Iron carbide particle, and fabrication method and application thereof

A technology of iron carbide and particles, which is applied in the field of materials, can solve the problems of high energy consumption in synthesis methods, impossibility of industrial production, and complicated preparation methods, and achieve good selectivity, mass production, and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the preparation method of the present invention, halide ammonium salt is selected as the carbonization inducer, and the halide ammonium salt is selected from ammonium halide or organic quaternary ammonium salt, or a mixture of two or more thereof. As non-limiting examples, ammonium halides such as ammonium fluoride, ammonium chloride, ammonium bromide, and ammonium iodide, while the organic quaternary ammonium salts may include: cetyltrimethylammonium bromide (CTAB) or Cetyltrimethylammonium chloride (CTAC), etc.

[0045] The present invention selects long-chain amine as the carbon source and solvent of the high-temperature liquid phase reaction at the same time, requiring the boiling point of the long-chain amine used to be higher than 250°C, for example, it can be selected from dodecylamine, hexadecylamine, octadecylamine, etc. One or more of amine, oleylamine, octadecyl tertiary amine and trioctylamine. The combination of the halide ammonium salt inducer and the ...

Embodiment 1

[0060] The present embodiment has prepared iron carbide particle, comprises the following steps:

[0061] (1) Mix 0.113g of cetyltrimethylammonium bromide (CTAB) and 20ml of cetylamine in a container to obtain a mixed solution, heat to 120°C and maintain a vacuum for 0.5 hours;

[0062] (2) Under a nitrogen protective atmosphere, heat the mixed solution to 180°C, add 0.5ml carbonyl iron, and maintain the temperature for 30 minutes;

[0063] (3) Heat up to 320°C at a heating rate of 5°C / min, and hold for 10 minutes;

[0064] (4) Cool the reaction system to 60°C and centrifuge at a speed of 11,500 rpm for 1 minute, collect the precipitate, wash the precipitate three times with n-hexane and absolute ethanol in sequence, and collect iron carbide particles by centrifugation.

[0065] Characterization of the above-mentioned iron carbide particles:

