Interior wall adornment leather and preparation method

A technology for decorative leather and interior walls, applied in textiles, papermaking, fiber treatment, etc., can solve problems such as poor flame retardancy, dirt resistance, and poor hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

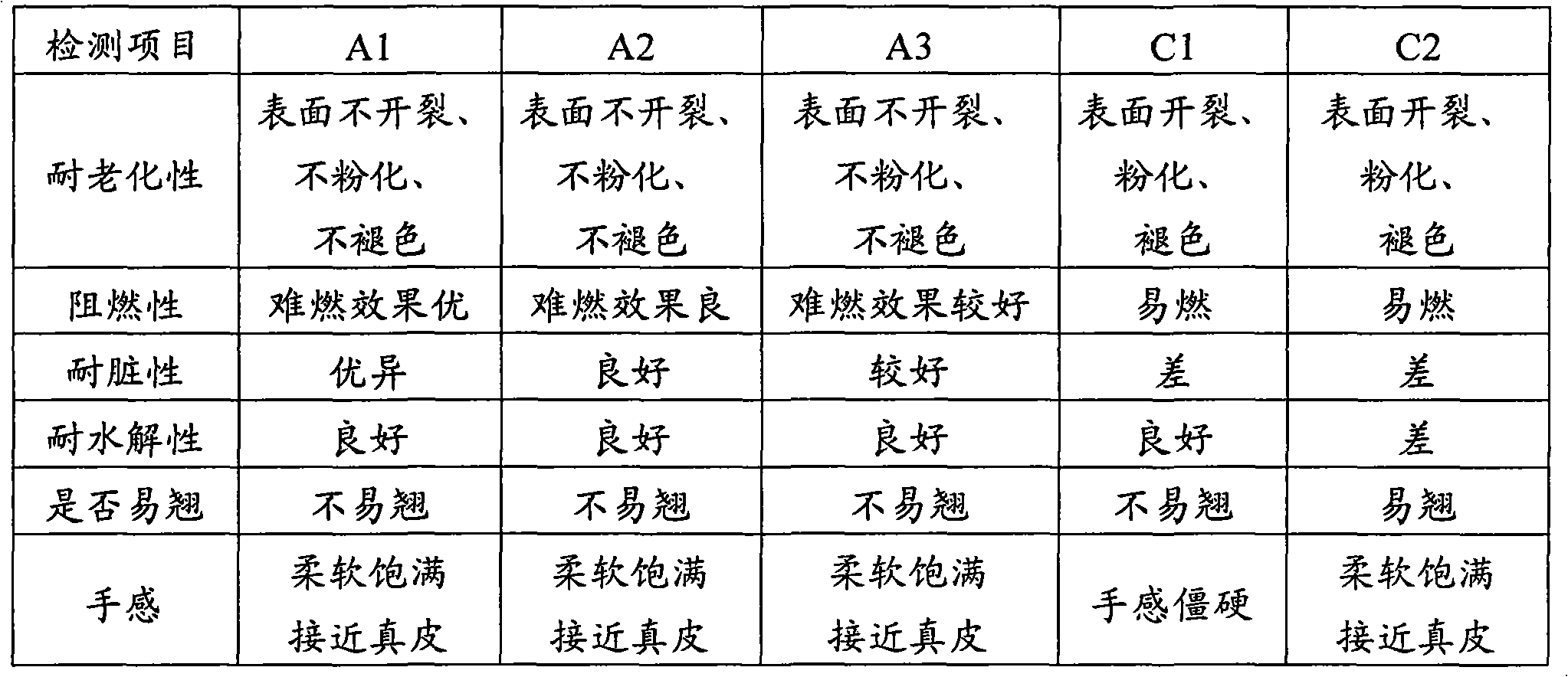

Examples

Embodiment 1

[0045] This example is used to illustrate the interior wall decorative leather provided by the present invention and its preparation method.

[0046] 1. Preparation of slurry

[0047] 1-1PUD-2 slurry

[0048] (1) Add 60.02g of isophorone diisocyanate to 150g of poly-1,4-butylene adipate diol (Mn=2000) and react at 80°C for 120 minutes;

[0049] (2) Add 45g of acetone, control the temperature of the reaction system at 50°C, add 11.40g of dimethylolpropionic acid and 16.01g of tris(dipropylene glycol) phosphite, and react at 75°C for 180 minutes until the NCO value drops to 1.5% by weight;

[0050] (3) Control the temperature of the reaction system at 40° C., add 8.59 g of triethylamine for neutralization reaction for 30 minutes;

[0051] (4) adding the neutralized and hydrophilic prepolymer into 350g deionized water for high-speed emulsification and dispersion to obtain a water-based polyurethane dispersion with a solid content of 40%;

[0052] (5) Add 4.6g of thickener, 2....

Embodiment 2

[0079] This example is used to illustrate the interior wall decorative leather provided by the present invention and its preparation method.

[0080] 1. Preparation of slurry

[0081] 1-1PUD-2 slurry

[0082] (1) Add 60.02g of isophorone diisocyanate to 150g of poly-1,4-butylene adipate diol (Mn=2000) and react at 80°C for 120 minutes;

[0083] (2) Add 45g of acetone, control the temperature of the reaction system at 50°C, add 11.32g of dimethylolpropionic acid and 14.42g of N,N-bis(2-hydroxyethyl)aminomethylphosphonic acid diethyl ester, in React at 75°C for 180 minutes until the NCO value drops to 1.5% by weight;

[0084] (3) Control the temperature of the reaction system at 40° C., add 8.53 g of triethylamine for neutralization reaction for 30 minutes;

[0085] (4) adding the neutralized and hydrophilic prepolymer into 350g deionized water for high-speed emulsification and dispersion to obtain a water-based polyurethane dispersion with a solid content of 40%;

[0086] (...

Embodiment 3

[0113] This example is used to illustrate the interior wall decorative leather provided by the present invention and its preparation method.

[0114] 1. Preparation of slurry

[0115] 1-1PUD-2 slurry

[0116] (1) Add 60.02g of isophorone diisocyanate to 150g of poly-1,4-butylene adipate diol (Mn=2000) and react at 80°C for 120 minutes;

[0117] (2) Add 45g of acetone, control the temperature of the reaction system at 50°C, add 11.25g of dimethylol propionic acid and 12.96g of N,N-di(2-hydroxyethyl)aminomethylphosphonic acid dimethyl, React at 75°C for 180 minutes until the NCO value drops to 1.5% by weight;

[0118] (3) Control the temperature of the reaction system at 40° C., add 8.45 g of triethylamine for neutralization reaction for 30 minutes;

[0119] (4) adding the neutralized and hydrophilic prepolymer into 350g deionized water for high-speed emulsification and dispersion to obtain a water-based polyurethane dispersion with a solid content of 40%;

[0120] (5) Add 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com