A kind of soil heavy metal composite stabilizer and its passivation method to soil heavy metal

A composite stabilizer and heavy metal technology, applied in chemical instruments and methods, restoration of polluted soil, soil conditioning materials, etc., can solve the problems of large demand for phosphate fertilizer addition, single stabilization effect, and restrictions on wider application, etc. Reduce harm, realize the effect of resource utilization, preparation and use methods are simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

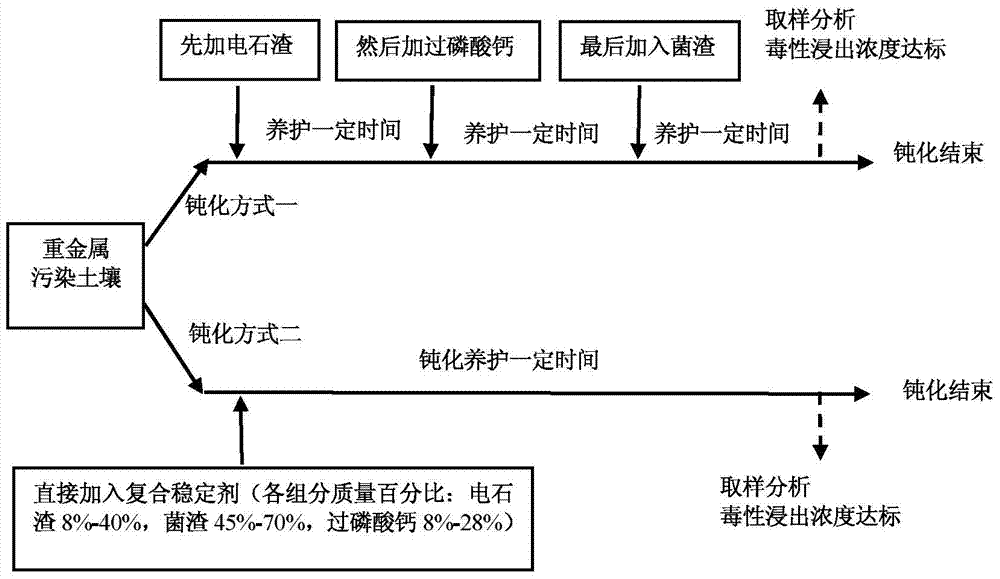

Method used

Image

Examples

Embodiment 1

[0055] A soil heavy metal pollution composite stabilizer comprises the following components, each component is by mass percentage:

[0056] Carbide slag 35%, fungus slag 57% and superphosphate 8%.

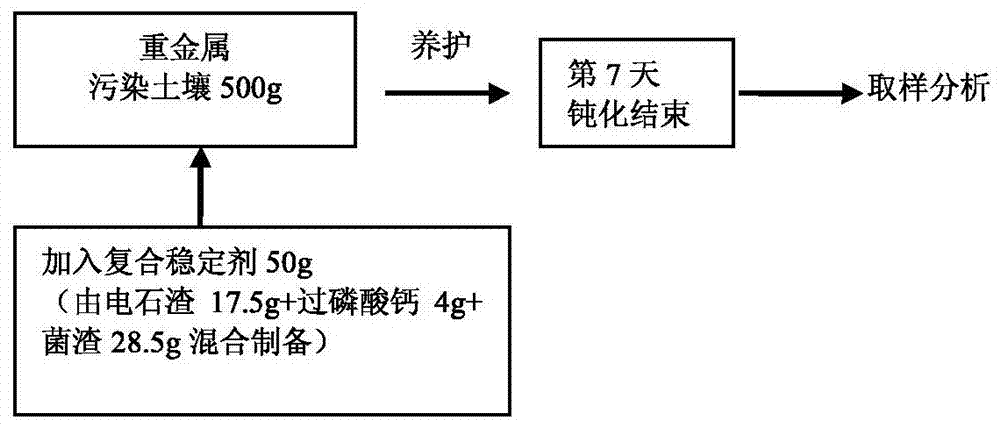

[0057] The passivation method of the soil heavy metal composite stabilizer to soil heavy metals is a complete mixed treatment method, comprising the following steps:

