Patents

Literature

87 results about "Water in oil microemulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

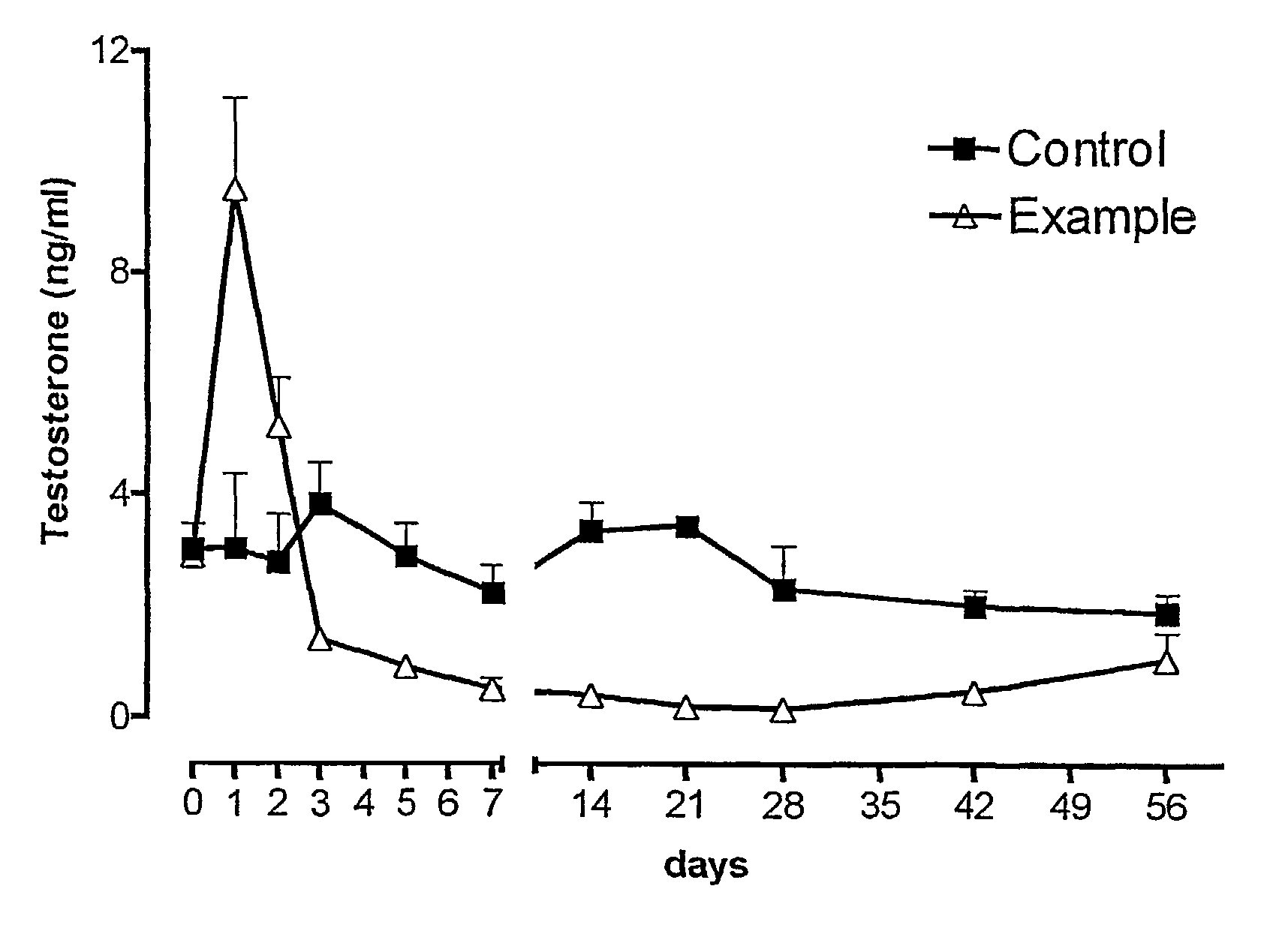

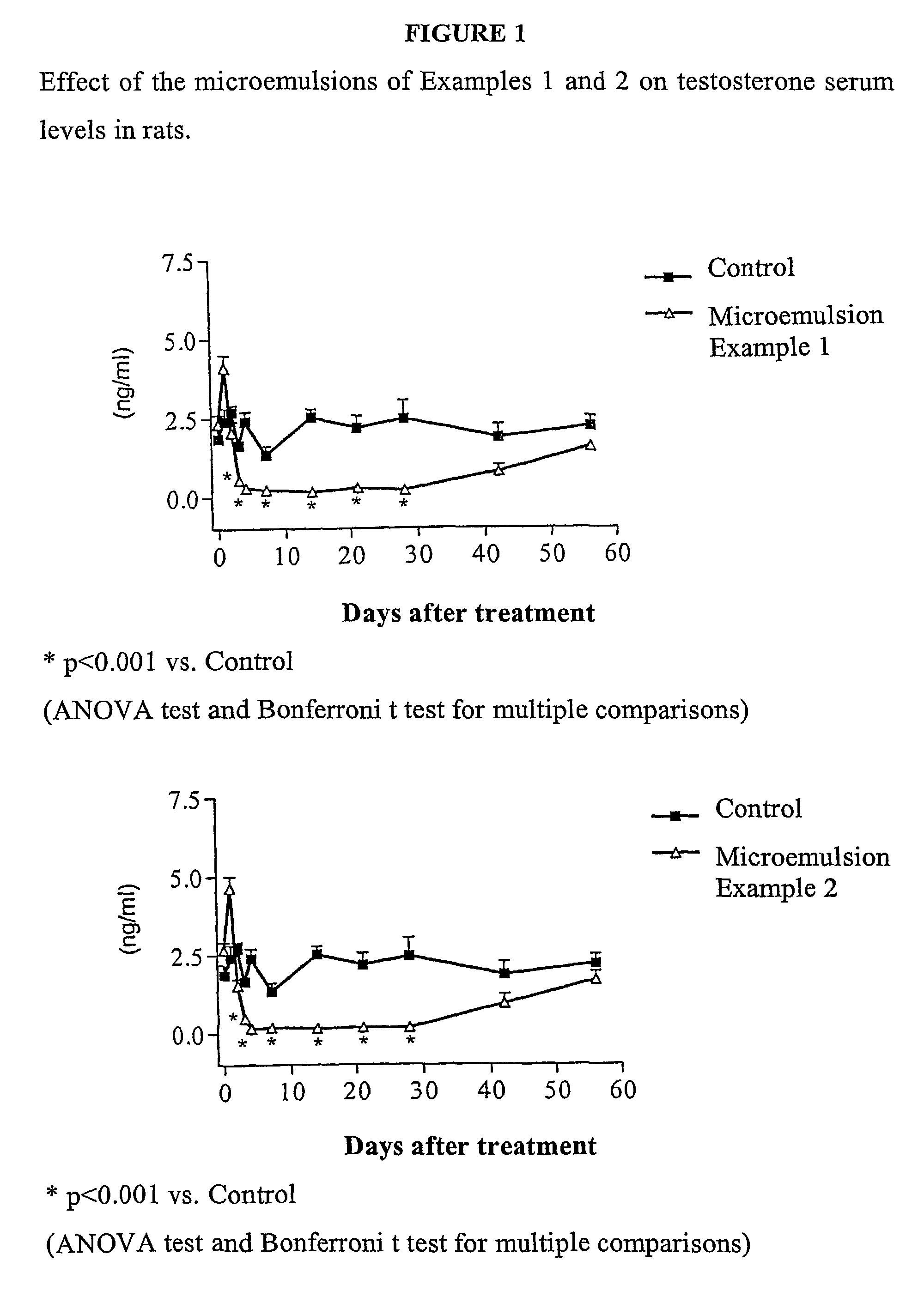

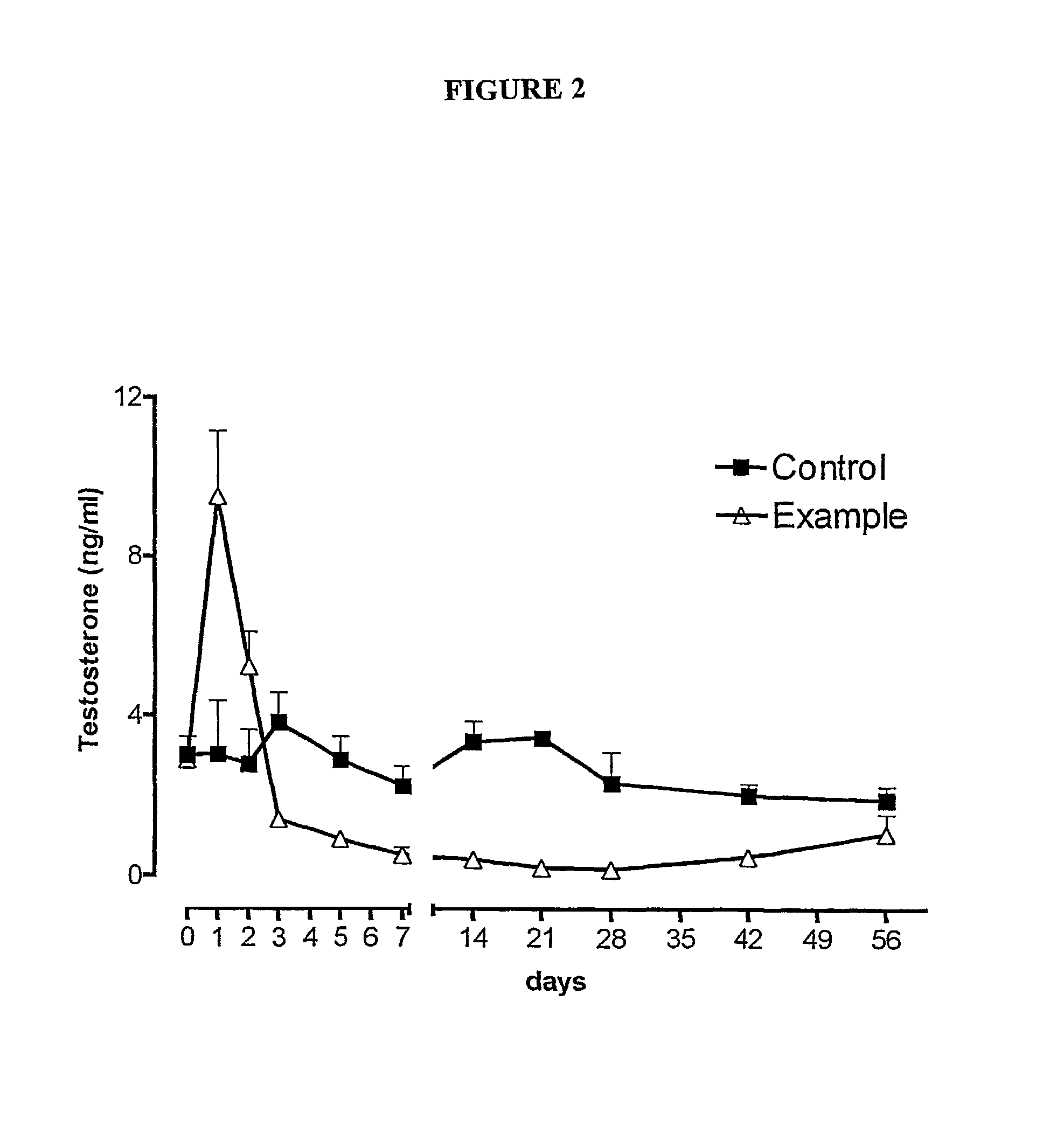

Sustained release pharmaceutical compositions for the parenteral administration of hydrophilic compounds

InactiveUS7157099B2Easy to prepareOrganic active ingredientsPeptide/protein ingredientsParenteral nutritionBULK ACTIVE INGREDIENT

