Preparation method of composite luminescent fiber nanomaterial

A technology of luminescent fibers and composite nanoparticles, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve problems such as the difficulty in preparing oriented fiber bundles or single nanofibers, and achieve luminous intensity and photobleaching resistance Reinforcement, high orientation, and strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

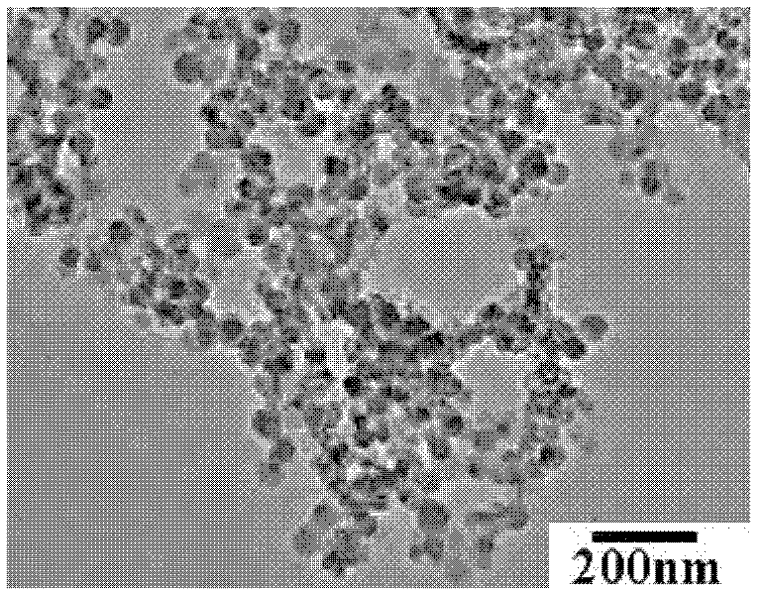

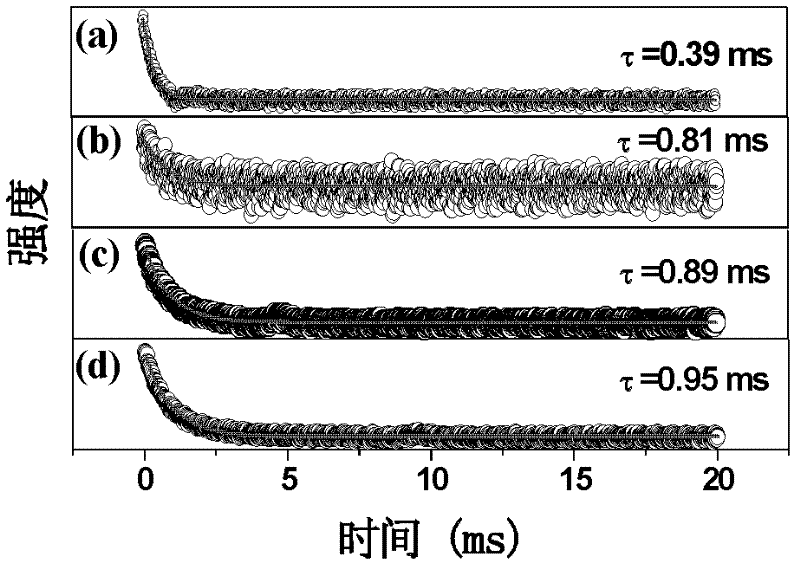

[0042] ①The 0.106g rare earth complex Eu(DBM) prepared by wet chemical method 3 Phen was dissolved in 25.0g N, N dimethylformamide, after ultrasonic dispersion for 30min, continued to add 2.40g of SDS (dissolved in 96.0g of water to form a solution), after the solution was homogenized, add styrene mono Body 5.32g, adjust the ultrasonic radiation power 600W to initiate the polymerization reaction, the reaction temperature is 25 ℃, the reaction time is 1.5h, the rare earth complex Eu(DBM) 3 Phen embedded in the polymer to form a core-shell structure Eu(DBM) 3 PhenPS complex; the whole reaction needs to be in high-purity N 2 under protection.

