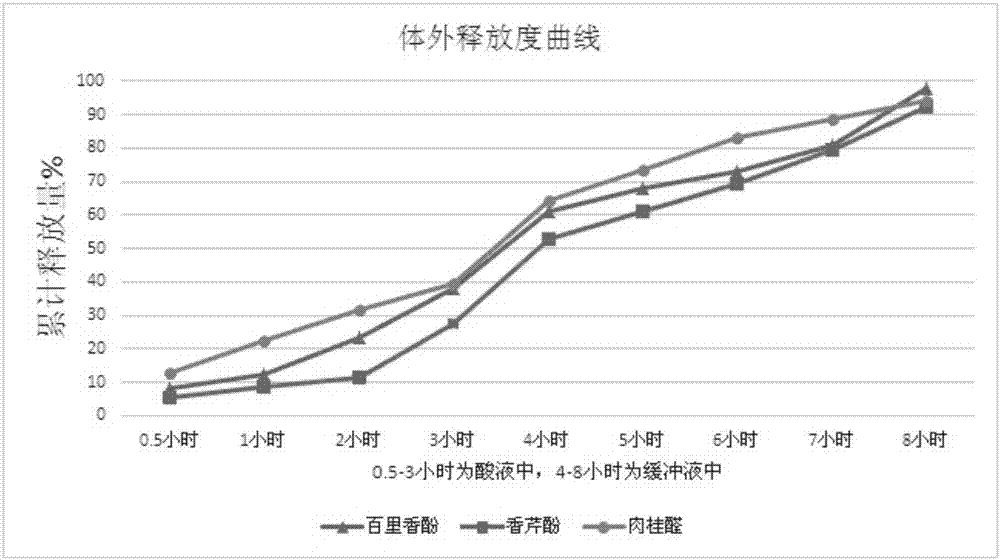

Mixed type feed additive plant essential oil particles and preparation method of plant essential oil particles

A technology of feed additive and plant essential oil, which is applied in the field of mixed feed additive plant essential oil granules and its preparation, can solve the problems of plant essential oil volatility and short storage period, reduce the production of mycotoxins, reduce production costs, and reduce losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] ①Preparation of bacterial suspension Take the nutrient agar slant culture of Escherichia coli, inoculate it into the nutrient broth medium, and cultivate it at 35-37°C for 18-24 hours. Dilute the prepared bacterial suspension 10 times to different concentrations with normal saline, and count the colonies to keep the concentration of the bacterial suspension at about 1×10 6 CFU / mL.

[0044] ②Preparation of detection plates Take a flat-bottomed double plate with a diameter of about 90 mm and a height of 16-17 mm, and sterilize it for use. Take the prepared bacterial suspension, add it in proportion (bacterial suspension: medium = 1:15) to the nutrient agar medium cooled to 50°C after sterilization, shake to mix evenly, and then pour 20ml of bacterial culture Put the base into the double dish, as a bacterial layer, place it on the horizontal surface, and wait for it to solidify.

[0045] ③ Detection method: Place 4 Oxford cups equidistantly in each pair of dishes, add 20...

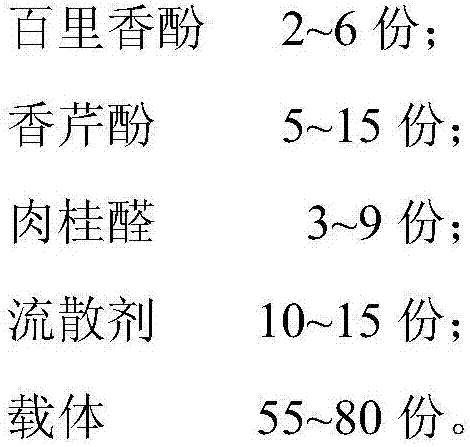

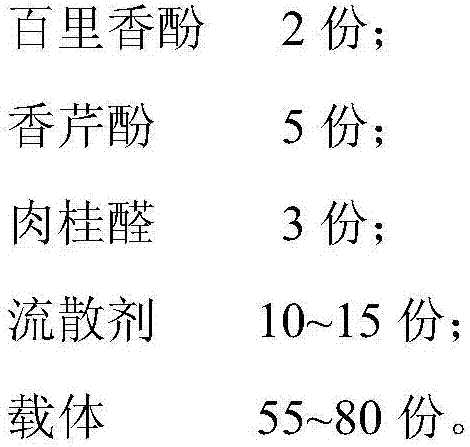

Embodiment 1

[0066] Weigh 750 kg of stearic acid / glyceryl monostearate, put it into a jacketed heating tank, control the temperature of the jacket at 100°C to 130°C, heat to melt, and dissolve the melted stearic acid / glycerol monostearate Transfer to the jacketed stirring homogeneous tank, maintain the jacket temperature of the stirred homogeneous tank at 80°C to 90°C, start the stirrer, put 75kg of silicon dioxide under stirring, add 20kg of thymol in turn after stirring evenly, Carvacrol 50kg and cinnamaldehyde 30kg, finally add 75kg of silicon dioxide, start the homogeneous pump, make the material mix evenly. Start the feeding pump, send the uniformly mixed materials to the centrifugal spray tower, control the inlet air temperature to ≤5°C, the speed of the centrifugal turntable at 3000-4000 rpm, and the air volume at 30000-40000 cubic meters per minute, and spray and cool the materials to form granules. Collect granular products and sieve them with a vibrating sieve to obtain a finishe...

Embodiment 2

[0068] Weigh 700 kg of stearic acid / glyceryl monostearate, put it into a jacketed heating tank, control the temperature of the jacket at 100°C to 130°C, heat to melt, and melt the melted stearic acid / glycerol monostearate Transfer to the jacketed stirring homogeneous tank, maintain the jacket temperature of the stirred homogeneous tank at 80°C to 90°C, start the stirrer, put 75kg of silicon dioxide under stirring, add 30kg of thymol in sequence after stirring evenly, Carvacrol 75kg and cinnamaldehyde 45kg, finally add 75kg silicon dioxide, start the homogeneous pump, make the material mix evenly. Start the feeding pump, send the uniformly mixed materials to the centrifugal spray tower, control the inlet air temperature to ≤5°C, the speed of the centrifugal turntable at 3000-4000 rpm, and the air volume at 30000-40000 cubic meters per minute, and spray and cool the materials to form granules. Collect granular products and sieve them with a vibrating sieve to obtain a finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com