High flame retardant and high transparency polyimide film and preparation method thereof

A polyimide film and transparency technology, which is applied in the field of high flame retardant and high transparency polyimide film and its preparation, can solve the problems of poor light transmittance of the film, unable to meet the colorless and high transparency of the film, etc. Effects of improved processability, excellent thermal stability, improved mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

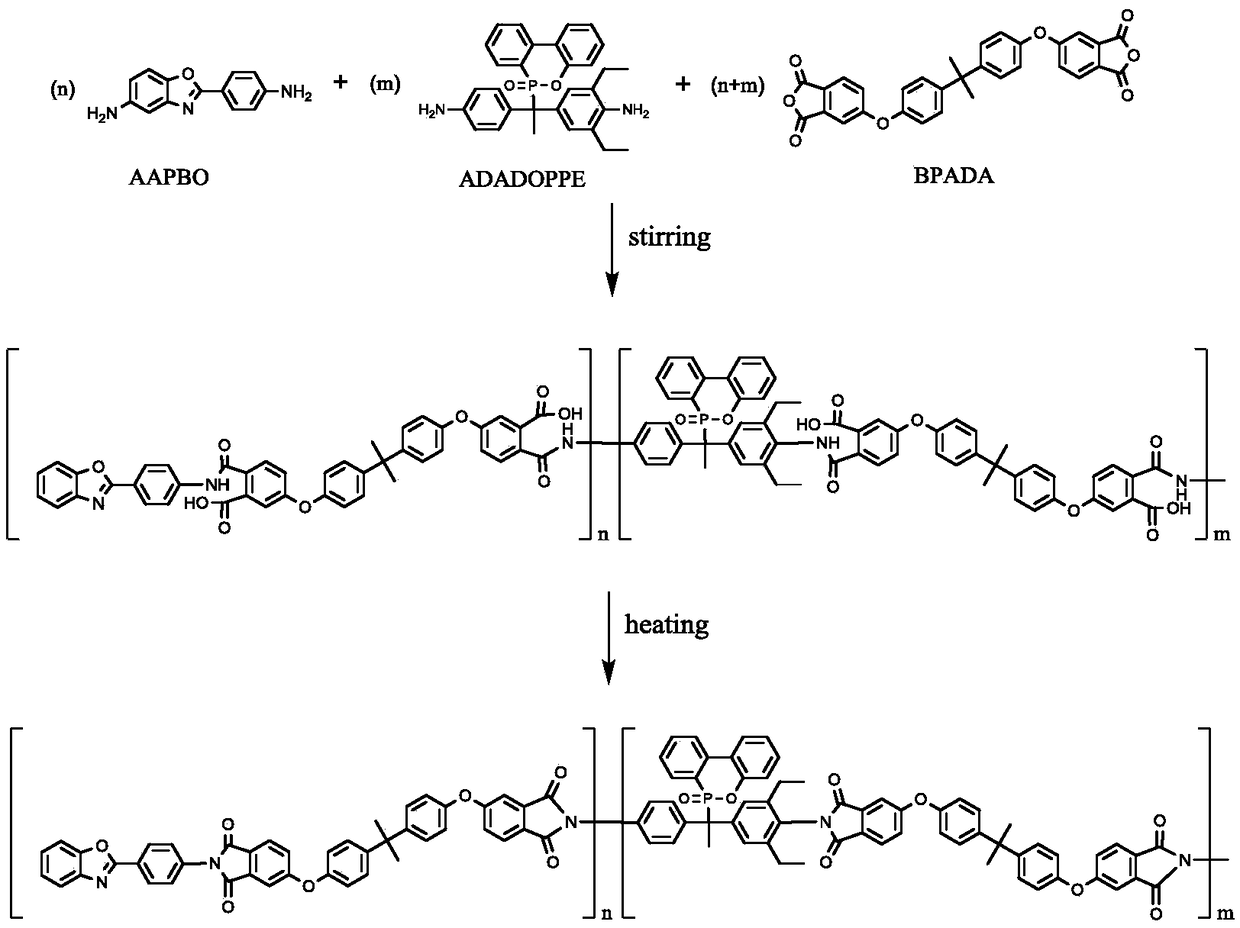

Method used

Image

Examples

Embodiment 1

[0032] 1) Clean all the glass instruments to be used in the experiment and dry them for later use. Add 0.0121g (0.125mmol) 4-aminophenyl-3,5 -Diethyl-4-aminophenyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-phosphorylethane (ADADOPPE) and 1.0980g (4.875mmol) 2-(4- Aminophenyl)-5-aminobenzoxazole (AAPBO), then add 14.9g N,N-dimethylacetamide (DMAc) solvent, stir at room temperature until ADADOPPE and AAPBO are all dissolved; The temperature is maintained at 20°C;

[0033] 2) After the dissolution is completed, quickly add 2.6024g (5mmol) bisphenol A diether dianhydride (BPADA) into the three-necked flask, and the total solid content is 20% (the total solid content is m ADADOPPE+AAPBO+BPADA / m ADADOPPE+AAPBO+BPADA+DMAc ); after the addition, react at 20°C for 12h to obtain light yellow polyamic acid glue;

[0034] 3) Apply the prepared polyamic acid glue solution evenly on a clean glass plate through a film applicator, and then place the glass plate in an oven to bake the f...

Embodiment 2

[0036] 1) Clean all the glass instruments used in the experiment and dry them for later use. Add 0.0243g (0.25mmol) 4-aminophenyl-3,5 -Diethyl-4-aminophenyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-phosphorylethane (ADADOPPE) and 1.0699g (4.75mmol) 2-(4- Aminophenyl)-5-aminobenzoxazole (AAPBO), then add 14.8g N, N-dimethylacetamide (DMAc) solvent, stir at room temperature until ADADOPPE and AAPBO are all dissolved; The temperature is maintained at 20°C;

[0037]2) After the dissolution is completed, quickly add 2.6024g (5mmol) bisphenol A diether dianhydride (BPADA) into the three-necked flask, and the total solid content is 20% (the total solid content is m ADADOPPE+AAPBO+BPADA / m ADADOPPE+AAPBO+BPADA+DMAc ); after the addition, react at 20°C for 12h to obtain light yellow polyamic acid glue;

[0038] 3) Apply the prepared polyamic acid glue solution evenly on a clean glass plate through a film applicator, and then place the glass plate in an oven to bake the film by p...

Embodiment 3

[0040] 1) Clean all the glass instruments used in the experiment and dry them for later use. Add 0.0362g (0.375mmol) 4-aminophenyl-3,5 -Diethyl-4-aminophenyl-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-phosphorylethane (ADADOPPE) and 1.0417g (4.625mmol) 2-(4- Aminophenyl)-5-aminobenzoxazole (AAPBO), then add 14.8g N, N-dimethylacetamide (DMAc) solvent, stir at room temperature until ADADOPPE and AAPBO are all dissolved; The temperature is maintained at 20°C;

[0041] 2) After the dissolution is completed, quickly add 2.6024g (5mmol) bisphenol A diether dianhydride (BPADA) into the three-necked flask, and the total solid content is 20% (the total solid content is m ADADOPPE+AAPBO+BPADA / m ADADOPPE+AAPBO+BPADA+DMAc ); after the addition, react at 20°C for 12h to obtain light yellow polyamic acid glue;

[0042] 3) Apply the prepared polyamic acid glue solution evenly on a clean glass plate through a film applicator, and then place the glass plate in an oven to bake the film b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com