Fiber bragg grating (FBG) testing device and testing method for rock three-dimensional stress state

A technology of optical fiber grating and three-dimensional stress, which is applied in the direction of measuring the change force of its optical properties when the material is stressed, can solve the problems of not realizing the three-dimensional stress test, and achieve mine safety monitoring and prediction. Good for disasters, high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

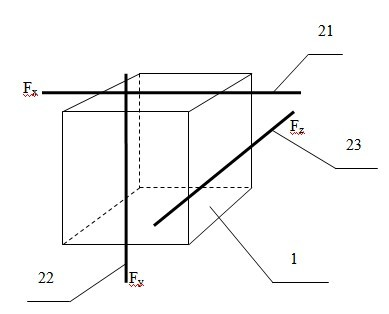

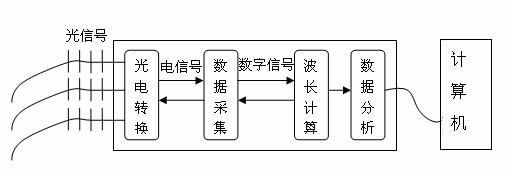

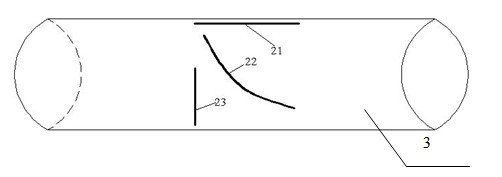

[0025] Such as figure 1 , figure 2 As shown, a test device for a rock three-dimensional stress state of the present invention includes a fiber grating network demodulator and a data processing module composed of a computer, as well as a fiber grating sensing structure, wherein the fiber grating sensing structure consists of three fiber grating sensors 21 . Glue is pasted on the three-dimensional direction of three adjacent surfaces of cube module 1; The signal output ends of three fiber grating sensors 21, 22, 23 are all connected with the signal input ends of the fiber grating network demodulator, and the fiber grating network demodulator The signal output terminal of the regulator is connected with the signal input terminal of the computer through the data line. The data processing module composed of the fiber grating network demodulator and computer is in the prior art, wherein the fiber grating network demodulator includes a photoelectric conversion module, a data acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com