Multifunctional polar polyolefin material as well as metal complex material, preparation method and application thereof

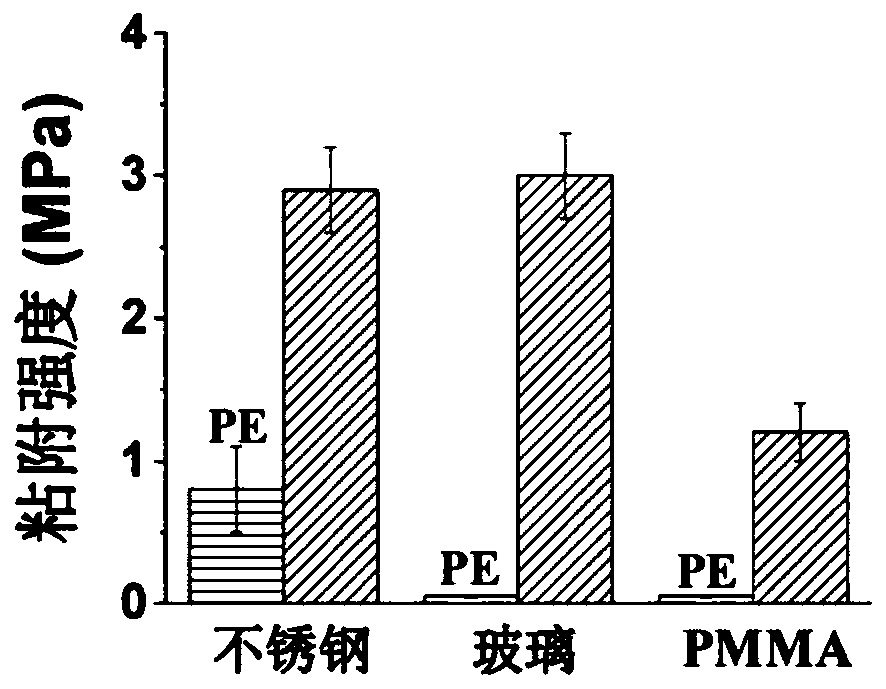

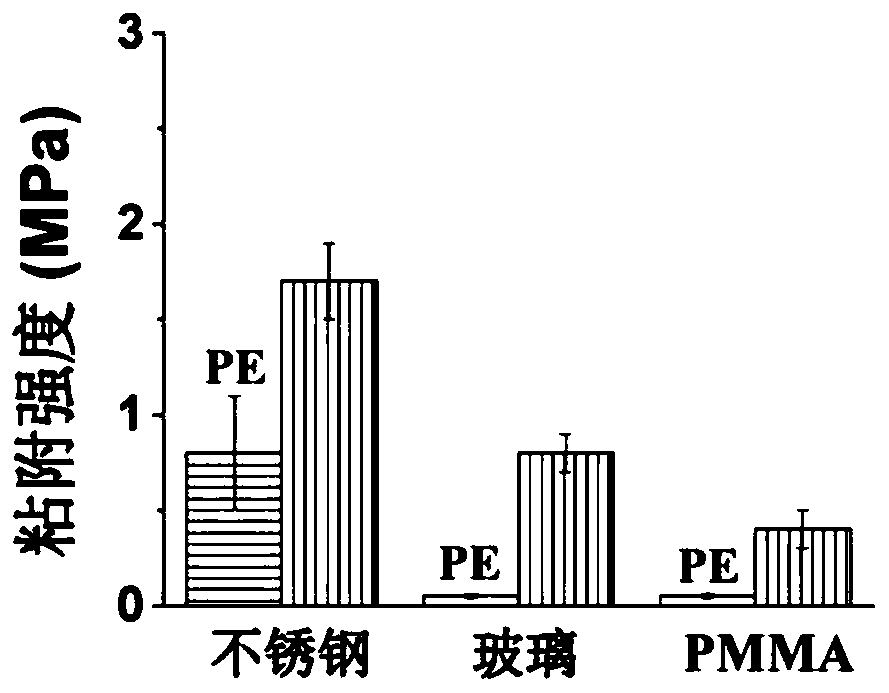

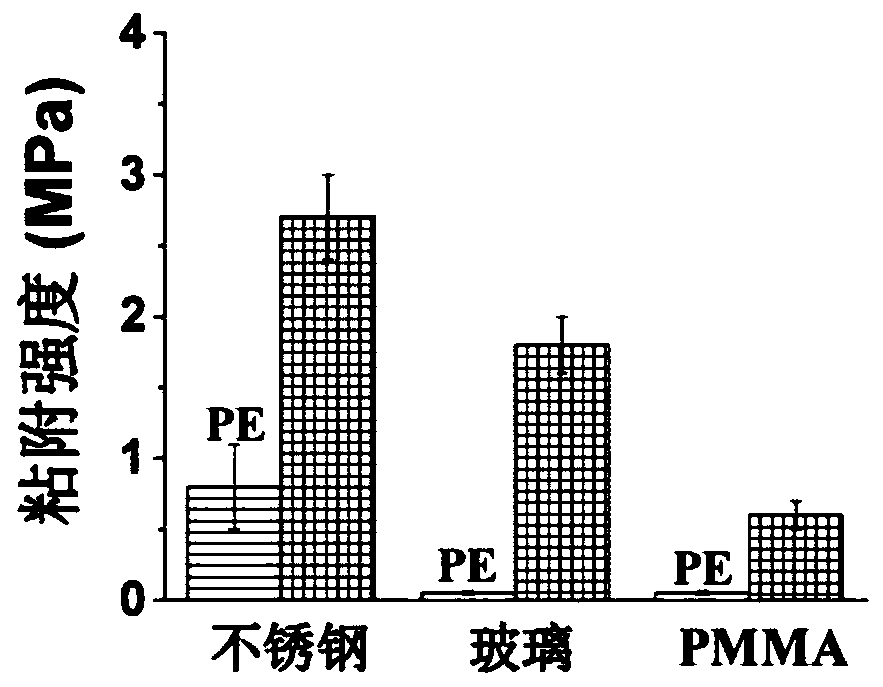

A technology of metal complexes and polyolefins, applied in adhesives, etc., can solve the problems of no ternary copolymerization, no polyolefin materials and their properties, no ternary copolymerization, etc., and achieve the effect of enhanced adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In the preparation method of the present invention, the polymerization temperature is preferably 50-100°C, such as 80°C; the ethylene pressure is preferably 1-15 atmospheres (atm), more preferably 3-9 atm; the α-olefin comonomer is a gas The pressure under the situation of can be 1~15atm, and under the situation of liquid, its concentration in reaction solvent can be 0.05~10mol / L, more preferably 0.1~4mol / L; Eugenol comonomer concentration is in The concentration in the reaction solvent is preferably 0.05-10 mol / L, more preferably 0.1-2 mol / L; polymerization time: 0.5-12 h, preferably 1-12 h, for example about 2 h.

[0049] In the present invention, the copolymerization reaction can be carried out in the presence of an additionally added organic solvent, that is, the copolymerization reaction is carried out in a solution, which can be called solution polymerization. Preferably, the organic solvent usable in the present invention is toluene, xylene, chlorobenzene, n-hexa...

Embodiment 1-12

[0069] Example 1-12: Preparation and performance testing of multifunctional polar polyolefin materials

[0070] (1) Preparation of Embodiment 1-10:

