Reprocessed polyurethane with dual-dynamic covalent bond crosslinking and preparation method of reprocessed polyurethane

A technology of dynamic covalent bonding and heavy processing, which is applied in the direction of additive processing, etc., can solve problems that have not been seen, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

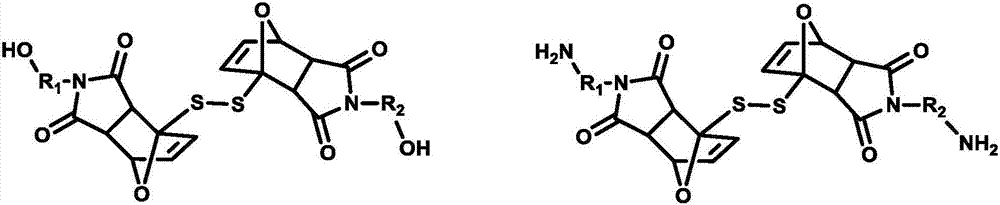

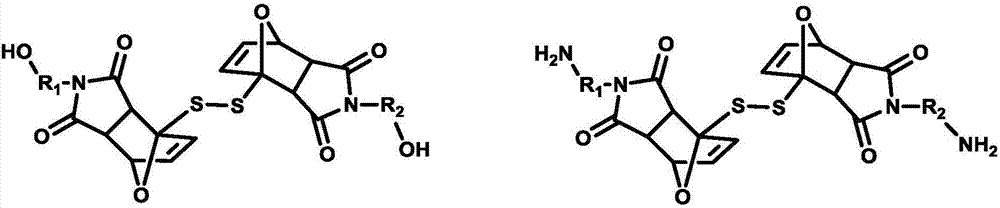

Method used

Image

Examples

Embodiment 1

[0027] (1), under the protection of an inert gas, 50g of toluene diisocyanate (TDI), 500g of polycaprolactone diol with a molecular weight of 2000 and 2g of dibutyltin dilaurate catalyst are added in proportion to the reactor, and the temperature is raised to 70~ 90°C, stirring and reacting for 0.5~2h;

[0028] (2), add 300 ml dioxane solution of 135g amino-terminated dynamic bond chain extender and 40g HDI trimer crosslinking agent to the product in (1), under the protection of inert gas, react at 45~90°C for 2~ After 72h, a reprocessable polyurethane with self-healing properties was obtained.

Embodiment 2

[0030] (1) Under the protection of an inert gas, add 38g of isophorone isocyanate (IPDI), 400g of polypropylene glycol with a molecular weight of 2000 and 2.5g of dibutyltin dilaurate catalyst into the reactor in proportion, and heat up to 70-90°C , stirring and reacting for 0.5 to 2 hours;

[0031] (2), add a mixed melt of 30g of amino-terminated dynamic bond chain extender and 42g of HDI trimer crosslinking agent to the product in (1), and react at 45-90°C for 2-72h under the protection of an inert gas to obtain Reworkable polyurethane with self-healing properties.

Embodiment 3

[0033] (1), under the protection of inert gas, 78g xylylene diisocyanate (XDI), 450g molecular weight are polytetrahydrofuran glycol of 2000 and 2.2g dibutyltin dilaurate catalyst are added in the reactor in proportion, heat up to 70-90°C, stirring for 0.5-2 hours;

[0034] (2), add the mixed dioxane solution of 72g amino-terminated dynamic bond chain extender and 40g TDI trimer cross-linking agent to the product in (1), under the protection of inert gas, 45~90 ℃ react 2~ After 72h, a reprocessable polyurethane with self-healing properties was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com