Self-repairing waterborne polyurethane film and preparation method thereof

A water-based polyurethane and self-repairing technology, which is applied in the field of self-repairing material preparation, can solve problems such as product value damage, mechanical property damage, accidental impact or scratches, etc., and achieve recovery of mechanical properties, good mechanical properties, and low VOC. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method for self-repairing water-based polyurethane film, comprising the following steps:

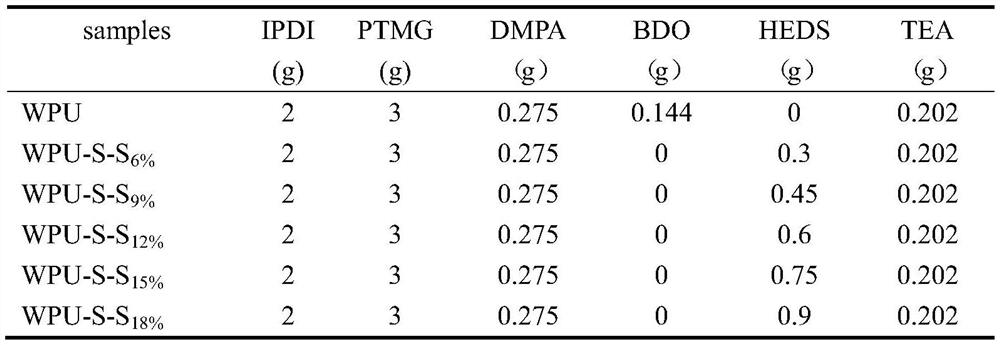

[0021] 1) Dissolve 3g of polytetrahydrofuran diol in 20mL of acetone after pumping water at 130°C, add 2g of isophorone diisocyanate and catalyst, and react at 70°C to 80°C for 2 hours to form a polyurethane prepolymer;

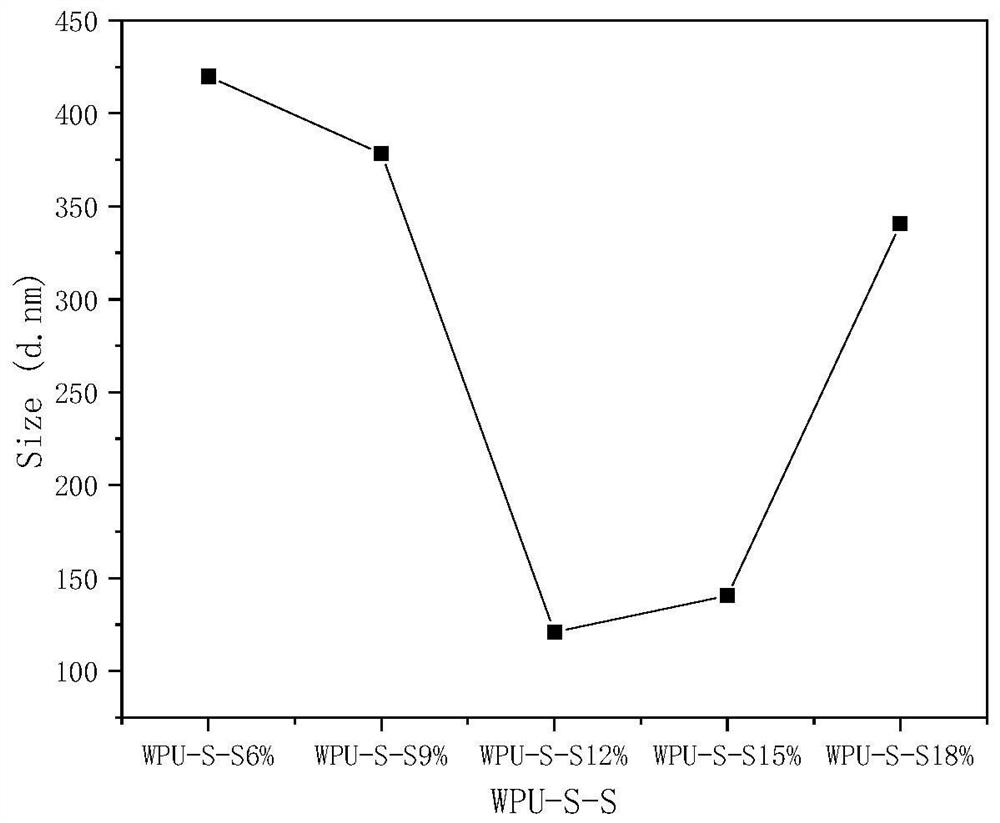

[0022] 2) After adding 5mL of N-methylpyrrolidone and 0.275g of 2,2-dimethylolpropionic acid to react for 2 hours, add 0.3-0.9g of 2-hydroxyethyl disulfide, cool to room temperature after two hours of reaction, and add 0.202g After reacting with triethylamine for 2-3 minutes, add 15 mL of water dropwise while stirring at a high speed to obtain a self-healing water-based polyurethane emulsion;

