Dynamic and static combined loading rock test machine and test method used for multiphase coupling

A rock testing machine and combined loading technology, which is applied in geotechnical engineering scientific research and mining engineering, can solve the problems of complex operation, single function, and inability to realize dynamic loading of coal and rock test pieces, and achieve the effect of simple operation and clear purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

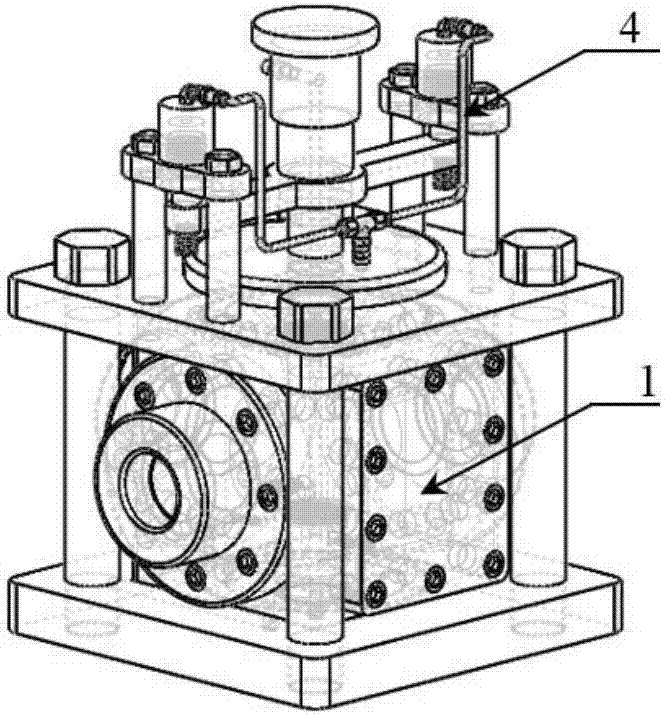

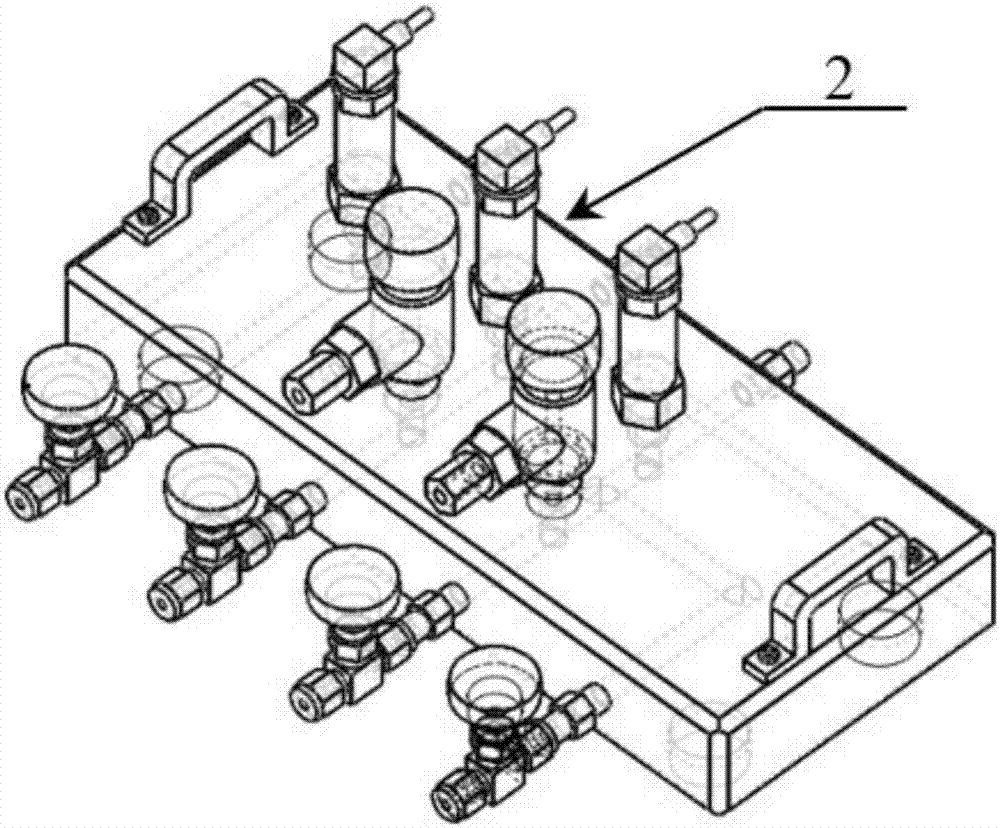

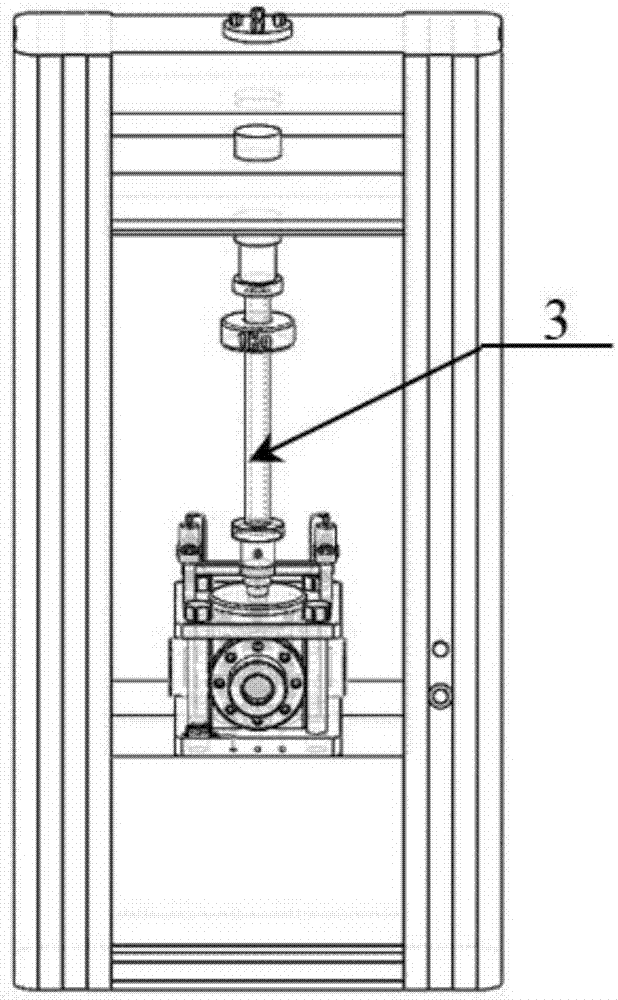

[0085] Such as figure 1 , figure 2 , image 3 Shown: The combined dynamic and static loading rock testing machine that can be used for multiphase coupling, including visual confining pressure loading chamber module 1, air pressure control module 2, dynamic loading module 3 and constant capacity module 4; each module has a clear division of power and cooperates with each other. The visual confining pressure loading chamber module 1 provides a visual test space for multi-phase coupling and triaxial loading of standard specimens; the air pressure control module 2 realizes the quantitative filling and control of the air pressure in each channel in the loading chamber; the dynamic loading module 3 completes the test specimen The dynamic impact test; the constant volume module 4 ensures that the volume of the reaction chamber is constant during the axial pressurization process to eliminate the interference of the pressure change on the test process. It can not only carry out high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com