Manufacturing method of patterning metal lines

A patterned metal, patterned technology, applied in metal material coating process, circuit, liquid chemical plating, etc., can solve the problem of poor adhesion between conductive lines and substrates, unsuitable for polymer substrates, and increased surface roughness. problems, to ensure continuity and conductivity, improve surface roughness, and reduce time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

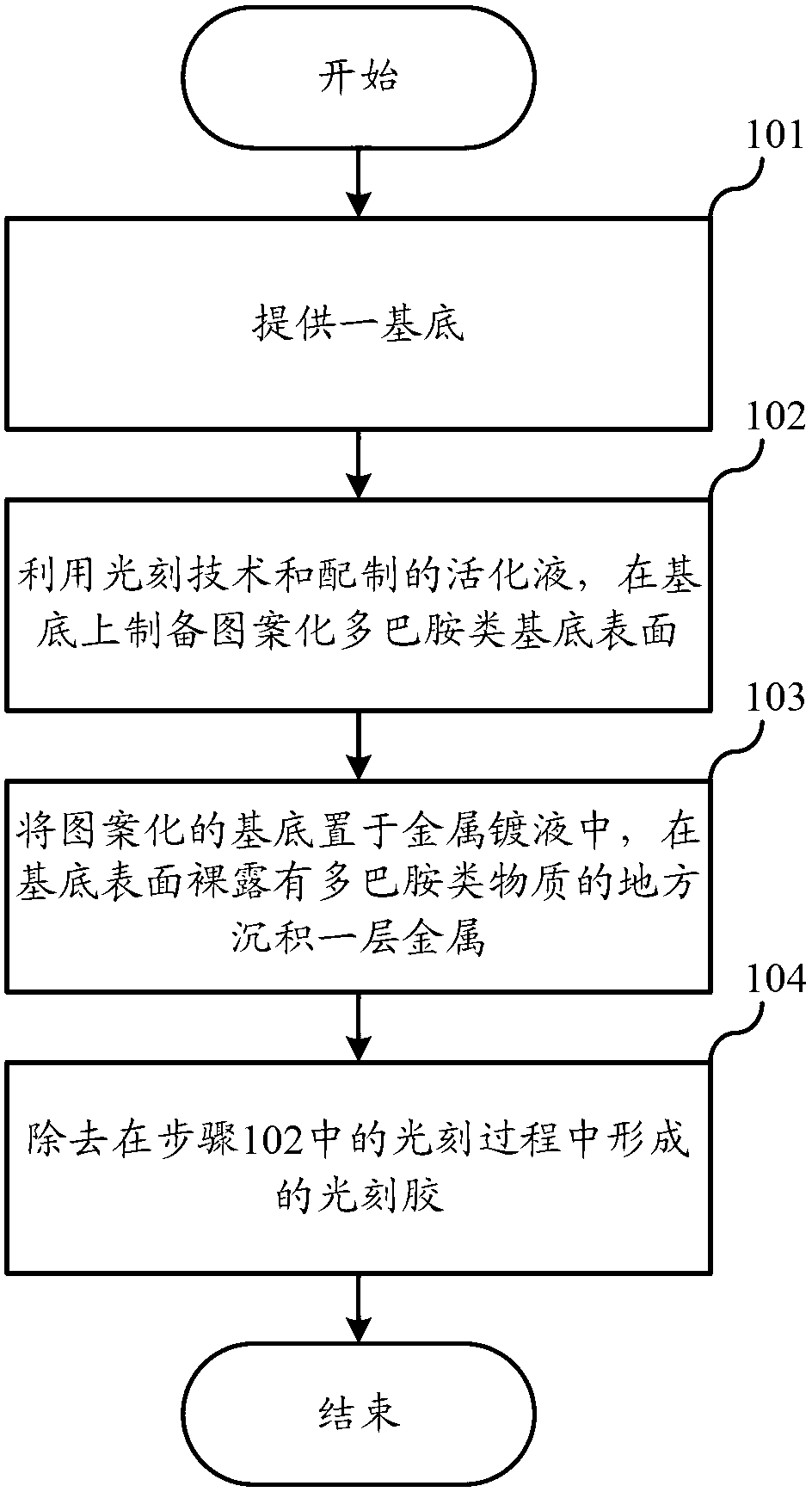

Method used

Image

Examples

