Preparation method of CdSe/SiO2 quantum dot composite fluorescent nanoparticles

A composite fluorescence and nanoparticle technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of increased light quantum yield, instability, and easy oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Reagents and instruments: APTMS and surfactant TritonX-100 are all analytically pure, purchased from Sigma; cadmium acetate dihydrate (Cd(Ac) 2 ·2H 2 O), sodium selenite (Na 2 SeO 3 ), ethylenediaminetetraacetic acid (C 10 H 16 N 2 O 8 , EDTA), isopropanol (C 3 H 8 O), ninhydrin (C 9 H 6 O 4 ) And sodium hydroxide (NaOH) were purchased from Shanghai Sinopharm Chemical Reagent Co., Ltd., both of which were analytically pure; mouse neural stem cells were provided by the School of Life Sciences, Shanghai University. All water used is deionized ultrapure water.

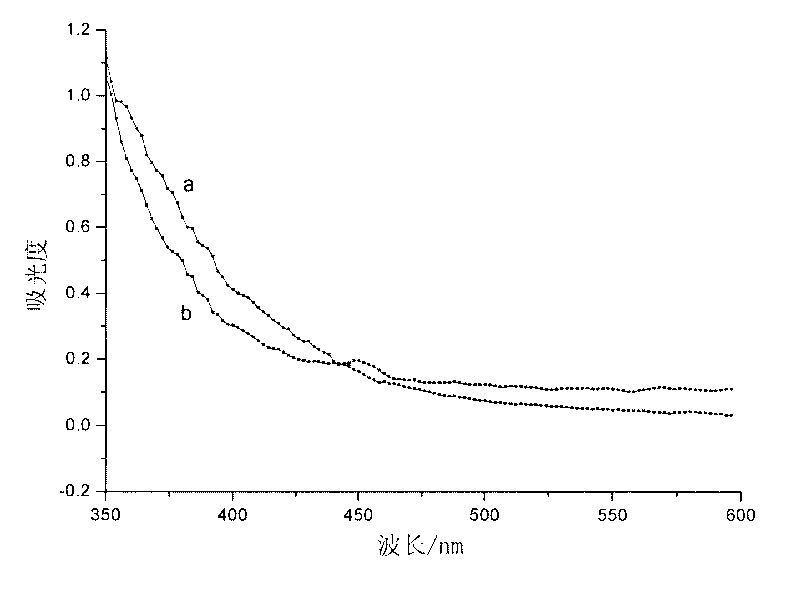

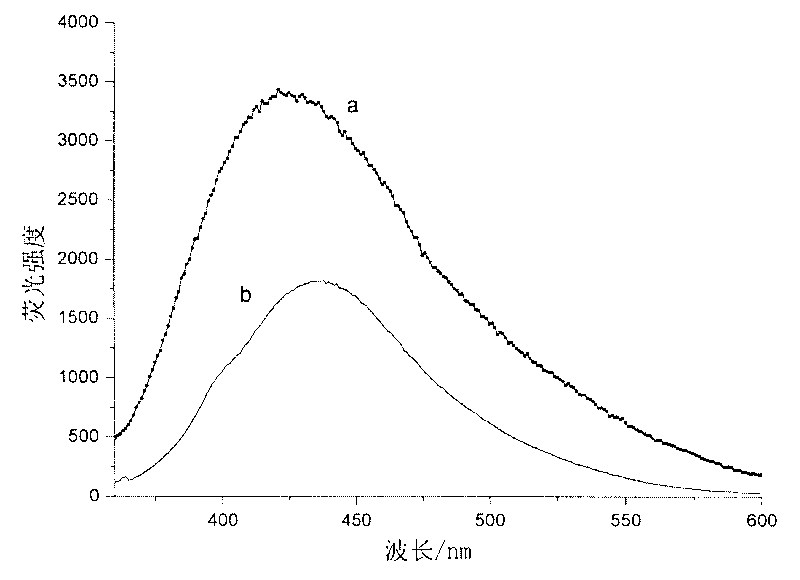

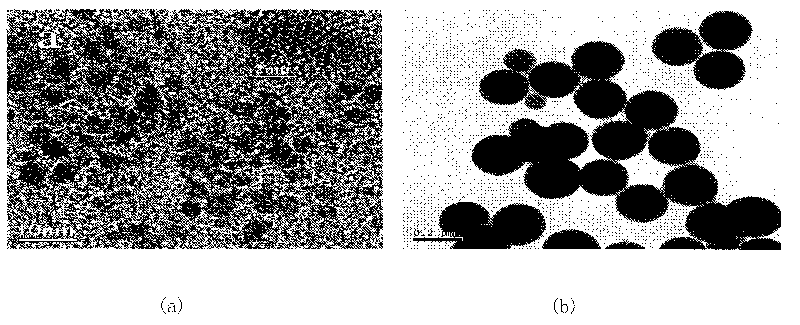

[0025] 2MeV 10mA GJ-2 electron accelerator (Shanghai Xianfeng Motor Factory), FV1000 laser confocal scanning microscope (Olympus, Japan); JEM-2010F high resolution transmission electron microscope (Shimadzu, Japan); JSM-2010F transmission electron microscope (Japan) JEOL company); F-7000 type fluorescence spectrophotometer (Japan Hitachi company); U-3010 type ultraviolet-visible spectrophotometer (Japan Hitachi company...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com