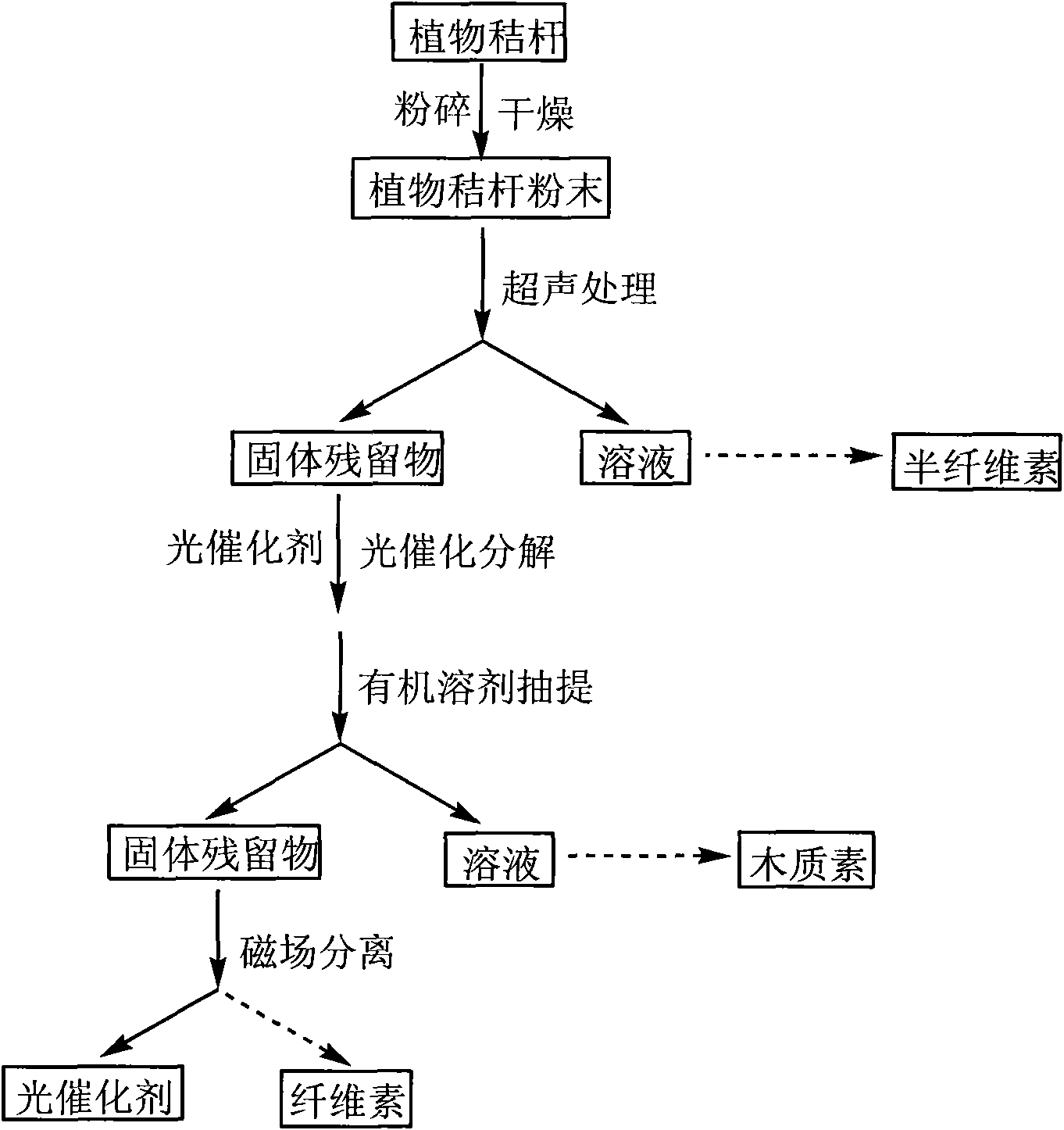

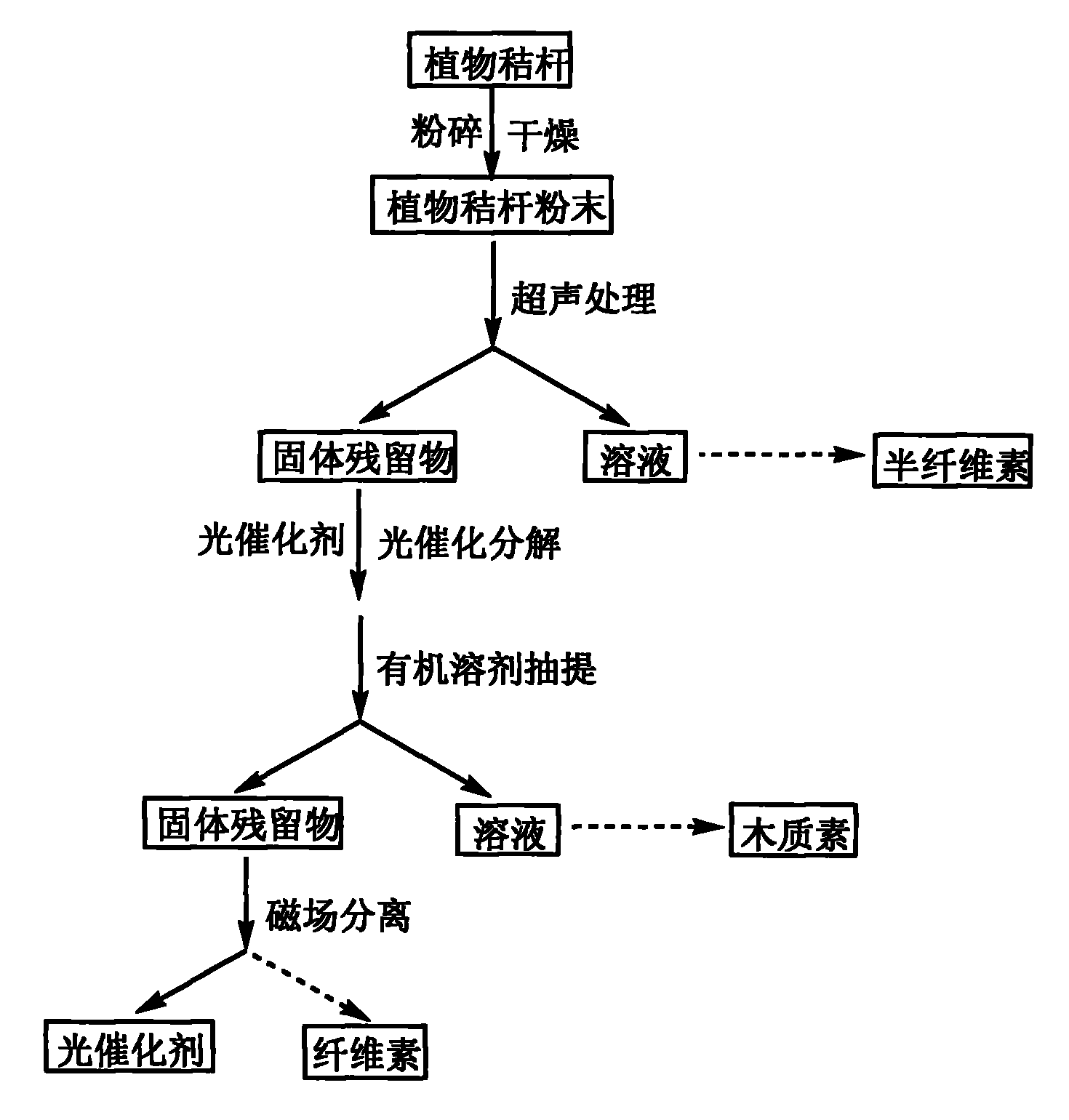

Method for ultrasonically catalyzing and extracting hemicellulose, cellulose and lignin from plant straws

A technology of hemicellulose and lignin, applied in chemical instruments and methods, lignin derivatives, fiber raw material processing and other directions, can solve the problems of harsh reaction extraction conditions, unsuitable for industrialized promotion and production, environmental pollution of organic solvents, etc. Facilitate industrial-scale production, reduce costs and energy consumption, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) First dry the corn stalks in the sun, then mechanically pulverize the corn stalks, collect the corn stalk powder through a 200-mesh sieve, and fully dry the collected corn stalk powders to remove moisture.

[0038] (2) Weigh 0.50 g of the collected dry corn stalk powder and disperse it in 40 mL of aqueous solution with pH=4 adjusted by 1 M HCl for ultrasonic treatment, and control the ultrasonic temperature at 30° C., and the ultrasonic time for 40 minutes, The ultrasonic power is 200 watts, the ultrasonic frequency is 20KHz, the hemicellulose in the corn stalk is dissolved in the aqueous solution, the hemicellulose aqueous solution is collected by separation, and the hemicellulose aqueous solution is freeze-dried to obtain 0.08 g of hemicellulose solid.

[0039] (3) the stalk residue obtained by the separation of the previous step is used with 10mg nano-Fe 3 o 4 @TiO 2 (wherein, nano-Fe 3 o 4 is the nucleus, the nano-Fe 3 o 4 The particle size is 20nm; TiO 2...

Embodiment 2

[0043] (1) After the wheat straw is dried in the sun, the wheat straw is mechanically pulverized, and the wheat straw powder is collected through a 200-mesh sieve, and the collected wheat straw powder is fully dried to remove moisture.

