Method of manufacturing rotating body of torque converter and rotating body of torque converter manufactured by the manufacturing method

A technology of torque converter and manufacturing method, which is applied in the direction of manufacturing tools, fluid transmission devices, transmission device control, etc., and can solve the problems of durability, strength reduction, uneven strength of driven plate, loss of characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

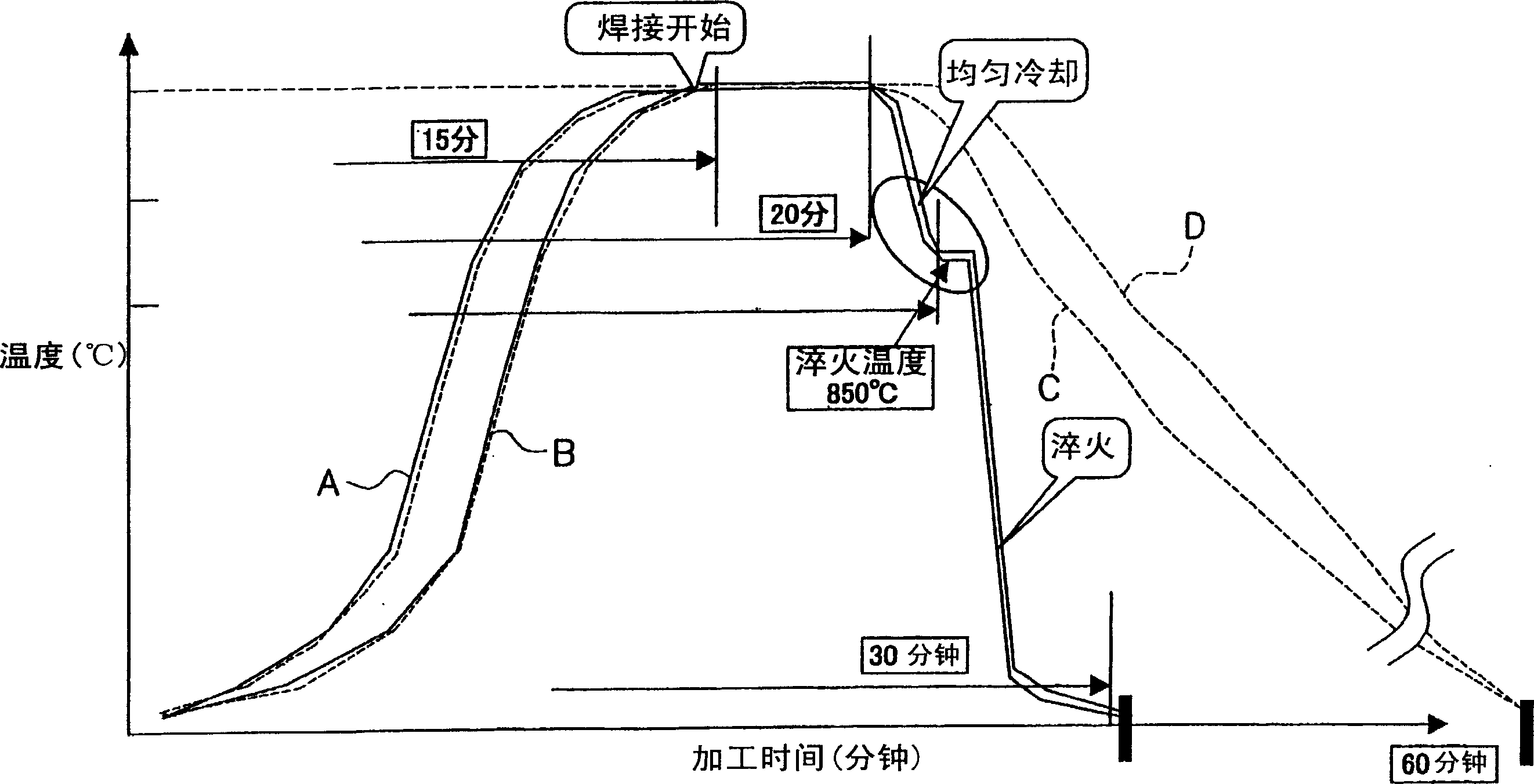

[0041] The present invention will be specifically described below based on examples.

[0042] Here, the degree of performance recovery of the volute of the rotating body and the turbine blade obtained by the manufacturing method of the present invention was evaluated according to the following procedure.

[0043] First, two types of test pieces (a tensile test piece and an impact test piece) were produced from the same material (SPHC) as the above-mentioned volute and turbine blades. The tensile test piece is a No. 5 tensile test piece (sheet thickness: 1.49 to 1.59 mm) prepared in accordance with JIS Z 2201. The impact test piece is a 2V test piece (thickness of 4.75-4.87mm of 3 overlapping plates) prepared in accordance with JIS Z 2202.

[0044] Next, three treatments were performed on each test piece: 1) without any heat treatment; 2) only brazing; 3) quenching was performed on the basis of brazing. During the quenching of 3), tempering was also performed.

[0045] In br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com