Powdery plant fat cream and preparation method thereof

A technology for powdered non-dairy fat and cream, which is applied in the production/processing of edible oil/fat, etc., can solve the problems of inability to form a foam structure, difficulty in forming a foam structure, partial coalescence of fat, etc., and achieves short cooking time and good stability. , The effect of high foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

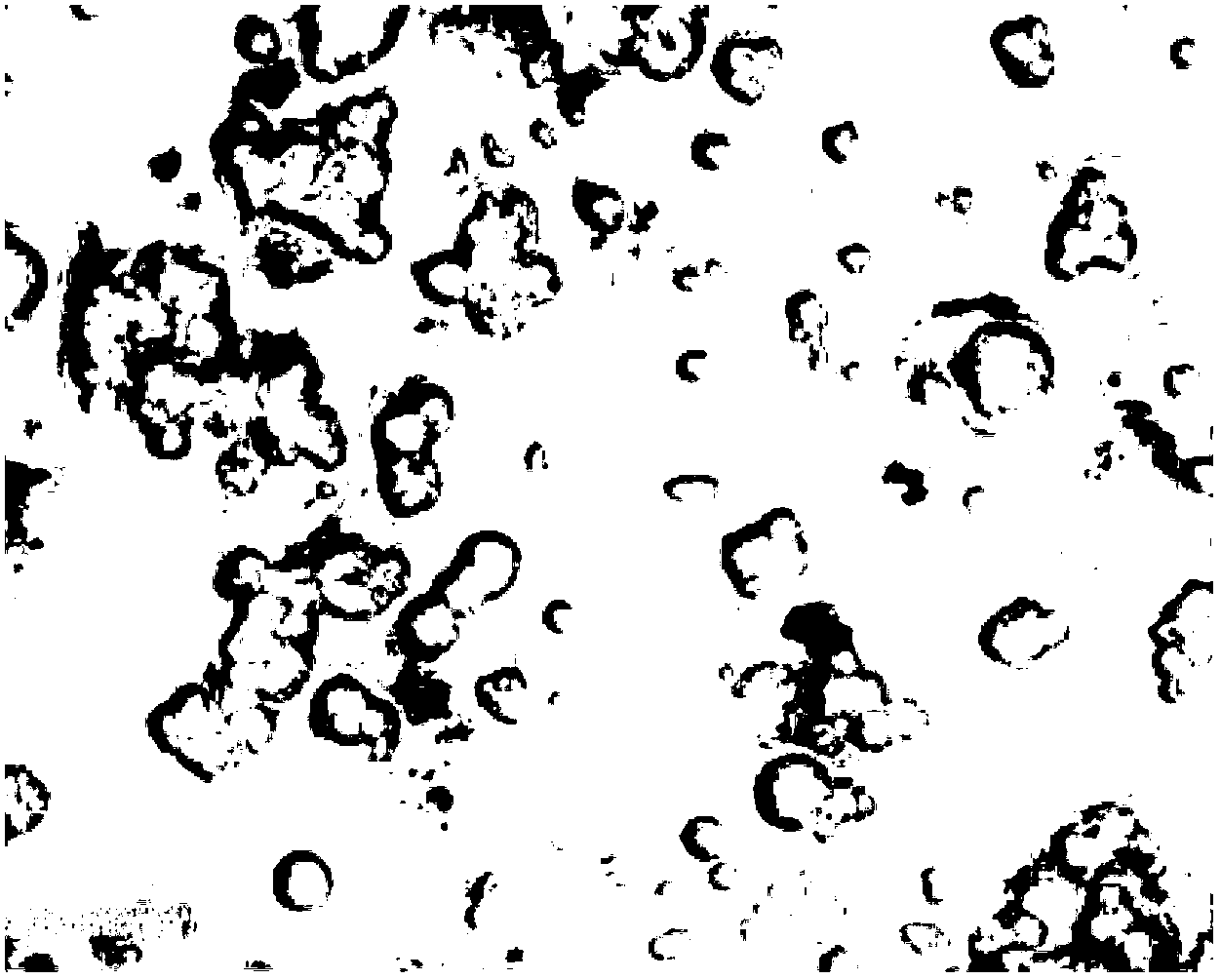

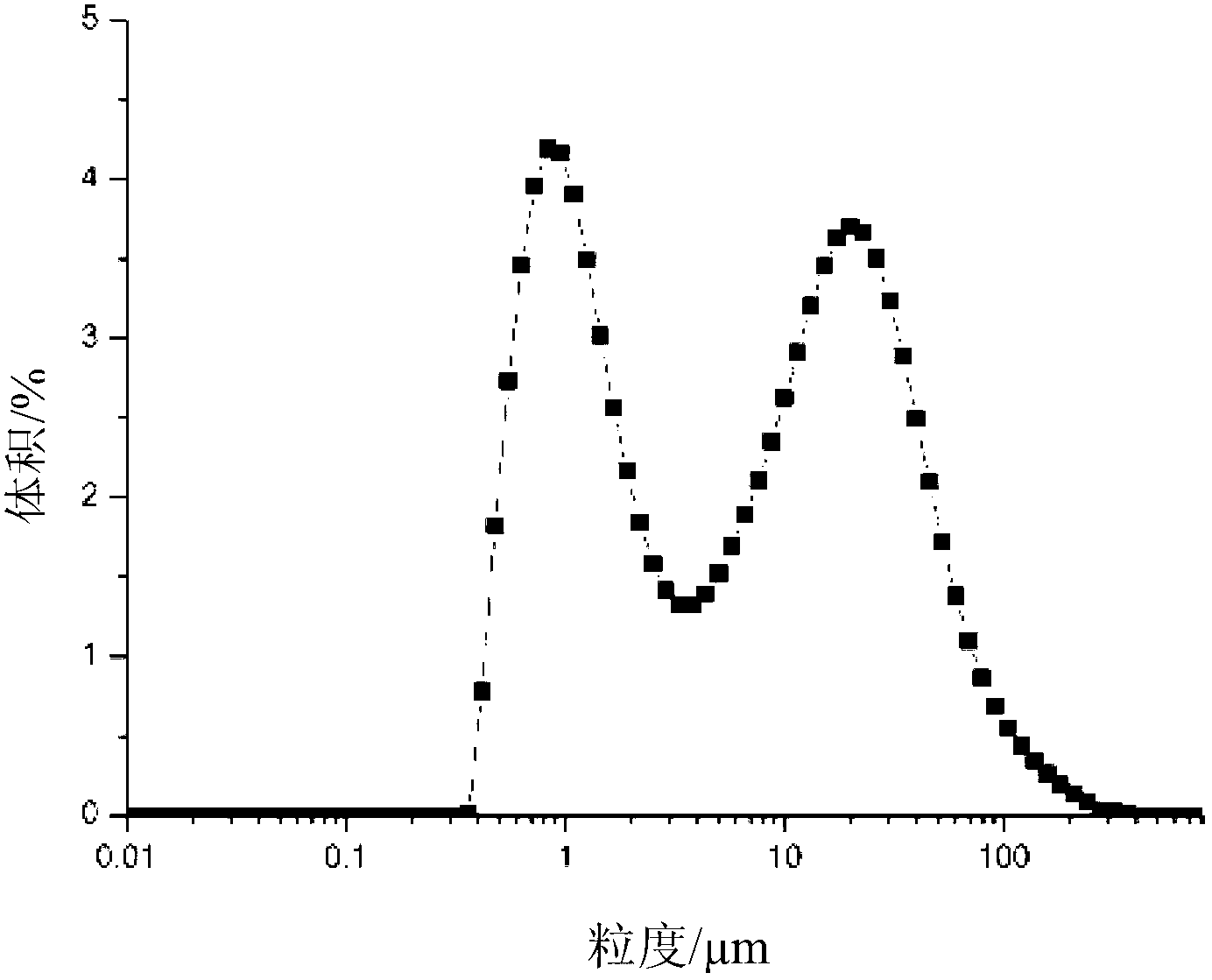

Embodiment 1

[0026] Melt 160g of hydrogenated vegetable oil, heat up to 60°C, add 10g of sodium caseinate, 1g of disodium hydrogen phosphate, 10g of Span60, 0.5g of sucrose fatty acid ester, 8g of soybean lecithin, 4g of HPMC and 5g of xanthan gum and stir to disperse evenly to obtain Oil phase mixture; at the same time, 40g sucrose, 150g glucose and 100g glucose syrup were dissolved in 510.5g water, and heated to 60°C to obtain a water phase mixture; the oil phase mixture and the water phase mixture were mixed evenly, stirred at a speed of 50rpm for 30min, and passed through Homogenize twice at 50MPa, then spray dry at an inlet air temperature of 170°C and an outlet air temperature of 70°C, then add 1g of butter essence and mix evenly to obtain powdered non-dairy cream with a moisture content of 5.4%.

[0027] At room temperature, the powdered non-dairy cream quickly dissolves in cold water, the whipping foaming rate reaches 3.88 times, and the whipping time is 5.5 minutes. It is stable an...

Embodiment 2

[0029] Melt 210g of hydrogenated vegetable oil, raise the temperature to 75°C, add 6g of sodium caseinate, 0.2g of disodium hydrogen phosphate, 6g of Span60, 2g of sucrose fatty acid ester, 2g of soybean lecithin, 1g of HPMC and 1g of xanthan gum, stir and disperse evenly to obtain oil phase mixture; at the same time, 100g sucrose, 50g glucose and 60g glucose syrup were dissolved in 557.3g water, and heated to 75°C to obtain a water phase mixture; the oil phase mixture and the water phase mixture were mixed evenly, stirred at a speed of 60rpm for 15min, and passed through two Sub-high pressure homogenization, the first homogenization pressure is 40MPa, the second homogenization pressure is 70MPa, and then the air inlet temperature is 180°C, the outlet air temperature is 90°C spray drying, and then 4g of chocolate essence and 0.5g of caramel coloring Add and mix evenly to obtain powdered whipped cream with a moisture content of 4.8%.

