Zero-sugar creamer and preparation method thereof

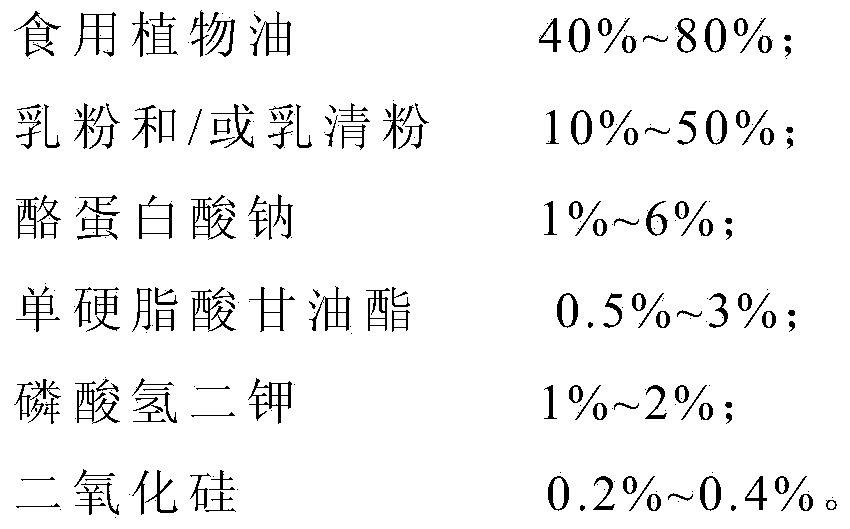

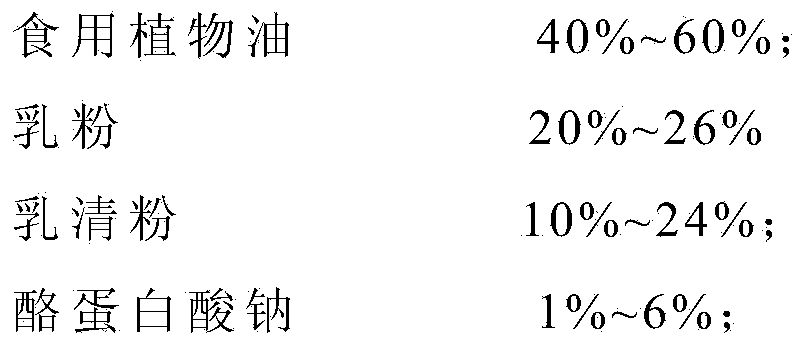

A technology for planting fat powder and edible vegetable oil, applied in the fields of edible oil/fat, food science, application, etc., which can solve the problems of great impact on product profit margin, increase logistics cost, increase product weight, etc., and reduce costs and carbon emissions. , high utilization rate, unique flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

