Self-repairing polyurethane nano-composite material and preparation method and application thereof

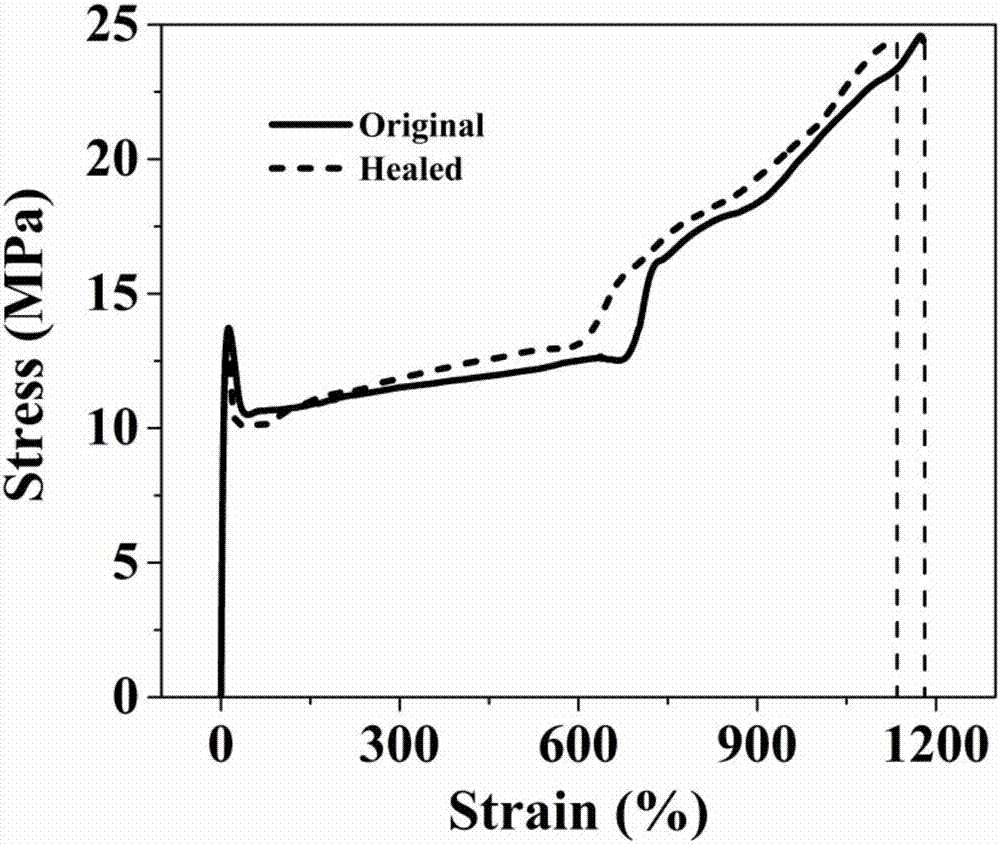

A nano-composite material and self-healing technology, applied in the field of self-healing polyurethane nano-composite materials and their preparation, can solve the problems of inability to self-repair, low repair efficiency, single repair method, etc., and achieve excellent self-healing performance, excellent mechanical properties, The effect of high tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Synthesis of Diels-Alder bond-containing diols: Dissolve equivalent amounts of furan 1 and maleic anhydride 2 in excess 1,4-dioxane, stir and react at room temperature for 24 h, mash the resulting precipitate, and pass Vacuum filtration, washing with ether, and drying to obtain product 3; product 3 and ethanolamine in equivalent amounts were dissolved in methanol respectively under ice bath conditions, and then the two were mixed and stirred at 70 °C for reflux reaction for 24 h. The mixed solution was put into the refrigerator for cooling and crystallization, vacuum filtered, washed with ether, and dried to obtain product 4; product 4 was added to excess toluene, stirred and refluxed for 12 h at 130 °C, and then the solution was filtered, and the filtrate was placed in the refrigerator. Crystallization by cooling, vacuum filtration, washing with ether, and drying to obtain product 5; product 5 and furfuryl alcohol in an equivalent amount were stirred and reacted with exc...

Embodiment 2

[0046] Synthesis of isocyanate-terminated polyε-caprolactone-4000: Weigh polyε-caprolactone diol and diphenylmethane diisocyanate in the ratio of substance amount -OH / -NCO=2 / 1, Under nitrogen protection, the reaction was stirred at 80° C. for 2 h to obtain isocyanate-terminated polyε-caprolactone, which was sealed for use.

