Double-face heat-sealed and anti-fogging type BOPP (biaxially-oriented polypropylene) film and preparation method thereof

A double-sided, anti-fog technology, used in chemical instruments and methods, coatings, layered products, etc., can solve the problem of easy washing or rubbing, and can only be used in some occasions where internal anti-fogging agents are ineffective Or applications that do not require persistence, can not achieve good anti-fog effect, poor durability, etc., to achieve the effect of excellent anti-fog performance, significant anti-fog performance, and slow migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

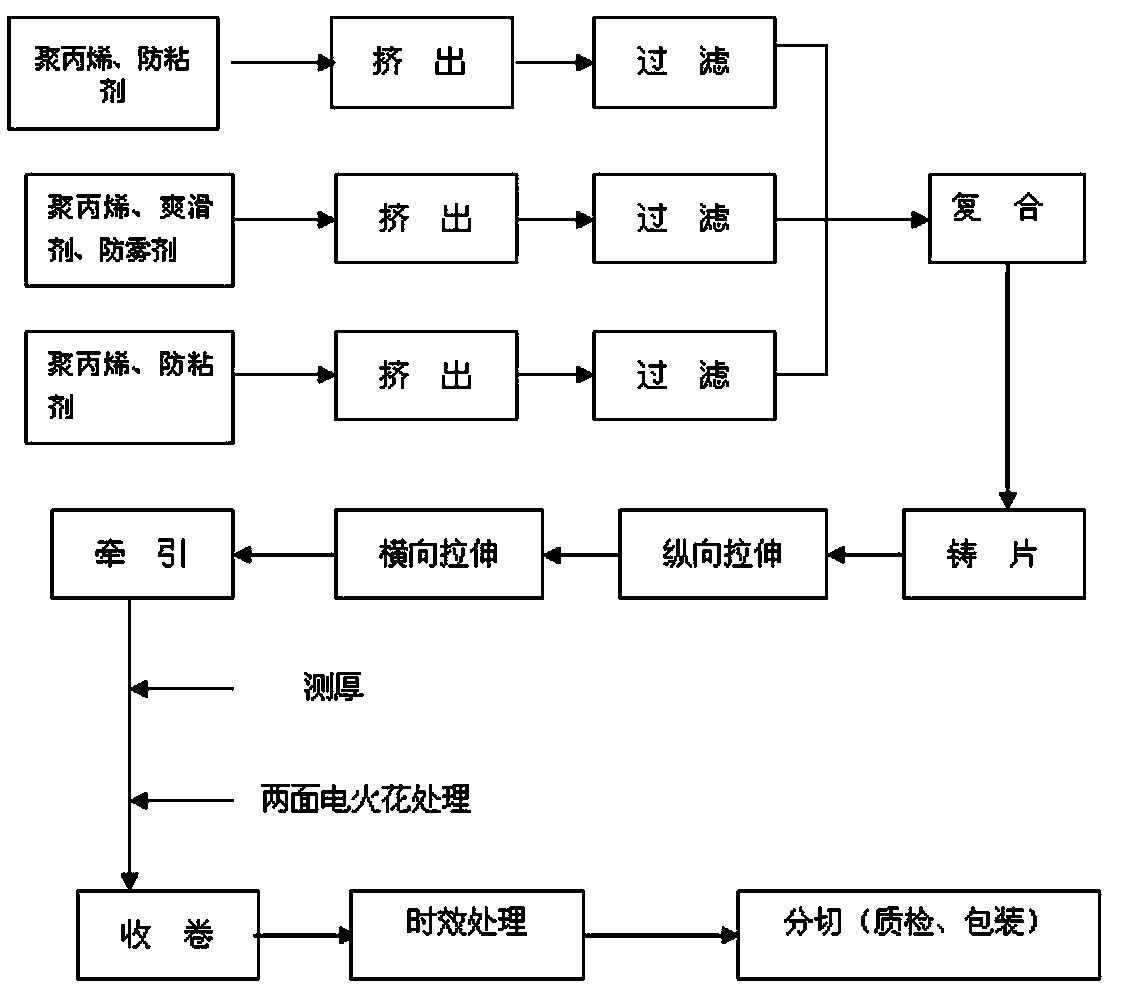

Method used

Image

Examples

Embodiment 1

[0026] Double-sided heat-sealed double-sided anti-fog BOPP film, which is composed of an inner surface layer, a core layer and an outer layer. The inner surface layer, the core layer and the outer layer are biaxially stretched after coextrusion. The material of the surface layer is composed of polypropylene and anti-sticking agent. The mass percentages of the components of the inner and outer layers are: polypropylene 97.5%, anti-sticking agent 2.5%; the core layer is made of polypropylene, anti-fog Composed of anti-fog agent and slip agent, the mass percentage of each component of the core layer is: polypropylene 95.9%, anti-fog agent 3.5%, slip agent 0.6%, and the anti-fog agent is composed of the following components in weight percentage : Sorbitan monostearate 50%, glyceryl monooleate 35%, polyethylene oxide (20) glyceryl monostearate 15%.

[0027] The thickness of the BOPP film described in Example 1 is 15 μm, wherein the thickness of the inner surface layer is 1.0 μm, th...

Embodiment 2

[0032] Double-sided heat-sealed double-sided anti-fog BOPP film, which is composed of an inner surface layer, a core layer and an outer layer. The inner surface layer, the core layer and the outer layer are biaxially stretched after coextrusion. The material of the surface layer is composed of polypropylene and anti-sticking agent. The mass percentages of the components of the inner and outer layers are: polypropylene 98.5%, anti-sticking agent 1.5%; the core layer is made of polypropylene, anti-fog Composed of agent and slip agent, the mass percentage of each component of the core layer is: polypropylene 97.1%, anti-fog agent 2.5%, slip agent 0.4%, and the anti-fog agent is composed of the following components in weight percentage : Sorbitan monostearate 50%, glyceryl monooleate 35%, polyethylene oxide (20) glyceryl monostearate 15%.

[0033] The thickness of the BOPP film described in Example 2 is 35 μm, wherein the thickness of the inner skin layer is 2.0 μm, the thickness ...

Embodiment 3

[0038]Double-sided heat-sealed double-sided anti-fog BOPP film, which consists of an inner surface layer, a core layer and an outer layer. The material of the surface layer is composed of polypropylene and anti-sticking agent. The mass percentages of the components of the inner and outer layers are: polypropylene 98.0%, anti-sticking agent 2.0%; the core layer is made of polypropylene, anti-fog Composed of agent and slip agent, the mass percentage of each component of the core layer is: polypropylene 96.5%, anti-fog agent 3.0%, slip agent 0.5%, and the anti-fog agent is composed of the following components in weight percentage : Sorbitan monostearate 50%, glyceryl monooleate 35%, polyethylene oxide (20) glyceryl monostearate 15%.

[0039] The thickness of the BOPP film described in Example 3 is 25 μm, wherein the thickness of the inner surface layer is 1.5 μm, the thickness of the outer surface layer is 1.5 μm, and the thickness of the core layer is 22.0 μm, and the polypropyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com