Nano calcium carbonate transparent dispersoid and preparation method thereof

A technology of nano-calcium carbonate and dispersion, which is applied in the field of dispersion, can solve problems such as complex processes, and achieve the effects of simple process flow, easy scale-up, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

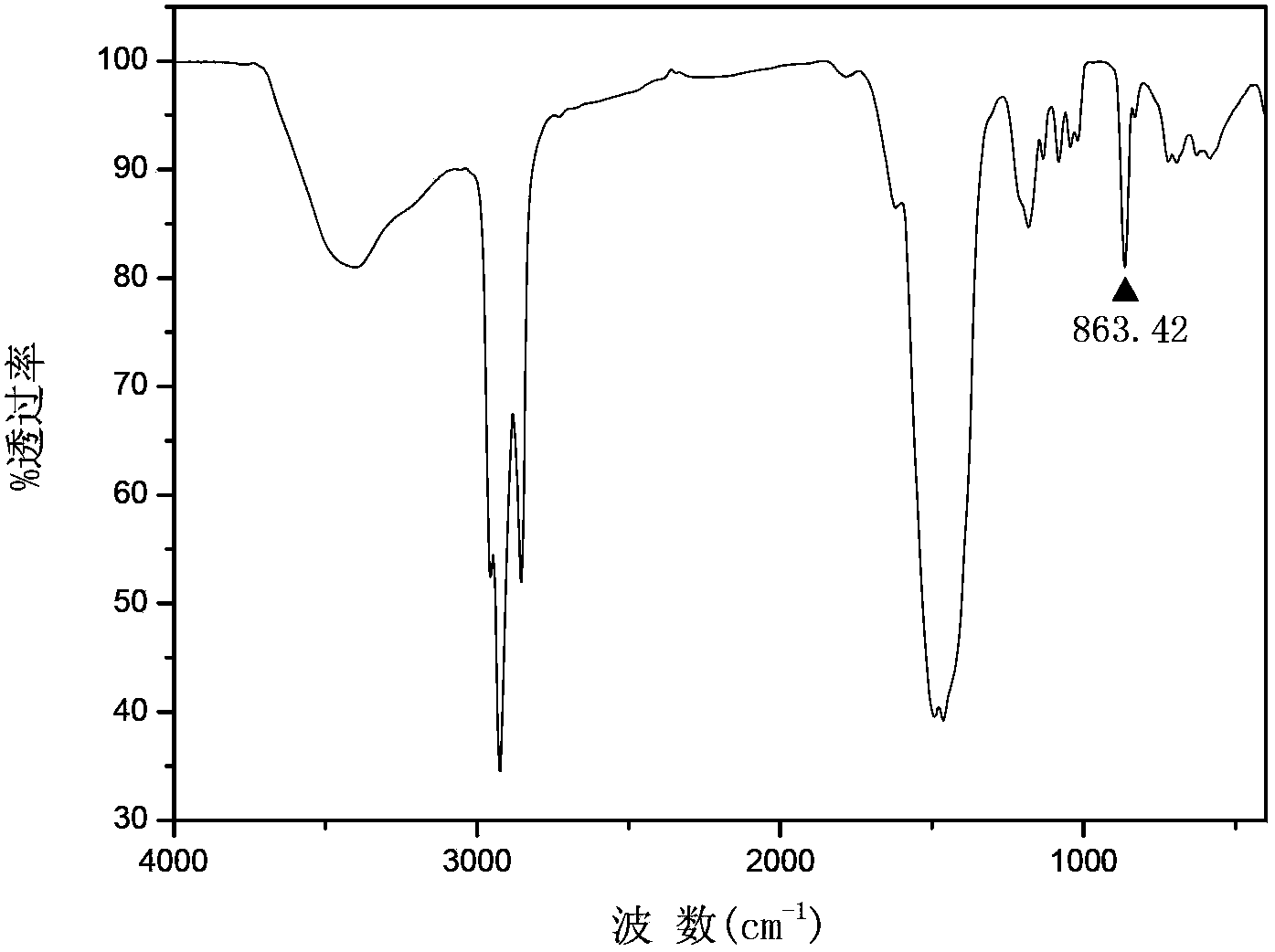

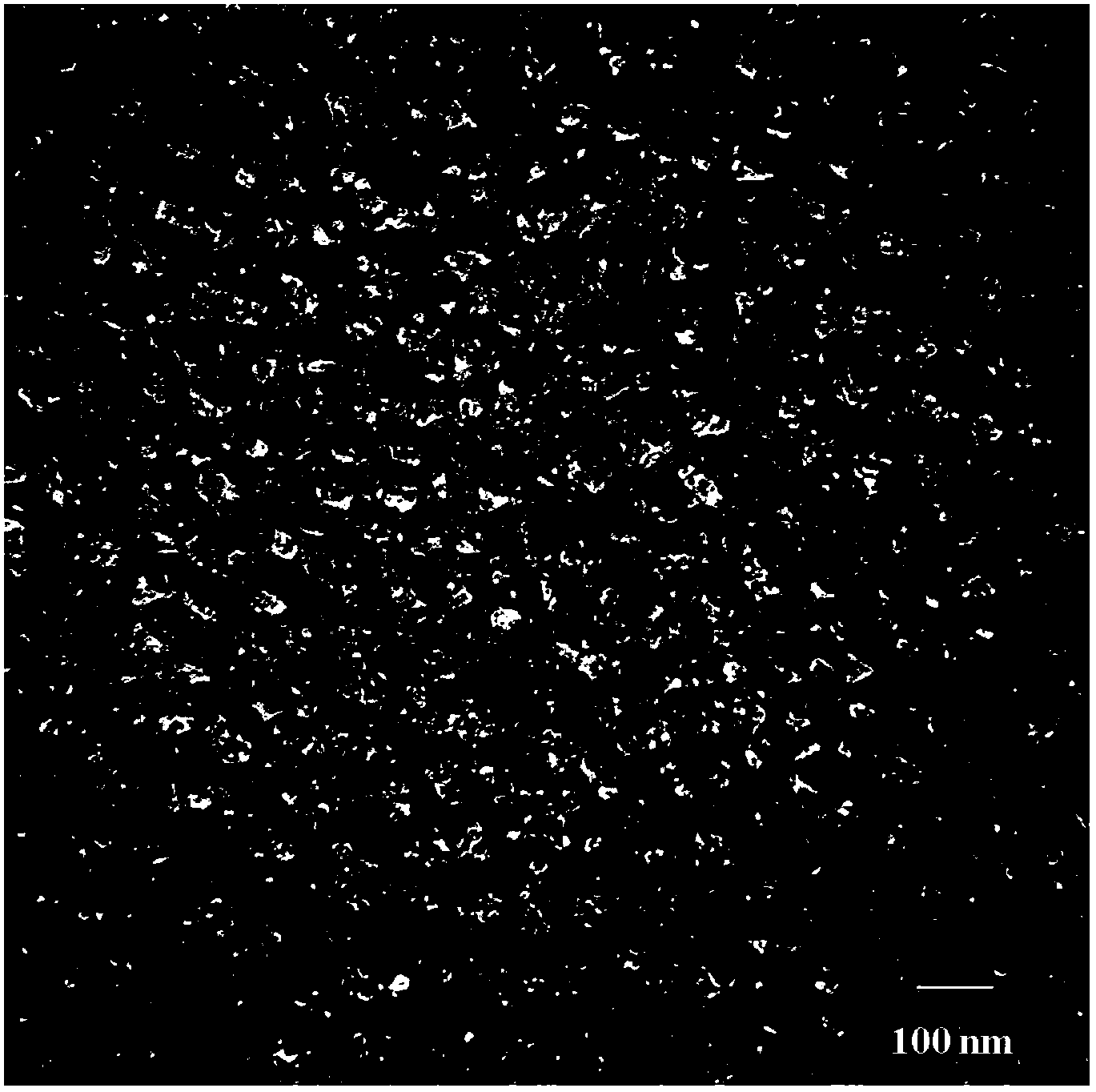

Image

Examples

Embodiment 1

[0027] Put 9.16g ammonium dodecylbenzenesulfonate, 13g white oil, 30g xylene, 10g Ca(OH) into the reactor with high-speed stirring 2 and 8g of ethanol, fully mixed for neutralization reaction, the stirring speed was 3000r / min, the temperature was raised to 40°C, and CO was introduced after 60min 2 , Stop ventilation after 45min of reaction. After pouring out the solution, distill under reduced pressure at 100°C to remove water and ethanol, add a certain amount of xylene and then centrifuge. The centrifugation speed is 3000rpm, and the centrifugation time is 40min. After the slag is removed, vacuum distillation at 90°C is carried out again to remove xylene to obtain the product. The product is transparent, with a solid content of 20%, an alkali value of 243.81mgKOH / g, and no sedimentation after standing for several months.

Embodiment 2

[0029] Put 6.14g of petroleum ammonium sulfonate, 7.14g of white oil, and 30g of petroleum ether into a 100mL four-neck flask with an electric stirring paddle, and then put 7.1g of Ca(OH) into it after stirring evenly with the stirring paddle. 