Liquid wound repairing film and preparation method thereof

A wound and liquid technology, applied in the field of liquid wound repair film and its preparation, can solve the problems of difficult to provide moist skin cell proliferation, wound healing, poor biocompatibility and biosafety, dust or water infiltration into the wound, etc. Restoration of appearance and function, good biocompatibility, prevention of skin cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of carboxymethyl chitosan: Take 10.0g of chitosan in a three-necked flask, add 100mL of isopropanol, stir at 50-60°C for 10min, and divide 10mol / L NaOH 25mL solution into 5 batches for 20 minutes while stirring After the internal addition, stir for another 10 minutes, let it swell at room temperature for 12 to 15 hours, add 60 g of chloroacetic acid into the swollen chitosan in 5 batches, then raise the temperature to 60 ° C, continue to stir for 3 hours, stop, vacuum filter, and filter the residue After washing with ethanol several times, dry at 50°C to obtain carboxymethyl chitosan, and store it in a desiccator.

[0027] Infrared spectrum analysis: using KBr tablet, Avatar 370 Fourier transform infrared spectrometer to measure the prepared carboxymethyl chitosan, the results are shown in the IR spectrum at 1635.56cm -1 and 1385.22cm -1 The characteristic absorption peak of carboxymethyl sodium salt appeared at , indicating that carboxymethylation reaction...

Embodiment 1

[0041] Bottom solution preparation: take the CMC physiological saline solution with a concentration of 0.5 mg / mL prepared in the screening examples as the bottom solution.

[0042] Preparation of film solution: Weigh 1.5g of polyvinyl butyral, measure 30mL of 80% ethanol, heat and stir in a three-neck flask, and after the film-forming substance is completely dissolved, the film solution can be used as a liquid bandage.

[0043] When using, first apply the base liquid to the wound, and then apply the film liquid. The film liquid coated on the surface dries within 90s, which can effectively maintain the moist and sterile environment of the bottom liquid, and provide good conditions for wound healing.

Embodiment 2

[0045] Bottom solution preparation: the CMC physiological saline solution with a concentration of 1.0 mg / mL prepared in the screening example was used as the bottom solution.

[0046] Membrane solution preparation: weigh 3.5g of polyvinyl butyral, 0.3g of chitosan, measure 35mL of 95% ethanol, stir while heating in a three-necked flask, and add glycerol after the film-forming substance is completely dissolved 1mL was mixed and stirred evenly to obtain a film liquid, and the stirring speed was 300-400rpm. The resulting membrane solution is used as a liquid bandage.

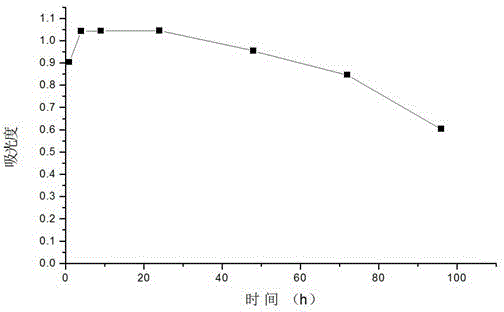

[0047] Apply the film solution on the glass, tear it off after film formation, weigh 0.1g, put it into 100mL phosphate buffer solution simulated gastric simulated intestinal fluid (pH 7.45), stir at 37°C at a speed of 100rpm, and release for 180min. Draw 2mL solution therefrom at regular intervals, measure the content of chitosan, supplement the same volume of phosphate buffered saline solution at the same time. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com