Tantalum and aluminum capacitor and preparation method thereof

A capacitor and electrode technology, applied in the manufacture of electrolytic capacitors, capacitors, electrolytic capacitors, etc., can solve problems such as internal dislocation damage and reduced safety performance, and achieve the effect of improving overall safety and restoring mechanical and electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

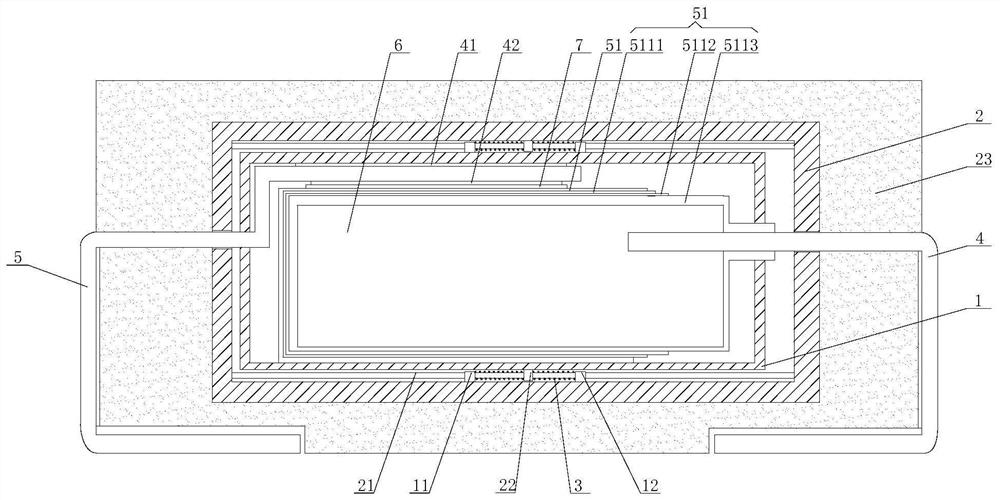

[0026] see figure 1 , a tantalum capacitor, including an inner shell 1 and an outer shell 2, the outer shell 2 covers the outside of the inner shell 1, a group of mutually symmetrical front plates 11 and rear plates 12 are respectively installed on the four side walls of the inner shell 1, and the inner wall of the outer shell 2 There is a limit rod 21 that runs through the front plate 11 and the rear plate 12. The outside of the housing 2 is also coated with epoxy resin 23. The limit rod 21 is fixed on the outer wall between the front plate 11 and the rear plate 12. The middle plate 22 connected to the outer shell 2, the spring 3 that is sleeved on the limit rod 21 is connected between the middle plate 22, the front plate 11 and the rear plate 12, and the setting of the spring 3 can make the connection between the inner shell 1 and the outer shell 2 An elastic connection method is formed. When a large relative shaking may occur between the inner shell 1 or the outer shell 2, ...

Embodiment 2

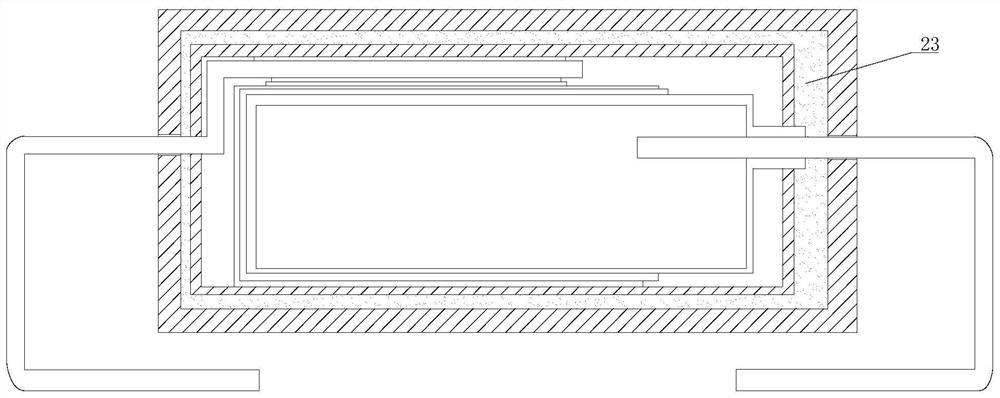

[0036] see figure 2 The inner shell 1 and the outer shell 2 in the aluminum capacitor are components made of aluminum material, the epoxy resin 23 is filled inside the inner shell 1 and the outer shell 2, and the positive terminal electrode 4 and the negative terminal electrode 5 are connected to the outer wall of the shell 2. There is an insulating tube, and an insulating adhesive 41 is filled in the gap between the positive terminal electrode 4 and the negative terminal electrode 5 and the inner shell 1 and the outer shell 2, including the inner shell 1 and the outer shell 2, and the outer shell 2 covers the outside of the inner shell 1, The negative end electrode 5 is located on the top outer wall of the port in the inner shell 1 and is coated with an insulating adhesive 41 fixed with the inner shell 1 for insulation treatment. The outer wall of the port bottom of the negative end electrode 5 is coated with silver glue 42. While carrying out firm connection between the neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com