Penetrated crack rock mass grouting slurry diffusion test method

A cracked rock mass and diffusion test technology, applied in the direction of diffusion analysis, measuring devices, instruments, etc., can solve the problems of lack of slurry diffusion law and its impact, and achieve the effect of reducing damage and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

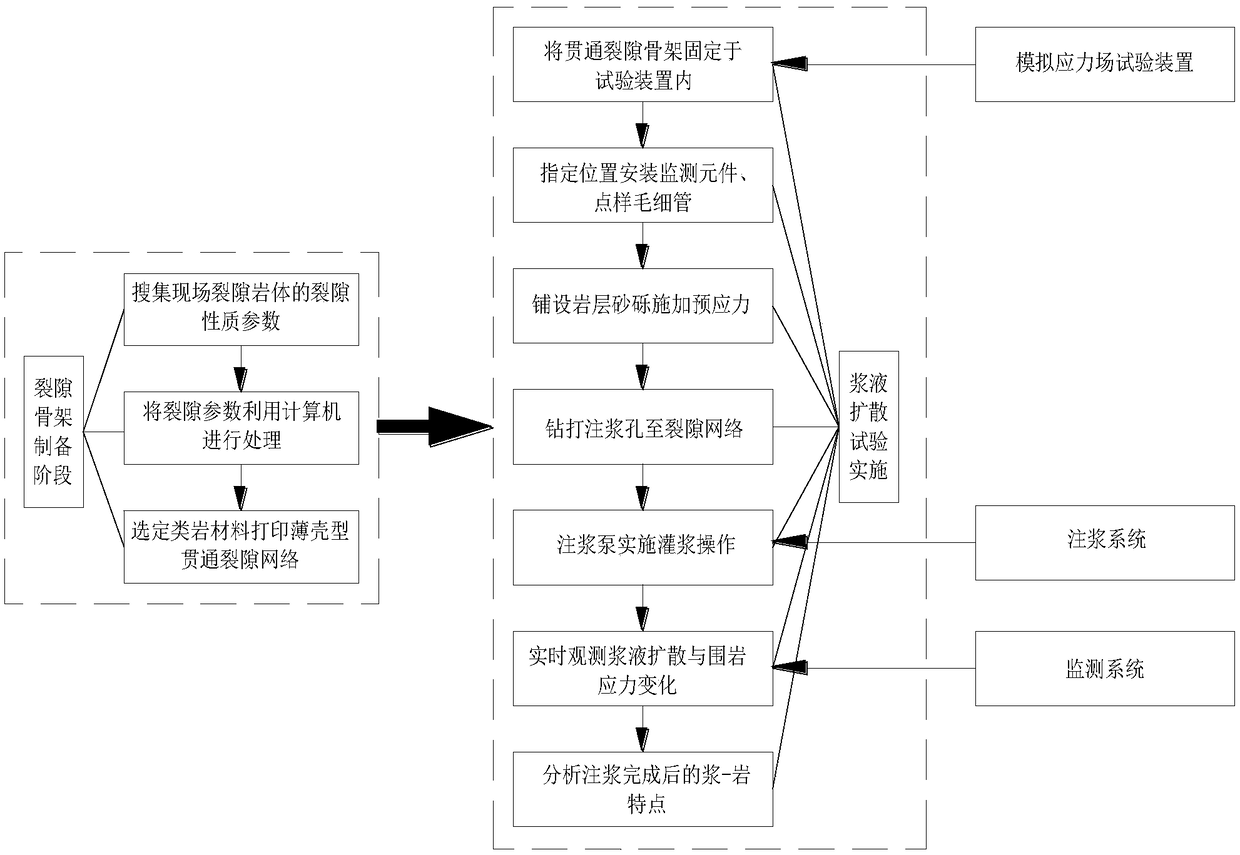

[0031] Such as figure 1 As shown, in addition to two major processes in the implementation of the entire test method: the preparation of through-cracks and the implementation of the slurry diffusion test, it also includes the comprehensive synergy of several external systems. The test device for simulating the in-situ stress field, which is the basic equipment for the test, provides a test site for the construction of the through-fissure rock mass and simulates the actual in-situ stress; the grouting system is composed of a grouting pump, a pipeline, and a grouting hole. The slurry is provided in the system; the monitoring system is composed of stress monitoring components, monitoring lines, thermal sensors, and PC terminals, and realizes real-time observation and stress monitoring of the diffusion of slurry in cracks.