2 And 4.8g methanol, start to carry out neutralization reaction, stirring speed is 3000r / min. Begin heating to 50°C. After 5 minutes of heat preservation, CO was introduced 2 , Stop ventilation after 55min of reaction. Pour out the solution, distill under reduced pressure at 50°C to remove water and methanol, add a certain amount of petroleum ether, and then centrifuge. The centrifugation speed is 4000rpm, and the centrifugation time is 40min. After removing the slag, conduct vacuum distillation again at 50°C to remove petroleum ether to obtain the product. The product is deep red and transparent, with a solid content of 40% and an alkali value of 358.96mgKOH / g, and it has not settled after standing for several months.

Embodiment 3

[0031] Put 9.3g of petroleum sulfonic acid, 11g of white oil, 45g of gasoline, and 10.5g of Ca(OH) into a 250mL four-neck flask with an electric stirring paddle 2 and 12g isopropanol, fully mixed to carry out neutralization reaction, the stirring speed is 3000r / min. Begin heating to 70°C. After 20 min of heat preservation, CO was introduced 2 , Stop ventilation after 30min of reaction. After pouring out the solution, distill under reduced pressure at 80°C to remove water and isopropanol, add a certain amount of gasoline and then centrifuge. The centrifugation speed is 5000rpm, and the centrifugation time is 30min. After deslagging, carry out vacuum distillation again at 80°C to remove gasoline to obtain the product. The product is deep red and transparent, with a solid content of 25.10% and an alkali value of 292.3mgKOH / g, and it has not settled after standing for several months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base value | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com