[0043] ②The complex obtained in step ① was demulsified with absolute ethanol, and centrifuged, washed repeatedly with deionized water and absolute ethanol, and vacuum-dried at 80°C for 8.0h to obtain Eu(DBM) 3 PhenPS composite nanoparticle powder;

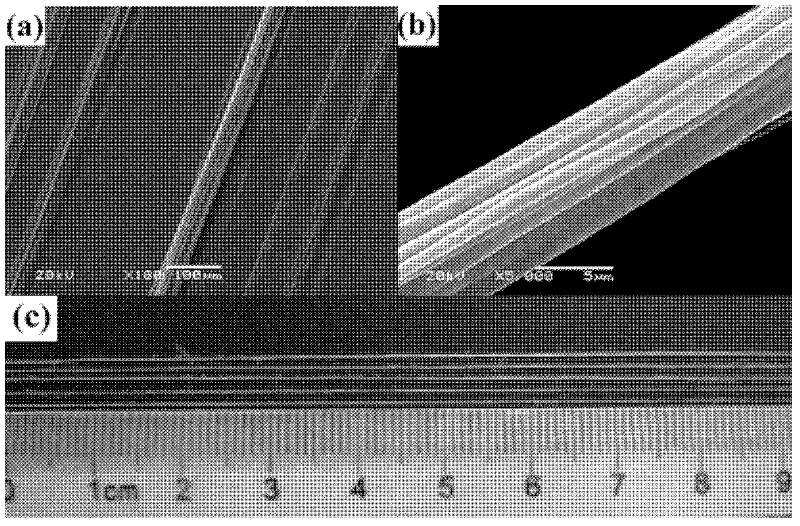

[0044] ③The 1.0g Eu(DBM) prepared in step ② 3 PhenPS composite nanoparticle powder was...

Embodiment 2

[0046] ①The 0.106g rare earth complex Tb(acac) prepared by wet chemical method 3 Dissolve Phen in 25.0g of N,N dimethylformamide, continue to add 2.40g of SDS (dissolved in 96.0g of water to make a solution) into the solution, and ultrasonically disperse for 30min. After the solution is homogenized, add styrene monomer 5.32g, adjust the ultrasonic radiation power to 800W to initiate the polymerization reaction, the reaction temperature is 40°C, and the reaction time is 1.5h, the rare earth complex Tb(acac) 3 Phen embedded in the polymer to form a core-shell structure Tb(acac) 3 PhenPS complex; the whole reaction needs to be in high-purity N 2 under protection.

[0047] ②The complex obtained in step ① was demulsified with absolute ethanol, and centrifuged, washed repeatedly with deionized water and absolute ethanol 4 times, and vacuum-dried at 80°C for 8.0h to obtain Tb(acac) 3 PhenPS composite nanoparticle powder;

[0048] ③The 1.0g Tb(acac) prepared in step ② 3 PhenPS co...

Embodiment 3

[0050] ①The 0.1g rare earth doped nanocrystalline YVO prepared by hydrothermal method 4 : Dy 3+ The concentration dispersed to 100ml is 2×10 -3 mol / L citric acid solution, then add 48.0g N,N-dimethylformamide, ultrasonically disperse for 1h, continue to add 0.204g azobisisobutyronitrile and 0.109g potassium persulfate to this solution, ultrasonically disperse After 30 minutes, after the solution was homogenized, 5.32 g of styrene monomer was added, and the ultrasonic radiation power was adjusted to 500 W to initiate the polymerization reaction. The reaction temperature was 90 ° C, and the reaction time was 3.0 h. 4 : Dy 3+ Embedded into the polymer to form a core-shell structure YVO 4 : Dy 3+ PS complex; the entire reaction needs to be in high-purity N 2 under protection.

[0051] ②The complex obtained in step ① was demulsified with absolute ethanol, and centrifuged, washed repeatedly with deionized water and absolute ethanol for 4-6 times, and vacuum-dried at 80°C for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com