Surface plasma fluorescence-enhanced nano composite structure film and preparation method thereof

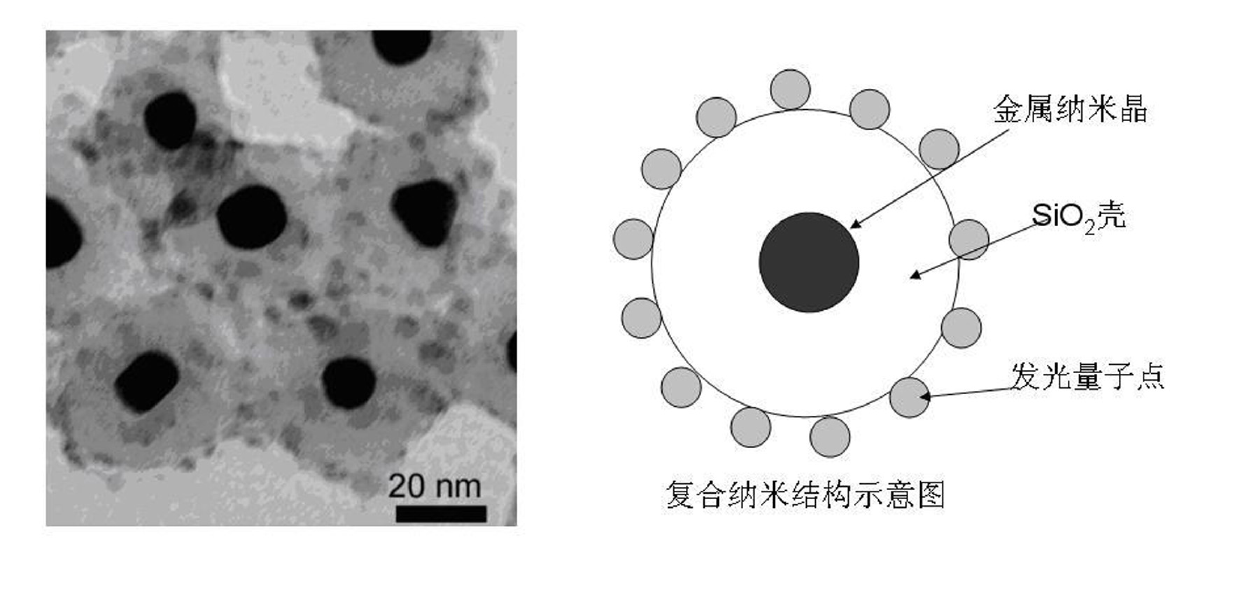

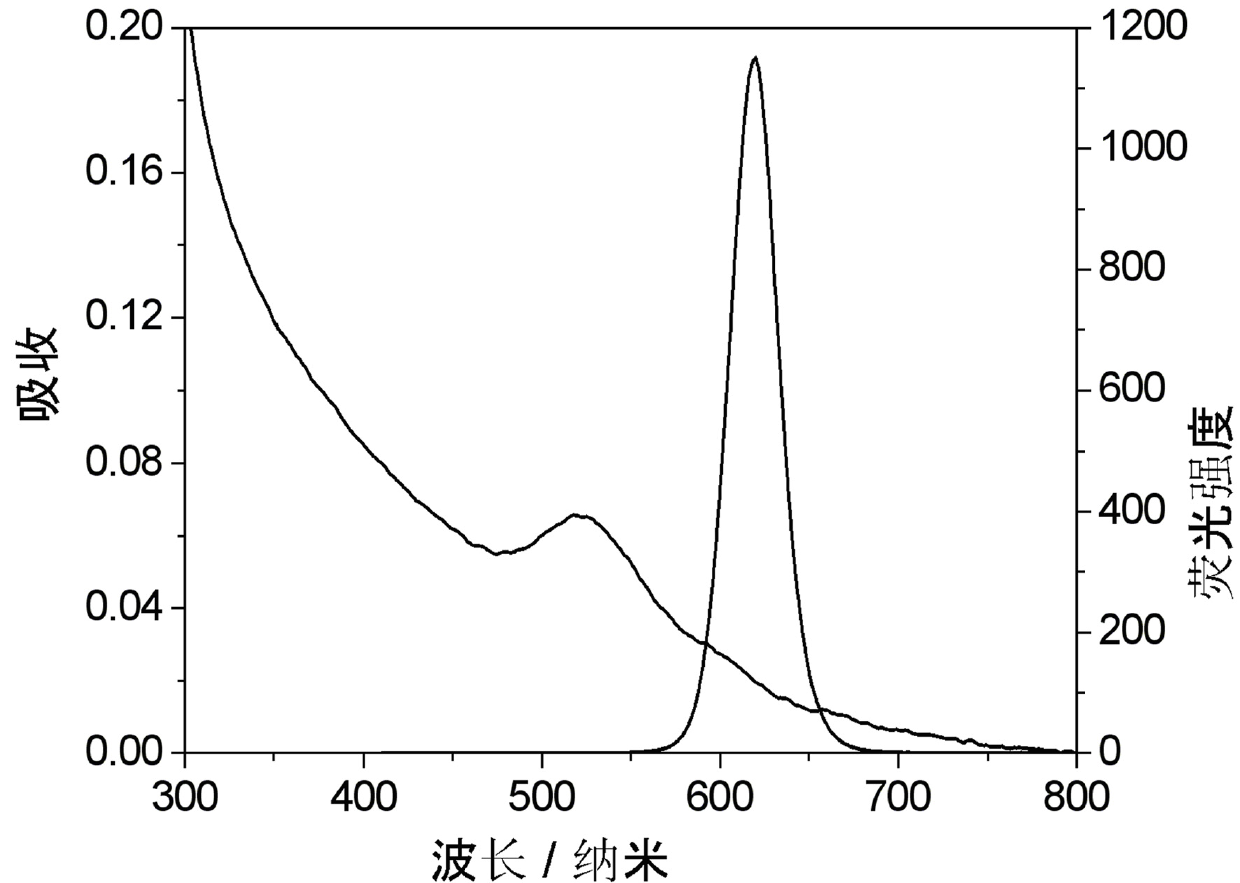

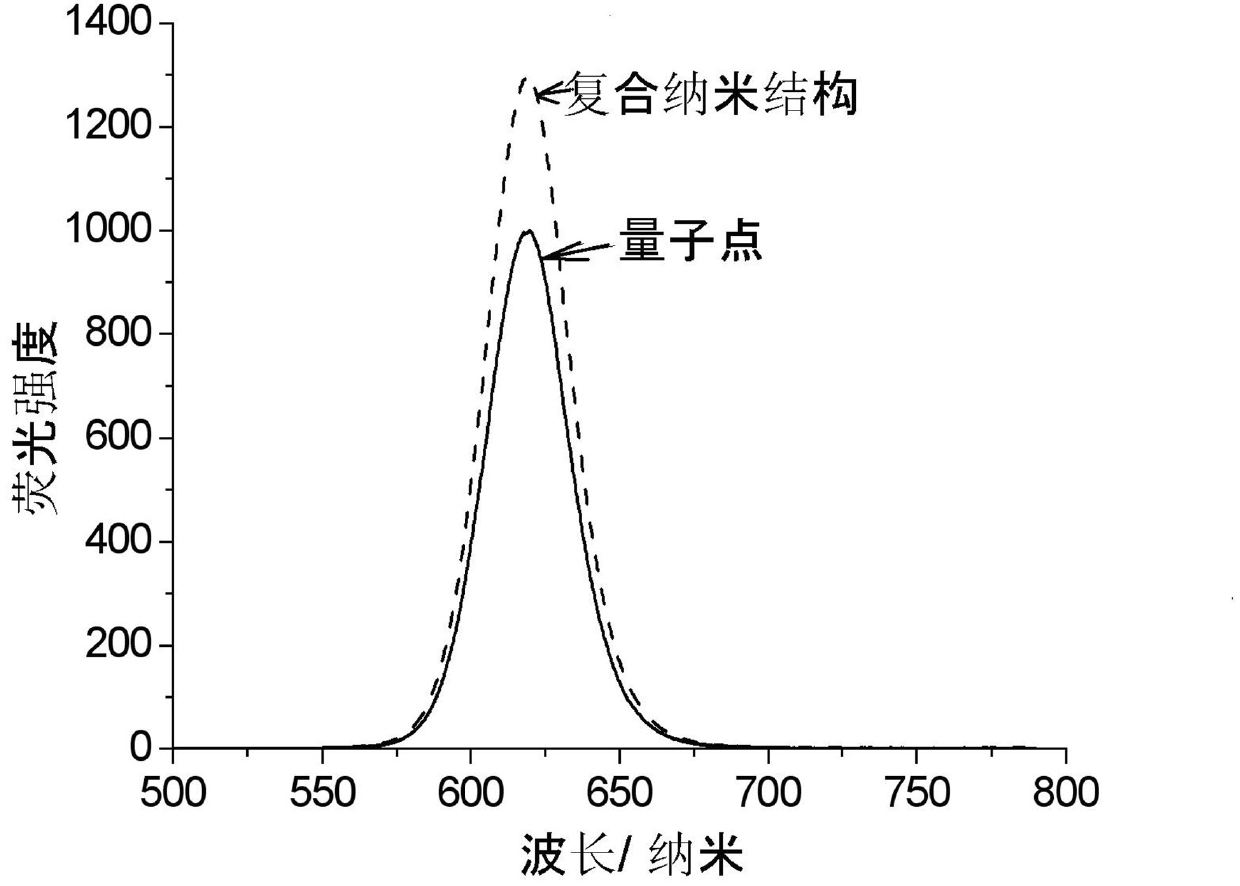

A surface plasmon and nanocomposite technology, which is applied in the thin film of metal nanoparticle/SiO2/quantum dot nanocomposite structure and its preparation, can solve the application limitations, poor light stability of luminescent quantum dots and organic light-emitting small molecules, etc. problem, to achieve the effect of eliminating the flicker effect, improving the fluorescence quantum efficiency, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1.1 Synthesis of CdSe quantum dots by organic method (see J. Phys. Chem. C, 2010, 114, 6205-6215 for details): First, 500 mg of cadmium oxide, 2 g of dioctylamine, and 2 g of nonanoic acid were mixed in three Mix in the neck flask, keep vacuum at 100°C for 15 minutes, then heat to 200°C under nitrogen protection to dissolve cadmium oxide, then lower it to 120°C, put 10 g of selenium in trioctylphosphine (TOP) solution (the mass of selenium Concentration is 10 %) injected quickly, in order to control the luminous color, the growth time is 10 minutes, after separation, washing, and finally dispersed in toluene solution.