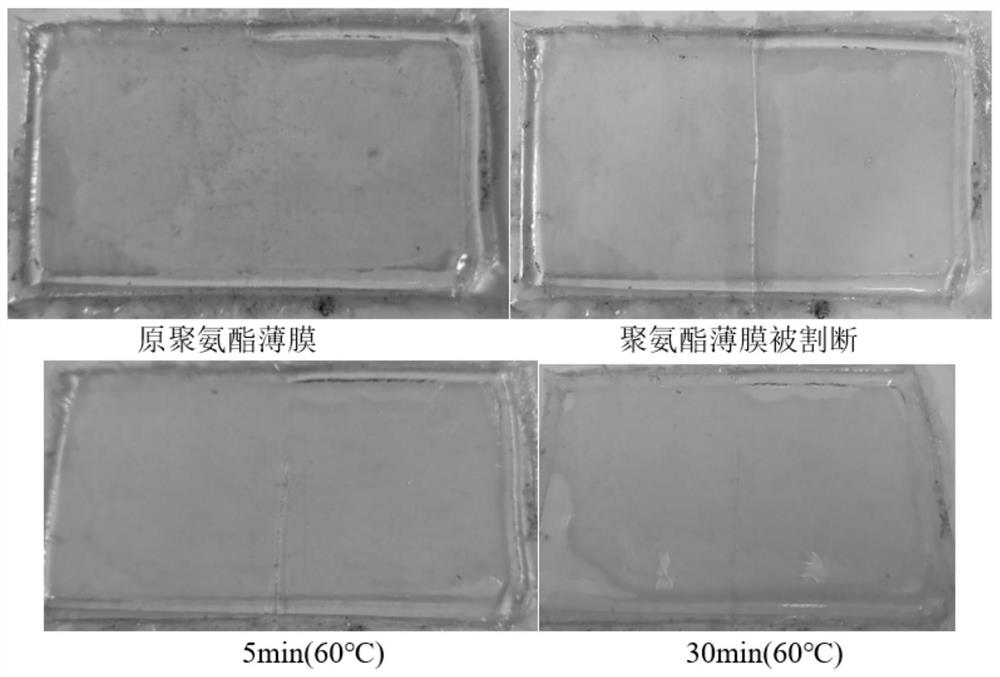

[0023] 3) Pouring the self-healing water-based polyurethane emulsion on the PTFE board and drying it at 40°C for two hours, then adding an appropriate amount of self-healing water-based polyurethane emulsion as needed, generally 4-5ml, and raising the tempera...

Embodiment 1

[0028] A preparation method for self-repairing water-based polyurethane film, comprising the following steps:

[0029] 1) Dissolve 3g of polytetrahydrofuran diol in 20mL of acetone after pumping water at 130°C, add 2g of isophorone diisocyanate and catalyst, and react at 70°C to 80°C for 2 hours to form a polyurethane prepolymer;

[0030] 2) After adding 5mL of N-methylpyrrolidone and 0.275g of 2,2-dimethylolpropionic acid to react for 2 hours, add 0.3g of 2-hydroxyethyl disulfide, react for two hours and cool down to room temperature, add 0.202g of triethyl After amine reaction for 2-3 minutes, add 15mL of water dropwise while stirring at a high speed to obtain a self-healing water-based polyurethane emulsion;

[0031] 3) Pouring self-healing water-based polyurethane emulsion on the PTFE board and drying at 40°C for two hours, then adding an appropriate amount of self-healing water-based polyurethane emulsion, after two hours, raising the temperature to 70°C and drying for 24...

Embodiment 2

[0033] A preparation method for self-repairing water-based polyurethane film, comprising the following steps:

[0034] 1) Dissolve 3g of polytetrahydrofuran diol in 20mL of acetone after pumping water at 130°C, add 2g of isophorone diisocyanate and catalyst, and react at 70°C to 80°C for 2 hours to form a polyurethane prepolymer;

[0035] 2) After adding 5mL of N-methylpyrrolidone and 0.275g of 2,2-dimethylol propionic acid to react for 2 hours, add 0.45g of 2-hydroxyethyl disulfide, react for two hours and cool down to room temperature, add 0.202g of triethyl After amine reaction for 2-3 minutes, add 15mL of water dropwise while stirring at a high speed to obtain a self-healing water-based polyurethane emulsion;

[0036] 3) Pouring self-healing water-based polyurethane emulsion on the PTFE board and drying at 40°C for two hours, then adding an appropriate amount of self-healing water-based polyurethane emulsion, after two hours, raising the temperature to 70°C and drying for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com