Polishing solution used for KDP crystal

A polishing liquid and crystal technology, which is applied in the cross-application field, can solve the problems of not taking into account the control of the interaction strength of water and KDP, the occurrence of corrosion pits at the polishing site, and the severe deliquescence, and achieve stable properties, simple preparation, and deliquescence. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The environment temperature for the preparation of the microemulsion is 20°C-25°C, the relative humidity is 40%-50%, and the air pressure is normal pressure.

[0028] The preparation of polishing fluid, with the quasi-three-dimensional phase diagram of oil, surfactant and a certain concentration of KDP aqueous solution as a technical means, by drawing the phase diagram, the single-phase region of the inverse microemulsion of KDP aqueous solution in oil is obtained; according to the same method , draw the phase diagrams of the corresponding systems of various concentrations of KDP aqueous solutions, and obtain a series of single-phase microemulsion regions. Microemulsions with different ratios or different systems were selected as polishing fluids, and the deliquescent polishing of KDP crystals was achieved by using a rotary gravity polishing machine.

Embodiment 1

[0030] (1) Obtaining the initial surface: a 35 mm×35 mm KDP crystal cut by single-point diamond flying is used as the crystal to be polished;

[0031] (2) Preparation of polishing fluid—functionalized microemulsion: first, draw the quasi-ternary phase diagram of decanol / Triton-100 / 10 mM KDP aqueous solution by conductivity method, and determine the inverse microemulsion of the quasi-ternary system Single-phase region, in which Polishing Solution A (55% decanol, 40% polyethylene glycol octylphenyl ether (Triton-100) and 5% 10 mM KDP aqueous solution) was selected.

[0032] (3) Polishing experiment—release of microemulsion function: a rotary gravity polishing machine was used, the dropping speed of polishing solution A was 15 ml / min, the load during polishing was 260 g, the rotation speed of the main disc was 60 rpm, and the rotation speed of the holding ring was 30 rpm , Polishing time 35min.

[0033] (4) Cleaning after polishing: use isopropanol, n-hexane, and acetic acid as ...

Embodiment 2-7

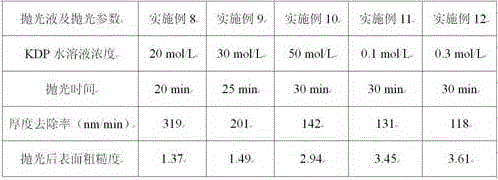

[0036] The embodiment of this embodiment is basically the same as that of Example 1, the main difference is that a series of polishing liquids with different proportions are selected in the single-phase microemulsion zone of decyl alcohol / Triton-100 / 10 mMKDP aqueous solution, during the polishing process , the dropping speed, polishing pressure, rotating speed of the main plate, and rotating speed of the holding ring of each polishing liquid remain unchanged, and the polishing time is slightly adjusted according to the difference in the removal rate. The specific experimental conditions and results are summarized in the table below.

[0037] The polishing liquid embodiment of other proportioning in the decyl alcohol / Triton / 10 mM KDP aqueous system

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com