Method for measuring calcium constituent in silicon aluminum calcium barium alloy

A technology of calcium element and calcium barium, which is applied in the field of analytical chemistry, can solve problems such as slow discoloration reaction, excessive hydrofluoric acid, and environmental pollution, and achieve the effects of reducing operation links, eliminating barium interference, and reducing uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

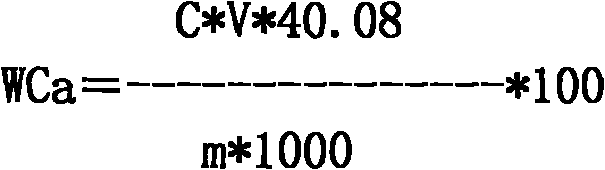

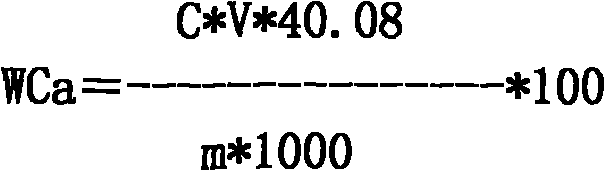

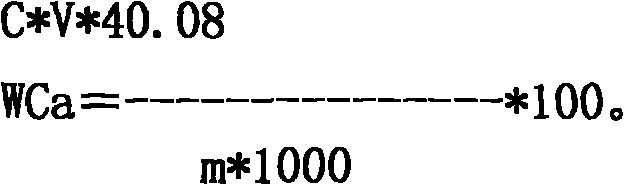

Image

Examples

Embodiment 1

[0031] A method for determining calcium in silicon-aluminum-calcium-barium alloy, and its steps:

[0032] 1) Take the sample (YSB14612 Ca: 9.25%) 0.1000 g sample and place it in a polytetrafluoroethylene beaker, and add deionized water until the sample is wet;

[0033] 2) Add 10 ml of nitric acid;

[0034] 3) Add 1 ml of hydrofluoric acid dropwise;

[0035] 4) Heat on the electric heating plate until the sample is completely dissolved;

[0036] 5) Add 4.5 ml of perchloric acid;

[0037] 6) Heat at 170℃ until the sample volume is reduced to 2 ml;

[0038] 7) Naturally cool to 25℃;

[0039] 8) Add 4.5 ml of perchloric acid and heat at 170°C until the sample volume is reduced to 2 ml;

[0040] 9) Add 10 ml of hydrochloric acid and 50 ml of deionized water;

[0041] 10) Heat at 100°C until the salt is dissolved, take it off and cool the sample to 38°C by natural cooling;

[0042] 11) Put the cooled sample into a 100 ml graduated volumetric flask, dilute to 100 ml graduated with deioni...

Embodiment 2

[0048] A method for determining calcium in silicon-aluminum-calcium-barium alloy, and its steps:

[0049] 1) Take a sample (YSB14612 Ca: 9.25%) 0.2800g sample and place it in a polytetrafluoroethylene beaker, and add deionized water until the sample is wet;

[0050] 2) Add 10 ml of nitric acid;

[0051] 3) Add 1 ml of hydrofluoric acid dropwise;

[0052] 4) Heat on the electric heating plate until the sample is completely dissolved;

[0053] 5) Add 4.5 ml of perchloric acid;

[0054] 6) Heat at 180℃ until the sample volume is reduced to 1.5ml;

[0055] 7) Naturally cool to 25℃;

[0056] 8) Add 4.5 ml of perchloric acid and heat it at 180°C until the sample volume is reduced to 1.5 ml;

[0057] 9) Add 10 ml of hydrochloric acid and 50 ml of deionized water;

[0058] 10) Heat at 100°C until the salt is dissolved, take it off and cool the sample to below 35°C by natural cooling;

[0059] 11) Put the cooled sample into a 100 ml graduated volumetric flask, dilute to 100 ml graduated wi...

Embodiment 3

[0065] A method for determining calcium in silicon-aluminum-calcium-barium alloy, and its steps:

[0066] 1) Take a sample (YSB14612Ca: 9.25%) 0.6 g of the sample and place it in a polytetrafluoroethylene beaker, and add deionized water until the sample is wet;

[0067] 2) Add 10.5 ml of nitric acid;

[0068] 3) Add 1.5 ml of hydrofluoric acid dropwise;

[0069] 4) Heat on the electric heating plate until the sample is completely dissolved;

[0070] 5) Add 5.0 ml of perchloric acid;

[0071] 6) Heat at 185℃ until the sample volume is reduced to 1.3ml;

[0072] 7) Naturally cool to 28℃;

[0073] 8) Add 5.0 ml of perchloric acid and heat at 190℃ until the sample volume is reduced to 1.3 ml;

[0074] 9) Add 9.5 ml of hydrochloric acid and 50 ml of deionized water;

[0075] 10) Heat to complete dissolution at 110°C, remove it, and cool the sample to 30°C by natural cooling;

[0076] 11) Put the cooled sample into a 100 ml graduated volumetric flask, dilute to 100 ml graduated with deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com