Owner:ITALFARMACO SPA

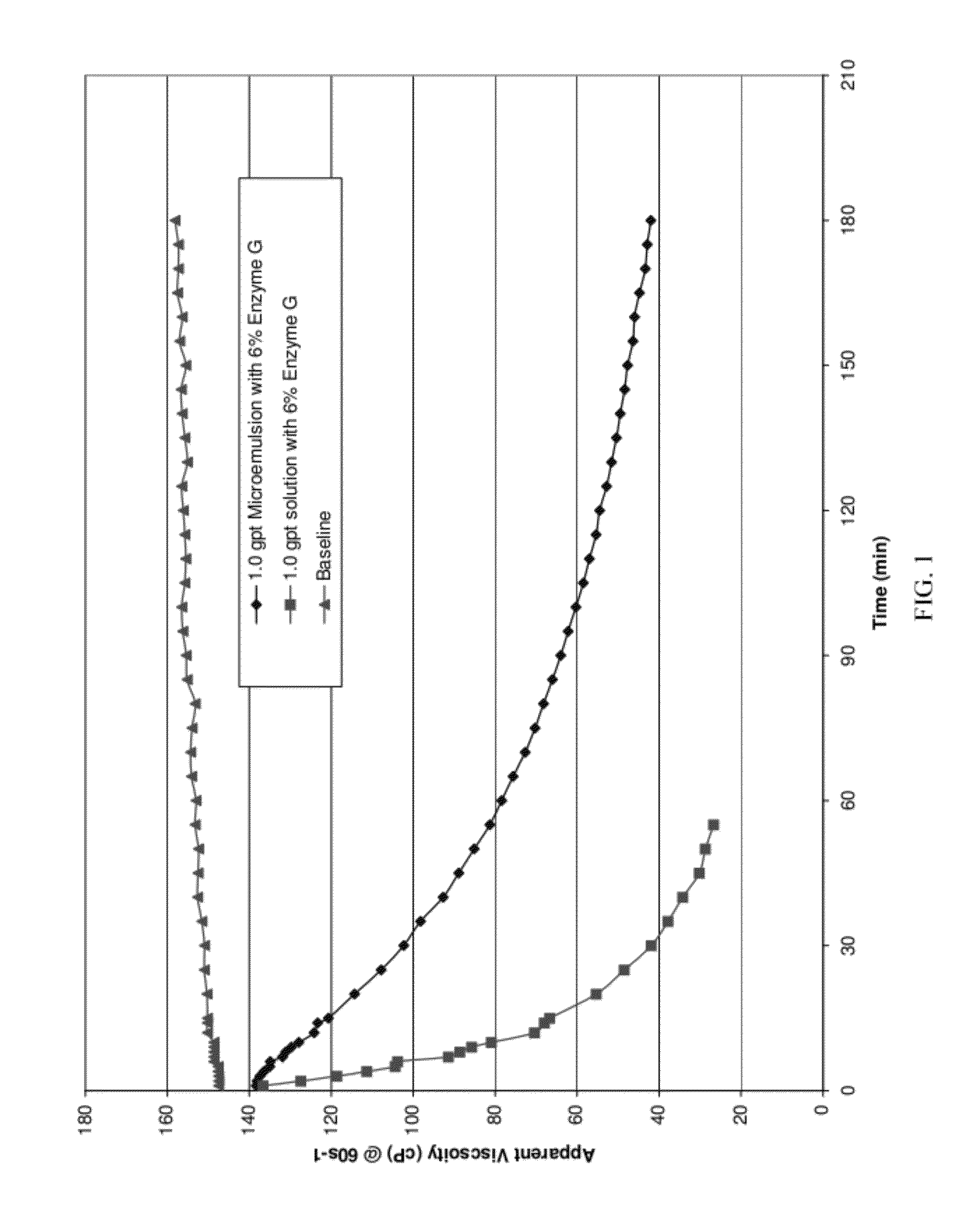

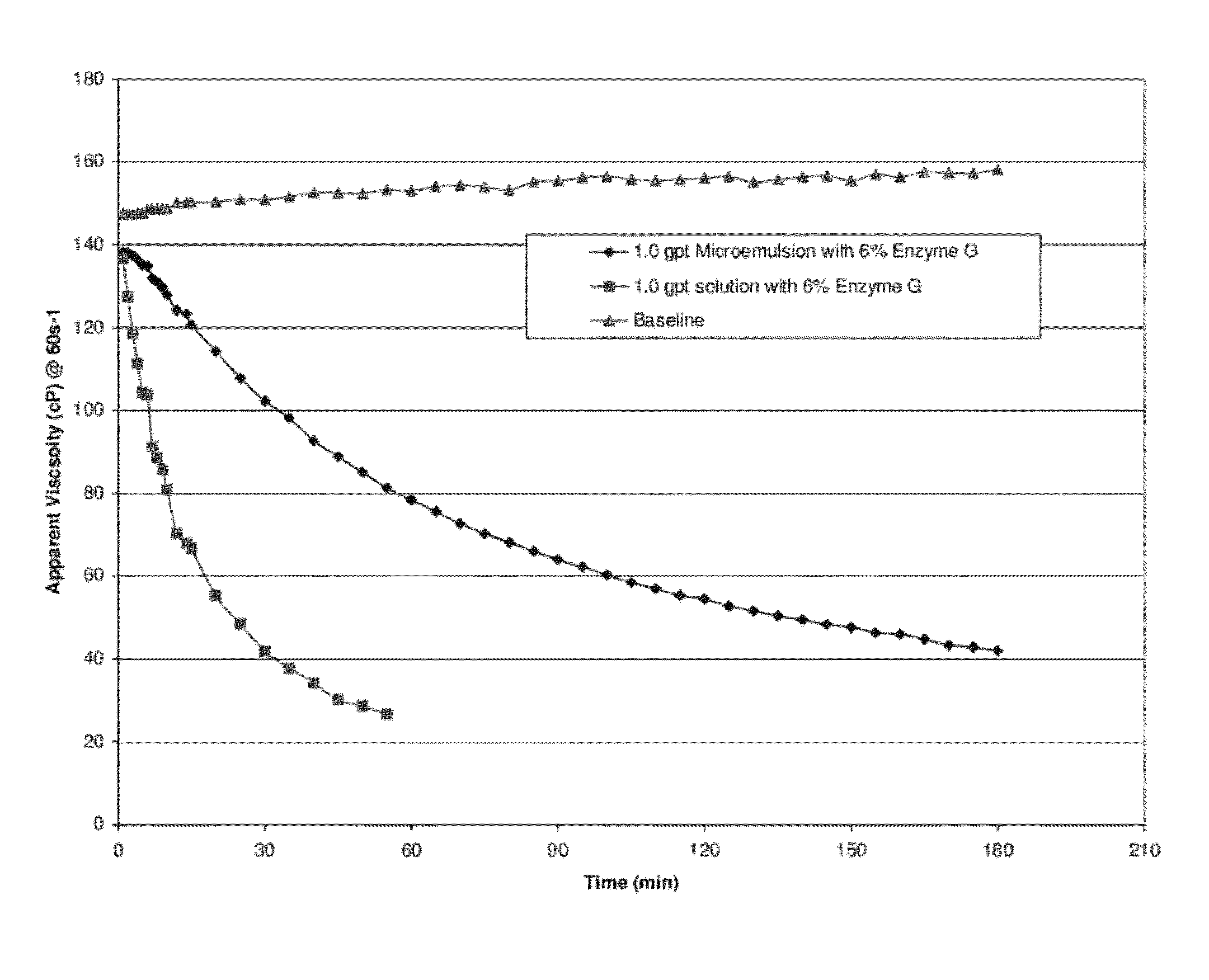

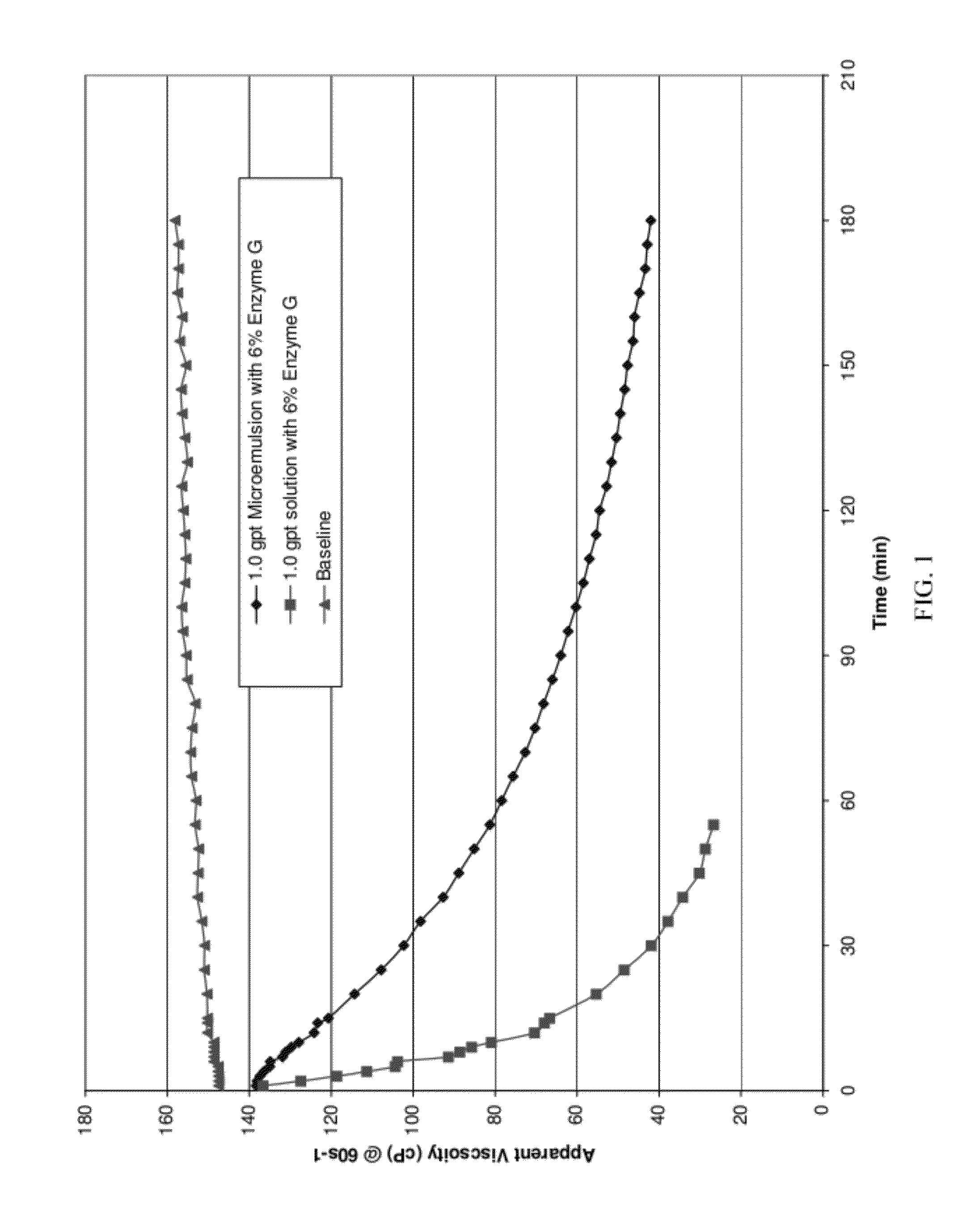

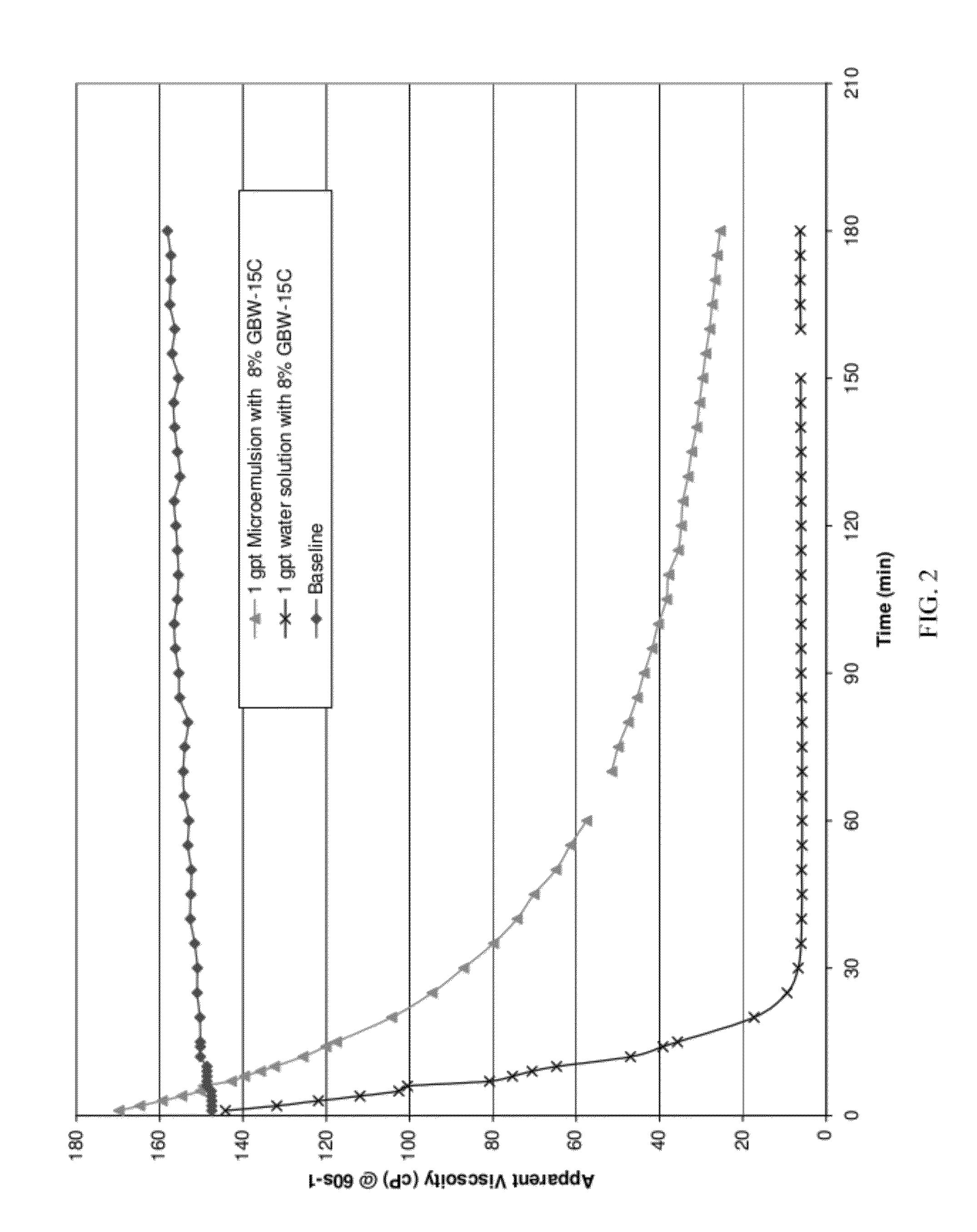

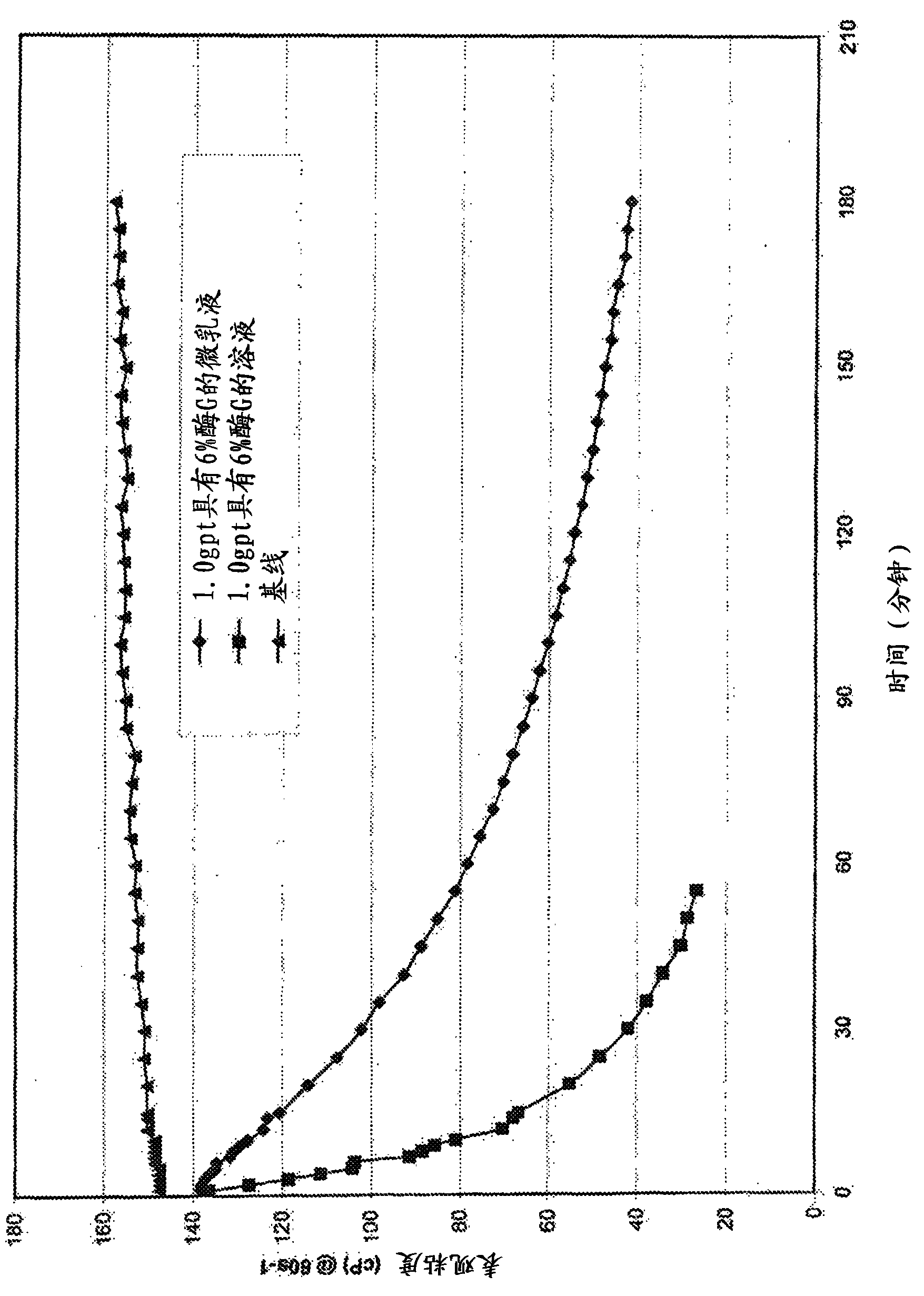

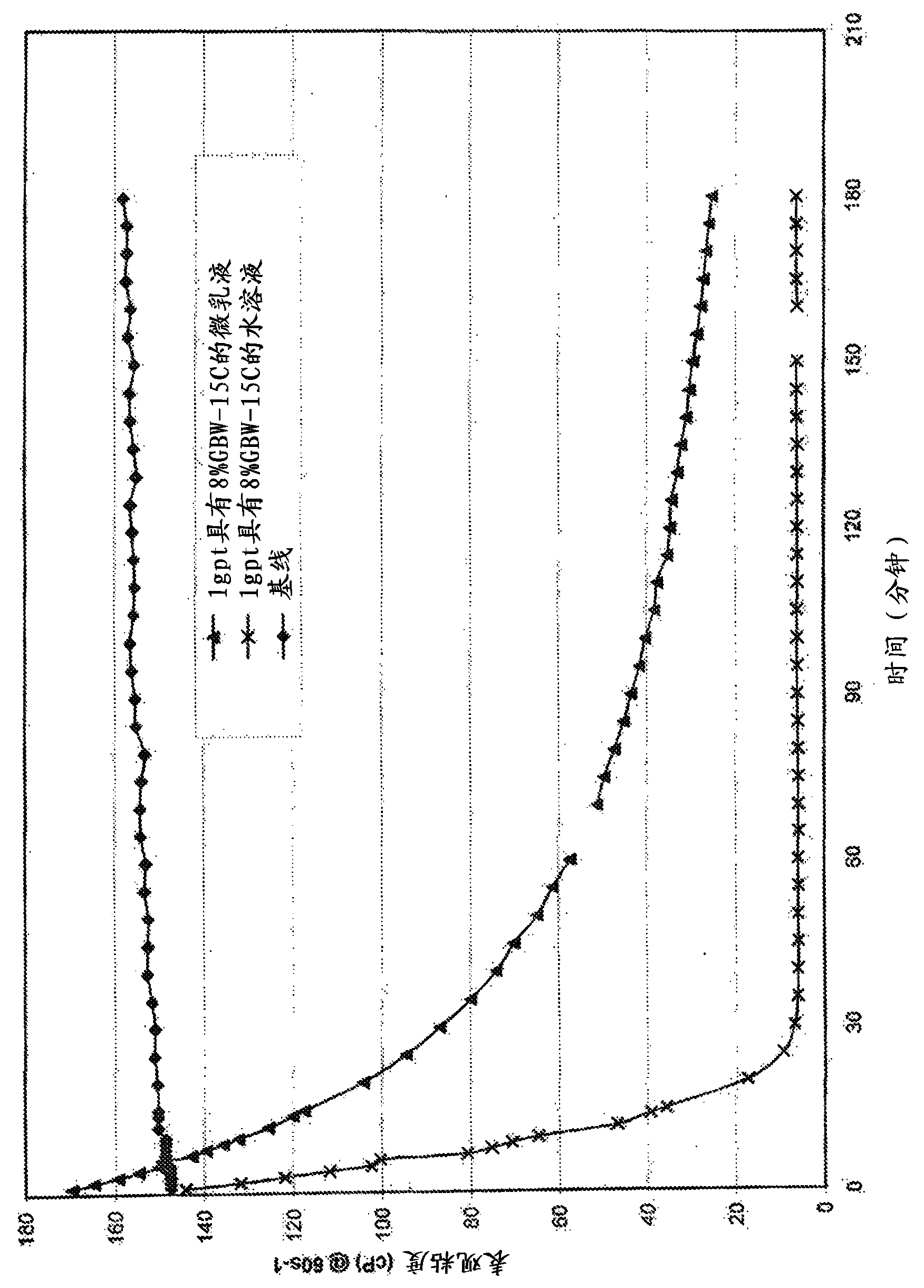

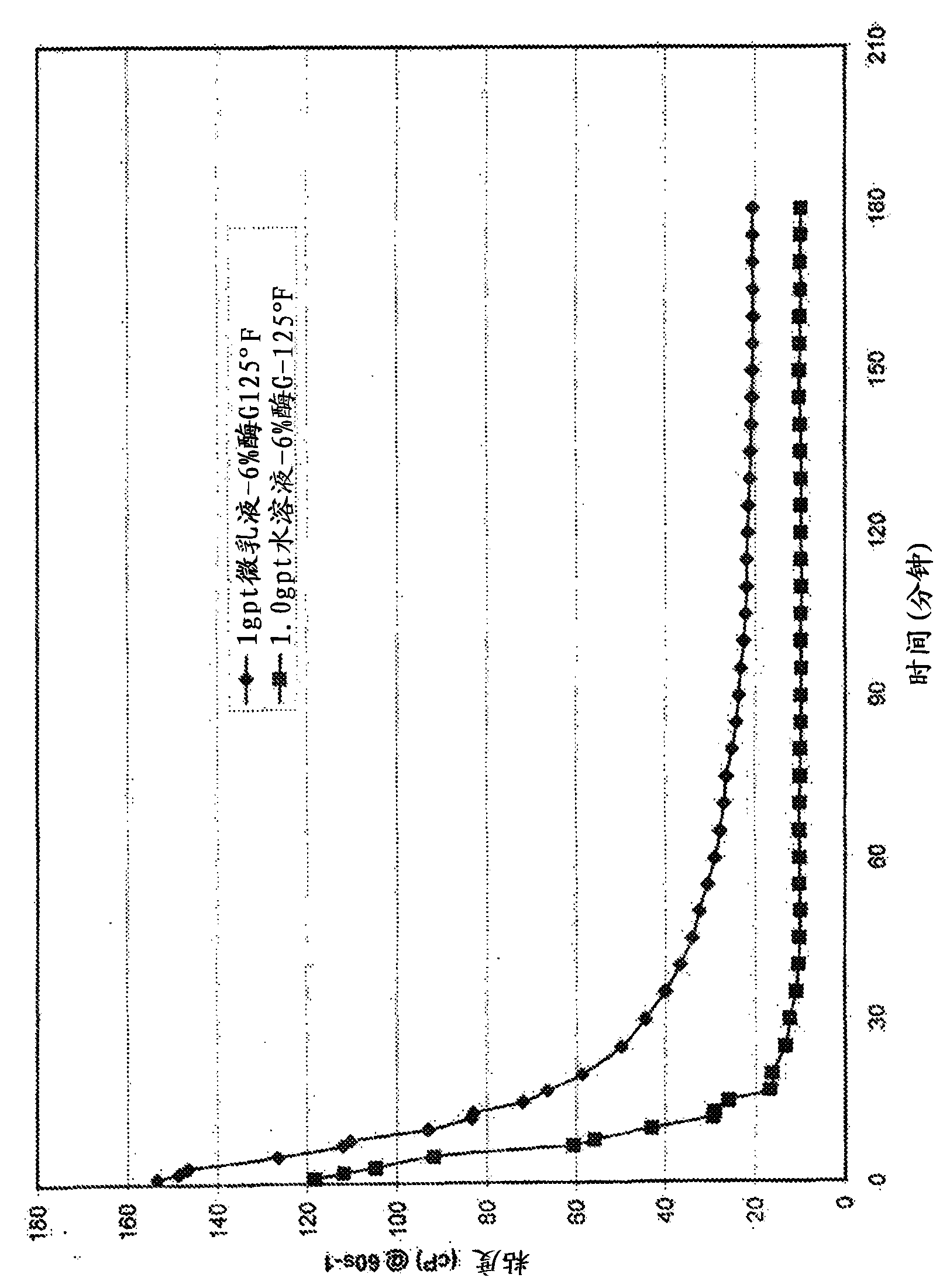

Method of inhibiting or controlling release of well treatment agent

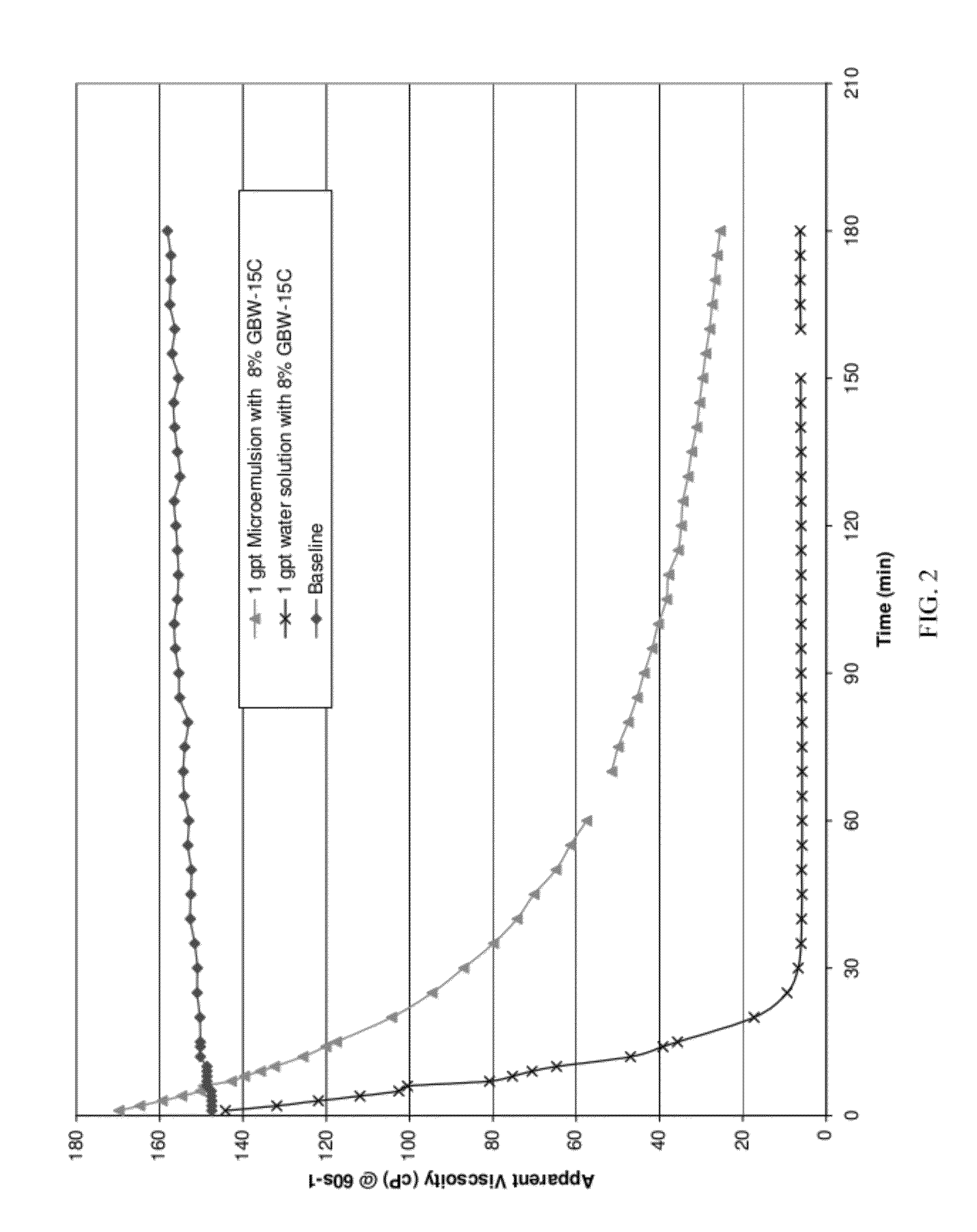

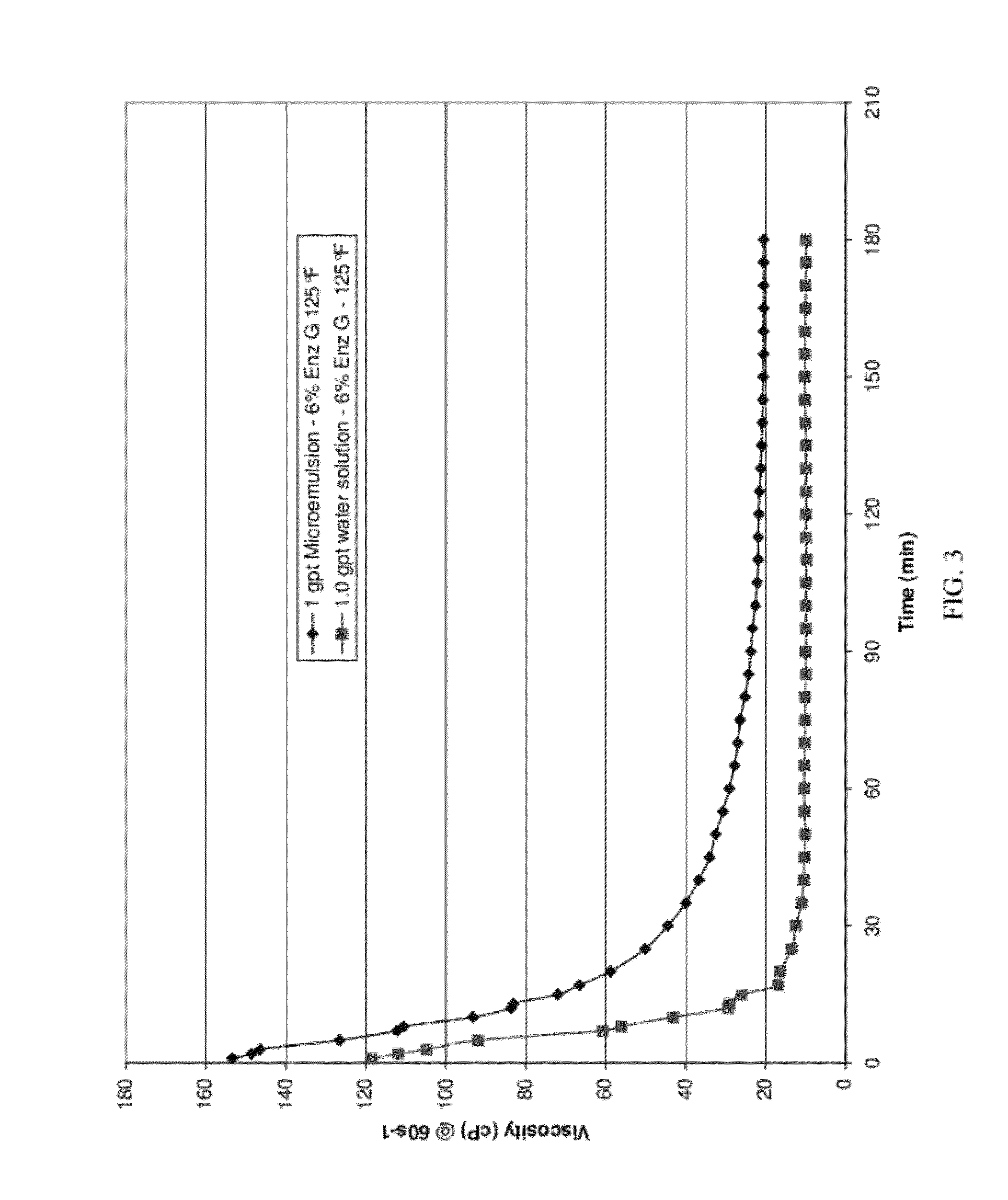

A microemulsion delivery system containing a well treatment agent in a water-in-oil microemulsion may be used for well remediation as well as in other treatment operations including stimulation, acidizing, and drilling. In addition, the water-in-oil microemulsion delivery system may be used to clean surface equipment and downhole equipment.

Owner:BAKER HUGHES INC

Composition and method of converting a fluid from oil external to water external for cleaning a wellbore

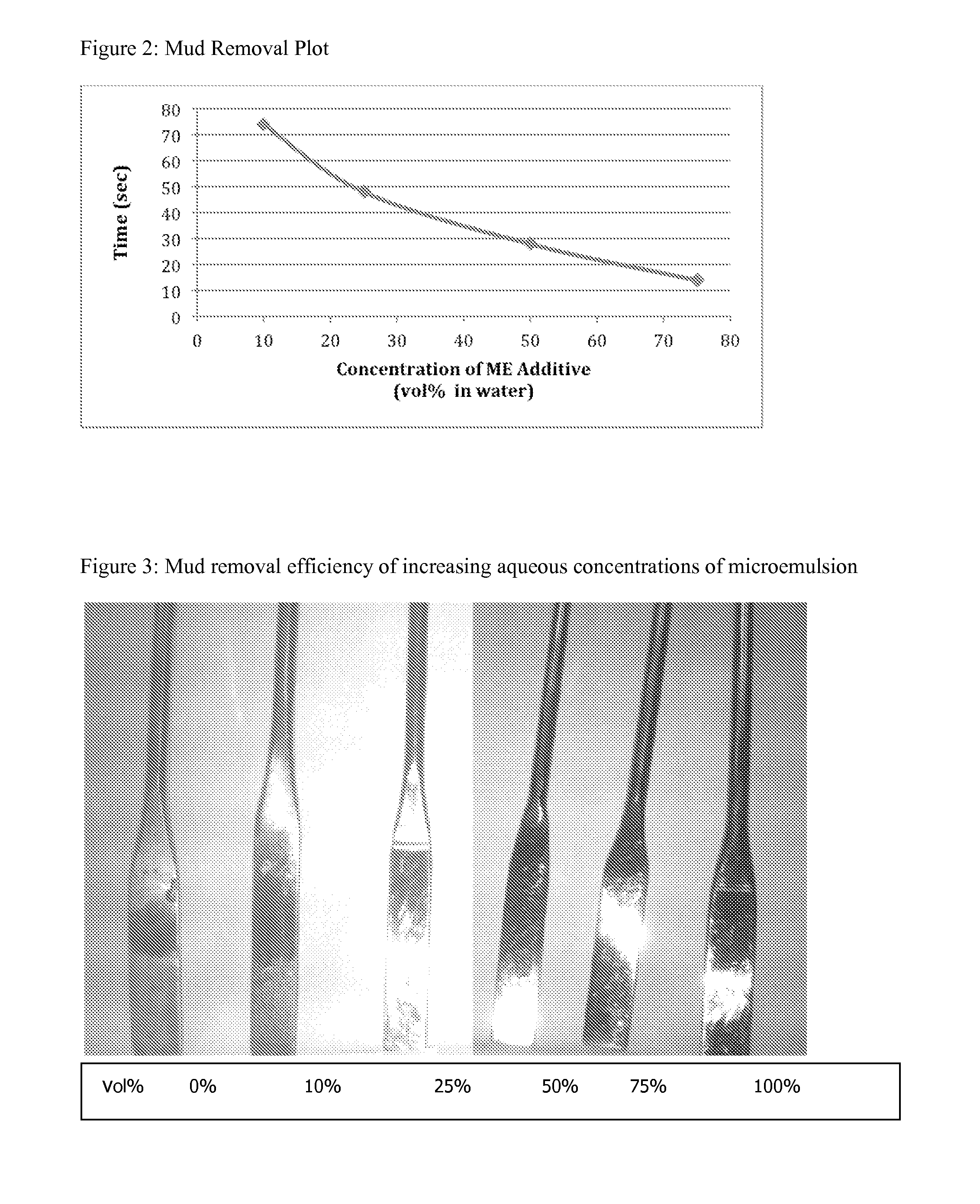

InactiveUS20130244913A1Effective mud removalGood dispersionFlushingDrilling compositionWater basedHydrocarbon solvents

An environmentally acceptable water-in-oil microemulsion composition includes at least one emulsifying surfactant, at least one biodegradable hydrocarbon solvent, at least one co-solvent, at least one hydrocarbon co-surfactant, and water. The microemulsion composition may be used in a method for rendering fluids from oil external to water external. The microemulsion composition may be combined with water or a water based fluid to produce a spacer fluid utilized in removing oil and oil-residues from a surface, particularly that of wellbores in the drilling of oil and gas wells.

Owner:BENCHMARK PERFORMANCE GROUP

Microemulsions for use in food and beverage products

ActiveUS20070087104A1Acceptable tasteImprove bioavailabilityEdible oils/fats with aqeous phaseFood gradeBeta-Carotene

Oil-in-water microemulsions which can be used to incorporate lipophilic water-insoluble materials, such as beta-carotene, into food and beverage compositions are disclosed. The microemulsions utilize a ternary food grade emulsifier system which incorporates a low HLB emulsifier, a medium HLB emulsifier, and a high HLB emulsifier. The microemulsions of the present invention allow for the incorporating of water-insoluble materials in an effective and easy-to-process manner while providing formulational flexibility and without significantly affecting the taste of the underlying food or beverage product. Food and beverage products including the microemulsions are also disclosed. Finally, the method of preparing the microemulsions is described. The invention also encompasses water-in-oil microemulsions for use in incorporating water-soluble materials into food and beverage products. Finally, the invention encompasses concentrate compositions used for making those microemulsions.