[0041] 1.2 Coating ZnS shell on the surface of CdSe quantum dots (see J. Phys. Chem. C, 2010, 114, 6205-6215 for details): freshly prepared CdSe quantum dots toluene solution 4 mL (quantum dot concentration 0.01 mg / mL) , 2 g of dioctylamine, mixed with 0.05 g of dimethyl zinc (dissolved in 2 mL of trioctylphosphine (TOP)), then heated to 60 ° C, and 10 g...

Embodiment 2

[0047] 2.1 The preparation method of CdSe / ZnS core-shell quantum dots is the same as that in Examples 1.1 and 1.2 above.

[0048] 2.2 The preparation of Au nanoparticles is the same as in Example 1.3 above.

[0049] 2.3 Take 1 mL of aminoethyltrimethylsilane, 0.3 mL of water, and 10 mL of methanol, mix and stir for 10 hours, remove the methanol in the solution at 60°C to obtain solution 1; add 0.2 mL of solution 1 to the newly synthesized CdSe / ZnS Quantum dots in 0.2 mL of toluene solution (quantum dot concentration 5 mg / mL) were stirred for 0.5 to 5 minutes to obtain solution 2.

[0050] 2.4 Mix 0.5 mL of Au nanoparticles solution (the concentration of nanoparticles is 0.05 ~ 10 mg / mL) with 0.2 mL of 25 wt% ammonia water and 4 mL of ethanol, add 10 μL of methyl orthosilicate, react for 3 hours, and then centrifuge , and dispersed the coated gold nanoparticles into 1 mL of water to obtain solution 3 (5-30% by mass).

