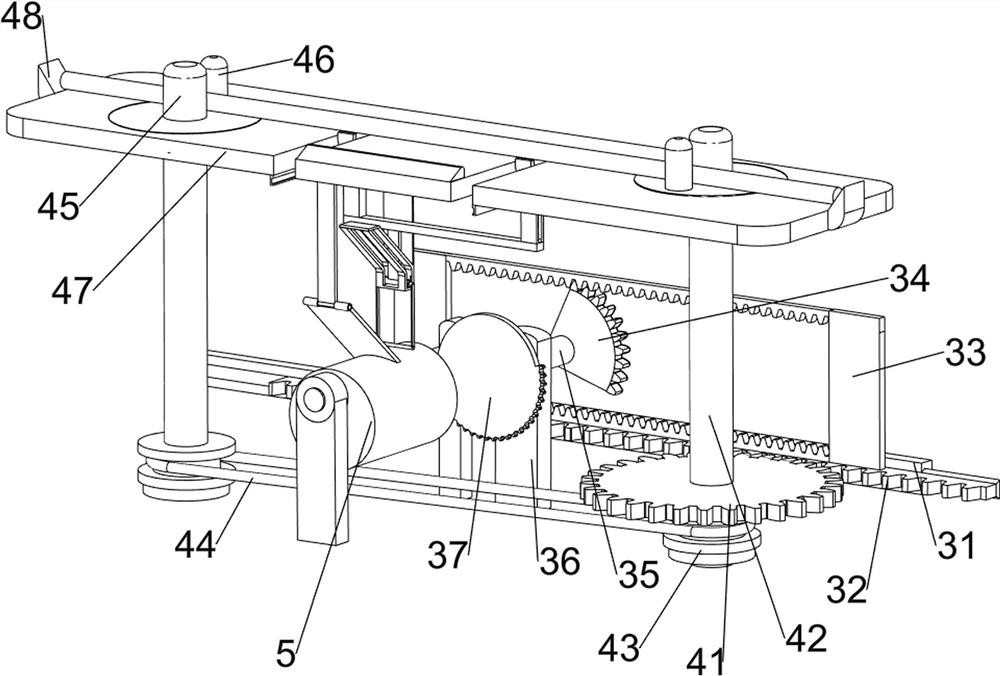

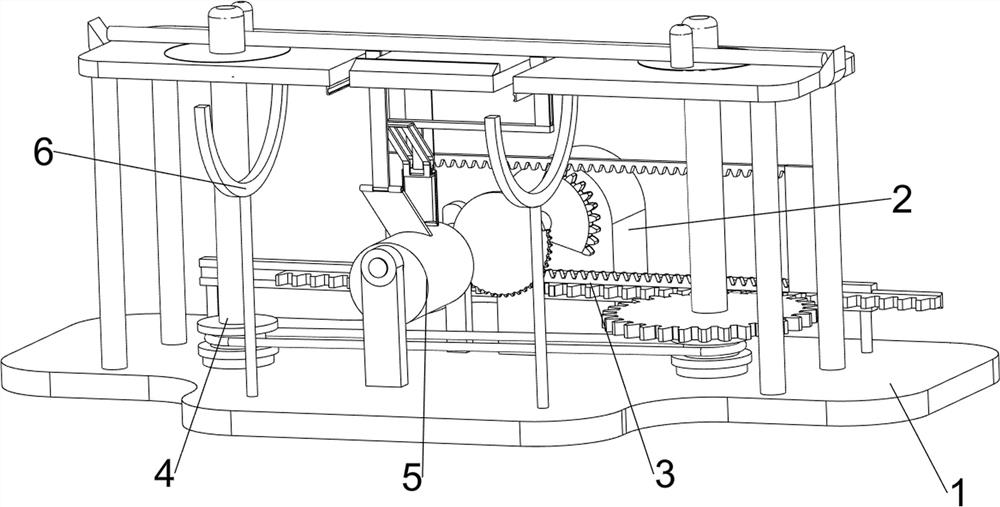

[0053] A fully automatic steel bar twisting equipment, such as figure 1 As shown, it includes a base 1, a geared motor 2, a transmission mechanism 3 and a twisting mechanism 4. The geared motor 2 is connected in the middle of the top rear side of the base 1, and the transmission mechanism 3 is connected between the base 1 and the output shaft of the geared motor 2. The base 1 A torsion mechanism 4 is connected with the transmission mechanism 3 .

[0054] When people need to bend the steel bar, the steel bar is first placed on the parts of the twist mechanism 4, then the gear motor 2 is started, and the output shaft of the gear motor 2 rotates to drive the parts of the transmission mechanism 3 to move, so that the parts of the twist mechanism 4 are opposite to the steel bar. Bending is carried out at both ends, and after completion, turn off the reduction motor 2 and take out the reinforcing bar.

