Non-hydrogenation mixed milk fat and plant fat cream and preparation method thereof

A plant-fat cream, non-hydrogenated technology, applied in cream preparations, dairy products, cream substitutes, etc., can solve the problems of poor flavor and taste, limited application, difficult operation, etc., to overcome the soft texture and meet the quality requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

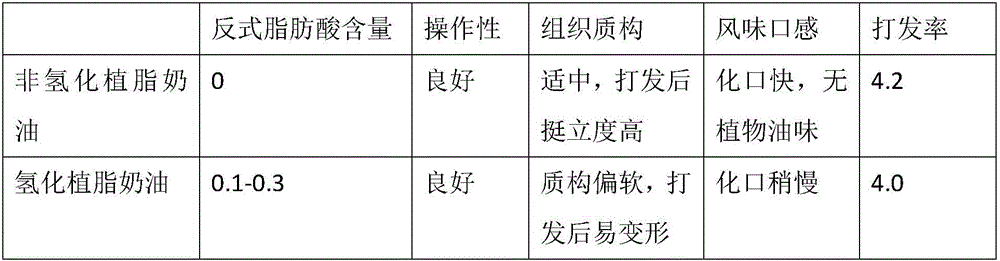

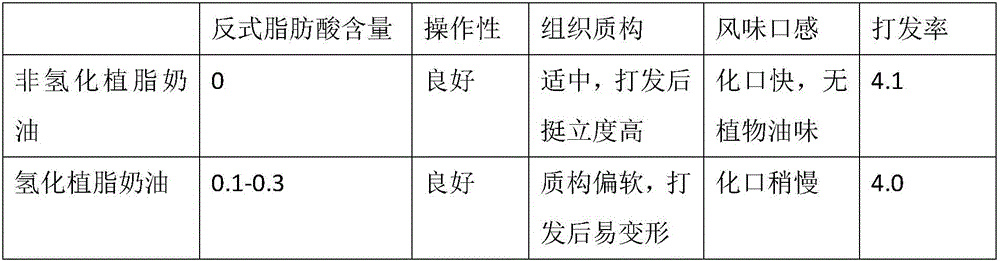

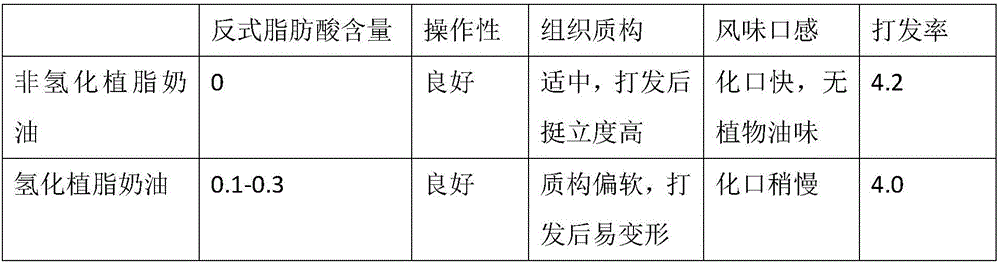

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: non-hydrogenated mixed milk fat whipped cream

[0032] Take 100 grams of non-hydrogenated palm kernel oil, 30 grams of non-hydrogenated coconut oil, 3.5 grams of sorbitan monostearate, 1.5 grams of citric fatty acid glycerides, 2.5 grams of mono- and diglycerides, lactic acid monoglycerides 2.3 grams of esters, 2.5 grams of sodium stearoyl lactylate, 2.5 grams of sucrose fatty acid esters, 0.5 grams of polyglycerol esters, 0.2 grams of carrageenan, 4 grams of microcrystalline cellulose, 1.5 grams of denatured cellulose, 4 grams of sodium caseinate, phosphoric acid Potassium dihydrogen 1g, sugar 60g, glucose syrup 45g, milk fat whipping cream 250g, water 489g.

[0033] Process preparation:

[0034] Melt non-hydrogenated vegetable oil and heat up to 65°C, add sorbitan monostearate, citric acid fatty acid glyceride, lactic acid monoglyceride, sodium stearoyl lactylate, mono- and diglyceride fatty acid ester, sucrose fatty acid ester , polyglycerol ester, carra...

Embodiment 2

[0039] Example 2: non-hydrogenated mixed milk fat whipped cream

[0040] Take 90 grams of non-hydrogenated palm kernel oil, 20 grams of non-hydrogenated coconut oil, 3.5 grams of sorbitan monostearate, 1.0 grams of citric acid fatty acid glycerides, 2.5 grams of mono- and diglycerides, lactic acid monoglycerides 3.8 grams of esters, 2.5 grams of sodium stearoyl lactylate, 2.5 grams of sucrose fatty acid esters, 0.5 grams of polyglycerol esters, 0.2 grams of carrageenan, 3.5 grams of microcrystalline cellulose, 2.0 grams of denatured cellulose, 4 grams of sodium caseinate, phosphoric acid Potassium dihydrogen 1g, sugar 60g, glucose syrup 45g, milk fat whipping cream 290g, water 469g.

[0041] Process preparation:

[0042] Melt non-hydrogenated vegetable oil and heat up to 65°C, add sorbitan monostearate, citric acid fatty acid glyceride, lactic acid monoolein, sodium stearoyl lactylate, mono- and diglyceride fatty acid ester, sucrose fatty acid Ester, polyglycerol ester, carr...

Embodiment 3

[0047] Example 3: non-hydrogenated mixed milk fat whipped cream

[0048] Take 95 grams of non-hydrogenated palm kernel oil, 25 grams of non-hydrogenated coconut oil, 3.5 grams of sorbitan monostearate, 1.5 grams of citric fatty acid glycerides, 2.5 grams of mono- and diglycerides, lactic acid monoglycerides 3.5 grams of ester, 2.5 grams of sodium stearoyl lactylate, 2.5 grams of sucrose fatty acid ester, 0.5 grams of polyglycerol ester, 0.2 grams of carrageenan, 3 grams of microcrystalline cellulose, 2.5 grams of denatured cellulose, 4 grams of sodium caseinate, phosphoric acid Potassium dihydrogen 1g, sugar 60g, glucose syrup 45g, milk fat whipping cream 270g, water 477.8g.

[0049] Process preparation:

[0050]Melt non-hydrogenated vegetable oil and heat up to 65°C, add sorbitan monostearate, citric fatty acid glyceride, lactic acid monoolein, sodium stearoyl lactylate, mono- and diglyceride fatty acid ester, sucrose fatty acid ester , polyglycerol ester, carrageenan, micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com