[0030] At room temperature, the powdered n...

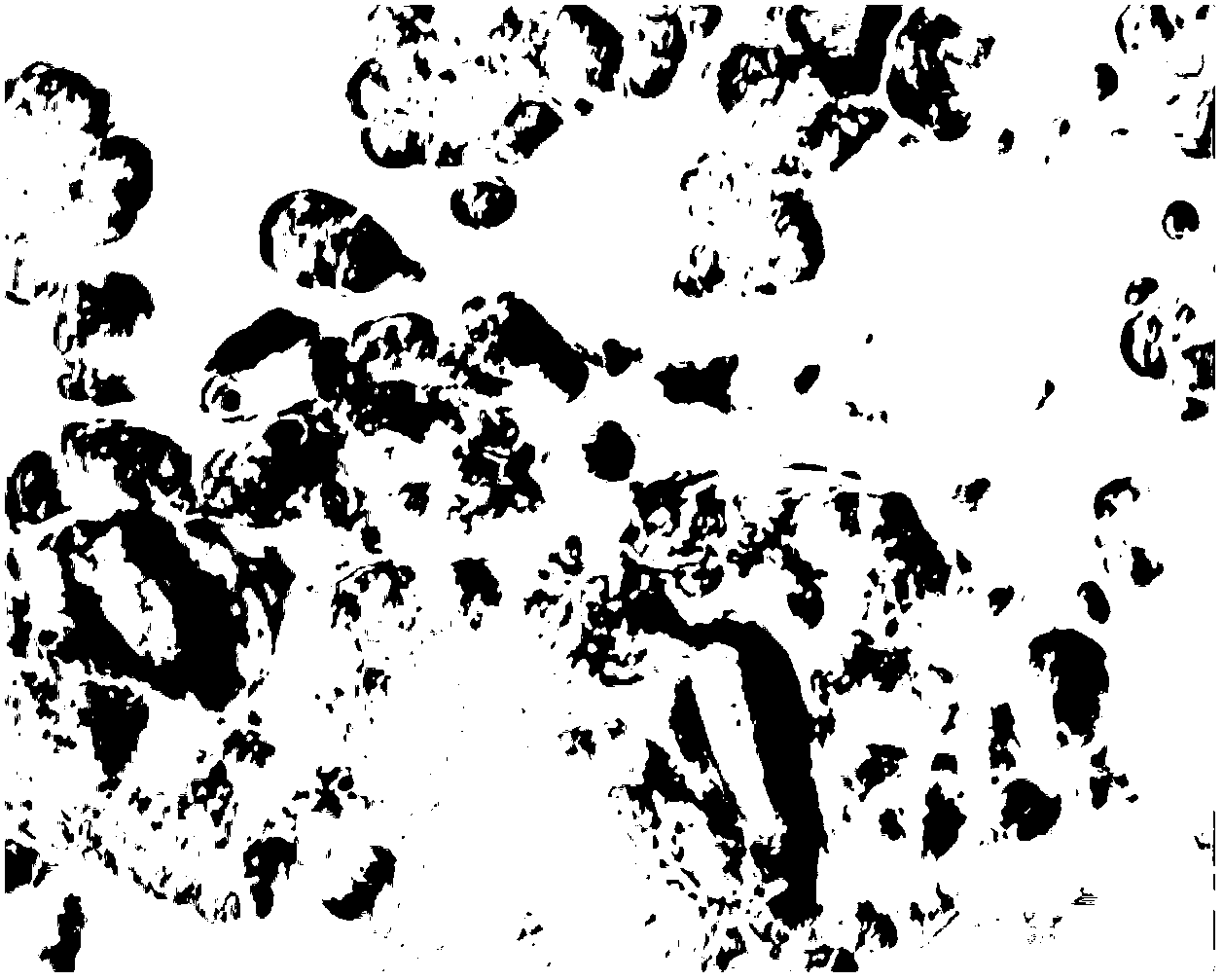

Embodiment 3

[0033] Melt 125kg hydrogenated vegetable oil, heat up to 85°C, add 7kg sodium caseinate, 0.5kg disodium hydrogen phosphate, 10kg Span60, 1kg sucrose fatty acid ester, 4kg soybean lecithin, 1.5kg HPMC and 1kg xanthan gum, stir and disperse evenly, Obtain the oil phase mixture; simultaneously dissolve 15kg of sucrose, 60kg of glucose and 50kg of glucose syrup in 223.5kg of water, and heat to 85°C to obtain the water phase mixture; mix the oil phase mixture and the water phase mixture evenly, stir at 70rpm for 5min, After two times of high-pressure homogenization, the first homogenization pressure is 50MPa, the second homogenization pressure is 60MPa, and then the air inlet temperature is 200 ℃, the air outlet temperature is 90 ℃ spray drying, and then 1.5kg strawberry essence and 0.005kg Carmine pigment was added and mixed evenly to obtain powdered non-dairy cream with a water content of 4.5%.

[0034] At room temperature, the powdered non-dairy cream quickly dissolves in cold w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com