Owner:WILD FLAVORS INC

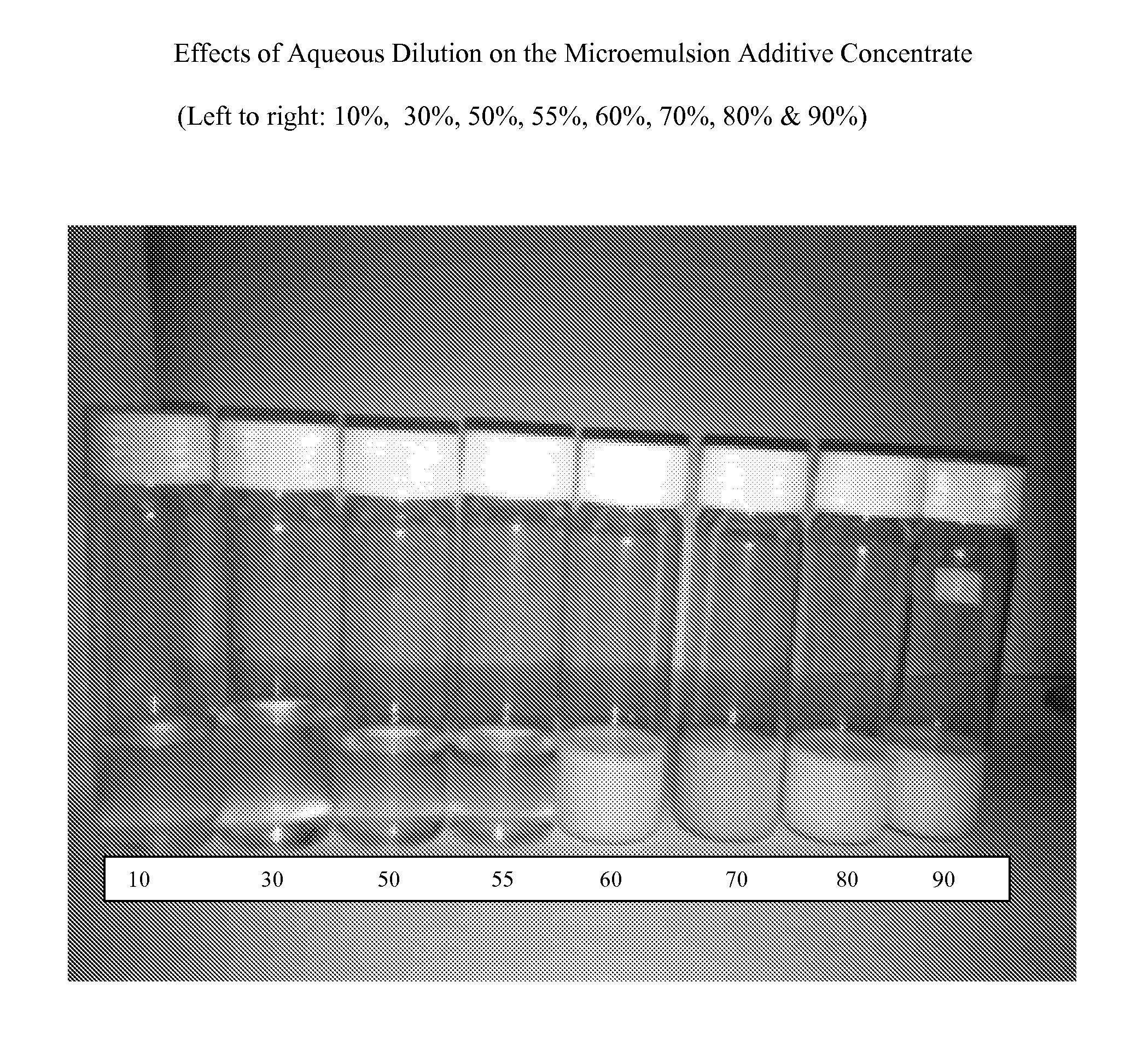

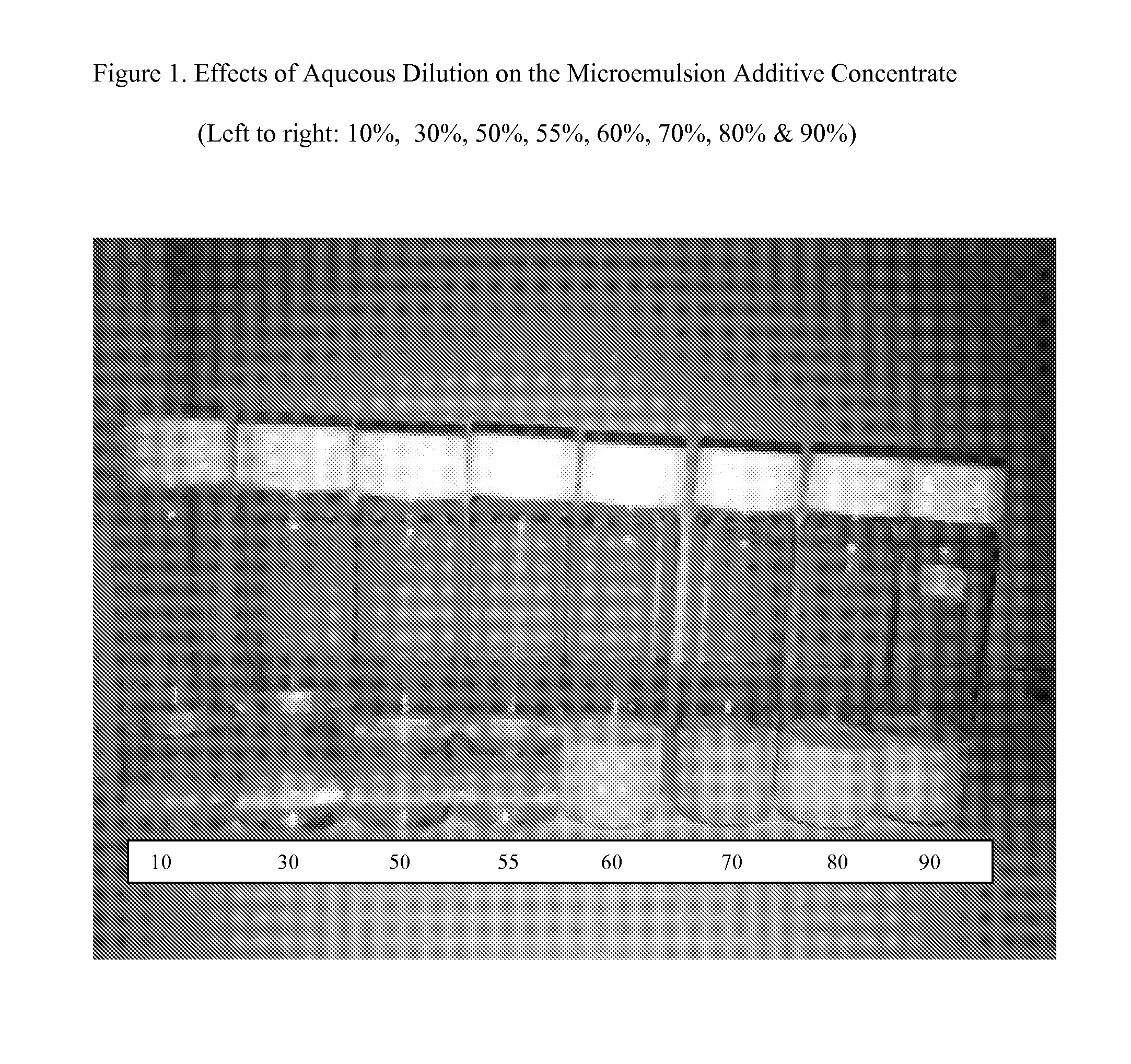

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:PNC BANK NAT ASSOC

Method for identifying cells

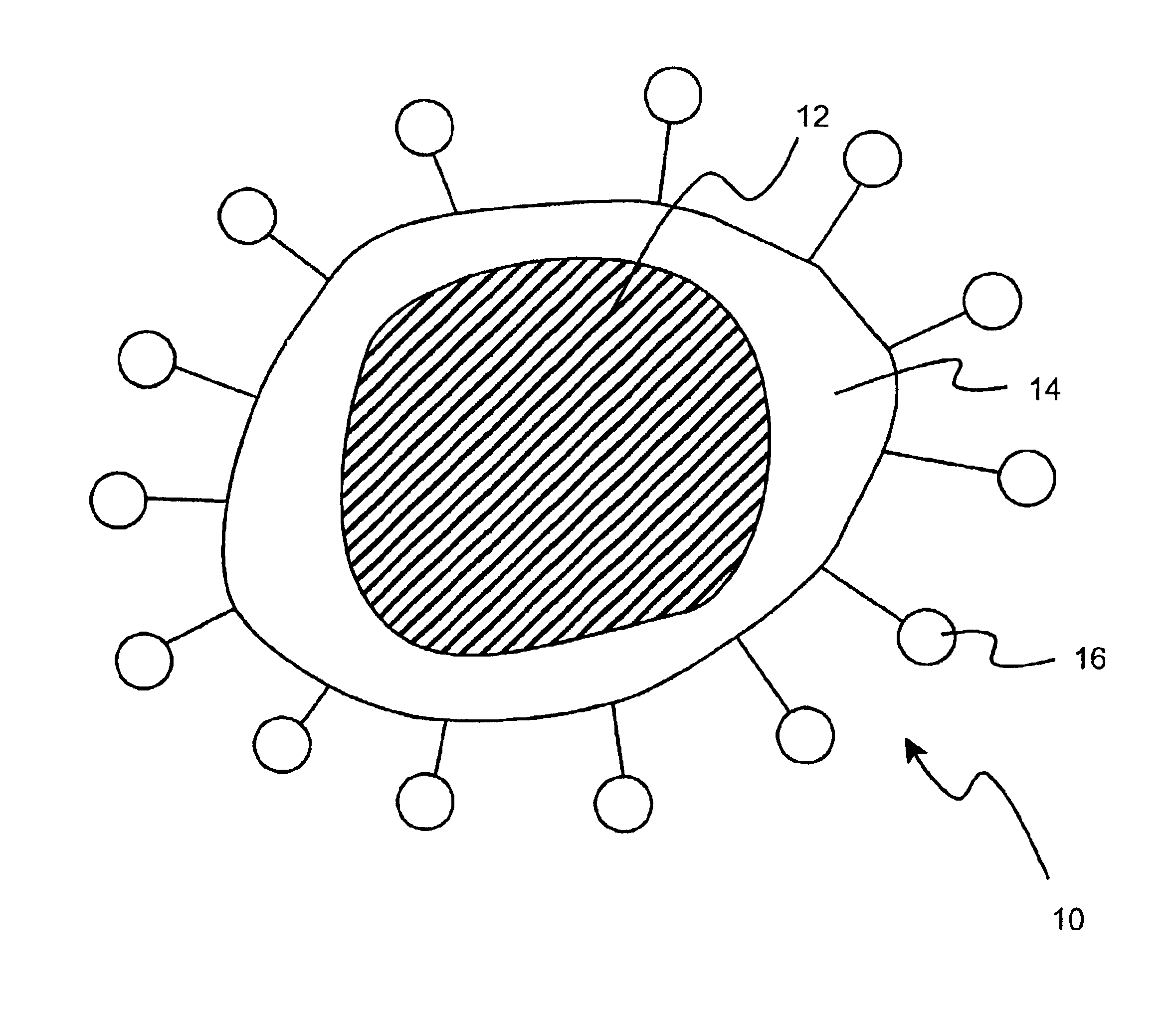

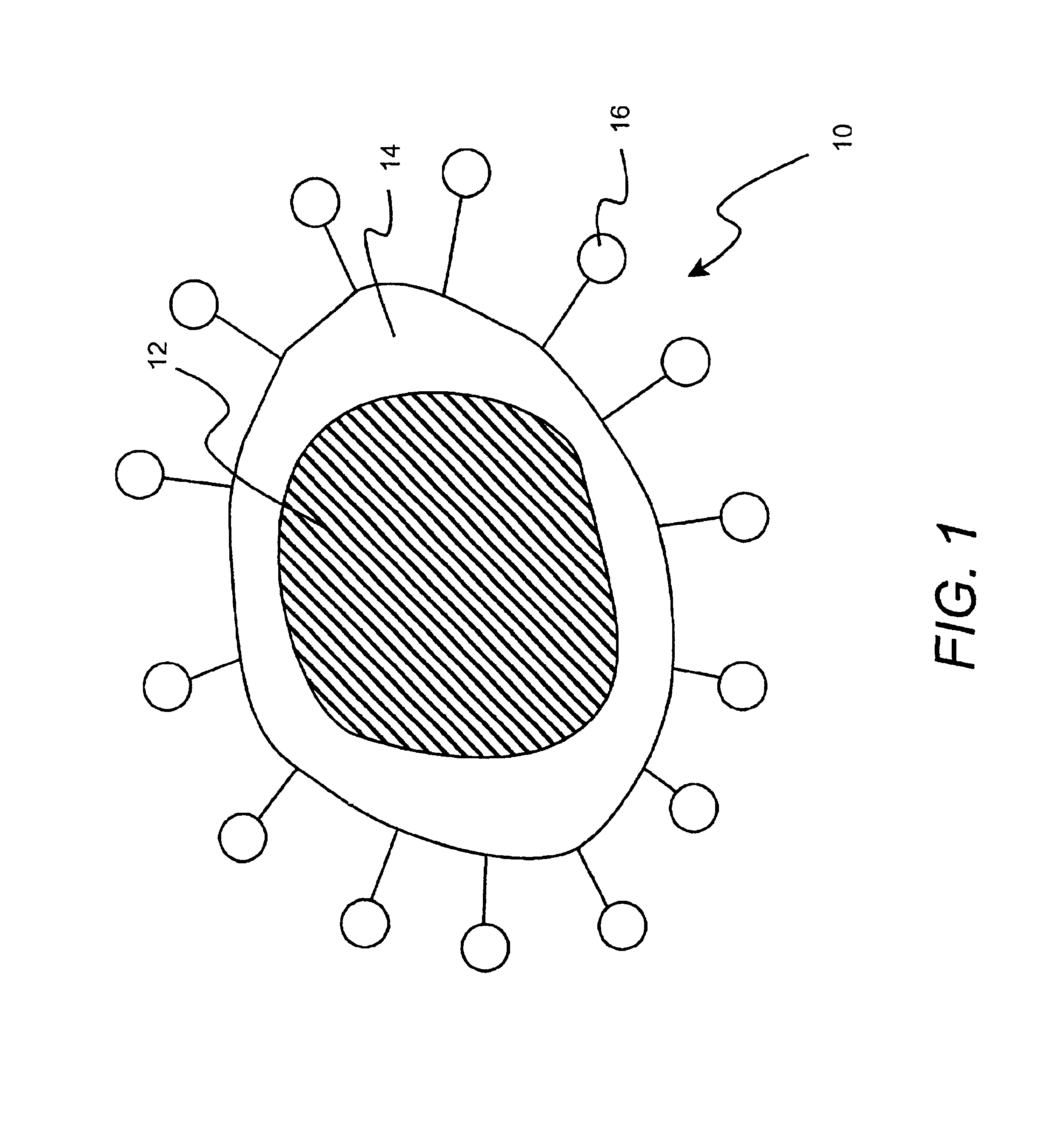

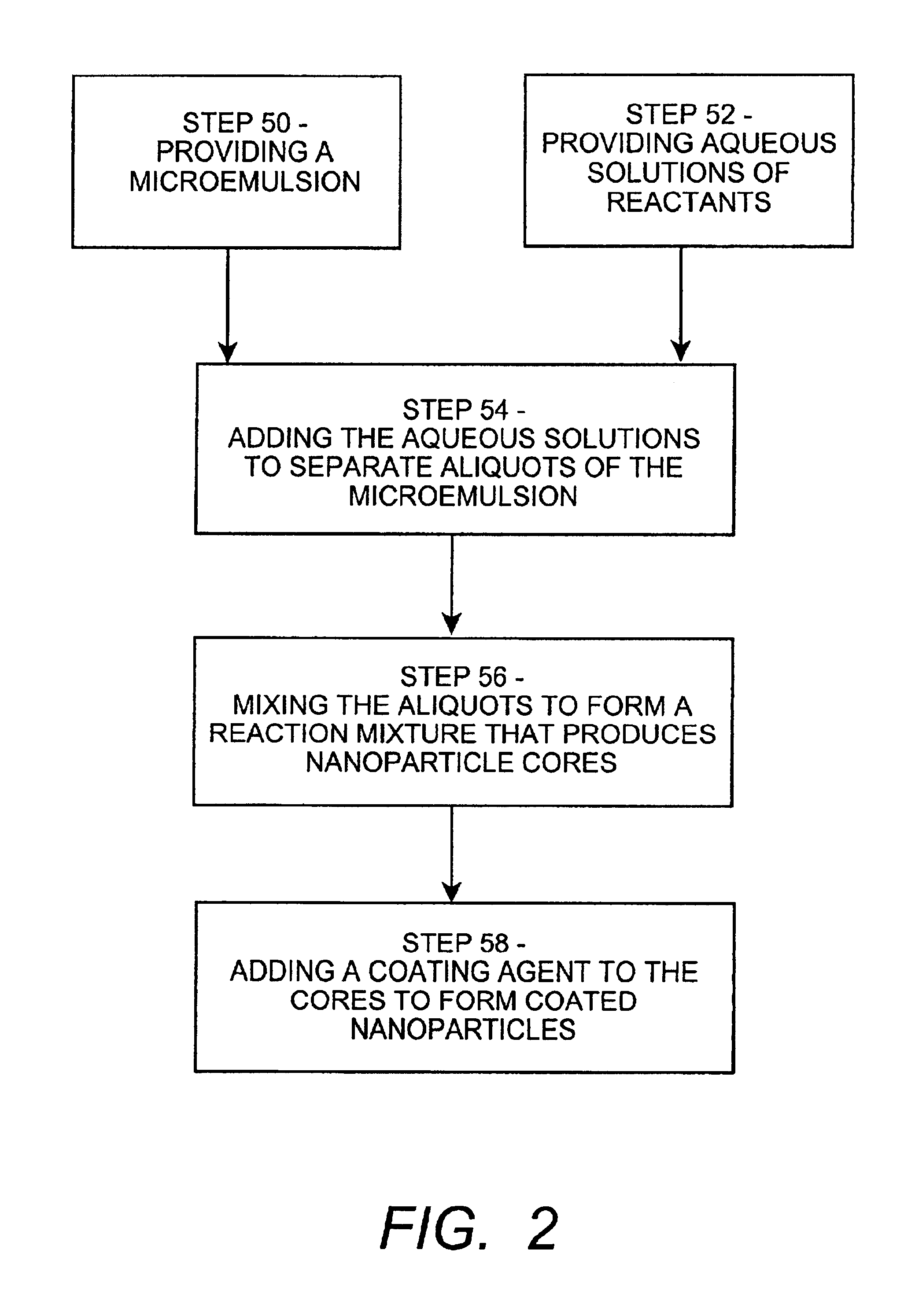

Disclosed are silica-coated nanoparticles and a process for producing silica-coated nanoparticles. Silica-coated nanoparticles are prepared by precipitating nano-sized cores from reagents dissolved in the aqueous compartment of a water-in-oil microemulsion. A reactive silicate is added to coat the cores with silica. Also disclosed are methods for functionalizing silica-coated nanoparticles for use in a variety of applications.

Owner:FLORIDA UNIV OF A FLORIDA

Method of inhibiting or controlling release of well treatment agent

A microemulsion delivery system containing a well treatment agent in a water-in-oil microemulsion may be used for well remediation as well as in other treatment operations including stimulation, acidizing, and drilling. In addition, the water-in-oil microemulsion delivery system may be used to clean surface equipment and downhole equipment.