[0051] 2.5 Take 0.1 mL of solution 2 and 0.15 mL of solut...

Embodiment 3

[0053] 3.1 The preparation method of CdSe / ZnS core-shell quantum dots is the same as that in Examples 1.1 and 1.2 above.

[0054] 3.2 The preparation of Au nanoparticles is the same as in Example 1.3 above

[0055] 3.3 Take 15 mL of aminomethyltrimethylsilane, add 2.5 mL of water and 50 mL of propanol, mix and stir for 30 hours, remove the propanol in the solution at 70°C to obtain solution 1; add 0.3 mL of solution 1 to the newly synthesized CdSe / ZnS quantum dots in 0.5 mL of toluene solution (quantum dot concentration 0.05 mg / mL) was stirred for 0.5 to 5 minutes to obtain solution 2.

[0056] 3.4 Mix 2 mL of Au nanoparticle solution (the concentration of nanoparticles is 0.05 ~ 10 mg / mL) with 0.5 mL of 25 wt% ammonia water and 10 mL of ethanol, add 15 μL of propyl orthosilicate, react for 2 hours, and then centrifuge , and dispersed the coated gold nanoparticles into 1 mL of water to obtain solution 3 (5-30% by mass).

[0057] 3.5 Take 0.4 mL of solution 2 and 0.2 mL of solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com