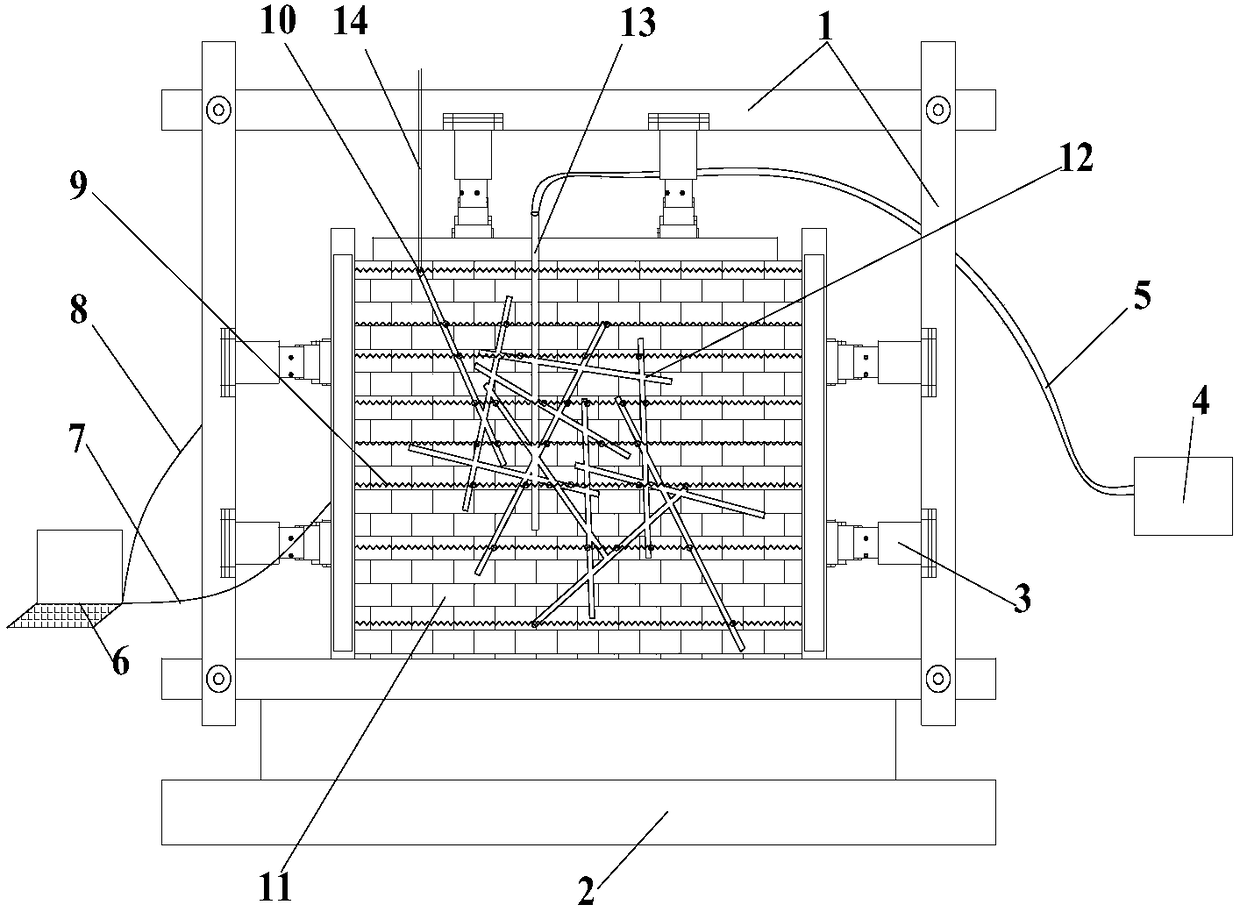

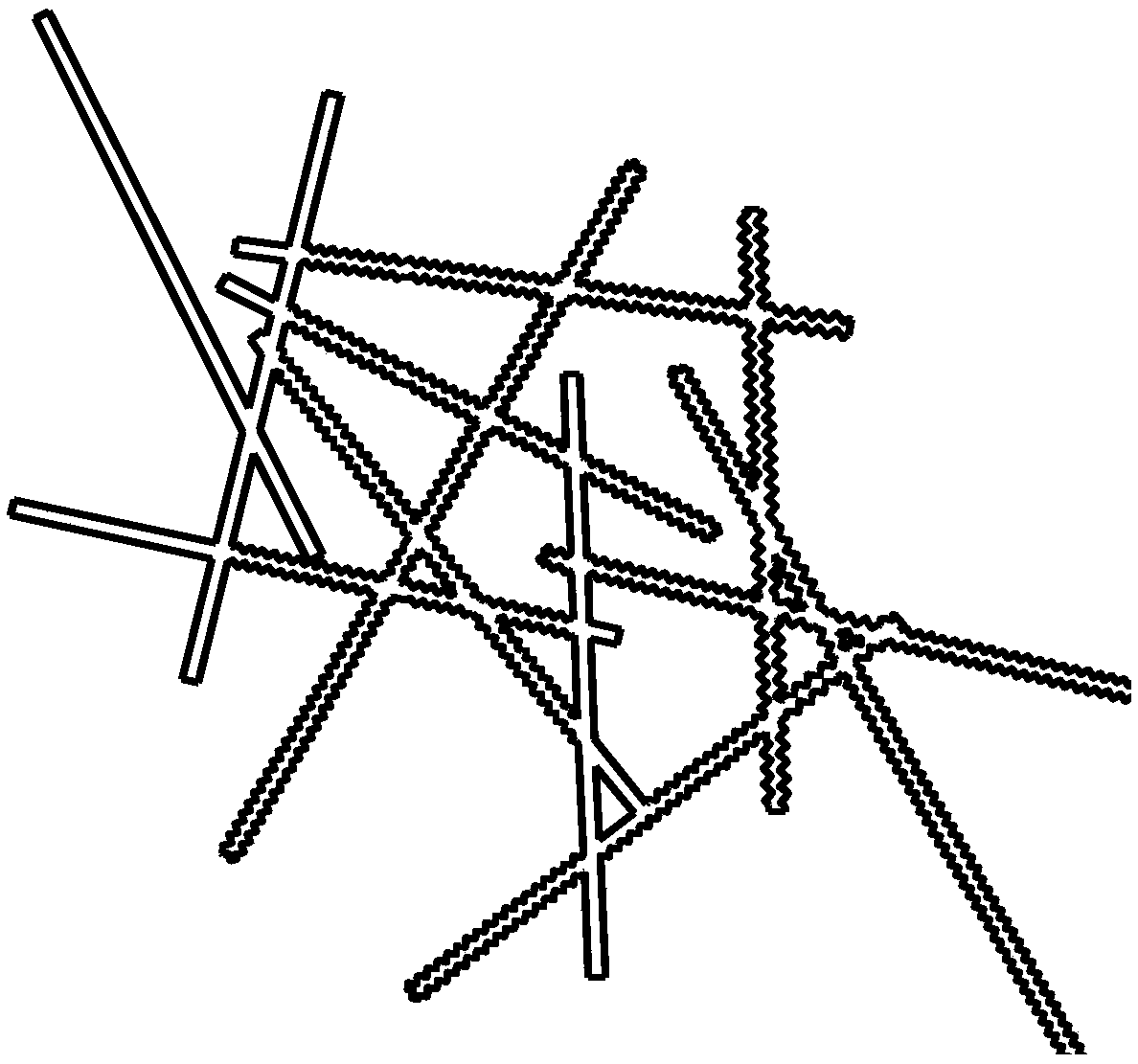

[0032] Such as figure 2 , 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com