Hole injection material for organic light-emitting device, as well as preparation method and application thereof

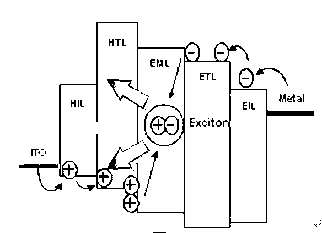

A technology of hole injection materials and electroluminescent devices, which is applied in the fields of electrical solid devices, semiconductor/solid device manufacturing, electrical components, etc. It can solve the problems of large film roughness, achieve good thermal stability, and reduce energy consumption for preparation , Improve the effect of organic solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

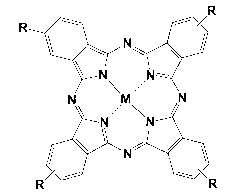

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 8 g of raw material 4-methylphthalonitrile in 300 ml of carbon tetrachloride, add 10 g of bromosuccinimide and 10 mg of benzoyl peroxide.

[0029] The prepared solution was heated to reflux for 12 hours, and then carbon tetrachloride was distilled for repeated use.

[0030] The remaining solvent was evaporated to dryness with a rotary evaporator, and the obtained raw material was dried under vacuum and dissolved in 150 ml of tetrahydrofuran, and 7.5 g of triphenylphosphine was added, heated at 40 °C for 8 hours, cooled to room temperature, added with 150 ml of ether, filtered through The formed solid matter was washed with diethyl ether, and the obtained product was recrystallized with a dichloromethane / hexane mixed solvent to obtain 4-phosphorus bromide phthalonitrile.

[0031]Dissolve 4-phosphorus bromide phthalonitrile in 10 ml of formaldehyde aqueous solution (38%), add 0.5 g of potassium carbonate at 0 °C, the reactant quickly becomes colorless, and the 4-...

Embodiment 2

[0035] Carry out according to the mode of embodiment 1, difference is to replace cupric chloride with zinc chloride.

Embodiment 3

[0037] Carry out according to the mode of embodiment 1, difference is to replace cupric chloride with nickel chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com