[0058] Step 1, mixing 17.5g of calcium carbide slag, 28.5g of fungus residue and 4g of superphosphate, fully stirring to obtain a composite stabilizer;

[0059] Step 2. Mix 50 g of the composite stabilizer in step 1 with 500 g of soil polluted by heavy metals, stir evenly, add 40% water according to the air-dried quality of the soil, and keep the soil at a certain humidity;

[0060] Step 3: After 7 days of reaction, the heavy metal ions in the polluted soil are transformed into relatively stable basic carbonates, hydroxide precipitates, phosphate minerals and insoluble heavy metal-organic complexes. The leaching to...

Embodiment 2

[0064] A soil heavy metal pollution composite stabilizer comprises the following components, each component is by mass percentage:

[0065] Carbide slag 35%, fungus slag 57% and superphosphate 8%.

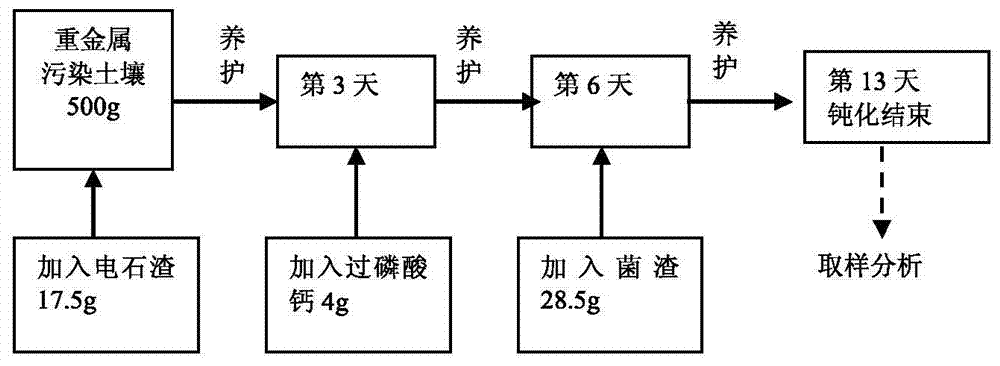

[0066] The passivation method of the soil heavy metal composite stabilizer to soil heavy metals is a separate dosing method, comprising the following steps:

[0067] Step 1. Mix 17.5g of calcium carbide slag with 500g of soil polluted by heavy metals, stir evenly, passivation is stable for 3 days, add 40% water according to the air-dried quality of the soil, and keep the soil at a certain humidity;

[0068] Step 2, mix 4g of superphosphate with the mixture obtained in step 1, stir evenly, passivation is stable for 3 days, and keep the soil moisture content the same as step 1;

[0069] Step 3: Mix 28.5g of the fungus residue with the mixture obtained in Step 2, stir evenly, passivation is stable for 7 days, keep the soil moisture content the same as Step 1, and the heavy metal ions...

Embodiment 3

[0074] Effects of different ratios of compound stabilizers on the stabilization efficiency of heavy metals in soil:

[0075] A soil heavy metal composite stabilizer is composed of the following three raw materials in different mass percentages:

[0076] Table 3 Composite stabilizers with different ratios

[0077]

[0078] The passivation method of the soil heavy metal composite stabilizer to soil heavy metals is a complete mixed treatment method, comprising the following steps:

[0079] Step 1, mix calcium carbide slag, fungus slag and superphosphate according to the ratio of above-mentioned table 3, fully stir and make composite stabilizer;

[0080] Step 2. Mix 55.55 g of the composite stabilizer in step 1 with 500 g of soil polluted by heavy metals, stir evenly, add 40% water according to the air-dried quality of the soil, and keep the soil at a certain humidity;

[0081] Step 3: After 7 days of reaction, the heavy metal ions in the polluted soil are transformed into re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com