Test method for deep rock explosion process model

An experimental method and process model technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of simulating rockburst process, differences, and inability to explain rockburst phenomena well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

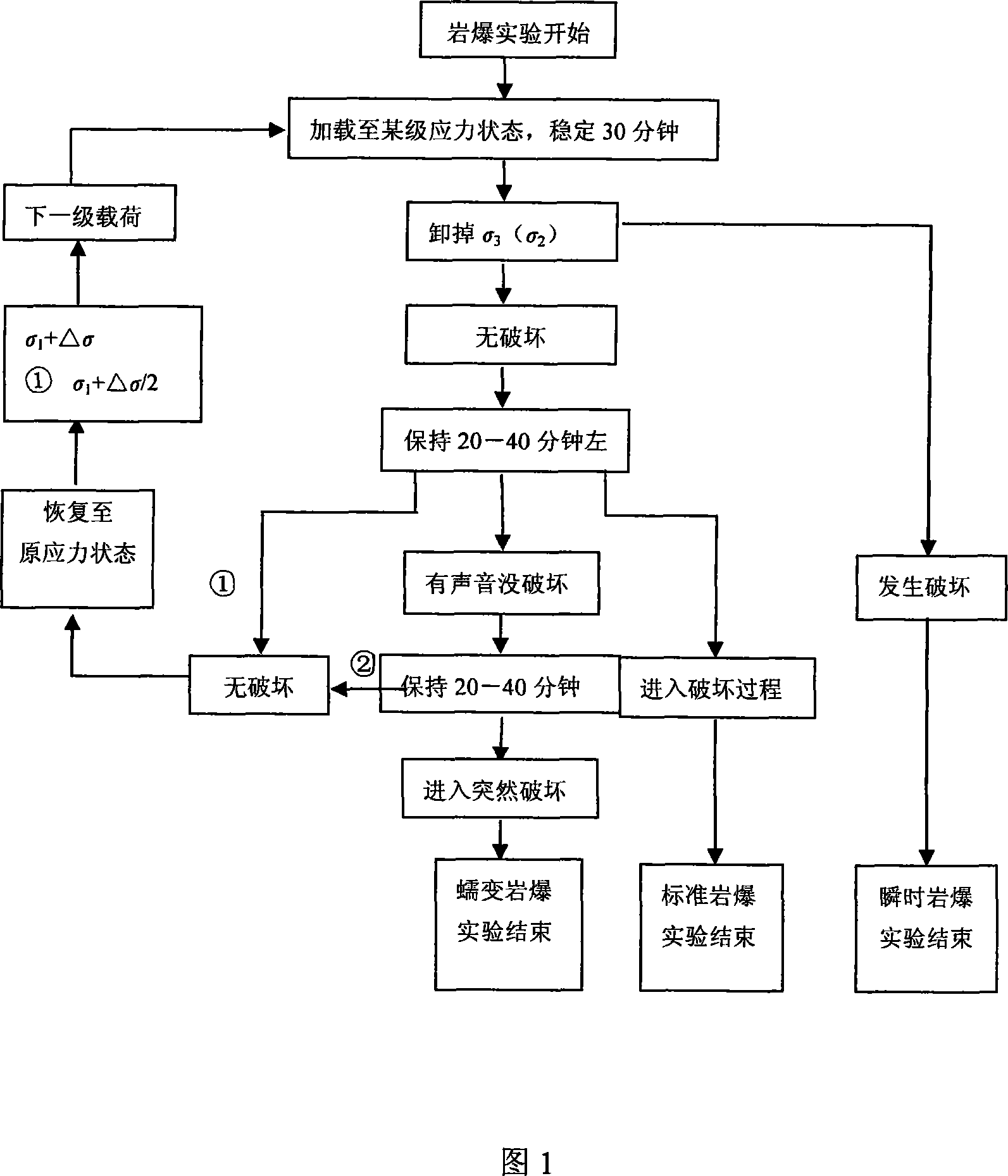

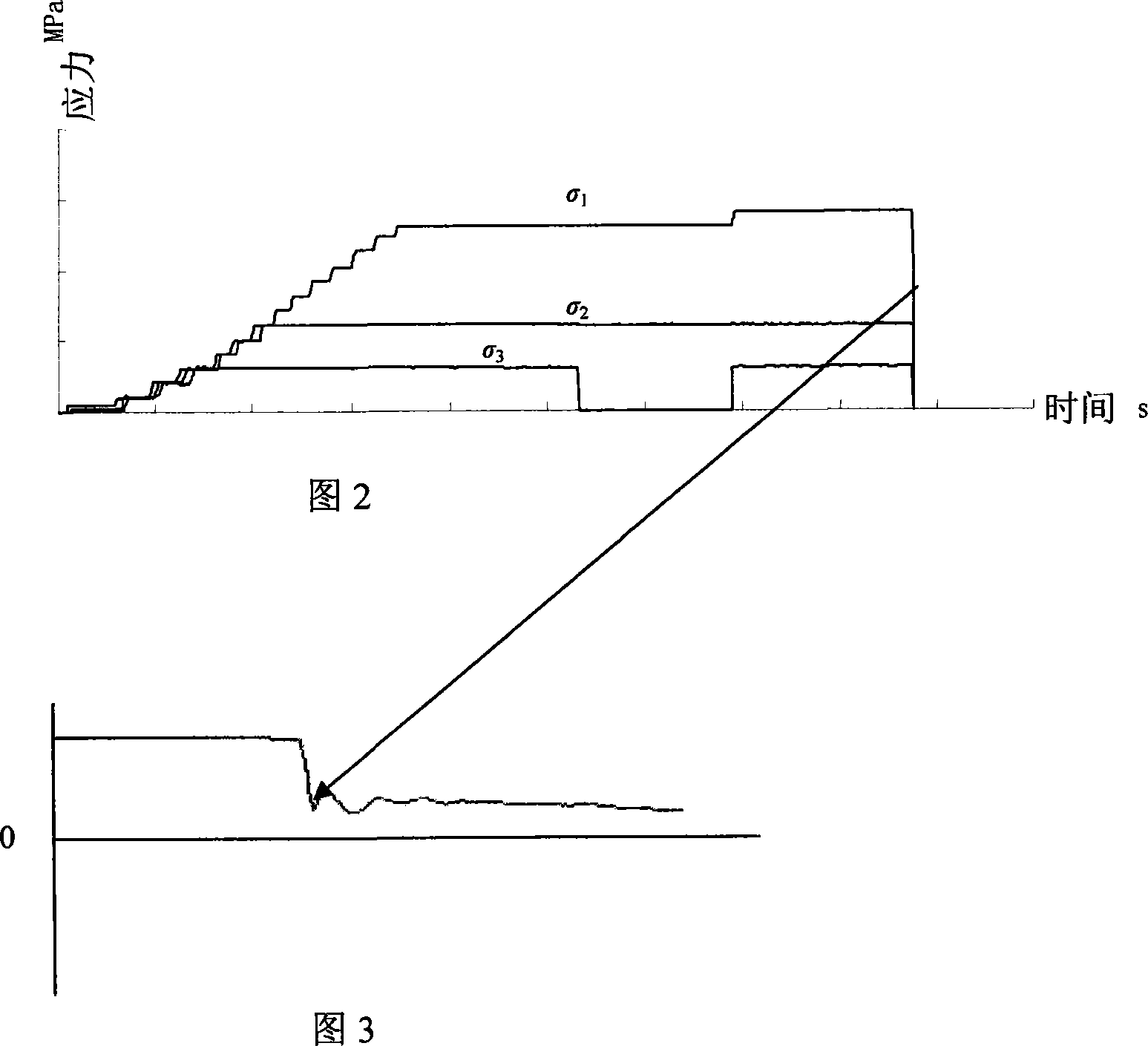

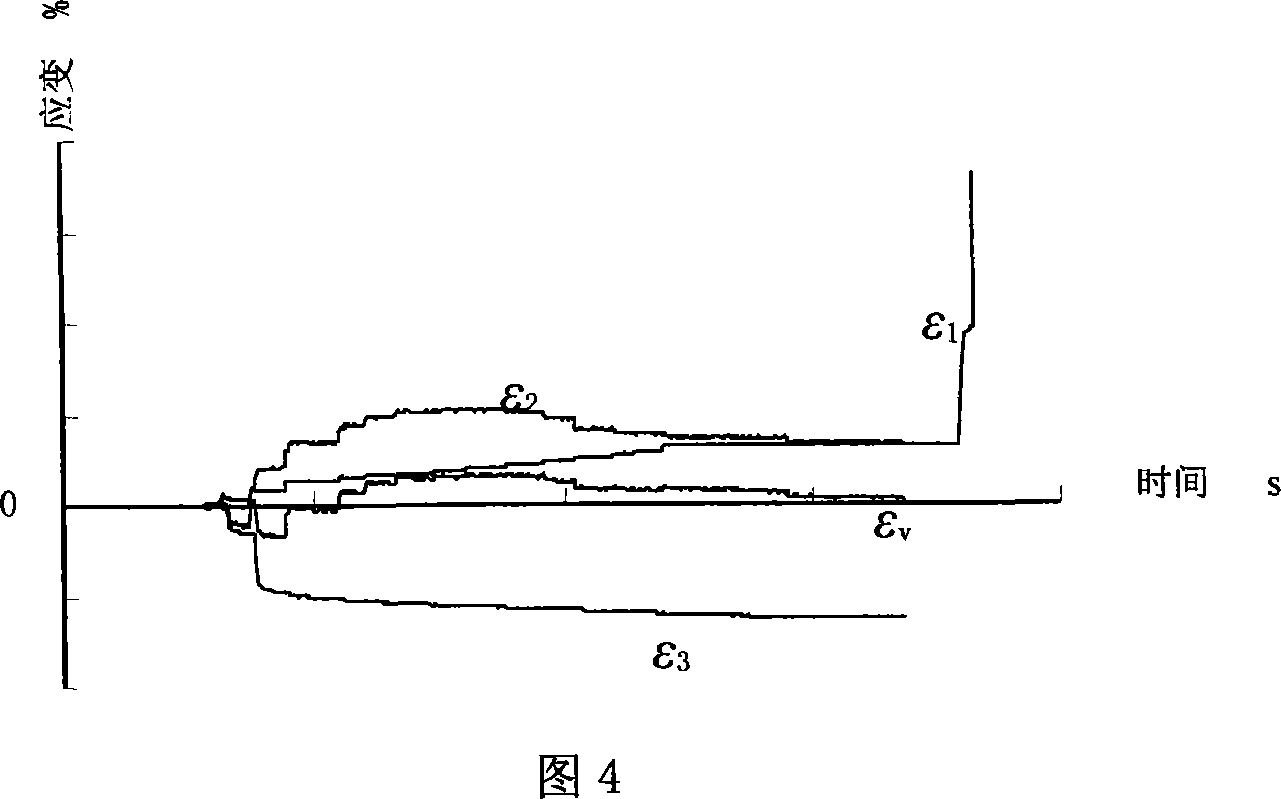

[0028] specific implementation plan

[0029] The actual situation when the rockburst occurs is: the on-site roadway is generally 3-4 meters high, and the depth of the rockburst is about 0.1 meters, which is about 1 / 30-1 / 40 of the depth of the roadway; the width of the rockburst is 1 / 8-1 / 8 of the roadway. 1 / 10, the height of the rockburst surface is approximately equal to the width; according to the above, the specimens designed for rockburst experiments are generally plate-shaped cuboids, called rockburst structures. Rockburst structures in different geology are not exactly the same. In this scheme, the maximum side length is about 150mm. In this example, 150mm×60mm×30mm is selected. In the actual experiment, it can be selected in the range of 150mm (±5mm)×60mm (±6mm)×30mm (±3mm). The error of the unevenness of the end surface of the length of the test piece shall not be greater than 0.05mm, the error of the height shall not be greater than 0.3mm, and the deviation of the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com