Owner:BAKER HUGHES INC

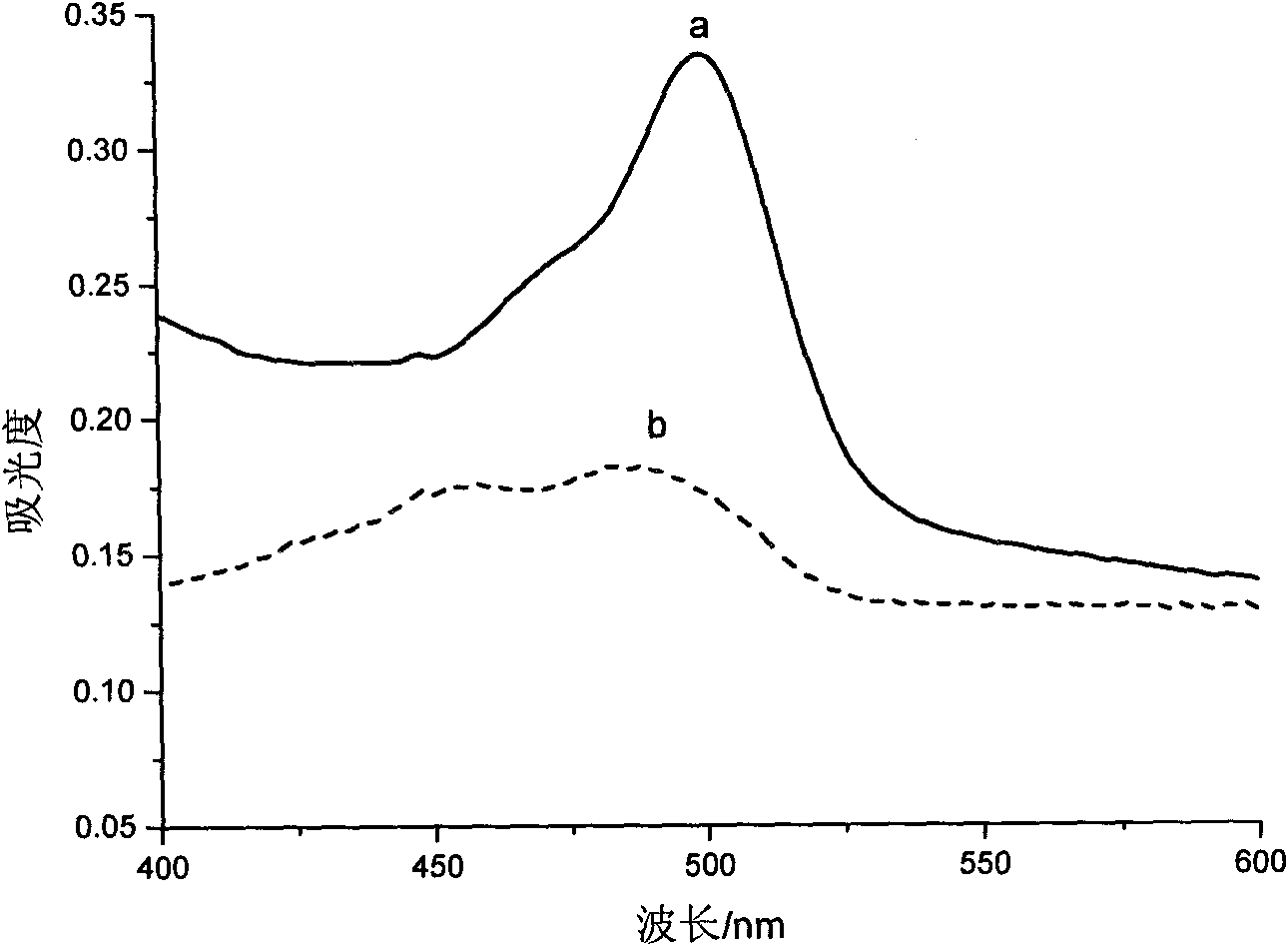

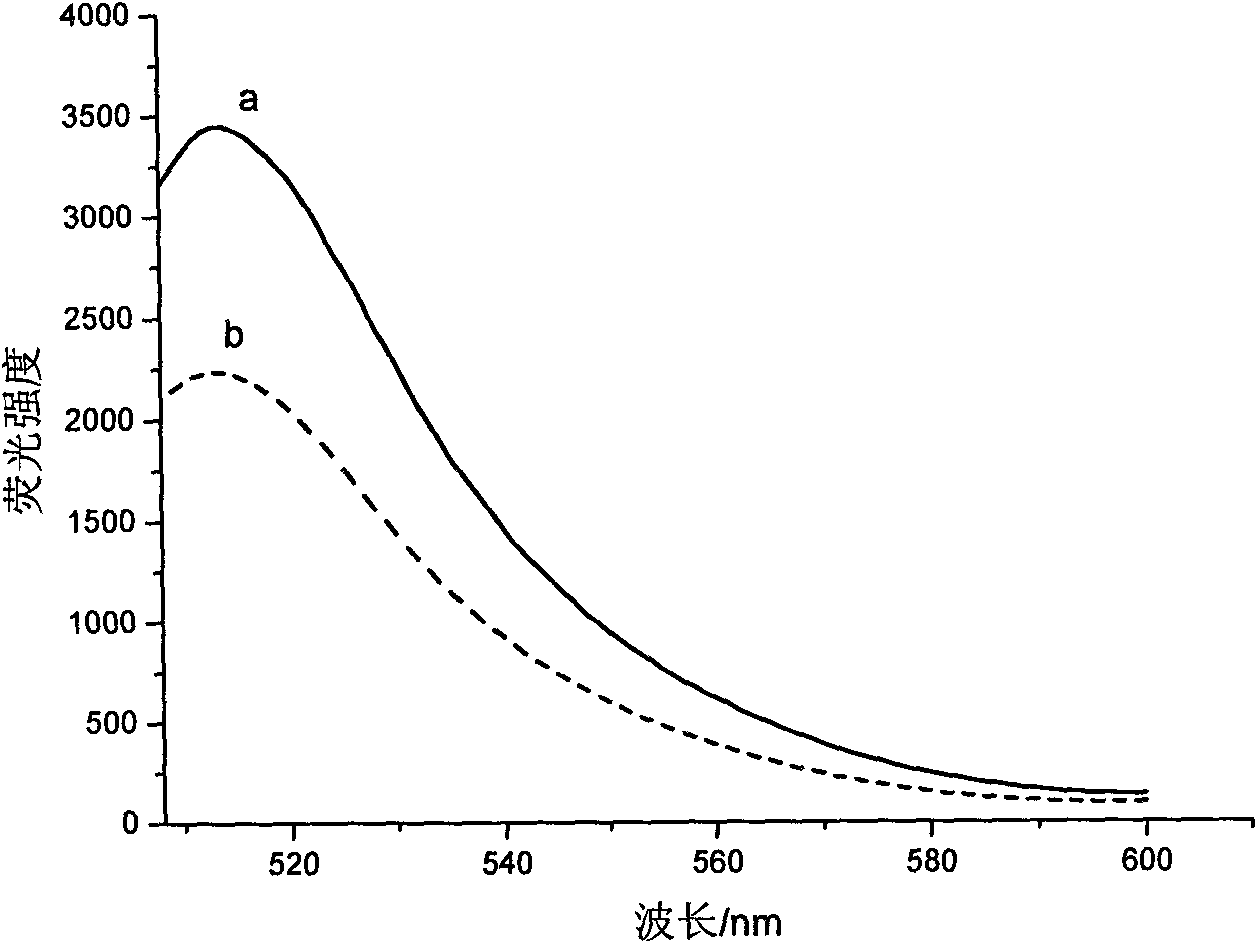

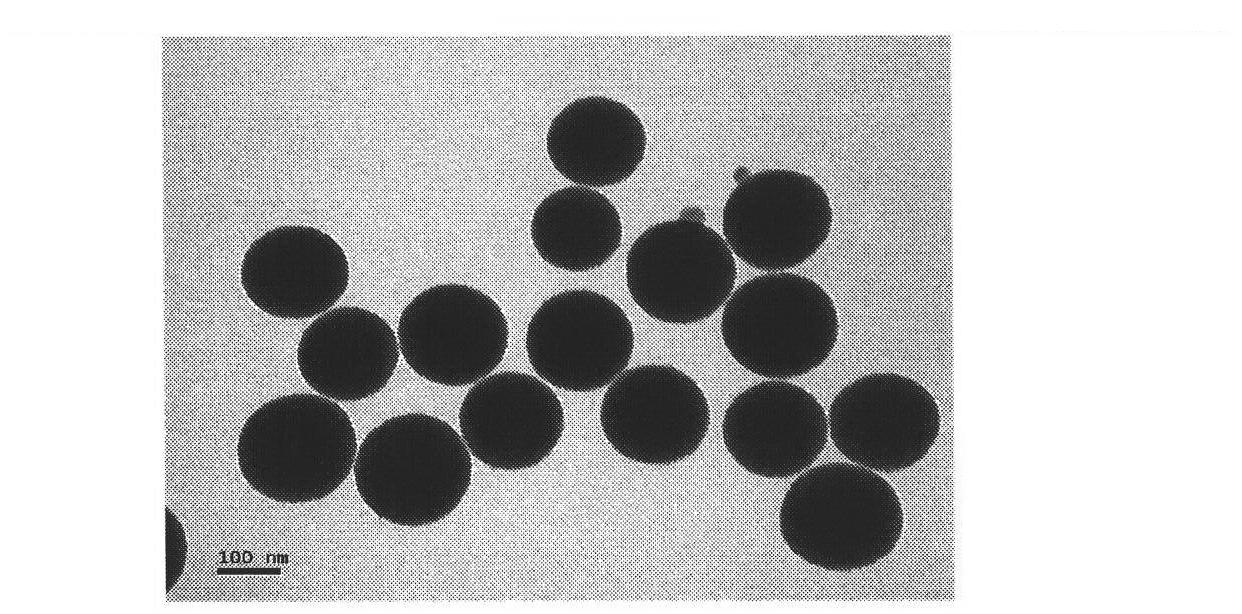

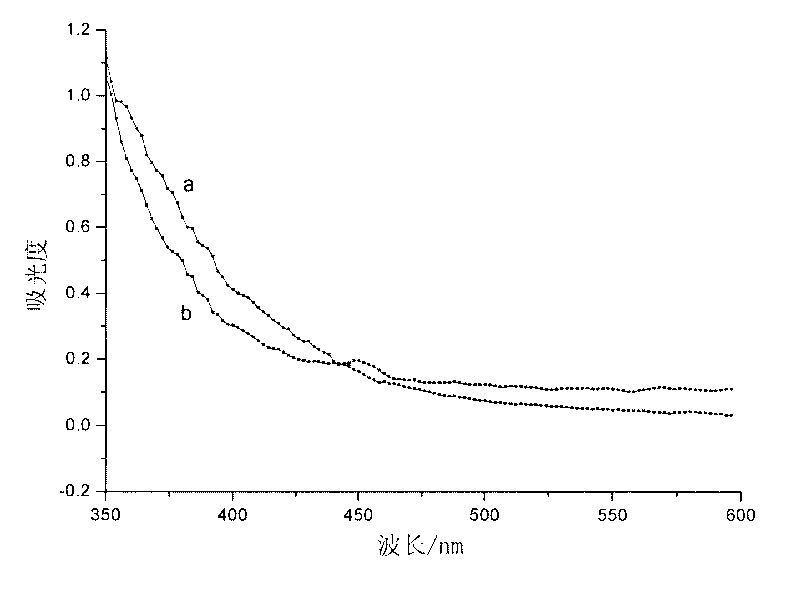

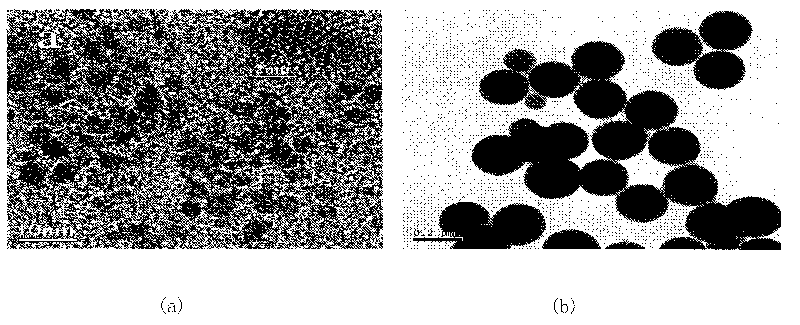

FITC-doped silica fluorescent nanoparticle and preparation method thereof

InactiveCN101805603APrevent leakageGood chemical stabilityFluorescence/phosphorescenceLuminescent compositionsFluorescein isothiocyanateSilicon dioxide

The invention relates to a silica fluorescent nanoparticle and a preparation method thereof, in particular to an FITC-doped silica fluorescent nanoparticle and the preparation method thereof. The method particularly comprises the preparation of a precursor solution and other steps. The FITC is reacted with 3-aminopropyl trimethoxysilane to prepare a precursor, and then the novel FITC-doped silica fluorescent nanoparticle is prepared by a water-in-oil microemulsion method. The prepared nanoparticle is uniformly spherical, has good monodispersity and light stability, difficultly generates dye leakage, has good response to the pH value and can be applied to the real-time monitoring of the pH value of cells.

Owner:SHANGHAI UNIV

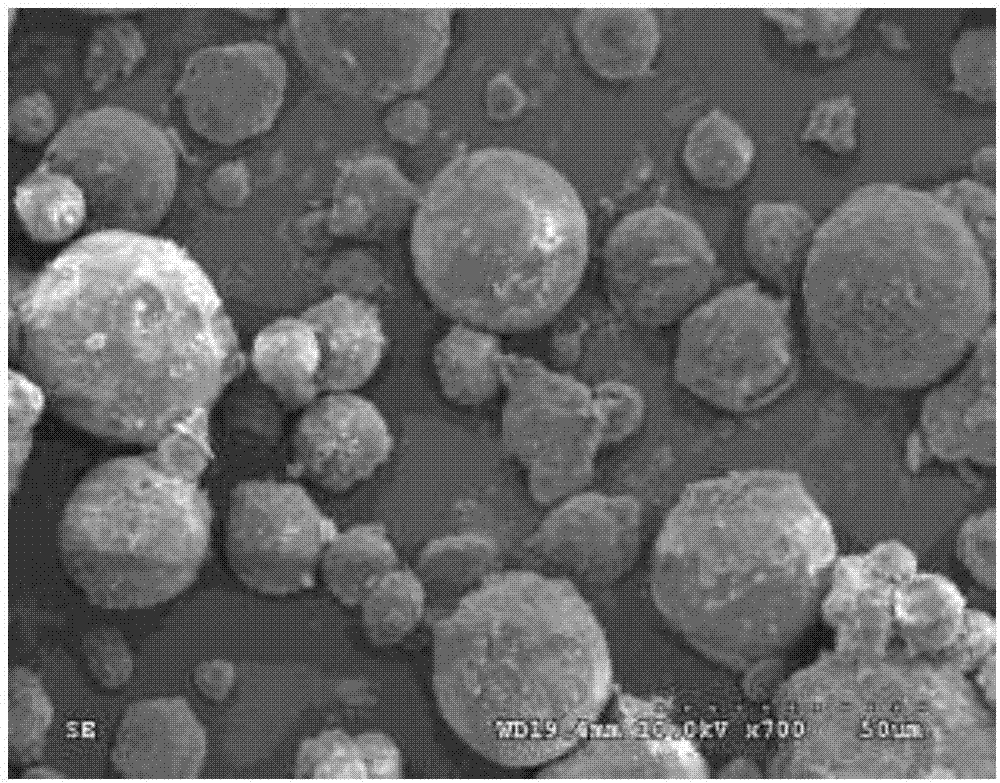

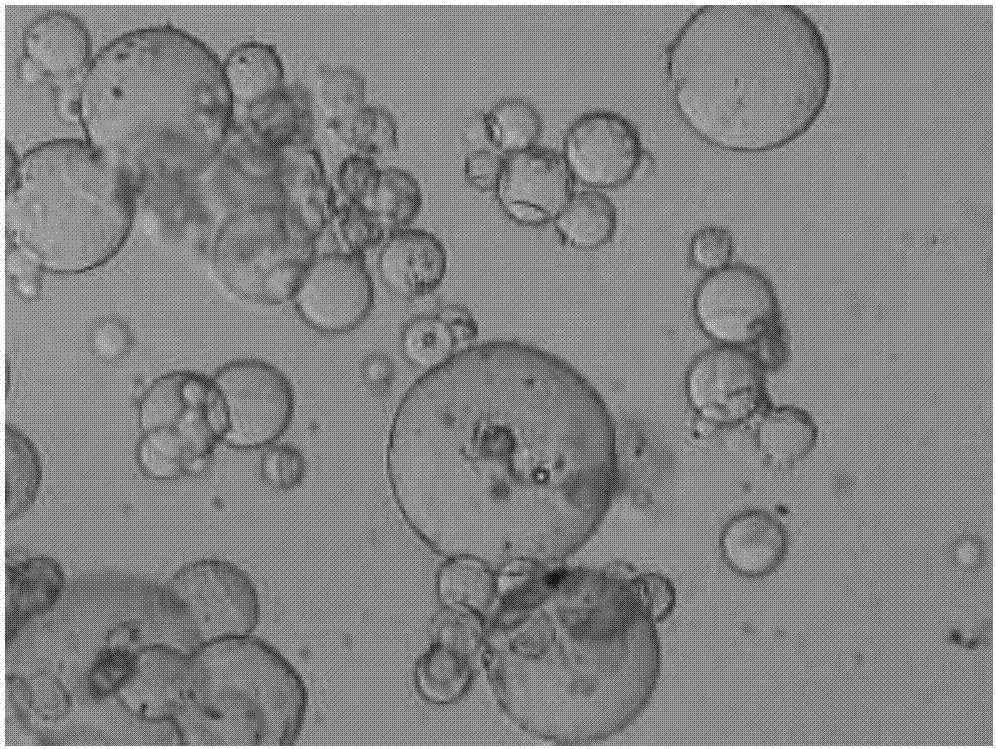

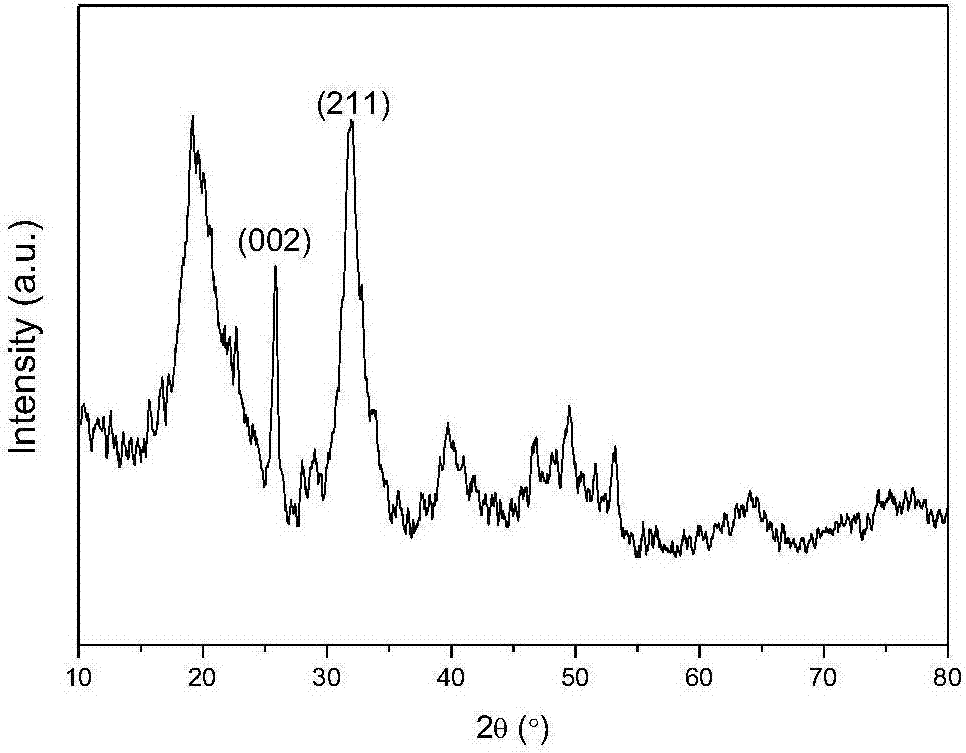

Preparation method of polyvinyl alcohol/hydroxyapatite (PVA/HA) composite microspheres

InactiveCN107376795AGood dispersionUniform internal structureCosmetic preparationsOther chemical processesFood additiveMicrosphere

A preparation method of polyvinyl alcohol / hydroxyapatite (PVA / HA) composite microspheres belongs to preparation methods of composite water-in-oil emulsion system microspheres. PVA and HA precursors are used as raw materials to prepare a clear and transparent mixed solution; the clear and transparent mixed solution is dispersed into an oil phase containing a surfactant to form a homogeneous water-in-oil microemulsion; and the PVA / HA composite microspheres can be finally obtained by successive crosslinking reaction under acid-catalyzed conditions, HA deposition under alkaline conditions, product centrifugation, washing, drying and other processes. The method has the advantages of simple process, good repeatability, low energy consumption and low cost, and effectively solves the problems that inorganic nanoparticles are easy to agglomerate in the microspheres to cause uneven structures and poor comprehensive performances and the like. The composite microspheres prepared by the method have the advantages of regular morphology, high dispersibility, uniform microstructure, good biocompatibility, biological activity and adsorption performance, and can be used as drug carrier materials, bone repair materials, environmental water treatment materials, cosmetics or food additives and the like.

Owner:CHINA UNIV OF MINING & TECH

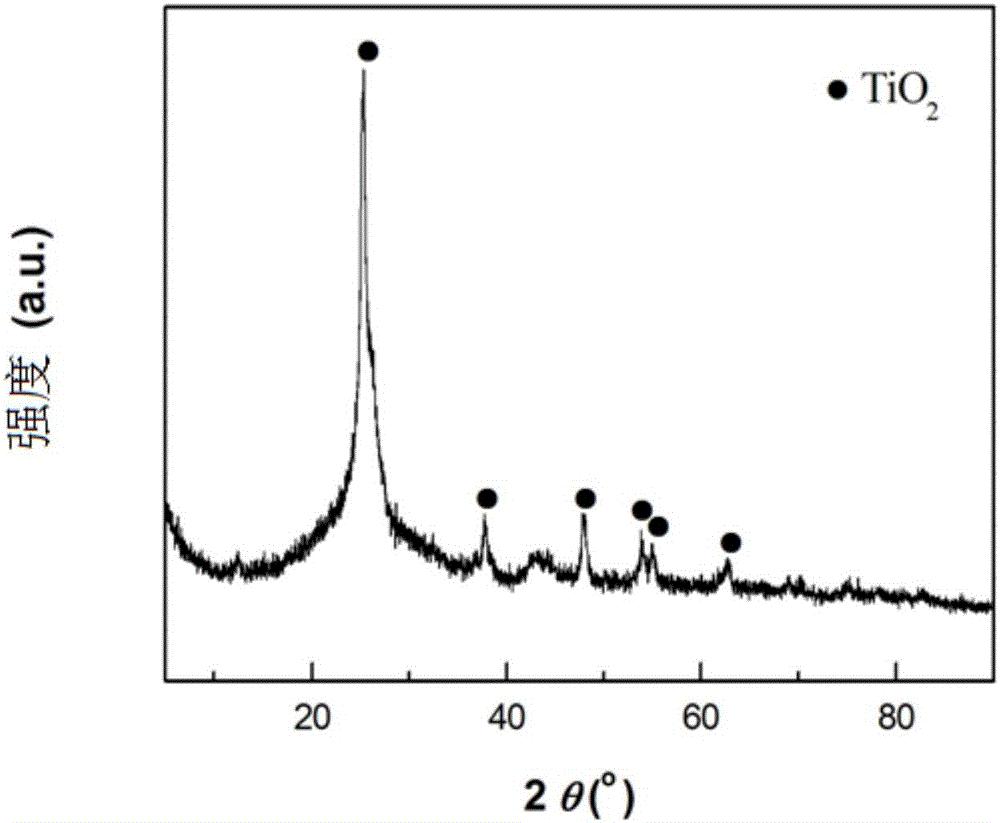

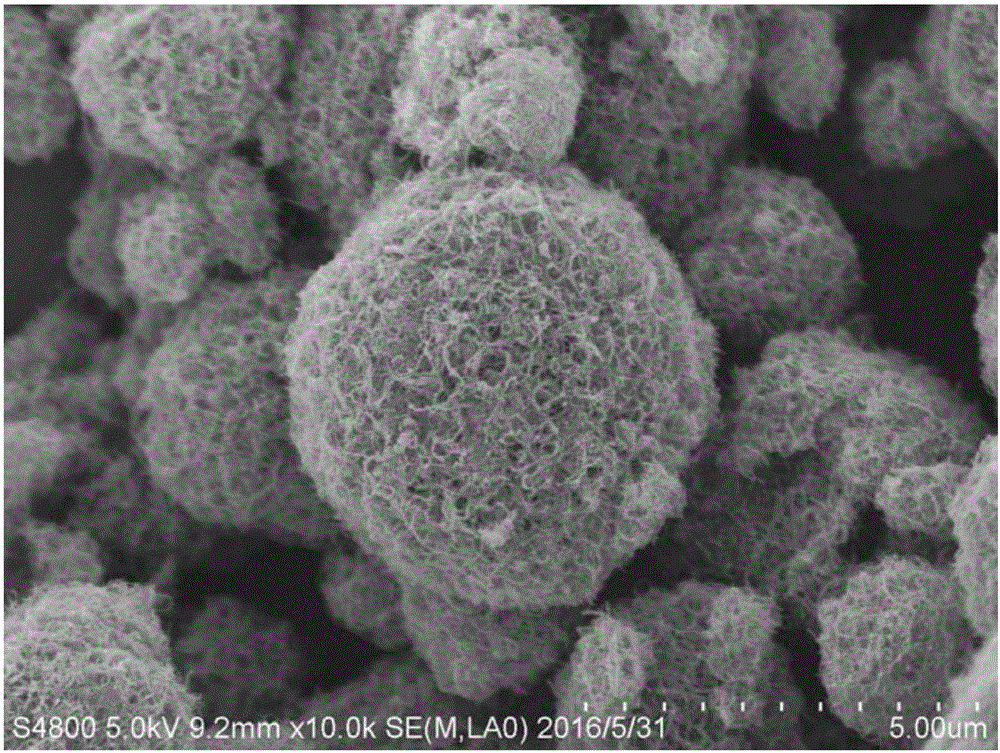

Lithium sulfur battery positive electrode material and preparation method thereof

ActiveCN106784819AHigh reversible capacityImprove cycle stabilityCell electrodesMicrosphereLithium–sulfur battery

The invention discloses a lithium sulfur battery positive electrode material and a preparation method thereof, wherein the lithium sulfur battery positive electrode material includes a sulfur carbon nano composite material, the sulfur carbon nano composite material includes carbon nanotubes, TiO2 nano particles and nano sulfur powder, the carbon nanotubes are intertwined to form micron grade carbon balls with nano micropore structures which are interconnected, the TiO2 nanoparticles areuniformly dispersed and embedded in the micron grade carbon balls to form composite carbon microspheres, and the nano sulfur powder is evenly filled in the composite carbon microspheres. Sulfur is infiltrated into the composite microspheres which are formed by coating of the TiO2 nanoparticles with the carbon nanotubes, and the lithium sulfur battery positive electrode material is prepared in a water-in-oil microemulsion system. The obtained material is a regular spherical structure with monodispersity and uniformity. After sulfur infiltration, the sulfur is uniformly filled into the microspheres, and the capacity is fully utilized during charging and discharging processes, and the structure can be controlled at the same time.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