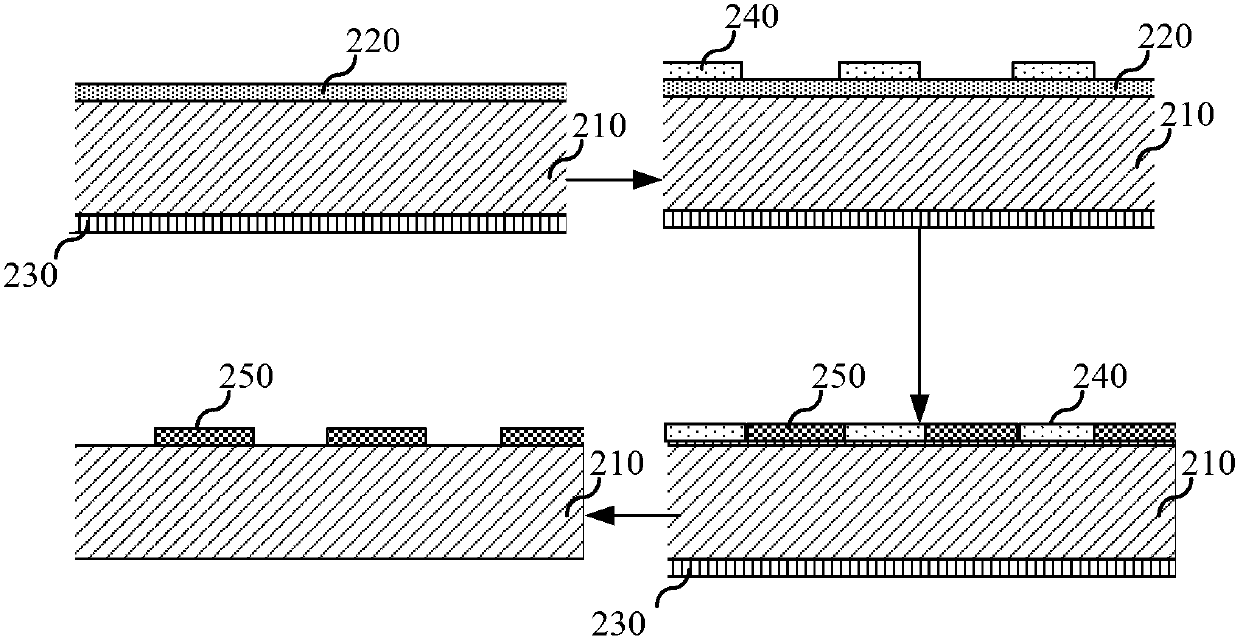

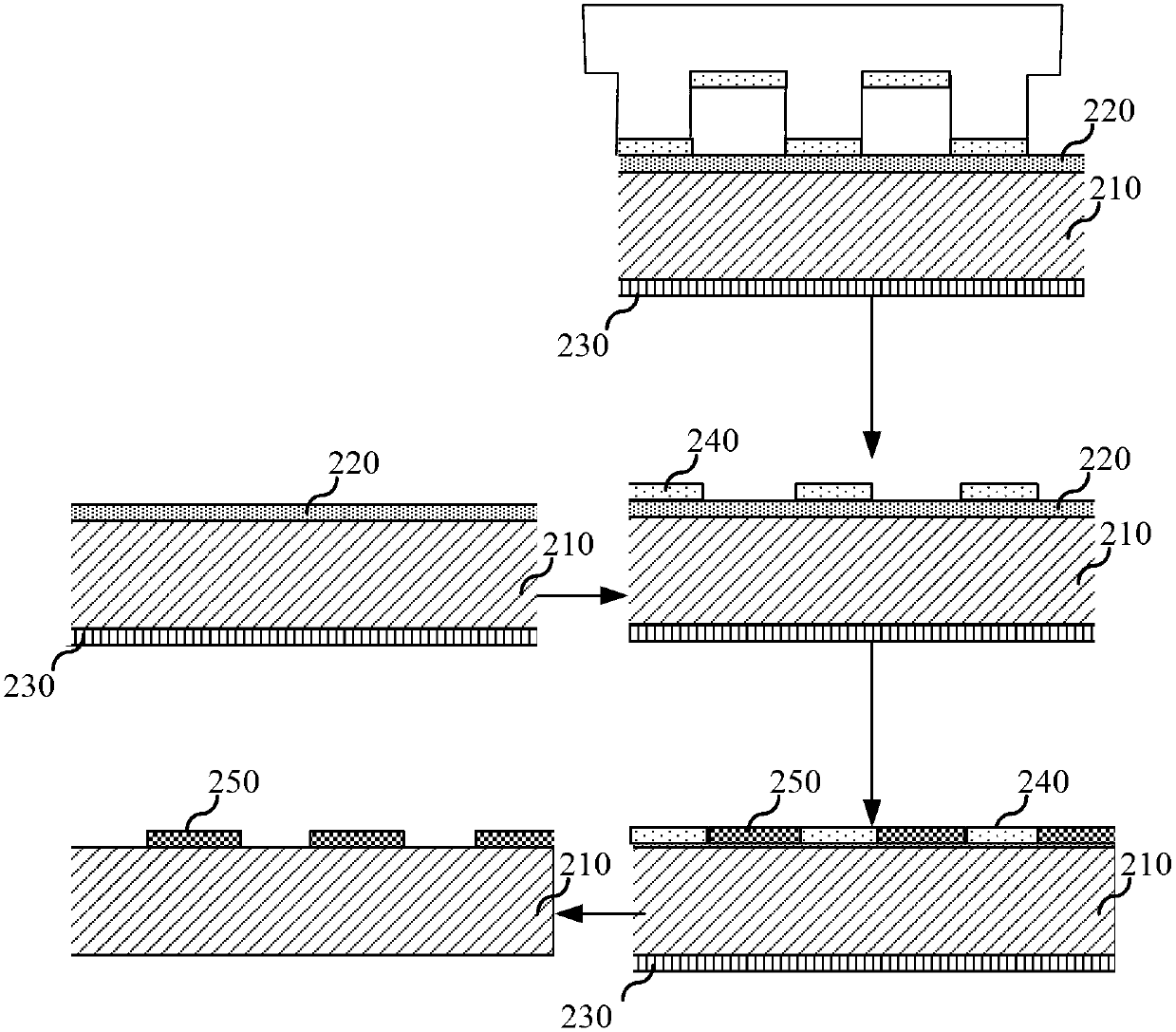

Embodiment approach

[0077] That is to say, this embodiment has the following advantages:

[0078] 1) High selectivity: metals are only deposited where dopamine exists;

[0079] 2) Wide adaptability: dopamine substances can not only deposit and adhere on hard inorganic substrates such as metal and glass, but also be loaded on substrates such as semiconductors and polymers;

[0080] 3) There is a layer of dopamine substances with excellent adhesion properties between the coating and the substrate, the binding force is better than the general method, and the metal coating does not fall off under ultrasonic conditions;

[0081] 4) All processes can be carried out at room temperature, and the time is short;

[0082] 5) The thickness of the coating can be adjusted from nanometers to micrometers, and the sheet resistance is small;

[0083] 6) After the film is bent, the film resistivity changes little;

[0084] 7) It is possible to make circuits on both sides of the substrate at the same time;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com