Dynamic polymer with hybrid cross-linked network

A hybrid cross-linking and polymer technology, applied in the field of smart polymers, can solve problems such as difficult to balance self-healing mechanical properties, weak interactions, and insufficient supramolecular hydrogen bond dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

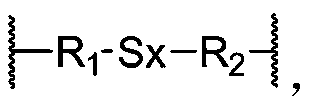

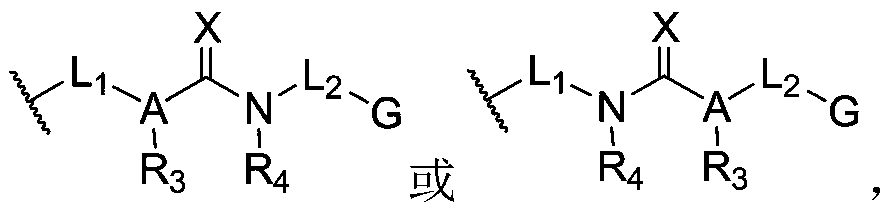

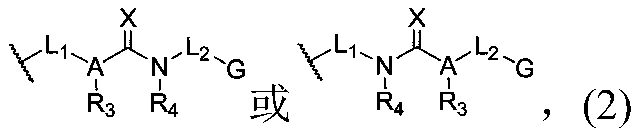

Method used

Image

Examples

preparation example Construction

[0214] The preparation method of a kind of dynamic polymer ionic liquid gel of the present invention, comprises the following steps: the raw material of the dynamic polymer that prepares hybrid cross-linked network is added in ionic liquid, makes the dynamic state of prepared hybrid cross-linked network The mass fraction of the polymer is 0.3-75%, the covalent cross-linking is carried out by the appropriate means, and after the reaction is completed, a dynamic polymer ion liquid gel is prepared. Another method for preparing a dynamic polymer ionic liquid gel of the present invention comprises the following steps: swelling a dynamic polymer having a hybrid cross-linked network in a solvent containing an ionic liquid, and making the prepared hybrid cross-linked network The mass fraction of the dynamic polymer is 0.3-75%, and the solvent is removed after fully swelling to prepare a dynamic polymer ion liquid gel. The ionic liquid is generally composed of organic cations and inorg...

Embodiment 1

[0223] The specific steps for preparing an ionic liquid gel are as follows:

[0224] (1) 84g of 1,4-pentadien-3-ol and 57g of methyl isocyanate are reacted in 250ml of methylene chloride with 2g of triethylamine as a catalyst to obtain a bis ene compound 1;

[0225] (2) Diene compound 1 and N,N'-bis(acryloyl)cystamine are added to 1-butyl-3-methyl with respect to 15 to 45 wt% of the side group of the ionic liquid with a carbamate group Imidazolium hexafluorophosphate ([C 4 MIM]PF 6 ) in the ionic liquid, then add the crosslinking agent pentaerythritol tetrakis (3-mercaptopropionate) relative to the monomer 0.1~20wt% and the photoinitiator benzoin dimethyl ether (DMPA) relative to the monomer 0.05~0.55wt% , stir and mix well, pour it into a glass plate mold with a silica gel gasket, put it in an ultraviolet crosslinking instrument for 1 to 10 hours of ultraviolet radiation, and you can get a high elongation and elastic modulus adjustable ion Liquid dynamic polymer gel.

[...

Embodiment 2

[0231] The concrete steps of preparing a kind of foam polyurethane material in the present embodiment are as follows:

[0232] Weigh the reaction material A in parts by weight: 112 parts of polyester diol with a molecular weight of 2000, 0.6 parts of N,N-di(2-hydroxyethyl)-N'-propyl-urine, 4,4'- 0.4 part of dihydroxydiphenyl disulfide, 0.2 part of chain extender, 0.2 part of dibutyltin dilaurate, 1 part of dichloromethane, 0.2 part of diethylenetriamine, 0.1 part of silicone oil, add to No. 1 mold , Stir evenly under the conditions of material temperature 30°C and stirring speed 180r / min; Reaction material B: 12 parts of isophorone diisocyanate (IPDI), 2.5 parts of foaming agent, 0.1 part of foam stabilizer, photoinitiator benzoin Add 0.2 parts of dimethyl ether (DMPA) into No. 2 mold, and stir evenly under the condition of material temperature 30°C and stirring speed 180r / min; The equipment was stirred rapidly until bubbles were generated, and left to stand for 72 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Fracture stress | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com