Test device of model for manufacturing rock masses containing interlayers and test method thereof

A model test device and interlayer technology, which is applied in the measurement device, the use of mechanical devices, the preparation of test samples, etc., can solve the problem of correct simulation reliability affecting the stable process of geotechnical engineering, and the inability to simulate the reality of rock mass joints containing interlayers. state, can not reflect the characteristics of rock deformation, etc., to achieve the effect of speeding up the test progress, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

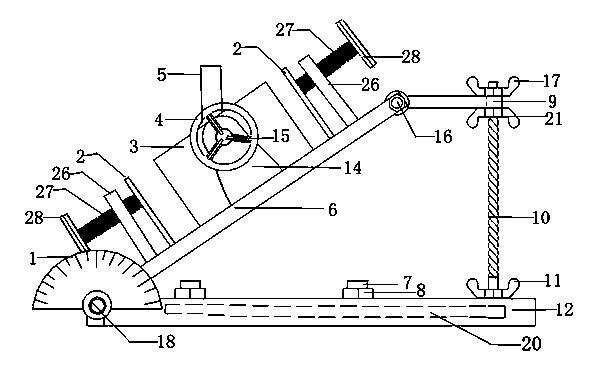

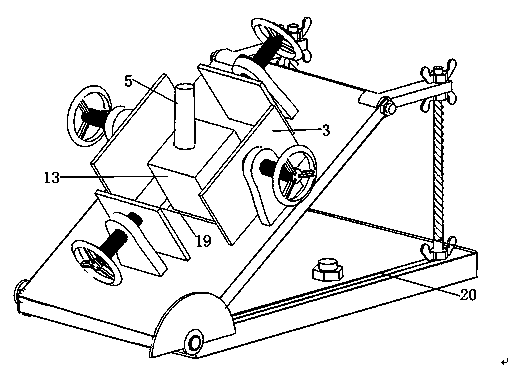

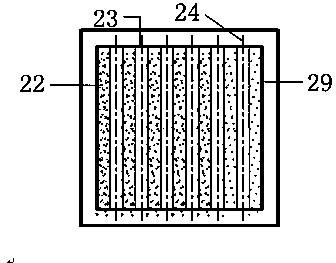

[0033] Such as figure 1 and figure 2As shown, the present invention includes a semicircle angler 1, upper and lower baffle plates 2, left and right side plates 3, a circular turntable 4, a corer drill bit 5, a flat plate 6, a flat plate angle control rod 9, a fixed screw 10, a base plate 12, Sandwich model test piece 13, U-shaped plate 14, U-shaped plate 26 and guide groove 20, U-shaped plate 26 and U-shaped plate 14 are vertically welded on the flat plate 6, and the upper and lower baffles 2 and the left and right side plates 3 are respectively connected through the On the screw rod 27 and the screw rod 15 of the U-shaped plate 26 and the U-shaped plate 14, and perpendicular to the flat plate 6, the front ends of the screw rod 27 and the screw rod 15 are respectively fixed with a circular rotating disk 28 and a circular rotating disk 4, by rotating the circular rotating disk 28 and The circular turntable 4 changes the position of the upper and lower baffles 2 and the left a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com