[0071] In a glove box, under a nitrogen atmosphere, comonomers (i.e., α-olefin comonomer (Hex) and eugenol mono The respective molar concentrations of the monomers (Eug, Eug-Si or Eug-OH) are indicated in brackets after the corresponding comonomers. For example, when the total reactant volume is 20mL, for the random obtained in Example 4 Copolymer E / Eug-Si(0.1) / Hex(4), the molar number of Eug-Si comonomer is 2mmol, and the molar number of Hex comonomer is 80mmol), and add and dissolve in 1mL 20 μmol of catalyst PO-Pd in dichloromethane. Then, connect the ethylene gas source pipeline to feed ethylene (monomer E) gas into the reactor, and after adjusting the ethylene pressure to 8atm or 3atm, under magnetic stirring, the reactor was heated to 80°C by heating in a water bath and heated in a water bath. React under magnetic stir...

Embodiment 13-14

[0100] Examples 13-14: Preparation of multifunctional polar polyolefin metal Fe complex materials and testing of their mechanical properties and scratch repair properties

[0101] (1) Preparation:

[0102] Under a nitrogen atmosphere, in a 100 mL reaction flask with a branch tube, dissolve 3 g of the multifunctional polyolefin material prepared in Example 11 or 12 above in 60 mL of tetrahydrofuran heated to 40 ° C by a water bath, and then add 1 mL of / L of ferric nitrate nonahydrate (FeNO 3 9H 2 (2) After the aqueous solution (deionized water) was mixed uniformly by magnetic stirring, the sodium hydroxide aqueous solution of 2.25mol / L was added dropwise to a pH value of about 8. Then filter under reduced pressure to obtain a solid precipitate, wash three times with 15ml of methanol, and dry it in a vacuum oven at 50°C to obtain the desired Fe complex material (expressed as E / Eug-Si(0.1) / Hex (4)-HCL-Fe).

[0103] (2) Mechanical performance test:

[0104] The obtained mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com