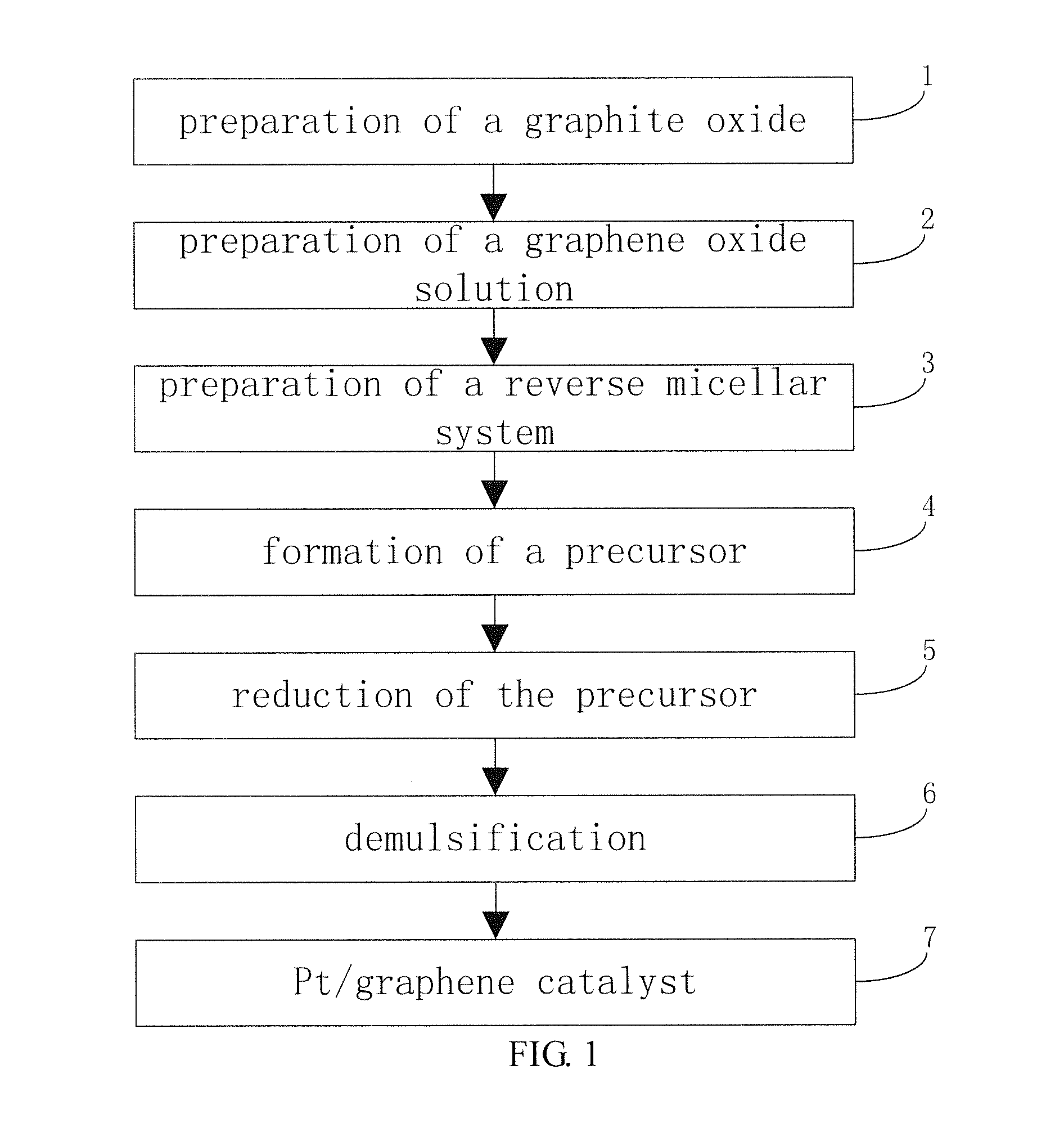

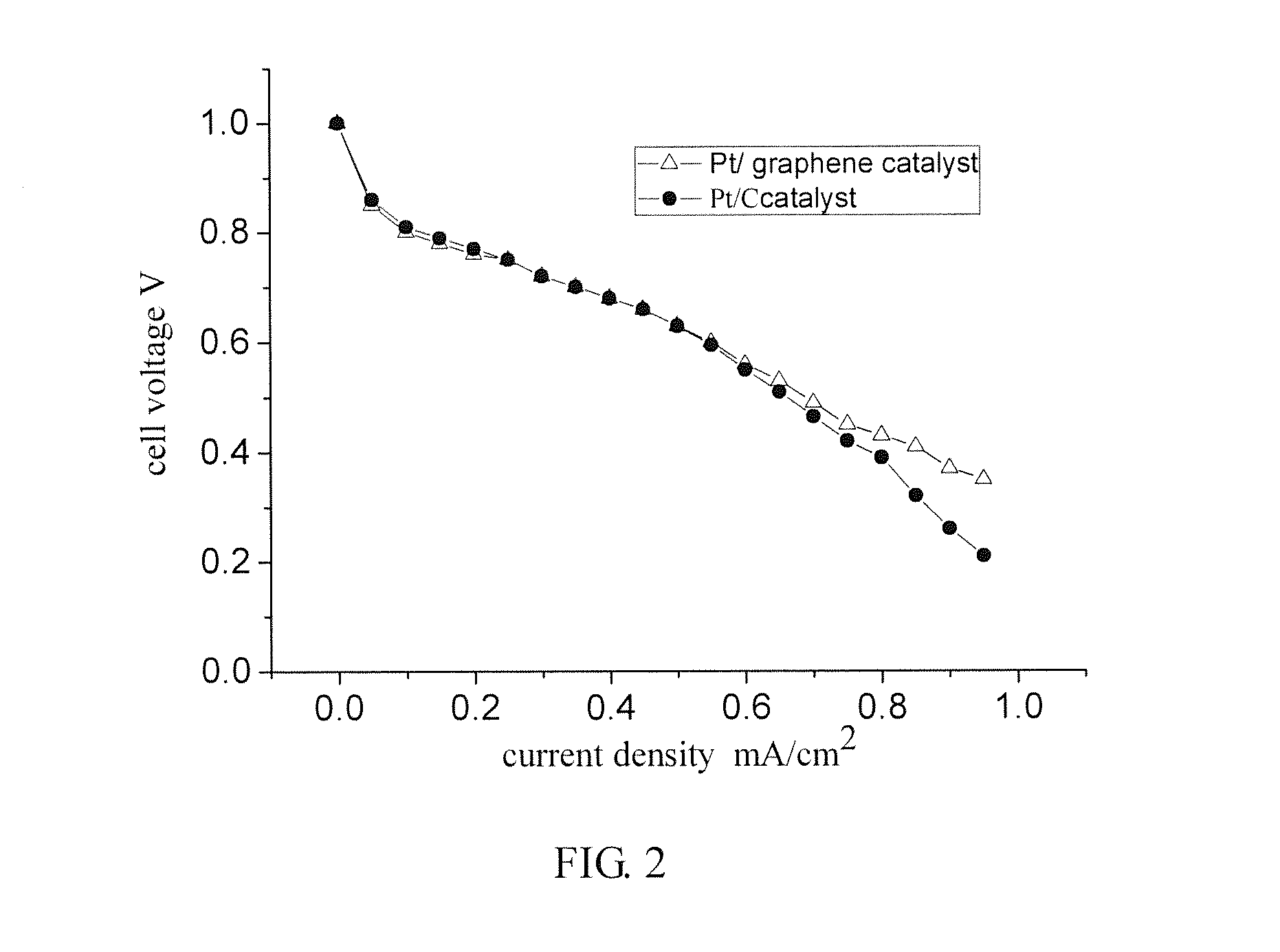

Pt/graphene catalyst, preparation method and use thereof

InactiveUS20130252138A1Improve catalytic stabilityEasy to superviseActive material electrodesCatalyst activation/preparationNanoparticleElectrochemistry

A Pt / graphene catalyst comprises graphene as carrier, and Pt loaded on the graphene. The use of graphene as carrier for the catalyst takes advantage of the ion effect and two-dimensional ductility of graphene, which increases the stability of the catalyst. The catalyst is prepared by a reverse micelles system method which provides a micro-environment (i.e. water-in-oil microemulsion), so that the particle size of the resulting nano-particles can be regulated easily and is more uniformly distributed. The use of the catalyst in electrochemostry is also disclosed.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Salt-shelled nano compound particles and preparation method thereof

ActiveCN106044810ANo sinteringEasy to useMaterial nanotechnologyAluminium oxide/hydroxide preparationNanoparticleCrystallinity

The invention discloses a method for preparing salt-shelled nano compound particles, comprising: dispersing nano compound particles in a soluble salt solution, mixing cyclohexane and octyl phenol polyethylene ether according to a certain ratio to prepare water-in-oil microemulsion, and demulsifying, centrifuging and drying the microemulsion to obtain the nano compound particles with surface soluble salt shells. The particles coated with soluble salt shells may be calcined at salt melting point and may be washed with water to obtain high-crystallinity disperse nano particles. The method greatly broadens a temperature range for preparing diverse nano materials, preventing the nano particles from being sintered at a high temperature.

Owner:SOUTHEAST UNIV

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:FLOTEK CHEM LLC

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:FLOTEK CHEM LLC

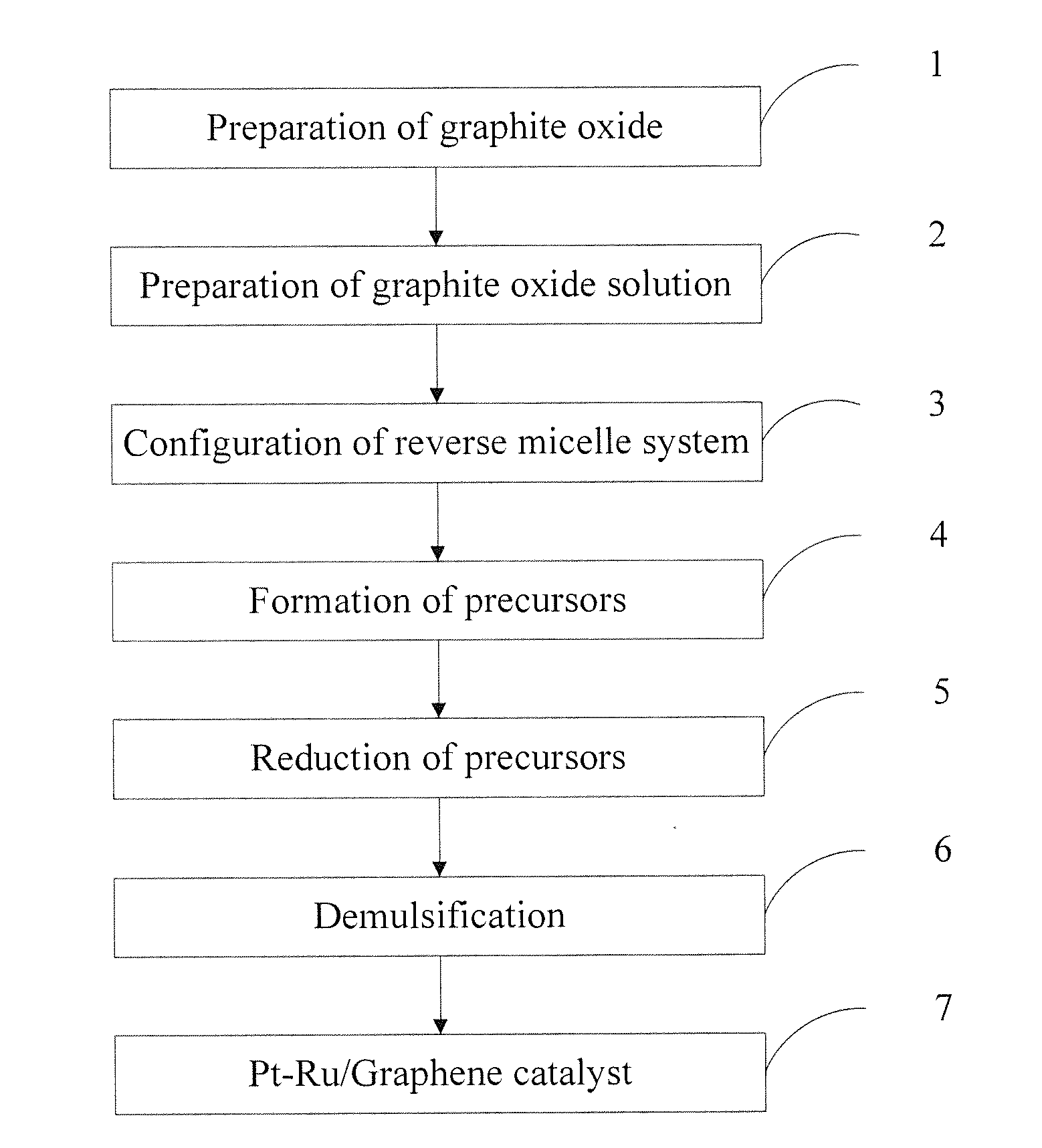

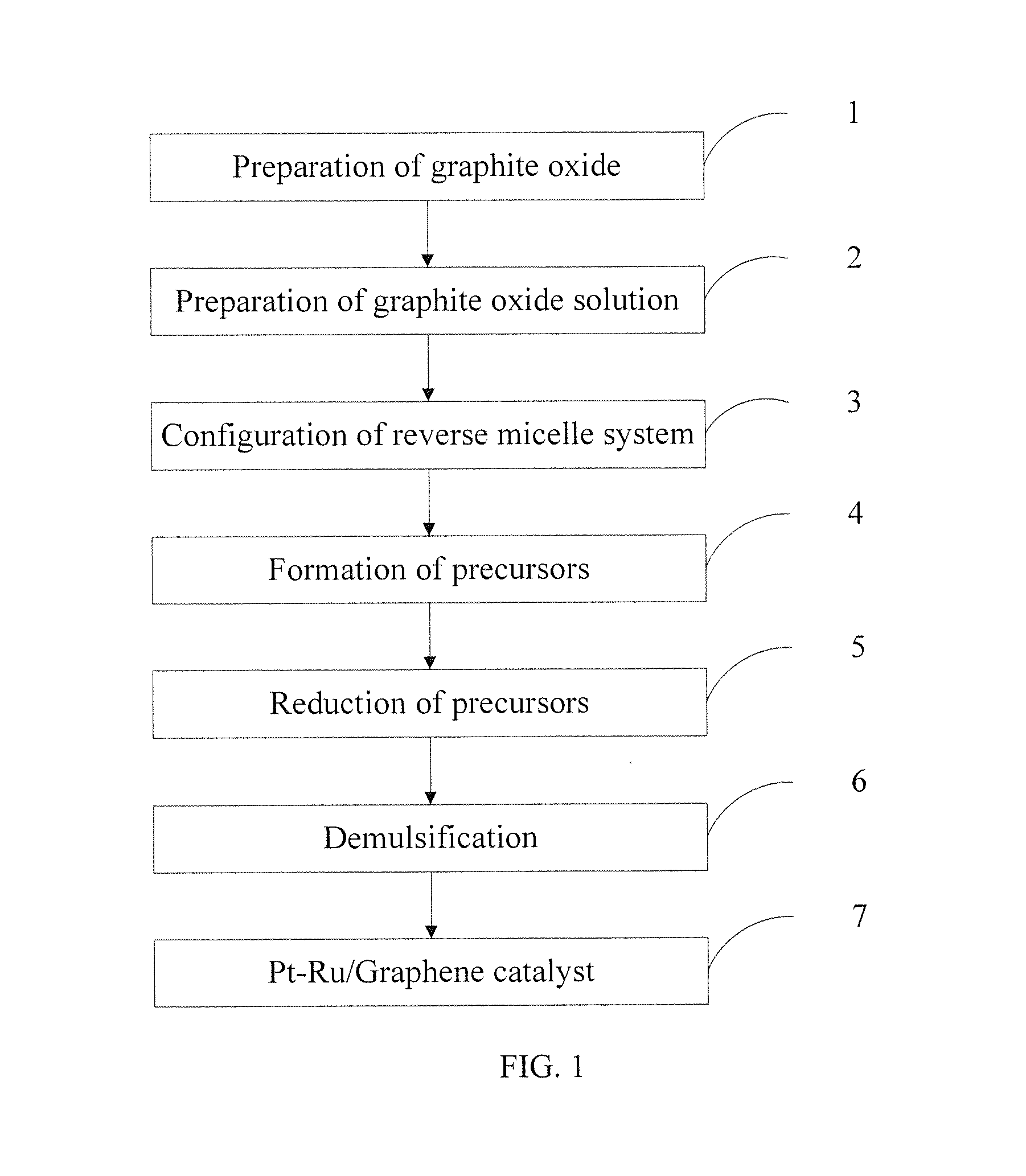

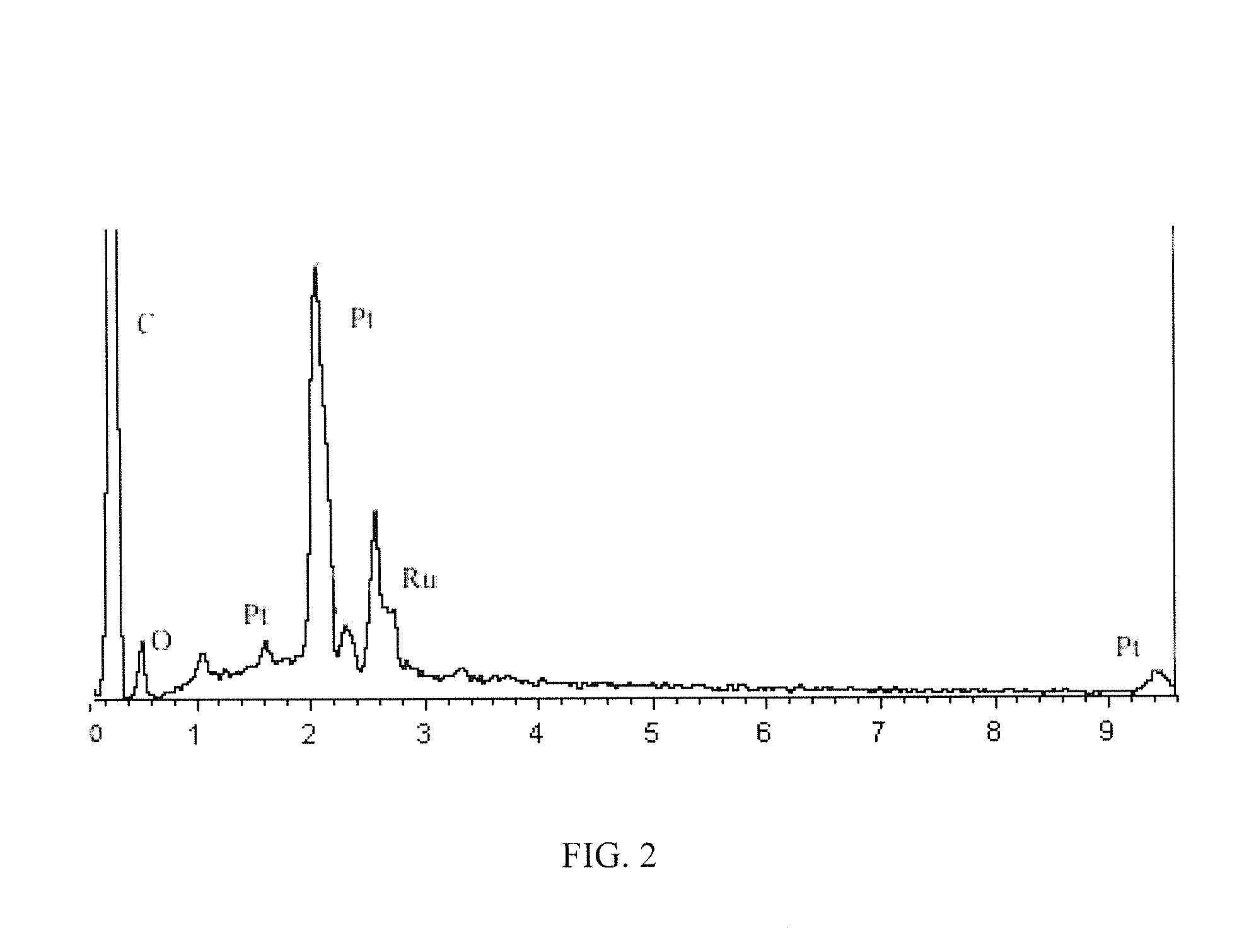

Pt-ru nano-alloy/graphene catalyst, preparation method and use thereof

InactiveUS20130252135A1Improve catalytic stabilityLarge particle sizeCell seperators/membranes/diaphragms/spacersActive material electrodesAlloyElectrochemistry

A Pt—Ru nano-alloy / graphene catalyst comprises graphene as a support, and a Pt—Ru nano-alloy loaded on the graphene. The use of graphene as support for the catalyst takes advantage of the ion effect and tow-dimensional ductility of graphene, which increase the stability of the catalyst. The catalyst is prepared by a reverse micelles system method which provides a micro-environment (i.e. water-in-oil microemulsion), so that the particle size of the resulting nano-alloy particles can be regulated easily and is more uniformly distributed. The use of the catalyst in electrochemistry is also disclosed.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

