Plastic composite material for tray

A composite material and plastic technology, applied in the field of plastic materials, can solve the problems of poor crack resistance and impact resistance, and achieve the effect of improving crack resistance and impact resistance, high crack resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

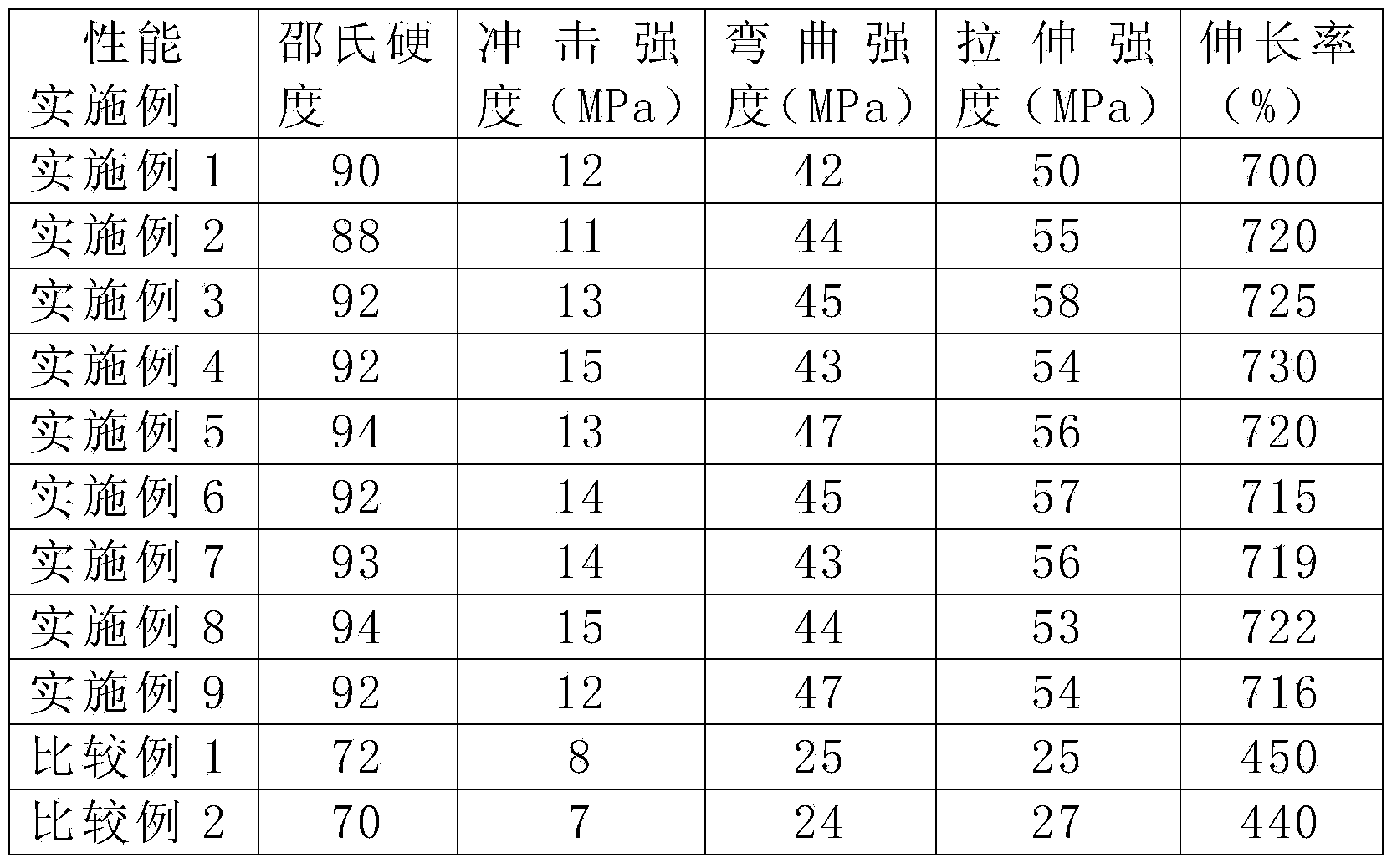

Examples

Embodiment 1

[0020] A plastic composite material, which mainly consists of the weight parts of the following components:

[0021] High density polyethylene: 85; Sorbitan monostearate: 3.0; Polytetrafluoroethylene: 0.5; Ethylene-methacrylic acid copolymer: 2.0; Silane coupling agent vinyl trichlorosilane: 0.8; Nano titanium dioxide: 10; silicone rubber: 10; glass fiber: 8.0; calcium carbonate: 4.0.

[0022] The above-mentioned plastic composite materials are used to make trays according to conventional manufacturing methods in the art. More specifically, the manufacturing method of the tray described in this embodiment is as follows:

[0023] Weigh the raw materials according to the weight ratio of the above ingredients, add them into the barrel, mix them evenly, heat and melt them, and then quickly inject them into the closed tray mold, pressurize, injection molding, open the mold and take out the products for proper trimming and trimming to obtain plastic tray.

Embodiment 2

[0025] A plastic composite material, which mainly consists of the weight parts of the following components:

[0026] High-density polyethylene: 70; sorbitan monostearate: 2.0; polytetrafluoroethylene: 1.0; ethylene-methacrylic acid copolymer: 5.0; silane coupling agent γ-methacryloxypropyl trimethyl Oxysilane: 0.5; Nano silica: 5.0; Synthetic rubber: 13; Glass fiber: 12; Flame retardant kaolin: 2.0; Antioxidant 1010: 2.0.

[0027] The above-mentioned plastic composite material is used to make the tray according to the conventional manufacturing method in the field, and the manufacturing method adopted is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] A plastic composite material, which mainly consists of the weight parts of the following components:

[0030] High-density polyethylene: 80; sorbitan monostearate: 2.8; polytetrafluoroethylene: 0.8; ethylene-methacrylic acid copolymer: 4.0; silane coupling agent γ-glycidyl ether oxypropyl trimethyl Oxysilane: 0.7; Nano calcium carbonate: 6.0; Silicone rubber: 12; Mineral fiber: 11; Flame retardant: 3.0; Antioxidant 168: 1.5.

[0031] Adopt above-mentioned plastic composite material, make pallet according to the conventional manufacturing method of this area, the manufacturing method that adopts is consistent with embodiment 1, repeats no more here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com