Organic-inorganic composite cement-based self-healing agent based on authigenic healing as well as preparation method and application thereof

A self-healing and inorganic composite technology, which is applied in the field of drilling and cementing in oilfield development, can solve problems such as unreported preparation methods, and achieve the effects of improving self-healing efficiency, high interface adhesion, and improving matrix compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

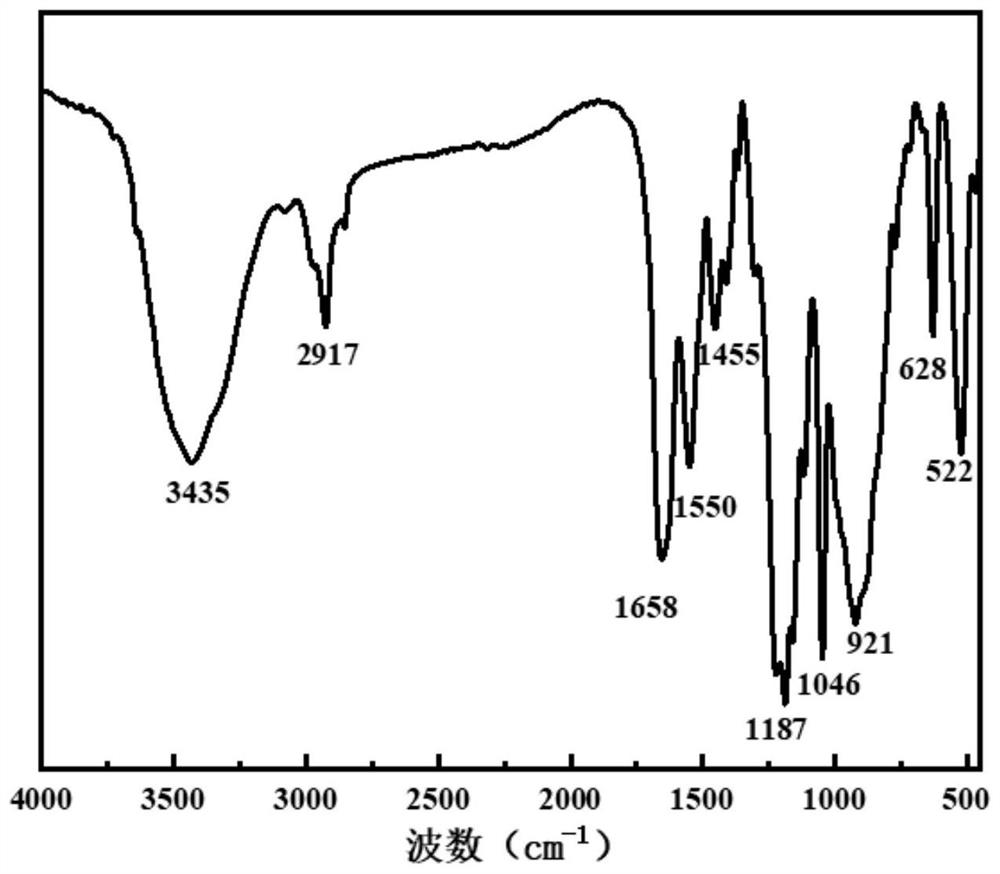

[0037] The preparation method of the organic-inorganic composite cement-based self-healing agent based on self-healing comprises the following steps:

[0038] (1) Dissolve 17.80 parts of 2-acrylamido-2-methylpropanesulfonic acid and 1.15 parts of acrylic acid in 101 parts of distilled water in order by mass, adjust the pH to 6, then add 4.60 parts of acrylamide, stir and heat up to 55°C , to obtain a mixed solution;

[0039] (2) Add 0.30 parts of silane coupling agent γ-methacryloxypropyltrimethoxysilane (KH-570) into 5 parts of absolute ethanol, and stir evenly to obtain a silane coupling agent solution; Agent potassium persulfate was added to 20 parts of distilled water, and stirred uniformly to obtain an initiator solution;

[0040] (3) Under stirring, drop the silane coupling agent solution and the initiator solution into the mixed solution at the same time; adjust the temperature to 75° C., and react for 2.5 hours to obtain a light yellow viscous liquid;

[0041] (4) Un...

Embodiment 2

[0043] The preparation method of the organic-inorganic composite cement-based self-healing agent based on self-healing comprises the following steps:

[0044](1) Dissolve 17.25 parts of 2-acrylamido-2-methylpropanesulfonic acid and 1.2 parts of itaconic acid in 110 parts of distilled water in order by mass, adjust the pH to 5.5, and then add 5.10 parts of acrylamide monomer N , N-dimethylacrylamide, stirred and heated to 50°C to obtain a mixed solution;

[0045] (2) Add 0.36 parts of silane coupling agent vinyltriethoxysilane to 4 parts of absolute ethanol, and stir evenly to obtain a silane coupling agent solution; add 0.12 parts of initiator azobisisobutylamidine hydrochloride to 12 Parts of distilled water, stirred evenly to obtain the initiator solution;

[0046] (3) Under stirring, drop the silane coupling agent solution and the initiator solution into the mixed solution obtained in step (1) at the same time; react at 70° C. for 4 hours to obtain a light yellow viscous l...

Embodiment 3

[0049] The preparation method of the organic-inorganic composite cement-based self-healing agent based on self-healing comprises the following steps:

[0050] (1) Dissolve 18.60 parts of 2-acrylamido-2-methylpropanesulfonic acid and 0.75 parts of maleic anhydride in 95 parts of distilled water in order by mass, adjust the pH to 7, and then add 4.20 parts of acrylamide monomer propylene Amide, stirred and heated to 60 ° C to obtain a mixed solution;

[0051] (2) Add 1.80 parts of silane coupling agent vinyltriisopropoxysilane into 8 parts of absolute ethanol, and stir evenly to obtain a silane coupling agent solution; add 0.168 parts of initiator azobisisobutylamidine hydrochloride 23 parts of distilled water, stirred evenly to obtain initiator solution;

[0052] (3) Under stirring, drop the silane coupling agent solution and the initiator solution into the mixed solution obtained in step (1) at the same time; react at 80° C. for 2 hours to obtain a light yellow viscous liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com