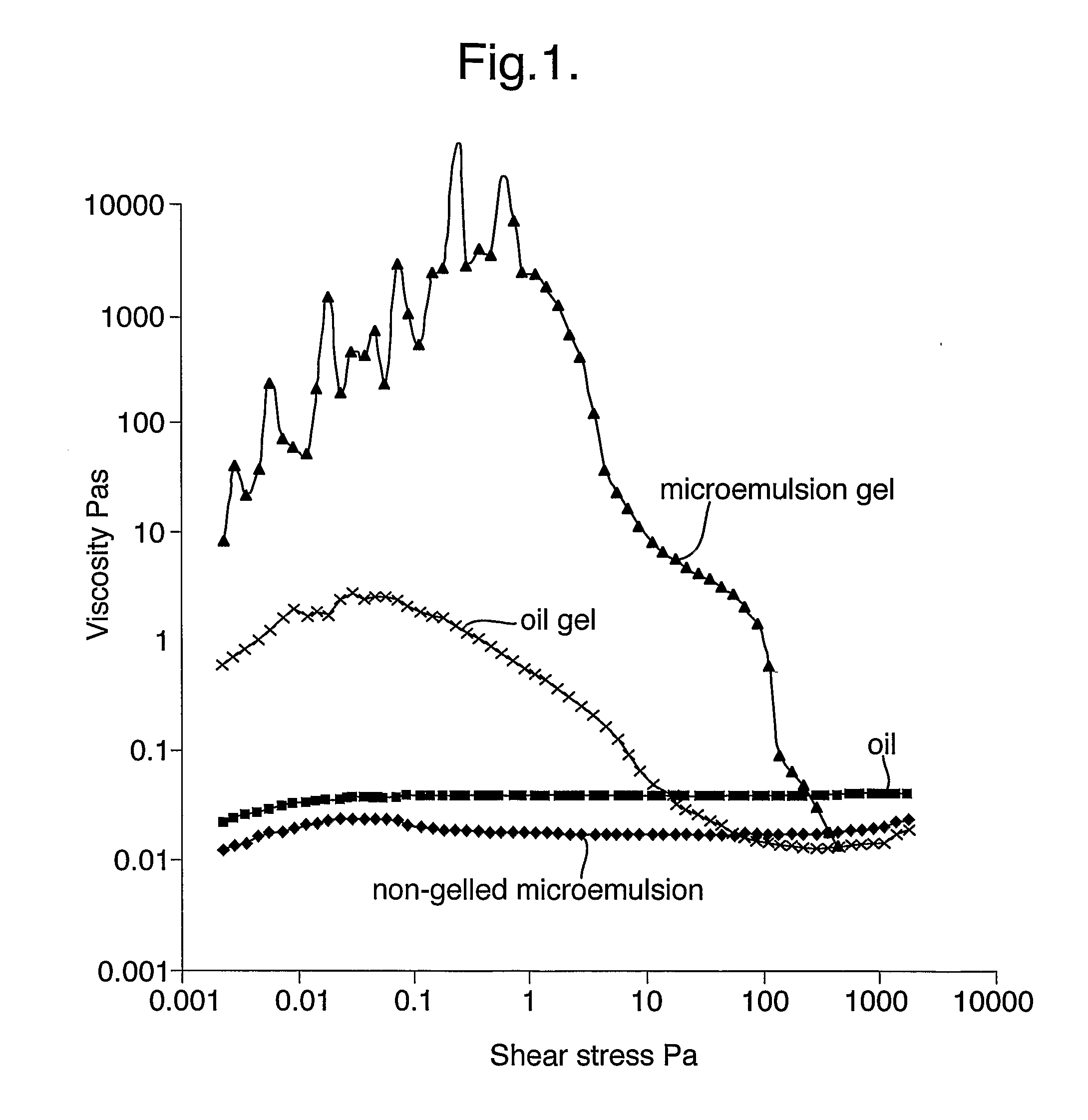

Gelled Water-In-Oil Microemulsions For Hair Treatment

The present invention provides a gelled water-in-oil microemulsion for hair treatment comprising: (a) an oil phase comprising: (i) a first oily component which is one or more glyceride fatty esters, and (ii) a second oily component which is one or more hydrocarbon oils of average carbon chain length less than 20 carbon atoms; (b) a hydrophilic phase comprising: (i) water, (ii) a nonionic emulsifier which is an ethoxylated alcohol having an HLB of at least 6, and (iii) preferably, a hair styling agent or hair conditioning agent, and (c) a gelling agent.

Owner:CONOPCO INC D B A UNILEVER

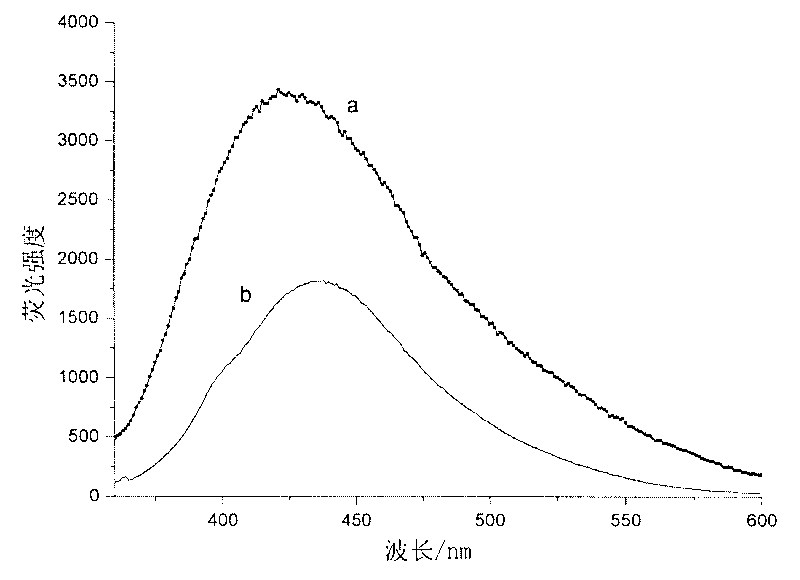

Preparation method of CdSe/SiO2 quantum dot composite fluorescent nanoparticles

InactiveCN101724402AIndividual molecule manipulationLuminescent compositionsComposite nanoparticlesSilicon dioxide

The invention relates to a preparation method of CdSe / SiO2 quantum dot composite fluorescent nanoparticles, which comprises the steps of: synthesizing CdSe quantum dots in a water solution at room temperature by using EDTA as a stabilizing agent and using the electron beam irradiation method; and then, preparing core-shell type fluorescent nanoparticles of which the CdSe quantum dots are coated by silicon dioxide with amino groups on surfaces by using the water-in-oil microemulsion method and using the cohydrolysis of 3-aminopropyl trimethoxysilane (APTMS) and tetraethoxysilane (TEOS). The prepared nanoparticles which are uniformly spherical have the particle diameter of 200+ / -8nm, have good monodispersity and light stability, and can not cause fluorescent molecule leakage easily. The quantum dot composite nanoparticles can be effectively absorbed by neural stem cells of a mouse, stronger fluorescence signals are detected in the cells, and a clear fluorescence imaging picture is obtained.

Owner:SHANGHAI UNIV

Preparing process of antiseptic graft polymer in micron and nanometer composite structure

The present invention is process of antiseptic graft polymer in micron and nanometer composite structure, and belongs to the field of polymer technology. The process includes adding solvent, triethylamine and acyl chloride with unsaturated C=C double bond into solution of tertiary amine with hydroxy radical to obtain product A; adding solvent and benzyl halide for reflux reaction to obtain product B; dissolving the product B separately in water and oily solvent; compounding water-in-oil microemulsion with the water solution, the oily solution and non-ionic surfactant and adding photoinitiator; irradiating with ultraviolet ray for reaction; extracting the grafted polymer with mixed solvent of water and acetone and drying. The antiseptic graft polymer in micron and nanometer composite structure has great specific surface area and specific antiseptic function and is used as antibiotic material for clothing, appliance, sanitary ceramic product, etc.

Owner:TSINGHUA UNIV

Composition containing polyglycerol/medium-chain fatty acid ester

ActiveCN1889926AGood dispersionGood self-emulsifying performanceCosmetic preparationsMake-upPolymer scienceActive agent

The object of the present invention is to provide a composition containing polyglycerol medium-chain fatty acid ester and cosmetics containing the composition. The composition can form a water-in-oil microemulsion capable of solubilizing a large amount of water, and its dispersibility in water is It is also excellent in self-emulsification. The present invention relates to a composition containing polyglycerol medium-chain fatty acid ester and cosmetics containing the polyglycerol medium-chain fatty acid ester composition. The composition containing polyglycerol medium-chain fatty acid ester contains Polyglycerol medium-chain fatty acid ester and nonionic surfactant obtained by esterification of medium-chain fatty acid of 6-10 and polyglycerol with average polymerization degree greater than or equal to 3 but less than 100.

Owner:TAIYO KAGAKU CO LTD +1

Polyacrylamide based agricultural compositions

ActiveUS20140323609A1Good dispersionReduce hydrationBiocideSynthetic resin layered productsTime of useSolid content

A polyacrylamide based agricultural composition as a microemulsion is provided in form of a water-in-oil microemulsion with polyacrylamide dissolved in the water phase where the polyacrylamide solids content is from about two up to about 15 percent by weight, which is then further diluted in water at the time of use to impart the desired characteristics of the polymer to the water phase or to the material to which the water phase is applied.

Owner:EXACTO

Composite functional liposome and preparation method and application thereof

InactiveCN101816632AReduce processing stepsStable in naturePharmaceutical non-active ingredientsLiposomal deliveryVitamin CDistillation

The invention discloses a composite functional liposome and a preparation method and application thereof. The composite functional liposome comprises the following components: granulesten, cholesterin, vitamin C and salicylic acid, wherein the mass ratio of the four components is 5-7:1.3-1.5:0.8-1.5:1. The method for preparing the composite functional liposome comprises the following steps of: dissolving the granulesten, the cholesterin and the salicylic acid in an organic solvent to obtain a mixture serving as oil phase; emulsifying the mixture and vitamin C-containing buffer solution which serves as water phase to form water-in-oil microemulsion; emulsifying the water-in-oil microemulsion and buffer solution to finally form water / oil / water multiple emulsion, wherein the emulsification process is completed by ultrasonication; and removing the organic solvent through decompression and distillation to obtain the composite functional liposome. The composite functional liposome has stable property, contains fat-soluble medicaments and water-soluble medicaments, exerts the effects of various medicaments to compound the functions of the liposome, is applied to cosmetics, improves the stability of the medicaments, and reduces the production cost.

Owner:GUANGDONG PHARMA UNIV

Water-in-oil type micro-emulsion

InactiveUS20060193810A1Improve securityReduce the amount requiredCosmetic preparationsHair cosmeticsBiological bodyAdditive ingredient

A water-oil type micro-emulsion having high safety to a living body by decreasing the amount of a surfactant to be used or not using the surfactant, and at a high ratio of aqueous phase capable of dissolving effective ingredients, the water-in-oil type micro-emulsion comprising polyvinyl pyrrolidone and one or more of members selected from the group consisting of fatty acids which are liquid at a normal temperature and higher alcohols which are liquid at a normal temperature.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

Method of inhibiting or controlling release of well treatment agent

A microemulsion delivery system containing a well treatment agent in a water-in- oil microemulsion may be used for well remediation as well as in other treatment operations including stimulation, acidizing, and drilling. In addition, the water-in-oil microemulsion delivery system may be used to clean surface equipment and downhole equipment.

Owner:BAKER HUGHES HLDG LLC

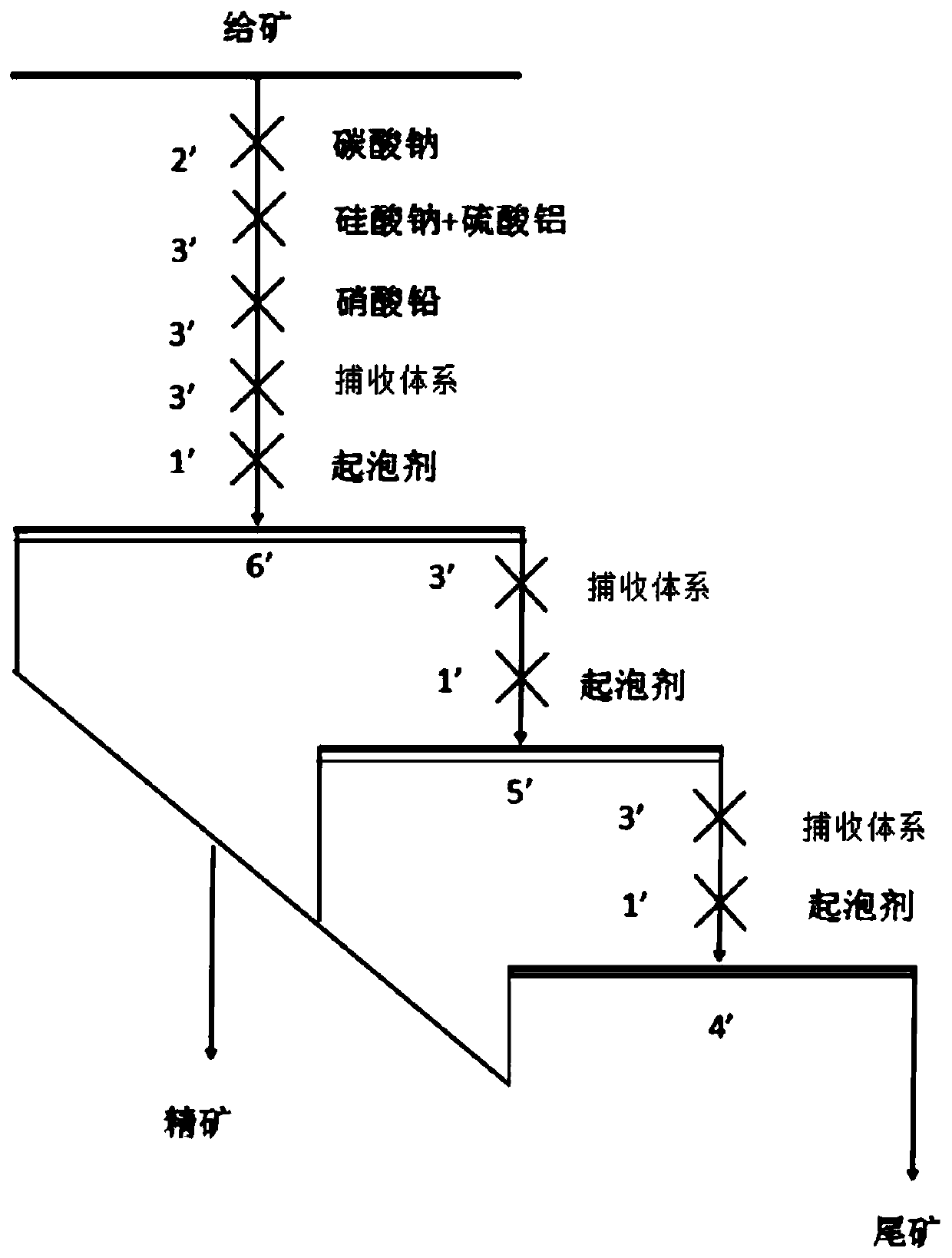

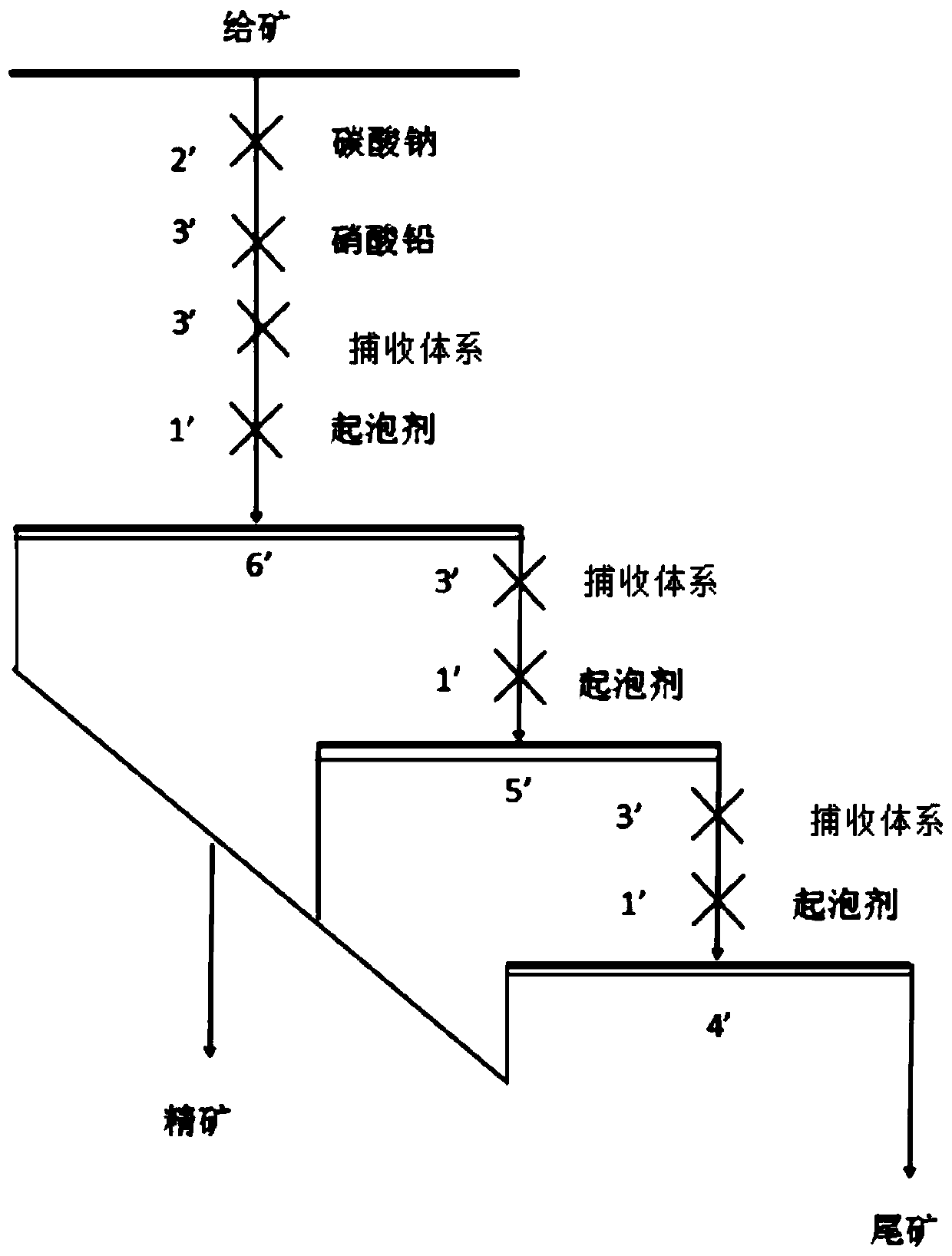

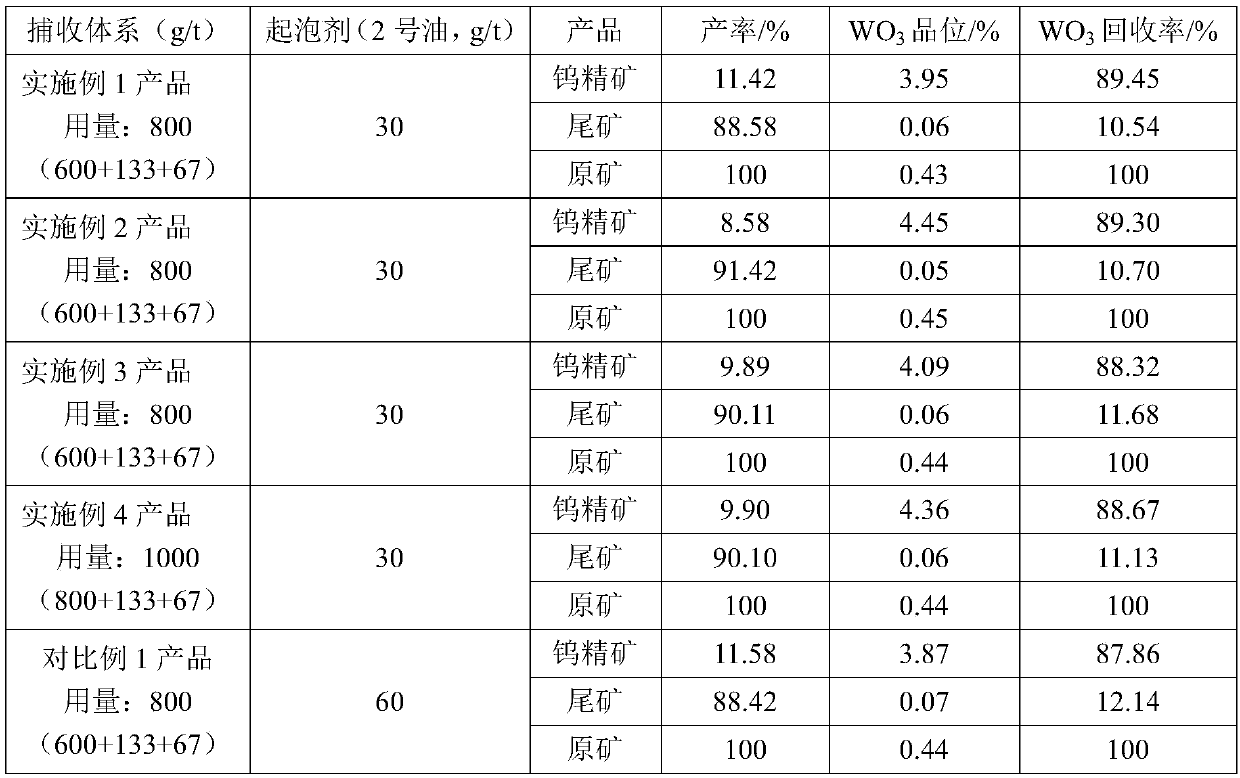

Collecting system prepared from W/O/W multiphase emulsion as well as preparation method and application thereof

