Lifting type multifunctional steel pipe spraying equipment

A spraying equipment and multi-functional technology, applied in the field of lift-type multi-functional steel pipe spraying equipment, can solve the problems affecting the efficiency and quality of spraying, the size of the fixture is single, and the thickness of the paint film is not easy to control, etc. The effect of high production, high work efficiency and convenient high-speed production in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

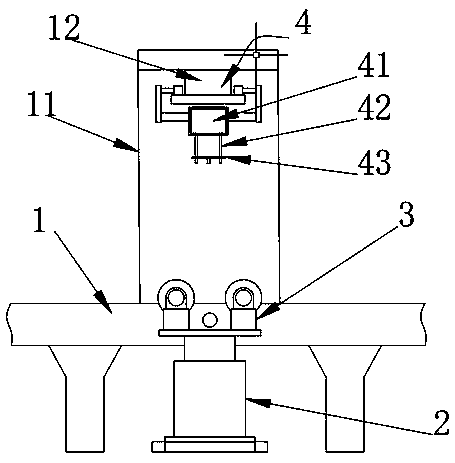

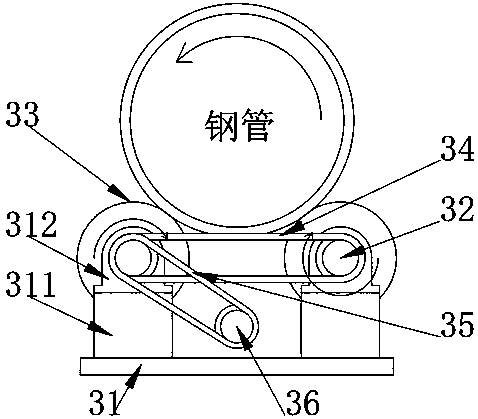

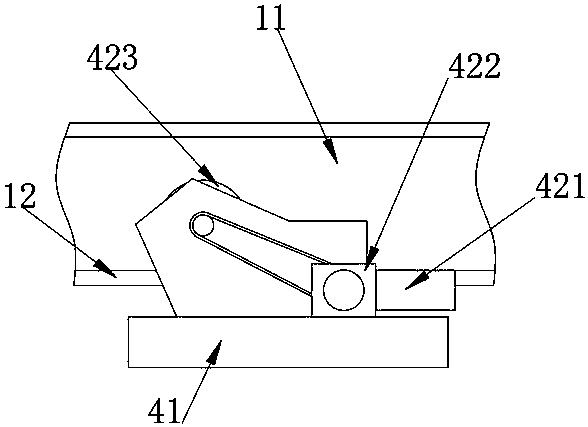

[0027] see Figure 1-3 , the present invention provides a technical solution: a lift-type multifunctional steel pipe spraying equipment, including a frame 1, a lifting assembly 2, a lifting roller set 3 and a spraying assembly 4, the lifting assembly 2 is installed on the support surface and Located on the inner side of the frame 1, and the output end of the lifting component 2 is equipped with a lifting roller group 3, the gantry frame 11 is fixed on the frame 1, the bottom of the gantry frame 11 is welded with a guide rail 12, and the spraying component 4 is connected to the guide rail by transmission 12, and the spraying assembly 4 is located above the lifting roller set 3.

[0028] In this embodiment, the lifting assembly 2 is installed on the support surface and is located inside the frame 1, and the output end of the lifting assembly 2 is equipped with a lifting roller set 3, and the steel pipe is transported laterally on the frame 1 through a transmission device , when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com