Embodiment 3

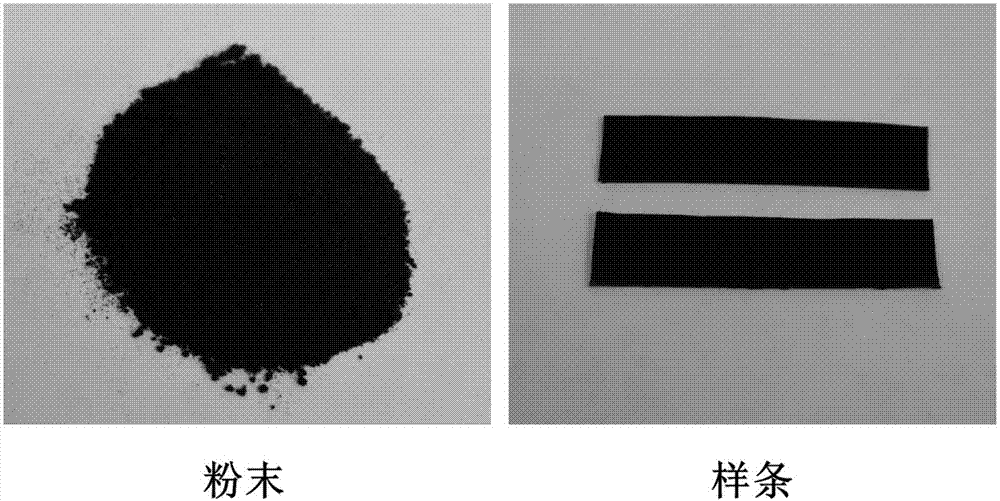

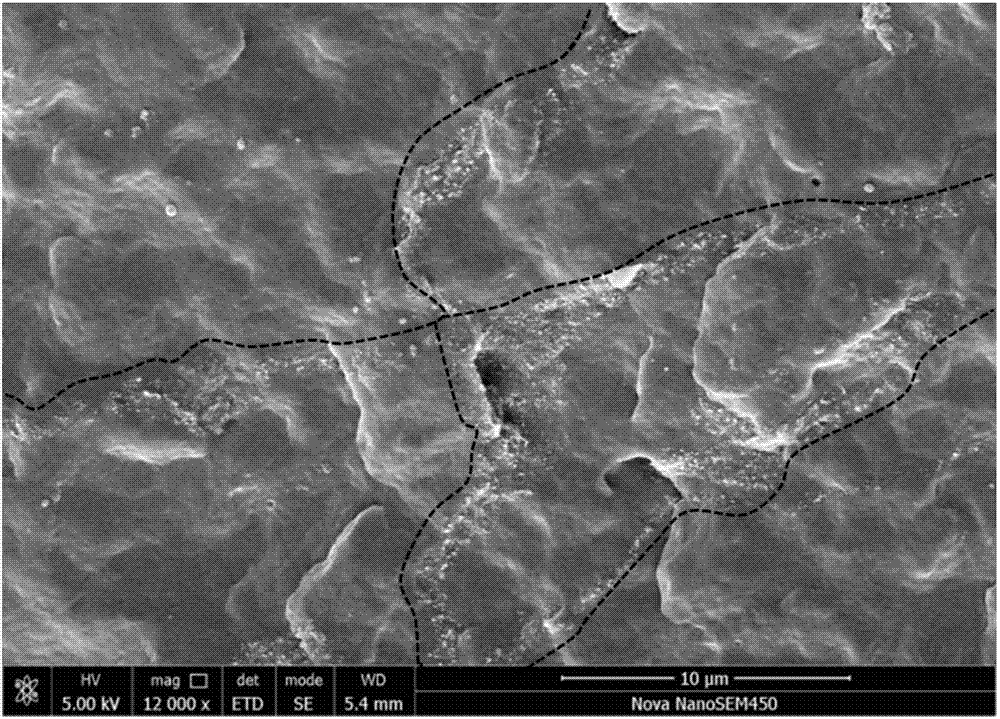

[0048] Preparation of self-healing polyurethane powder material containing Diels-Alder bonds: 0.896 g of the Diels-Alder bond-containing diol synthesized in Example 1, 13.5 g of the isocyanate-terminated poly(ε-hexane) synthesized in Example 2 Lactone-4000, 0.252 g of hexamethylene diisocyanate trimer were dissolved in 15 mL of anhydrous 1,4-dioxane. The mixture was degassed under reduced pressure and cast into open Teflon molds. It was placed in an oven at 80° C. for curing for 96 h to obtain a polyurethane containing Diels-Alder bonds. Finally, it is further prepared into a self-healing polyurethane powder material containing Diels-Alder bonds with a particle size of 10-150 μm by freeze-drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com