[0044] (2) Weigh 0.50 g of the collected dry wheat straw powder and disperse it in a certain 40 mL of water with pH=7 for ultrasonic treatment, and control the ultrasonic temperature at 40° C., ultrasonic time for 30 minutes, ultrasonic power of 200 watts, and ultrasonic frequency of 20 KHz. The hemicellulose in the wheat straw is dissolved in the aqueous solution, and the hemicellulose aqueous solution is collected by separation, and the hemicellulose aqueous solution is rotary evaporated to remove water, and then vacuum-dried to 0.06 g of hemicellulose solid.

[0045] (3) the stalk residue obtained by the separation of the previous step is used with 10mg nano-Fe 3 o 4 @TiO 2 (wherein, nano-Fe 3 o 4 is the nucleus, the nano-Fe 3 o 4 The...

Embodiment 3

[0049] (1) The rape straw is first dried in the sun, then the rape straw is mechanically pulverized, and the rape straw powder is collected through a 400-mesh sieve, and the collected rape straw powder is fully dried to remove water.

[0050] (2) Weigh 0.50 g of the collected dry rape stalk powder and disperse it in a certain 40 mL aqueous solution with a concentration of 1 M NaOH to adjust pH=10 for ultrasonic treatment, and control the ultrasonic temperature at 50 ° C, ultrasonic time for 20 minutes, ultrasonic With a power of 400 watts and an ultrasonic frequency of 25KHz, the hemicellulose in the rape straw is dissolved in the aqueous solution, the hemicellulose aqueous solution is collected by separation, and the hemicellulose aqueous solution is freeze-dried to obtain 0.11 g of hemicellulose solid.

[0051] (3) the stalk residue obtained by the separation of the previous step is used with 10mg nano-Fe 3 o 4 @TiO 2 (wherein, nano-Fe 3 o 4 is the nucleus, the nano-Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com