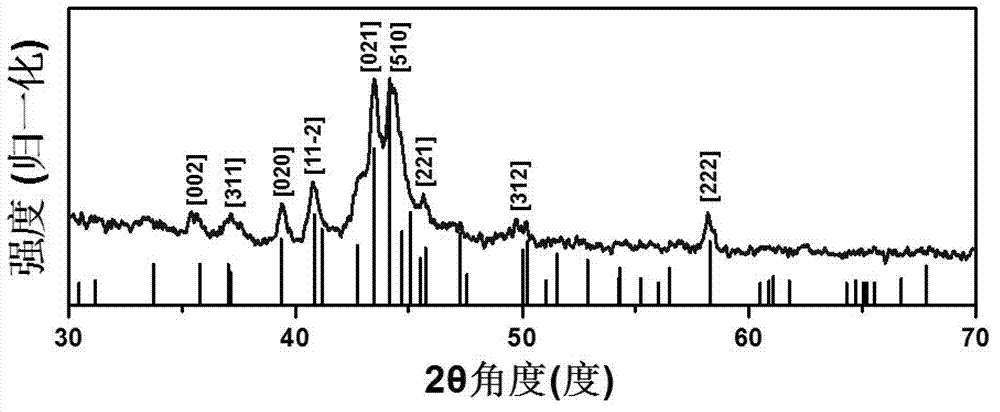

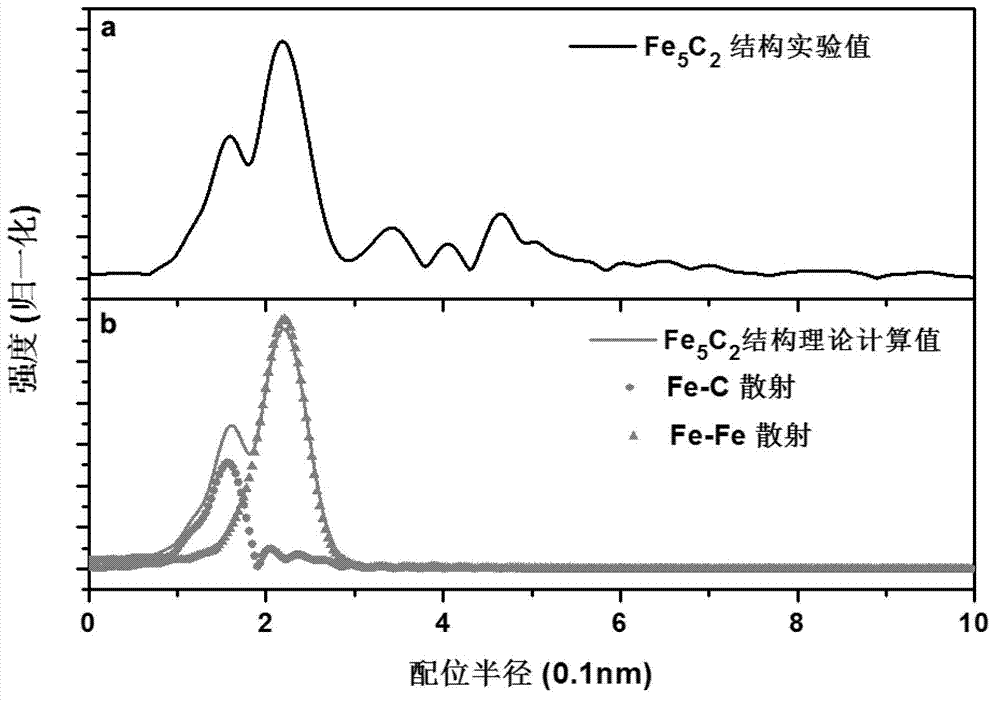

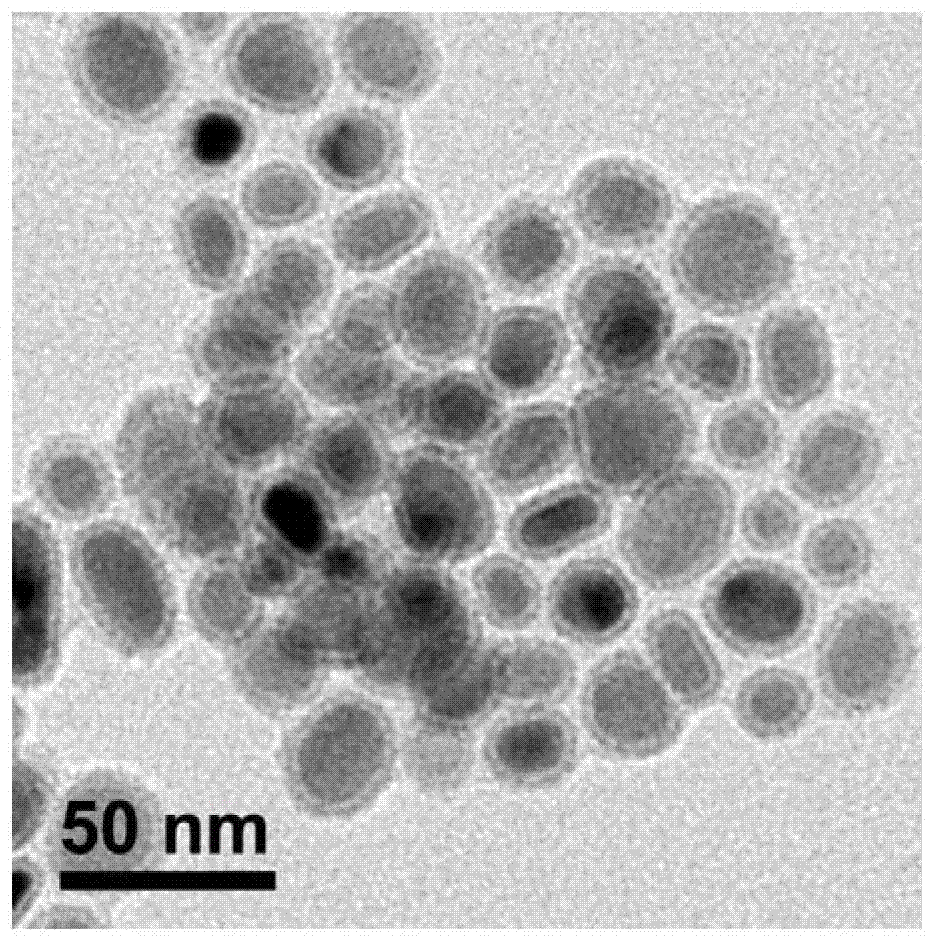

[0066] figure 1 For the powder diffraction pattern of the iron carbide particles prepared in embodiment 1; figure 2 Among them, a ...

Embodiment 2

[0075] The present embodiment has prepared iron carbide particle, comprises the following steps:

[0076] (1) Mix 0.113g of cetyltrimethylammonium bromide (CTAB) and 20ml of cetylamine in a container to obtain a mixed solution, heat to 120°C and maintain a vacuum for 0.5 hours.

[0077] (2) Under a helium protective atmosphere, heat the mixed solution to 180°C, add 3ml of iron pentacarbonyl in n-hexane solution (including 0.5ml of pentacarbonyl iron and 2.5ml of n-hexane) to the mixed solution, and maintain the temperature Keep warm for 30 minutes;

[0078] (3) Heat up to 320°C at a heating rate of 5°C / min, and hold for 10 minutes;

[0079] (4) After the reaction system is cooled to room temperature, solid-liquid centrifugation is carried out, and the solid obtained by solid-liquid separation is washed three times with non-polar solvent n-hexane and polar solvent anhydrous ethanol in sequence, and centrifuged to obtain iron carbide particles.

[0080] Dissolving the metal pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com