A kind of preparation method of quantum dot photodetector

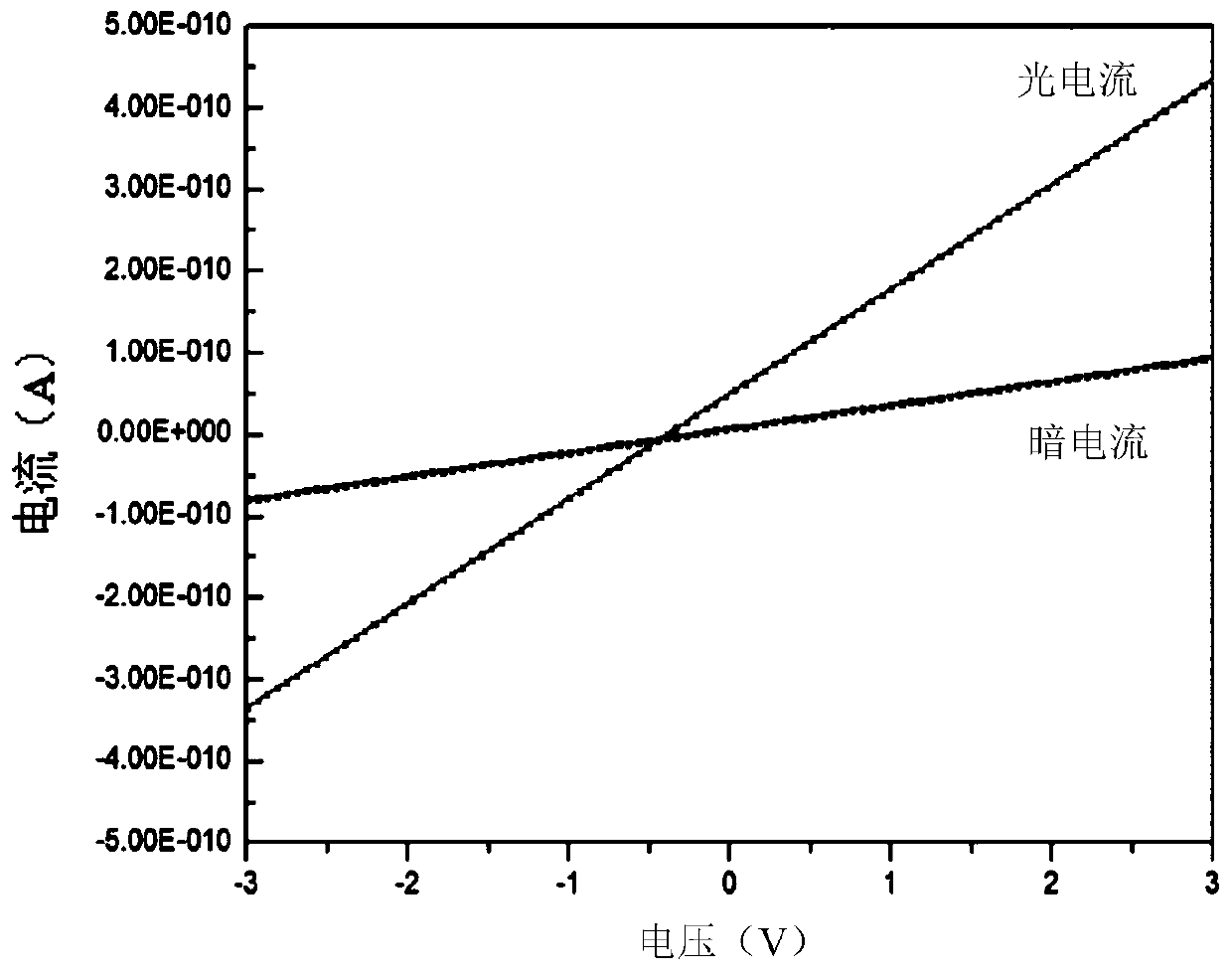

A photodetector and quantum dot technology, applied in photovoltaic power generation, electric solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficult operation, slow response time, and long response time, and achieve high light-to-dark current ratio , Guarantee the effect of uniformity and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

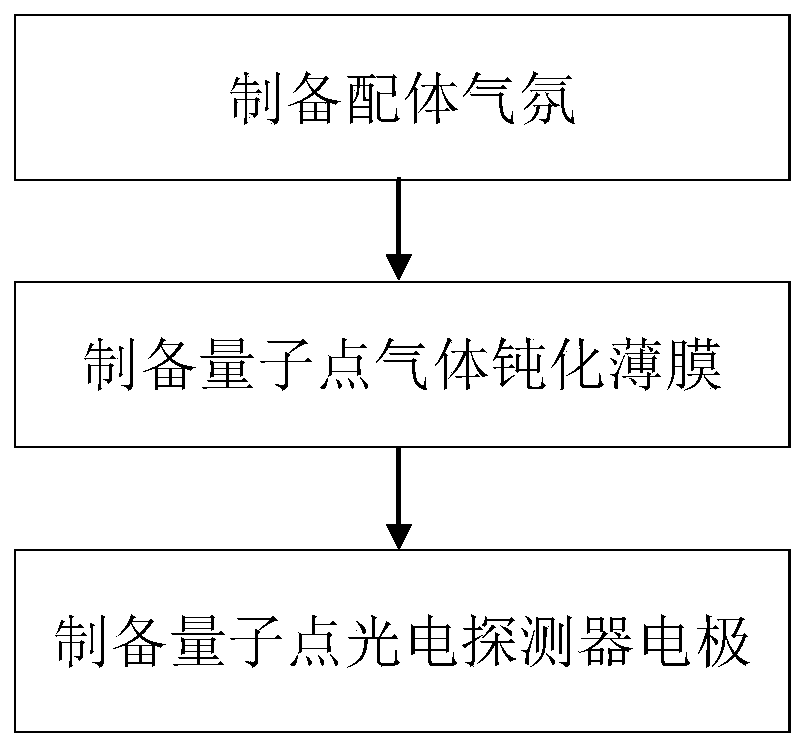

[0042] Such as figure 1 As shown, a method for preparing a quantum dot photodetector provided by an embodiment of the present invention includes the following steps:

