Method for preparing vermicular mesoporous tungsten carbide/charcoal composite material

A carbon composite material, tungsten carbide technology, applied in chemical instruments and methods, chemical/physical process, physical/chemical process catalyst, etc., can solve the problem of ineffective catalytic effect, easy agglomeration of tungsten carbide particles, small specific surface area, etc problem, to achieve the effect of saving platinum catalyst, uniform distribution of tungsten carbide particles, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

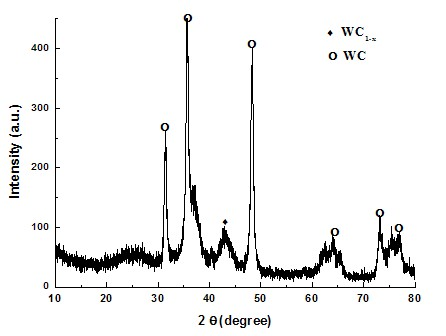

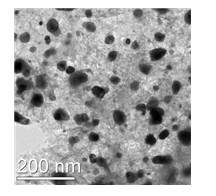

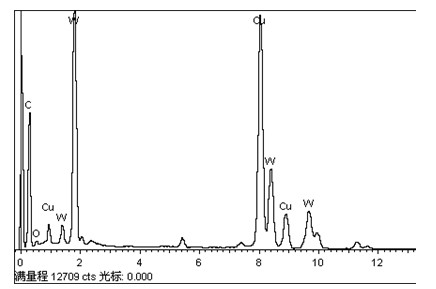

Embodiment 1

[0025] At 40°C, weigh 10.0g of surfactant F127 and completely dissolve it in a mixed solution of 120.0g of ethanol and 30.0g of water, then add 5.0g of melamine-formaldehyde prepolymer and 2.5g of ammonium metatungstate aqueous solution (wt.%= 33.3), and vigorously stirred for 30 minutes to obtain a "water-in-oil" microemulsion. The above-mentioned microemulsion was placed in an open vessel, and stood at 40°C for 24 hours to obtain a colorless sticky substance, and then placed in an oven, and cured at 105°C for 12 hours to obtain a resinous material. Then grind it into pieces, place it in a tube furnace, feed a mixture of nitrogen and hydrogen with a flow rate of 30 mL / min and a volume ratio of 3:1, gradually raise the temperature to 900°C, and calcinate for 3 hours at a programmed heating rate 5°C / min. Then it is naturally cooled and ground to obtain a worm-like mesoporous tungsten carbide / carbon composite material.

Embodiment 2

[0027] At 40°C, weigh 10.0g of surfactant F127 and completely dissolve it in a mixed solution of 100.0g of ethanol and 50.0g of water, then add 5.0g of melamine-formaldehyde prepolymer and 5.0g of ammonium metatungstate aqueous solution (wt.%= 33.3), and vigorously stirred for 30 minutes to obtain a "water-in-oil" microemulsion. The above microemulsion was placed in an open petri dish, and stood at 40°C for 24 hours to obtain a colorless viscous liquid, then placed in an oven, and cured at 105°C for 48 hours to obtain a resinous material. Then grind it into pieces, place it in a tube furnace, feed a mixture of nitrogen and hydrogen with a gas flow rate of 40 mL / min and a volume ratio of 3:1, gradually raise the temperature to 1000°C, and calcinate for 3 hours at a programmed heating rate 5°C / min. Then it is naturally cooled and ground to obtain a worm-like mesoporous tungsten carbide / carbon composite material.

Embodiment 3

[0029] At 40°C, weigh 8.0g of surfactant P123 and completely dissolve it in a mixed solution of 100.0g of ethanol and 20.0g of water, then add 5.0g of phenol-formaldehyde prepolymer and 2.0g of ammonium metatungstate aqueous solution (wt.%= 33.3), and vigorously stirred for 30 minutes to obtain a "water-in-oil" microemulsion. The above microemulsion was placed in an open petri dish, and stood at 40°C for 24 hours to obtain a colorless viscous liquid, then placed in an oven, and cured at 105°C for 24 hours to obtain a resinous material. Then grind it into pieces, place it in a tube furnace, feed a mixture of nitrogen and hydrogen with a flow rate of 30 mL / min and a volume ratio of 3:1, gradually raise the temperature to 900°C, and calcinate for 3 hours at a programmed heating rate 5°C / min. Then it is naturally cooled and ground to obtain a worm-like mesoporous tungsten carbide / carbon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com