Embodiment 2

[0056] On the basis of Example 1, such as figure 2 As shown, the transmission mechanism 3 includes a first card slot 31, a spur rack 32, a built-in spur rack 33, a first rotating shaft 35, a first missing gear 34, a first support rod 36 and a second missing gear 37, the base 1 A first card slot 31 is connected between the left and right sides of the rear part, and a spur rack 32 is slidably connected in the first card slot 31, and the spur rack 32 is engaged with the parts of the twist mechanism 4, and the top of the spur rack 32 is connected The spur rack 33 is attached inside, the first support rod 36 is connected in the middle of the rear side of the base 1, the first support rod 36 is located on the front side of the geared motor 2, the upper part of the first support rod 36 is rotatably connected with the first rotating shaft 35, and the first rotating shaft 35 rear sides are connected with the first missing gear 34, the first missing gear 34 rear side is connected with ...

Embodiment 3

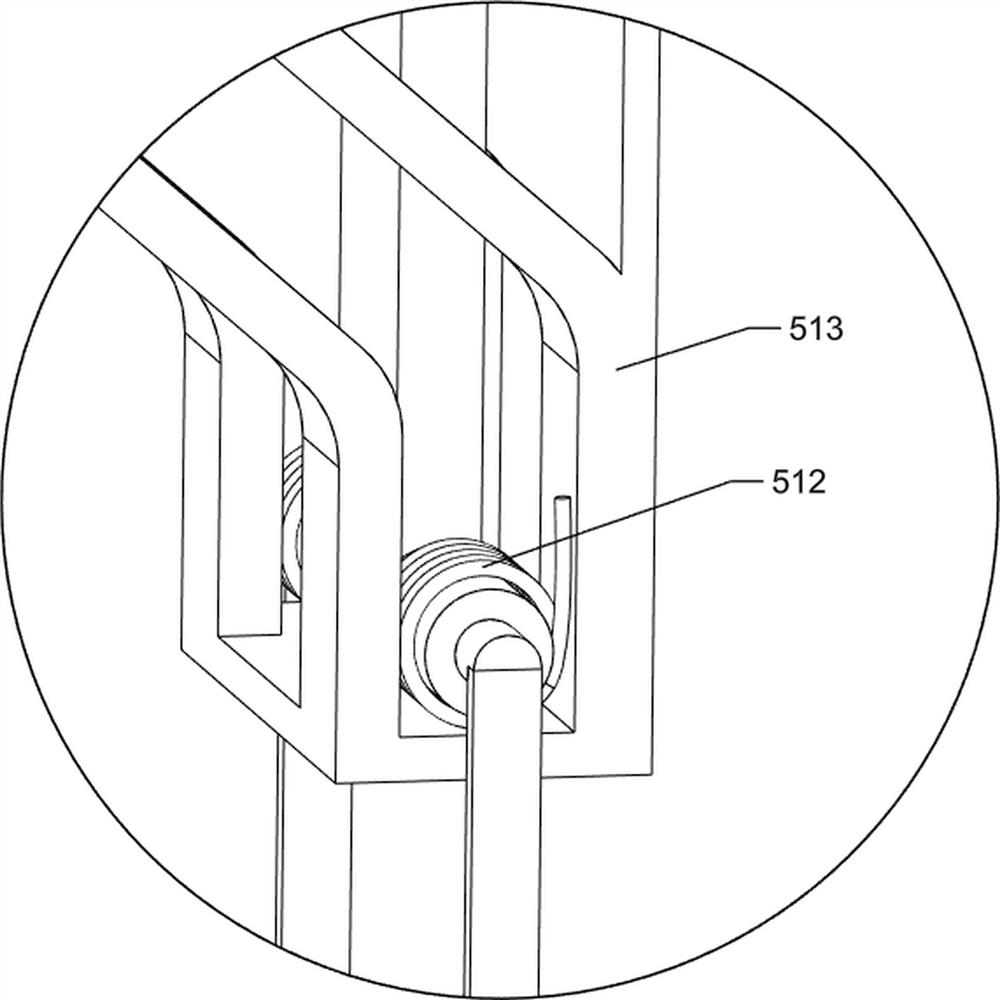

[0061] On the basis of Example 2, such as Figure 3-5 As shown, a pusher mechanism 5 is also included, and the pusher mechanism 5 includes a second support rod 501, a third rotating shaft 502, a second gear 503, a cam 504, a push rod 505, a grooved bracket 506, a cylindrical slide block 507, The second draw-in slot 508, the fixed rod 509, the inclined push plate 510, the third draw-in slot 511, the torsion spring 512 and the fourth draw-in slot 513, the base 1 is connected with the second support bar 501 on the left side, the front and rear sides, the second A third rotating shaft 502 is rotatably connected between the upper parts of the support rods 501, the second gear 503 is connected to the rear of the third rotating shaft 502, the second gear 503 meshes with the second missing gear 37, and a cam 504 is connected to the front of the third rotating shaft 502 , the left rear part of the bottom of the torsion table 47 is connected with a fourth card slot 513, the fourth card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com