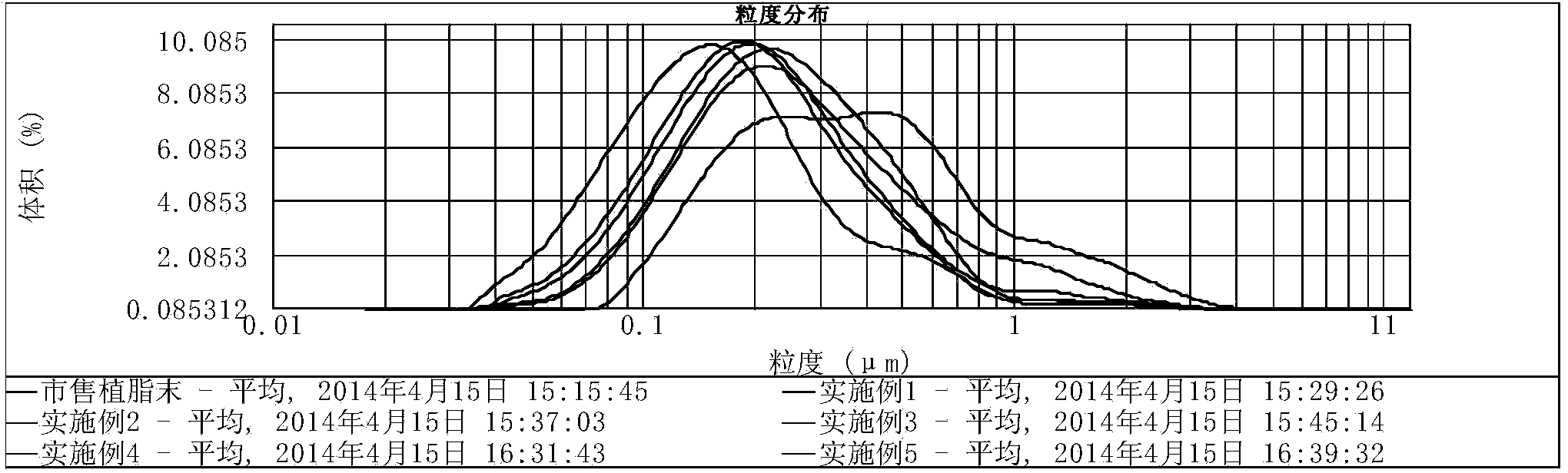

Image

Examples

Embodiment 1

[0035] The edible vegetable oil in this embodiment is soybean oil, and the above-mentioned raw materials are prepared according to the formula amount in Table 1 according to the following steps.

[0036] (1) Dipotassium hydrogen phosphate is dissolved in water to prepare a dipotassium hydrogen phosphate aqueous solution with a concentration of 15%, and sodium caseinate and whey powder are dissolved with water at a temperature of 60°C to prepare a sodium caseinate with a concentration of 20%. mixed with whey powder in aqueous solution;

[0037] (2) Stir and mix the above-mentioned dipotassium hydrogen phosphate aqueous solution and the above-mentioned sodium caseinate and whey powder mixed aqueous solution;

[0038] (3) heating soybean oil to 60°C, adding glyceryl monostearate and stirring to mix evenly;

[0039] (4) Pour the solution prepared in step (2) and the solution prepared in step (3) into the emulsification tank at the same time. After fully emulsifying at a temperatu...

Embodiment 2

[0042] The edible vegetable oil in this embodiment is sunflower oil, according to the formulation amount in Table 1, the above-mentioned raw materials are produced according to the following steps.

[0043] (1) Dissolve dipotassium hydrogen phosphate with water to prepare a dipotassium hydrogen phosphate aqueous solution with a concentration of 25%, and dissolve sodium caseinate, milk powder and whey powder with water at a temperature of 60°C to prepare a mixed solution with a concentration of 20%. aqueous solution;

[0044] (2) Stir and mix the above-mentioned dipotassium hydrogen phosphate aqueous solution and the above-mentioned mixed aqueous solution;

[0045] (3) Heat the sunflower oil to 60°C, add glyceryl monostearate and stir to mix evenly;

[0046] (4) Pour the solution prepared in step (2) and the solution prepared in step (3) into the emulsification tank at the same time. After fully emulsifying at a temperature of 55°C, inject the emulsified slurry into the homoge...

Embodiment 3

[0049] The edible vegetable oil in the present embodiment is coconut oil, and according to the formula amount in Table 1, the above-mentioned raw materials are produced according to the following steps.

[0050] (1) Dipotassium hydrogen phosphate is dissolved in water to prepare an aqueous solution of dipotassium hydrogen phosphate with a concentration of 40%, and sodium caseinate and whey powder are dissolved with water at a temperature of 65°C to prepare a concentration of 10% sodium caseinate mixed with whey powder in aqueous solution;

[0051] (2) Stir and mix the above-mentioned dipotassium hydrogen phosphate aqueous solution and the above-mentioned sodium caseinate and whey powder mixed aqueous solution;

[0052] (3) Coconut oil is heated to 70 ℃, adds glyceryl monostearate and stirs and mixes evenly;

[0053] (4) Pour the solution prepared in step (2) and the solution prepared in step (3) into the emulsification tank at the same time, and after fully emulsifying at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com