Lithium sulfur battery positive electrode material and preparation method thereof

A lithium-sulfur battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low utilization rate of active materials, low cycle life, low safety performance, etc., achieve excellent electrical conductivity and mechanical properties, guarantee utilization, improve the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In one embodiment, a preparation method for preparing the positive electrode material of the lithium-sulfur battery comprises the following steps:

[0039] S1. Preparation of TiO 2 Uniform mixture of nanoparticles, PVA, carbon nanotubes;

[0040] S2. Using the homogeneous mixed solution, under the water-in-oil emulsion system, prepare a solution containing carbon nanotube microspheres by a water-in-oil method;

[0041] S3. After removing the moisture in the system by heating in a water bath, vacuum drying to obtain a solid powder material of spherical structure particles;

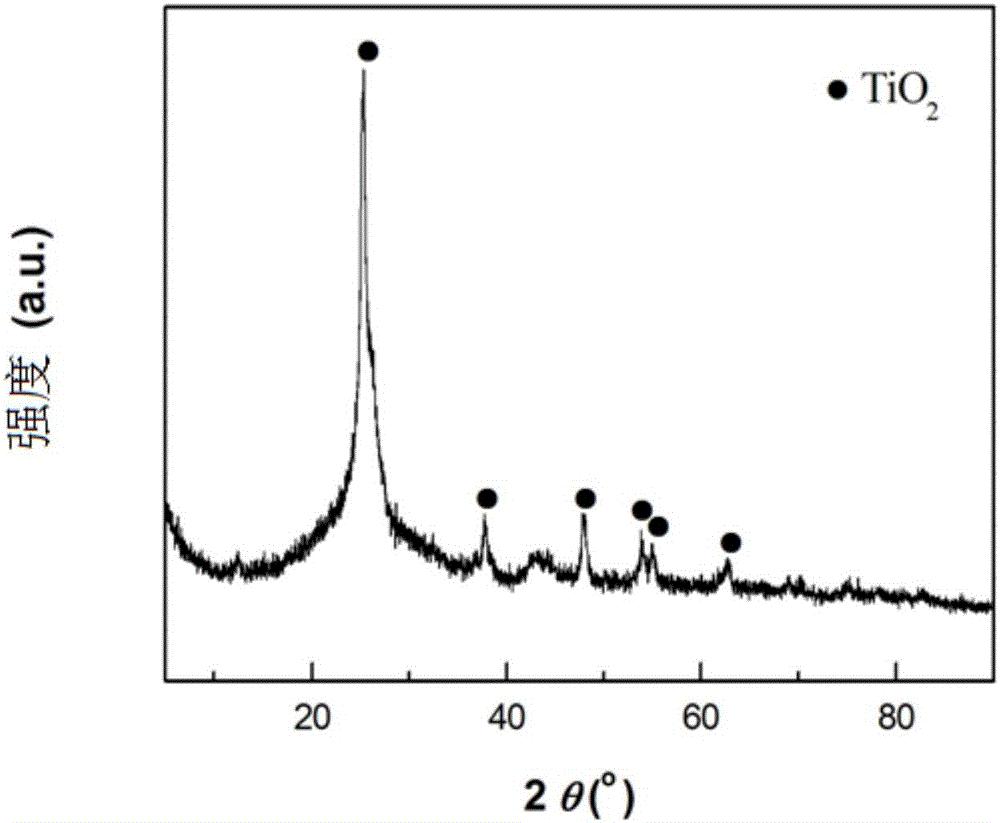

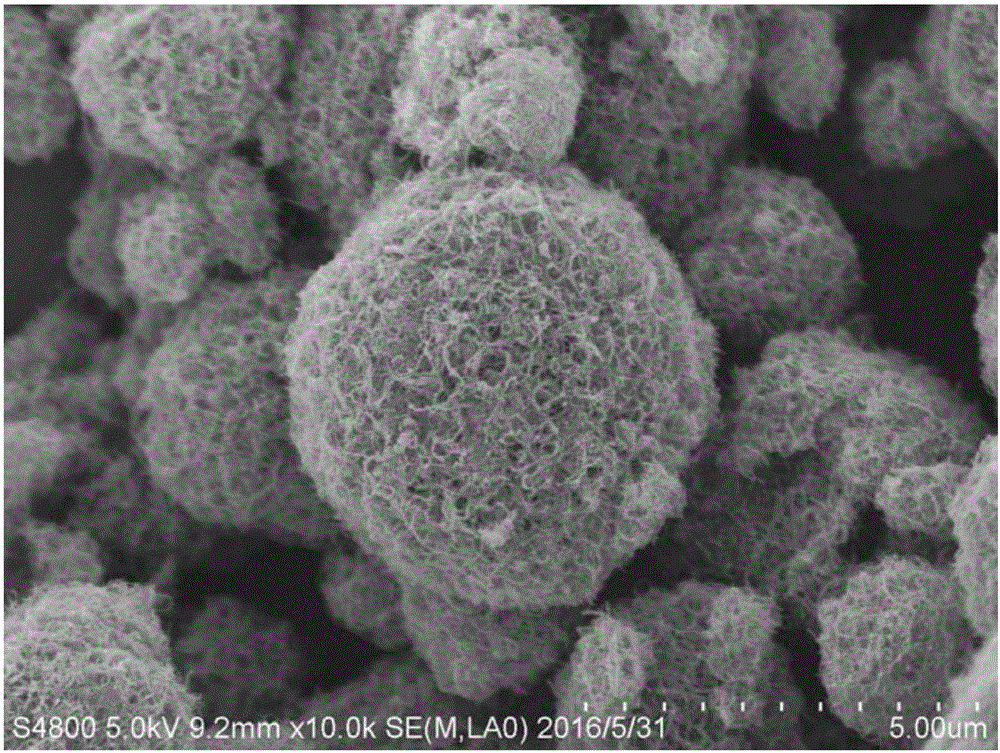

[0042] S4. Carbonize the obtained solid powder material to cause cyclization, oxidation, and crosslinking reactions of PVA molecules to form ladder molecules and aromatization structures, and then obtain interconnected nanostructures formed by intertwining carbon nanotubes. Micron-sized carbon spheres with microporous structure, TiO 2 Nanoparticles are evenly dispersed and embedded in the micron-s...

Embodiment 1

[0051] Step 1: Prepare a uniform mixture of PVA and CNTs. Weigh 0.2g of PVA powder, add it to a certain amount of deionized water, heat and stir at 80°C until completely dissolved, add 0.1g of carbon nanotubes into the system, and weigh 10wt% nano-TiO 2 The nanoparticles were added to the above solution, and the stirring was continued for 2 h to obtain a uniform mixed solution. Among them, the molecular weight M of PVA w for 10,000.