[0043] S1 preparation of ligand atmosphere

[0044] The organic ligand is dissolved in a solvent to form a ligand solution, so that the ligand solution fills the entire closed space in the form of gas, and then the ligand atmosphere is prepared, including the following sub-steps:

[0045] S11 is equipped with a ligand solution with a concentration of 1mg / ml~100mg / ml (mg per milliliter), and then put the ligand solution into a closed container filled with an inert gas. The inert gas is preferably one or more of nitrogen and argon. kind;

[0046] S12 Adjust the temperature and pressure in the airtight container so that the concentration of the gas in the airtight container reaches the required concentration. Specifically, the temperature and pressure will affect the saturated vapor pressure of the ligand gas. By...

Embodiment 1

[0064] 1) Prepare a ligand solution with a concentration of 1mg / mL, and then put the ligand solution into a closed container filled with nitrogen protection, wherein the organic ligand is MPA, and the solvent is toluene;

[0065] 2) At 30°C, 10 4 Under the condition of Pa, make the ligand fill the whole airtight container, and make the gas concentration reach 50mg / L;

[0066] 3) The glass substrate was ultrasonically cleaned in acetone, ethanol and water for 10 minutes respectively, and then the glass substrate was blown dry with nitrogen;

[0067] 4) activating the glass substrate with a plasma cleaning machine for 30 minutes in an oxygen atmosphere to activate the surface of the substrate;

[0068] 5) configure a PbSe quantum dot solution with a concentration of 1 mg / ml, and use this as a raw material for preparing quantum dot photodetectors;

[0069] 6) heating the glass substrate at 100° C. for 1 h to remove residual impurities of the substrate;

[0070] 7) Set the rota...

Embodiment 2

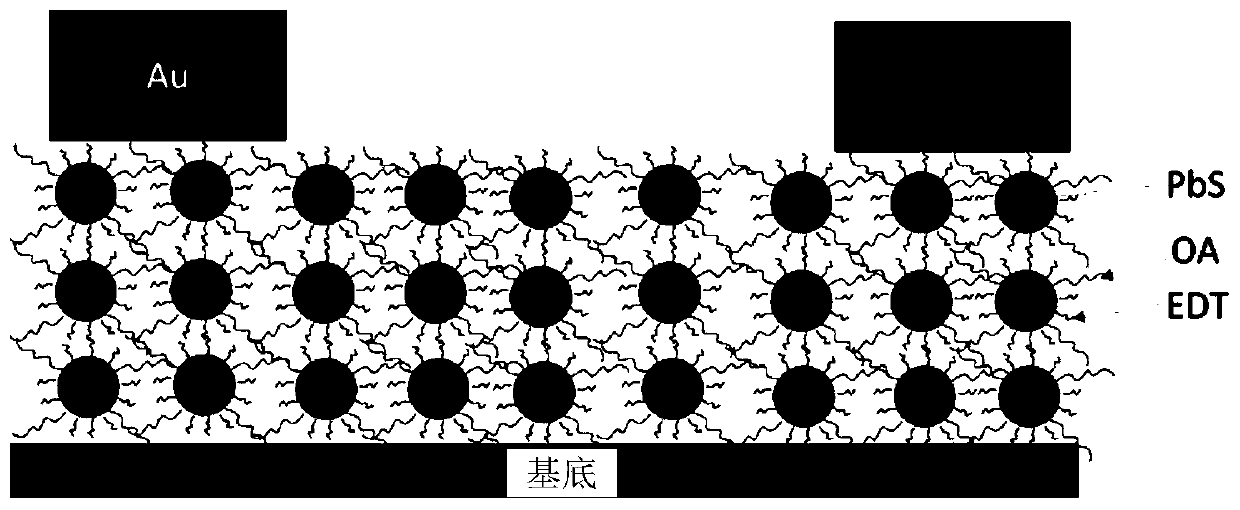

[0076] 1) Prepare a ligand solution with a concentration of 50mg / mL, and then put the ligand solution into an airtight container filled with argon protection, in which the organic ligand is EDT, and the solvent is chloroform;

[0077] 2) At 20°C, 10 5 Under the condition of Pa, make the ligand fill the whole airtight container, and make the gas concentration reach 1mg / L;

[0078] 3) The glass substrate was ultrasonically cleaned in acetone, ethanol and water for 5 minutes respectively, and then the glass substrate was blown dry with nitrogen;

[0079] 4) activating the glass substrate in an oxygen atmosphere for 10 minutes using a plasma cleaning machine to activate the surface of the substrate;

[0080] 5) Prepare CsPbCl with a concentration of 7mg / ml 3 Quantum dot solution, which is used as a raw material for preparing quantum dot photodetectors;

[0081] 6) heating the glass substrate at 50° C. for 2 hours to remove residual impurities of the substrate;

[0082] 7) Set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com