Wet-type spraying dust falling device for tunnel blasting

A dust-reducing device and wet-type technology, which is applied in spraying devices, safety devices, dust-proofing, etc., can solve problems such as unstable wind direction, failure to achieve dust removal effect, and low dust removal efficiency of fans.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

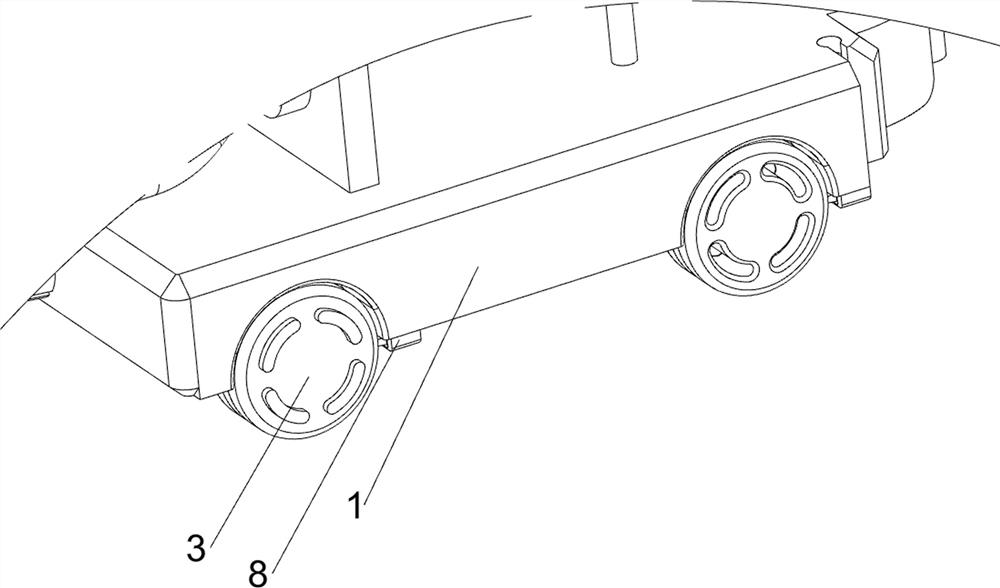

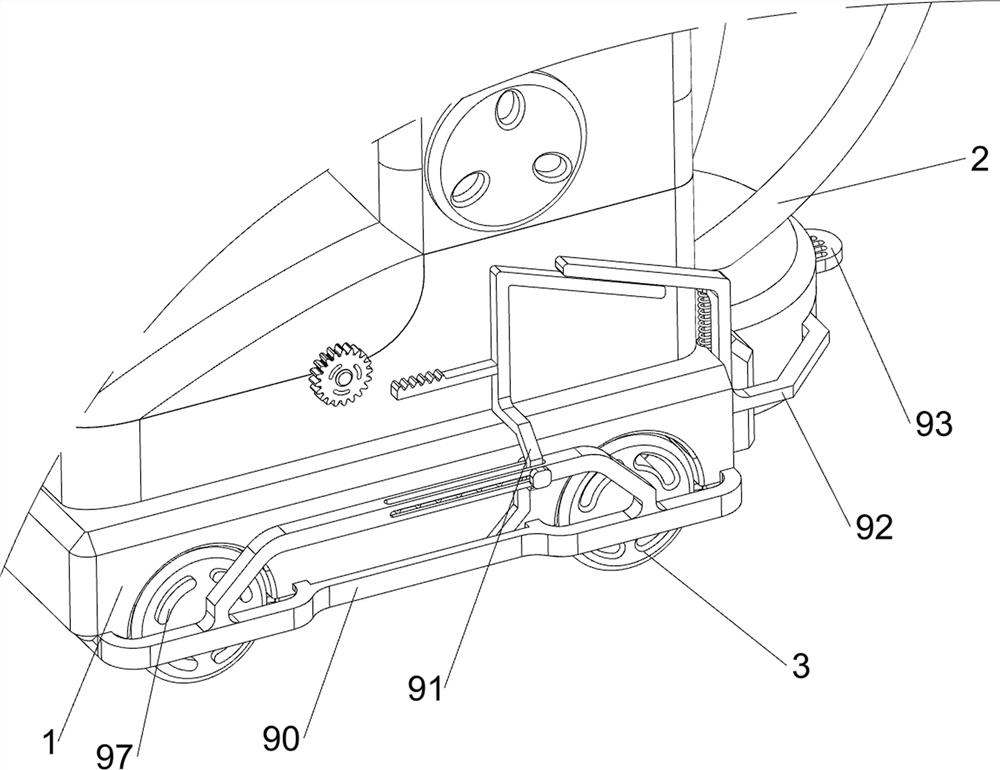

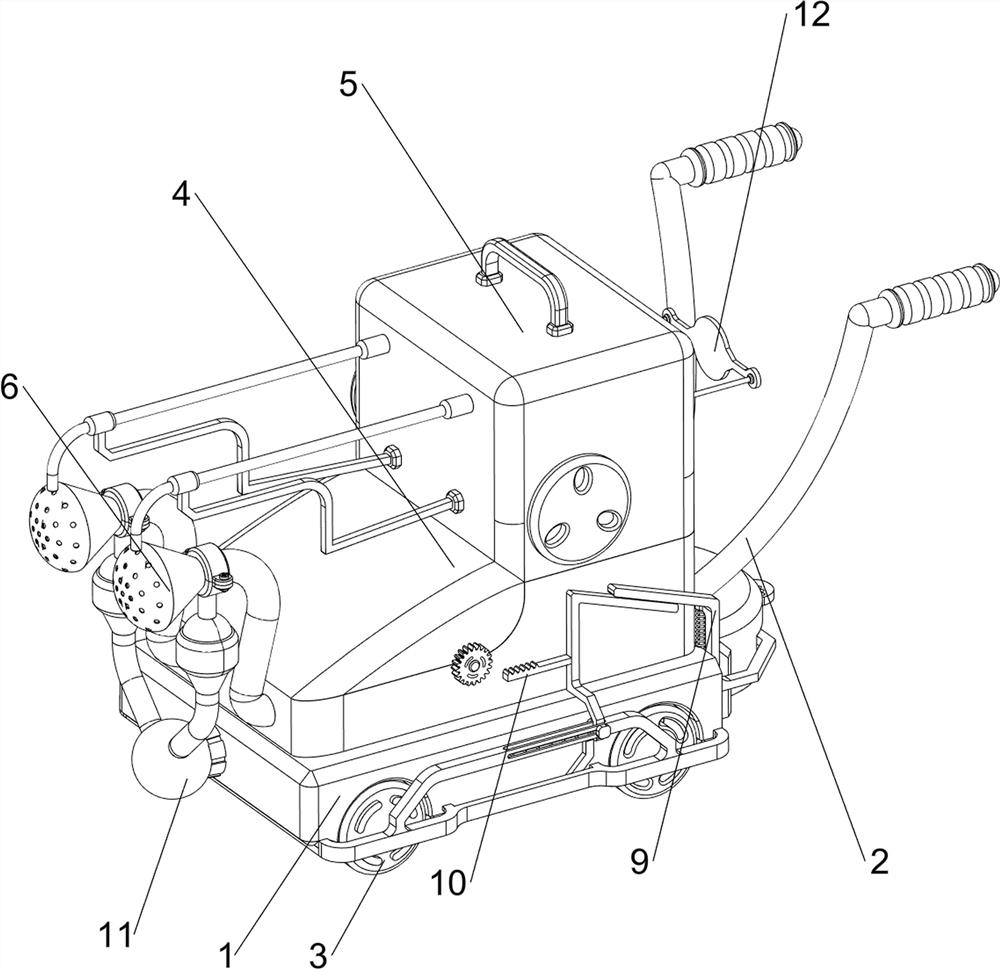

[0031] A wet spray dust suppression device for tunnel blasting, such as figure 1 , figure 2 , image 3 , Figure 5 , Image 6 and Figure 8 As shown, it includes a first support block 1, a first push rod 2, a transmission wheel 3, a water tank 4, a cover 5, a nozzle 6, a valve 7, a braking mechanism 9 and a rotating mechanism 11. The top right side of the first support block 1 is front and rear. The first push rod 2 is symmetrically arranged, and the front and rear sides of the first support block 1 are symmetrically provided with left and right rotations. There are four transmission wheels 3. The top of the first support block 1 is provided with a water tank 4, and the left side of the water tank 4 A spray head 6 is installed symmetrically on the side, front and rear, a cover 5 is slidably provided on the top of the water tank 4, a valve 7 is provided on the right side of the spray head 6, a braking mechanism 9 is arranged at the bottom of the first support block 1, and ...

Embodiment 2

[0038] On the basis of Example 1, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 9 and Figure 10 As shown, it also includes a mud scraping mechanism 8. The mud scraping mechanism 8 includes a limit block 80, a scraper 81 and a first return spring 82. The bottom of the first support block 1 is evenly provided with four limit blocks 80. The limit block 80 The scrapers 81 are slidably provided inside, and a first return spring 82 is connected between the scrapers 81 on the same side and the limit blocks 80 on the same side.

[0039] When people need to uniformly remove dust from the blasted tunnel interior environment, the drive wheel 3 will contact the ground inside the tunnel when it rotates, and the drive wheel 3 will be stained with a lot of soil. When the soil is in contact with the scraper 81, the scraper 81 will The soil will be scraped off, and the scraper 81 will always be in contact with the transmission wheel 3 under the action of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com