Pretreatment method for heavy metal element detection in solid sample and application of pretreatment method

A heavy metal and sample technology, which is applied in the pretreatment field of heavy metal element detection in solid samples, can solve the problems of long sample digestion time, general accuracy and reproducibility of analysis results, large residual rate, etc. Sample loss, good reproducibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

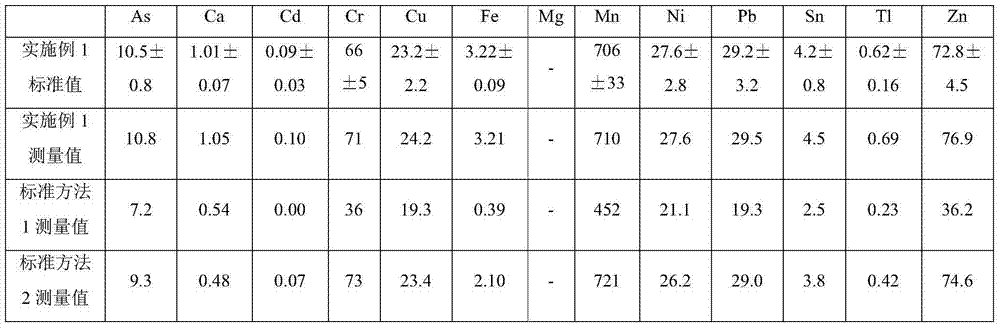

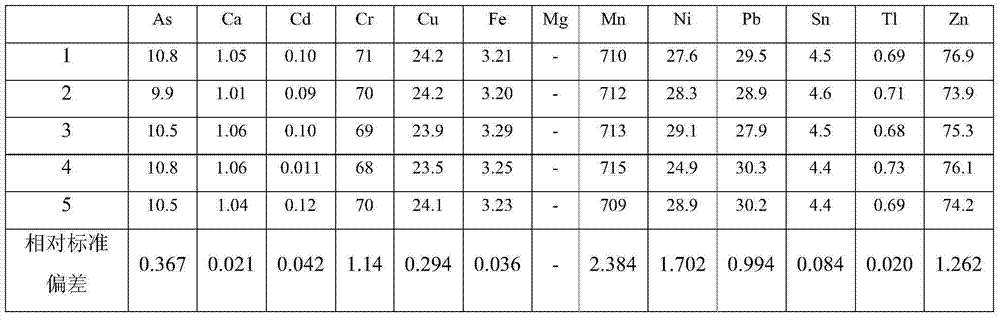

Embodiment 1

[0036] (1) Pre-digestion stage: Weigh 0.2000g soil sample (standard material for soil composition analysis GBW07410) into a 50mL polytetrafluoroethylene crucible; add 10mL nitric acid (excellent grade, mass concentration 65%) into the polytetrafluoroethylene crucible , covered, and digested on an electric heating plate in a fume hood at 240°C for 4 hours to decompose the soil sample;

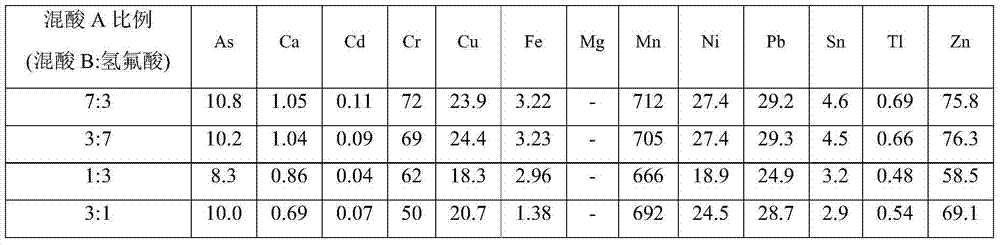

[0037] (2) Mixed acid digestion stage: After the soil pre-digestion is completed, open the cover, add 10mL of mixed acid A to the polytetrafluoroethylene crucible, cover it, and digest it for 16h on the electric heating plate in the fume hood at 220°C; the mixed acid A It is mixed acid B and hydrofluoric acid whose volume ratio is 1:1; said mixed acid B is nitric acid and perchloric acid whose volume ratio is 1:4, and used nitric acid, perchloric acid, and hydrofluoric acid are excellent-grade pure reagents, The mass concentrations are 65%, 70% and 40% respectively;

[0038] (3)H 2 o 2 Digest...

Embodiment 2

[0052] (1) Pre-digestion stage: Weigh 0.2000g of river sediment sediment sample (standard material for river sediment composition analysis GBW08301) into a 50mL polytetrafluoroethylene crucible; add 6mL nitric acid (excellent grade, mass concentration 65%), covered, and digested on the electric heating plate in the fume hood at 180°C for 4 hours to decompose the sample;

[0053] (2) Mixed acid digestion stage: after the pre-digestion, open the cover, add 6 mL of mixed acid A to the polytetrafluoroethylene crucible, cover it, and digest it on the electric heating plate in the fume hood at 240 ° C for 16 hours; the mixed acid A is the volume Mixed acid B and hydrofluoric acid with a ratio of 7:5; the mixed acid B is nitric acid and perchloric acid with a volume ratio of 1:4, and the nitric acid, perchloric acid and hydrofluoric acid used are all superior grade pure reagents, and the mass concentration 65%, 70% and 40% respectively;

[0054] (3)H 2 o 2 Digestion stage: After t...

Embodiment 3

[0066] (1) Pre-digestion stage: Weigh 0.2000g coal sample (standard substance for analysis of inorganic elements in anthracite GSB06-2097-2007) into a 50mL polytetrafluoroethylene crucible; add 10mL nitric acid (premium pure , with a mass concentration of 65%), covered, and digested on an electric heating plate in a fume hood at 240°C for 6 hours to decompose the sample;

[0067] (2) Mixed acid digestion stage: After the pre-digestion is completed, open the cover, add 14 mL of mixed acid A to the polytetrafluoroethylene crucible, cover it, and digest it on the electric heating plate in the fume hood at 220 ° C for 24 hours; the mixed acid A is the volume Mixed acid B and hydrofluoric acid with a ratio of 7:3; the mixed acid B is nitric acid and perchloric acid with a volume ratio of 1:4, and the nitric acid, perchloric acid and hydrofluoric acid used are all superior grade pure reagents, and the mass concentration 65%, 70% and 40% respectively;

[0068] (3)H 2 o 2 Digestion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com