[0052] The second step: preparing carbon nanotube microspheres by the water-in-oil method. Put the n-dodecane solution under the high-speed dispersing homogenizer, and add Span 80 as an emulsifier under the effect of the rotating speed of 12000 rpm, and slowly add the homogeneous solution prepared in the first step to the normal solution after 1 minute of reaction. In the dodecane solution, continue to act for 1 min under the high-speed dispersing homogenizer.

[0053] Step 3: Stir the obtained solution at 90° C. for 2 hours to completely eva...

Embodiment 2

[0057] Step 1: Prepare a uniform mixture of PVA and CNTs. Weigh 0.2g of PVA powder, add it to a certain amount of deionized water, heat and stir at 80°C until it is completely dissolved, add 0.1g of carbon nanotubes into the system, and weigh nano-TiO with a mass fraction of 20wt%. 2 The nanoparticles were added to the above solution, and the stirring was continued for 2 h to obtain a uniform mixed solution. Among them, the molecular weight M of PVA w for 10,000.

[0058] The second step: preparing carbon nanotube microspheres by the water-in-oil method. Put the n-dodecane solution under the high-speed dispersing homogenizer, and add Span 80 as an emulsifier under the effect of the rotating speed of 12000 rpm, and slowly add the homogeneous solution prepared in the first step to the normal solution after 1 minute of reaction. In the dodecane solution, continue to act for 1 min under the high-speed dispersing homogenizer.

[0059] Step 3: Stir the obtained solution at 90° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com