ActiveCN110142143ADisadvantages of preventing low utilizationIncreased solubilization benefitFlotationHydroxylamineHydroxylamine Hydrochloride

The invention relates to a collecting system prepared from W / O / W multiphase emulsion as well as a preparation method and application thereof. The method comprises the following steps: adding a hydroxylamine water solution into a methyl benzoate and surfactant system; after the system is uniformly dispersed to form water-in-oil microemulsion, adding alkali and neutralizing to form the water-in-oil-in-water W / O / W multiphase emulsion; carrying out oximation reaction; then dropwise adding concentrated sulfuric acid to obtain the collecting system. The collecting system provided by the invention selects water as a solvent and is green and environmentally friendly; the W / O / W multiphase emulsion is constructed so that the utilization rate of hydroxylamine is improved and the reaction of the hydroxylamine is accelerated; and the yield of benzohydroxamic acid is high and the energy consumption is low. The collecting system prepared by the method contains the benzohydroxamic acid, a surfactant and other impurity components; the surfactant can have a foaming effect and can be used for reducing the dosage of a foaming agent when being applied to mineral dressing engineering; and in a floatation process, the cost of medicaments is reduced and the collecting effect is relatively good.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

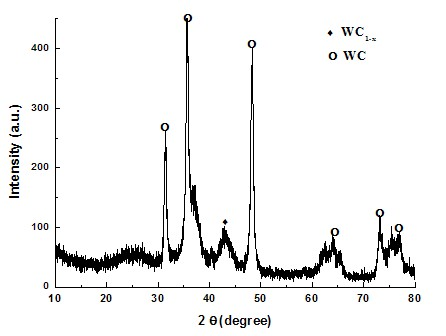

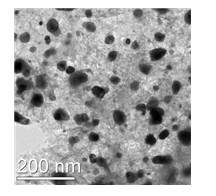

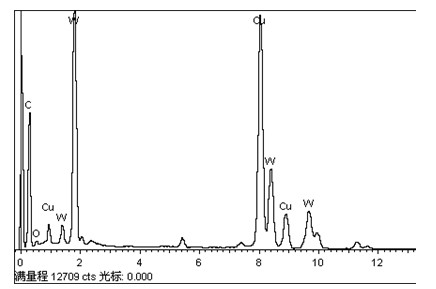

Method for preparing vermicular mesoporous tungsten carbide/charcoal composite material

InactiveCN102658187AEvenly distributedAvoid easy cloggingPhysical/chemical process catalystsCell electrodesReducing atmosphereSolvent

The invention discloses a method for preparing a vermicular mesoporous tungsten carbide / charcoal composite material. The method comprises the following steps: (1) dissolving a surfactant in a mixed solution of ethanol and water, sequentially adding a carbon source and a tungsten source, and violently stirring for 15 to 60 minutes to form water-in-oil microemulsion; (2) putting the microemulsion obtained in the step (1) in an open utensil, evaporating at the temperature of between 30 and 60 DEG C to remove a mixed solvent, and curing at the temperature of between 100 and 150DEG C for 6 to 48 hours to obtain a solid product; and (3) in reducing atmosphere, calcining the solid product obtained in the step (2) at the temperature of between 700 and 1,600DEG C for 1 to 7 hours, and cooling and grinding to obtain the vermicular mesoporous tungsten carbide / charcoal composite material. The method has simple steps, quick and time-saving; and the prepared vermicular mesoporous tungsten carbide / charcoal composite material has the characteristics of vermicular pores, uniform distribution of tungsten carbide particles, single phase and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

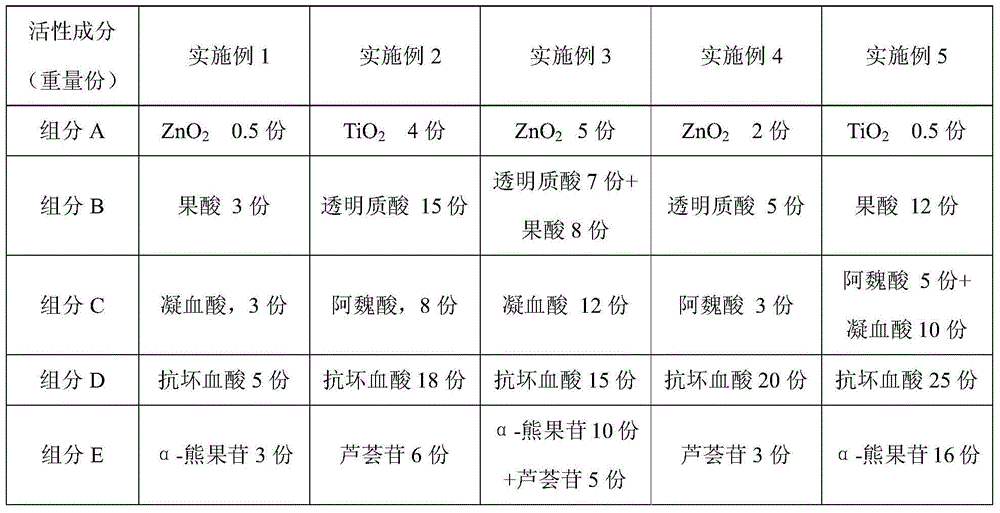

Spot-removing essence emulsion and preparation method thereof

ActiveCN104127330APrevent oxidationFreckle removal effect is goodCosmetic preparationsToilet preparationsAdditive ingredientTranexamic acid

The invention relates to a spot-removing essence emulsion. Active ingredients of the spot-removing essence emulsion comprise 0.5-8 parts of an ingredient A selected from zinc dioxide and titanium dioxide, 3-15 parts of an ingredient B selected from hyaluronic acid and tartaric acid, 3-15 parts of an ingredient C selected from tranexamic acid and ferulic acid, 5-25 parts of an ingredient D selected from ascorbic acid and 3-16 parts of an ingredient E selected from arbutin and barbaloin. The spot-removing essence emulsion is obtained by mixing emulsification of water-in-oil microemulsions comprising the ingredients C, D and E, an oil-in-water emulsion comprising the ingredient A, a coated emulsion comprising the ingredient B and a colorant. The spot-removing essence emulsion is designed based on a skin cell directional penetration technology (5XCell-Technology) and realizes directional penetration and layer-by-layer action of different active ingredients in different skin cell layers thereby producing substantial spot removing efficacy.

Owner:上海雷霆生物科技股份有限公司

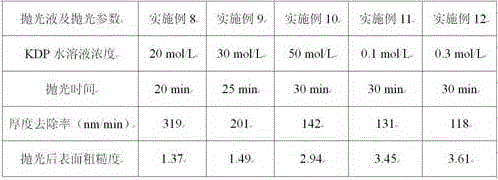

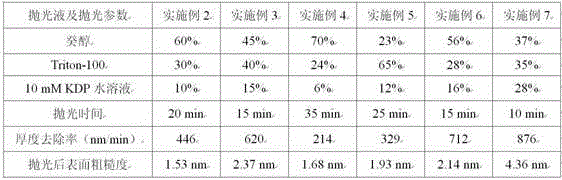

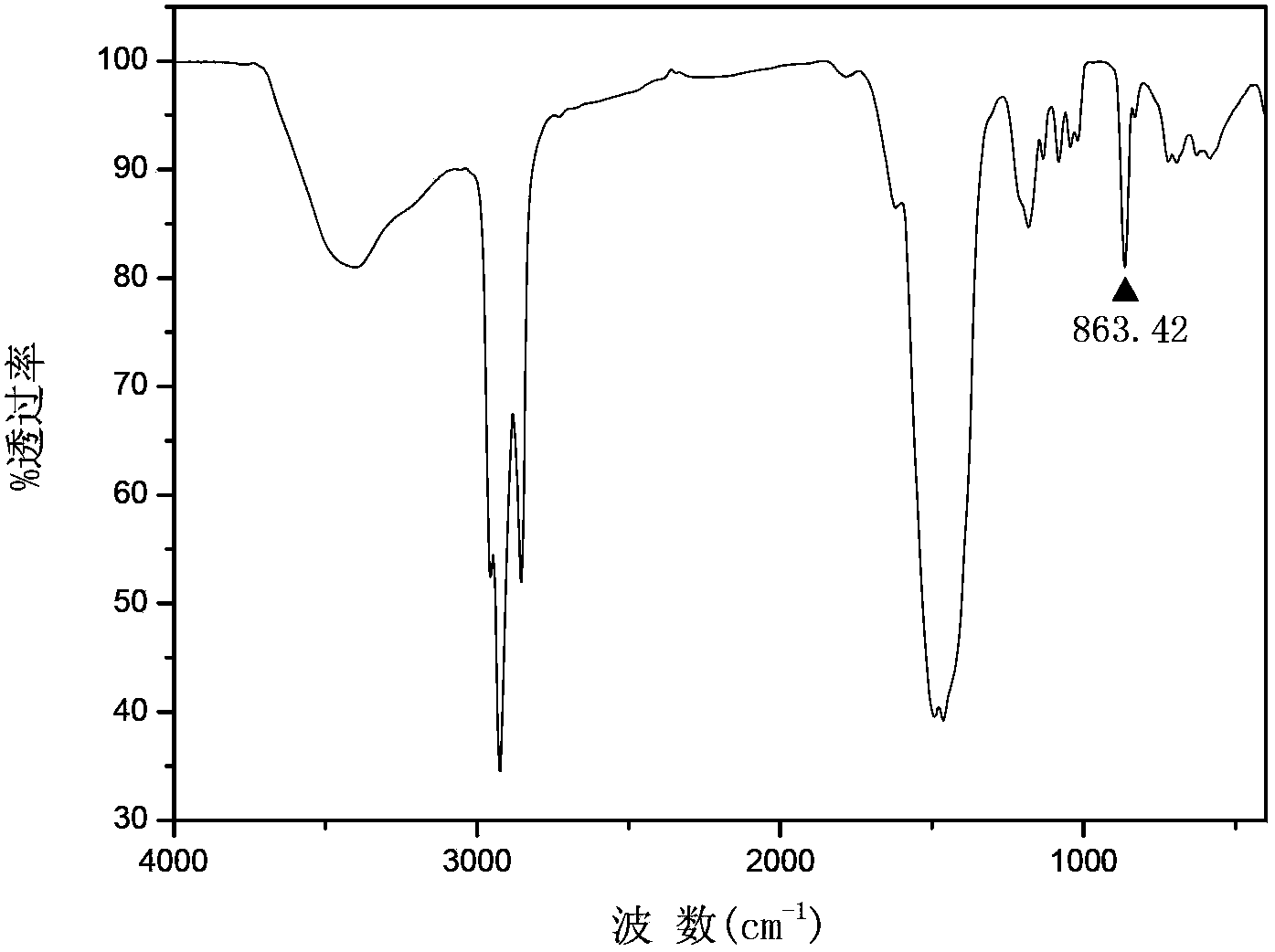

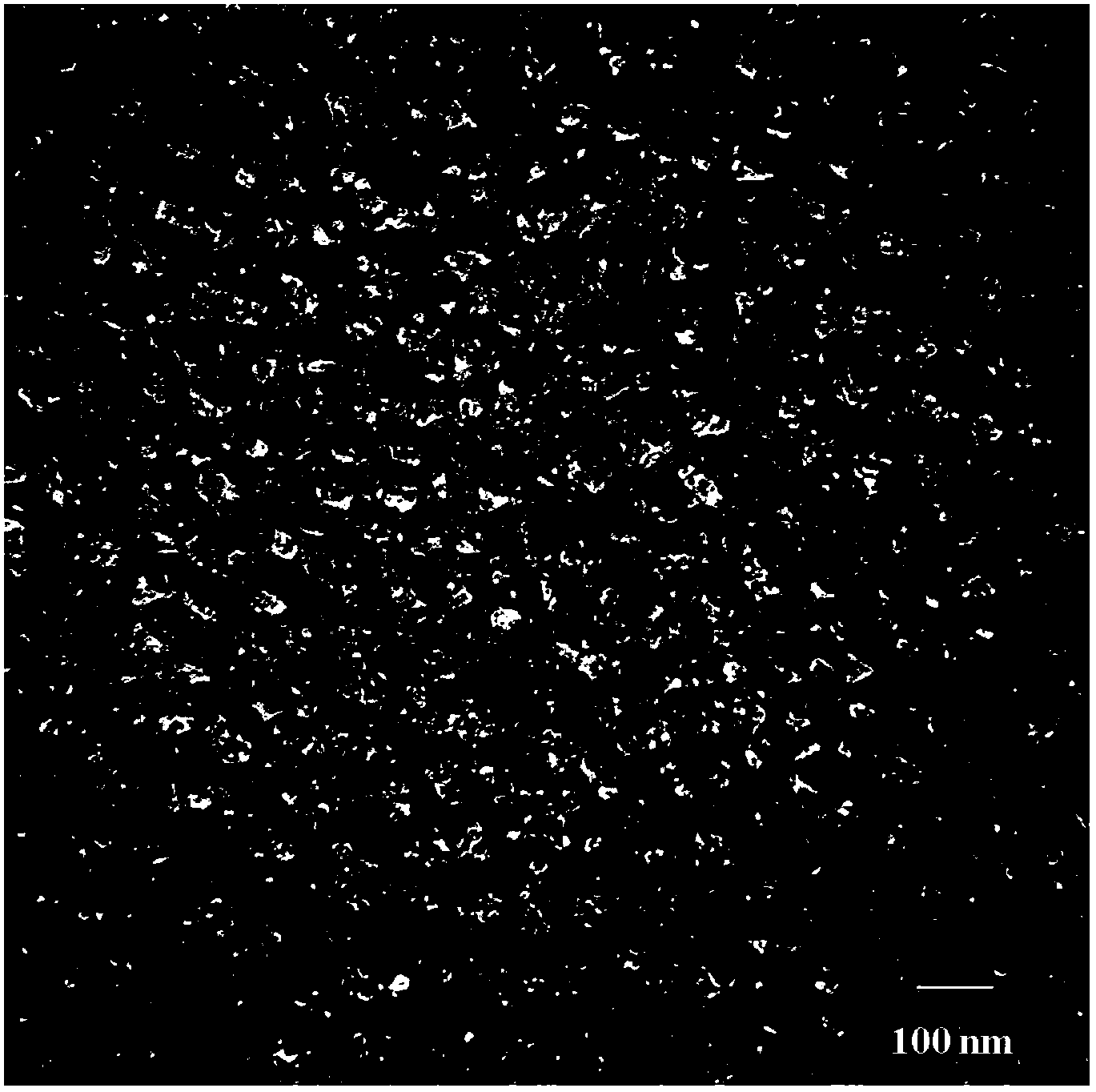

Polishing solution used for KDP crystal

InactiveCN106519989AAchieve precision removalEasy to makeAqueous dispersionsSurface cleaningMonopotassium phosphate

The invention provides a polishing solution used for monopotassium phosphate (KDP) crystal. The polishing solution is composed of an oil phase, a surface active agent and a KDP aqueous solution, and is a special water-in-oil microemulsion. Under the role of the surface active agent, the KDP aqueous solution with certain concentration is dispersed as a dispersion phase into the oil phase in a nanoscale liquid drop form. In the polishing process, due to extrusion force and friction stress, the KDP aqueous solution liquid drop breaks through an interfacial film composed of the surface active agent and molecules of the oil phase, reaches the surface of the KDP crystal, and generates a slow-release deliquescence effect with an embossment part on the surface of the KDP crystal; by changing the concentration of the KDP aqueous solution to conduct adjustment and control on the deliquesce effect, finally removal of precision parts on the surface of the KDP crystal is achieved; no new substances generate in the polishing process and external residues are organic matters, surface cleaning can be achieved through the cleaning with a matched organic solvent, and secondary damages are not caused. A preparing method of the polishing solution is simple, the property of the polishing solution is stable, and the polishing solution can effectively weaken flying cut knife grain, reduce surface roughness, and provide favorable technological supports for creating super smooth and clean KDP surface.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Method for mfg. lanthana nanopowder

A process for preparing lanthanum oxide nanoparticles includes preparing water-in-oil microemulsion from the solution of surfactant, co-surfactant, non-polar organic solvent, dimethyl oxalate and lanthanum nitrate, heating, reaction, vacuum evaporation of solvent, washing precipitate with alcohol and water, drying and calcining.

Owner:XI AN JIAOTONG UNIV

Nano calcium carbonate transparent dispersoid and preparation method thereof

ActiveCN103725044AImprove stabilityImprove product qualityPigment treatment with non-polymer organic compoundsDispersed mediaOrganic solvent

The invention discloses a nano calcium carbonate transparent dispersoid and a preparation method thereof and belongs to the technical field of the dispersoids. The nano calcium carbonate white oil dispersoid is prepared in one step by using white oil as a dispersing medium, and a method for enabling nano calcium carbonate to form inverted water-in-oil microemulsion in an organic solvent. The preparation method comprises the following steps: a surface active agent, the white oil, the organic solvent, Ca(OH)2 and an accelerator are used as raw materials, and CO2 is inlet to synthesize the nano calcium carbonate white oil dispersoid with the solid content of 10-60 percent and the alkaline value of 200-500 milligrams of KOH per gram. A product synthesized by the preparation method disclosed by the invention is high in transparency; the particle size of the obtained nano calcium carbonate is small and uniform in distribution, and the particle diameter is 5-50 nm. The technology process is simple, the operation is easy, the repetitiveness is high, and the product stability is high.

Owner:BEIJING UNIV OF CHEM TECH

Microemulsion containing radix arnebiae extract, preparation method and application thereof

ActiveCN108096094ADifficult to disperseAvoid destructionAntibacterial agentsCosmetic preparationsDispersityMedicine

The invention discloses microemulsion containing radix arnebiae extract, a preparation method and application thereof. The preparation method comprises the following steps: extracting fat-soluble components in radix arnebiae by a subcritical fluid extraction technology, then dispersing the obtained radix arnebiae extract in camellia oil and preparing into radix arnebiae oil; uniformly mixing the radix arnebiae oil with a dispersing agent, then adding water-in-oil type co-emulsifier and a water-in-oil type emulsifier, heating to 70-78 DEG C and preparing into an oil phase of the microemulsion;heating water to 65-75 DEG C and preparing into a water phase of the microemulsion; under a stirring condition, adding the water phase into the oil phase and obtaining the microemulsion containing theradix arnebiae extract. The microemulsion containing the radix arnebiae extract disclosed by the invention has the advantages of small particle diameter, good dispersity, high stability and long shelf life, and is suitable for being applied to cosmetics.

Owner:广州增城潮徽生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com