Drilling method and drilling tool for step-by-step strengthening soft coal rock strength

A step-by-step strengthening and soft coal rock technology, which is applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of easy hole collapse and difficult drilling in soft coal rock drilling, so as to improve the depth and Drilling efficiency, prevention of borehole collapse, and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

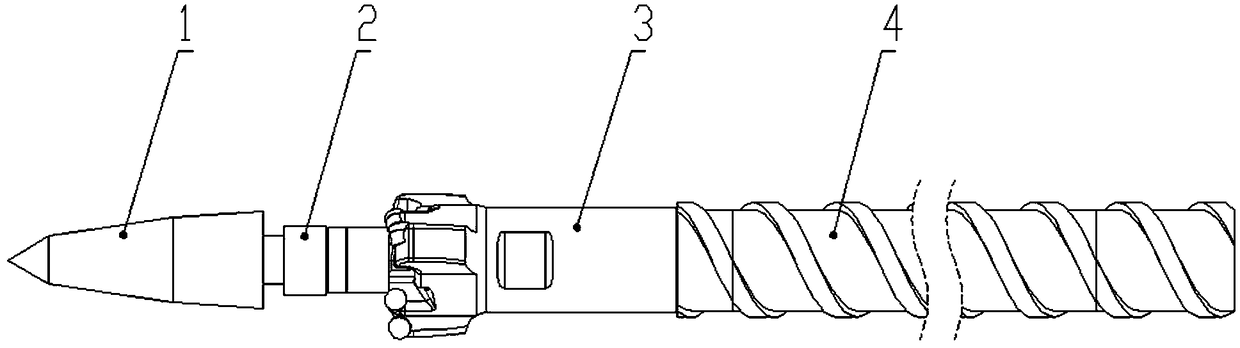

Image

Examples

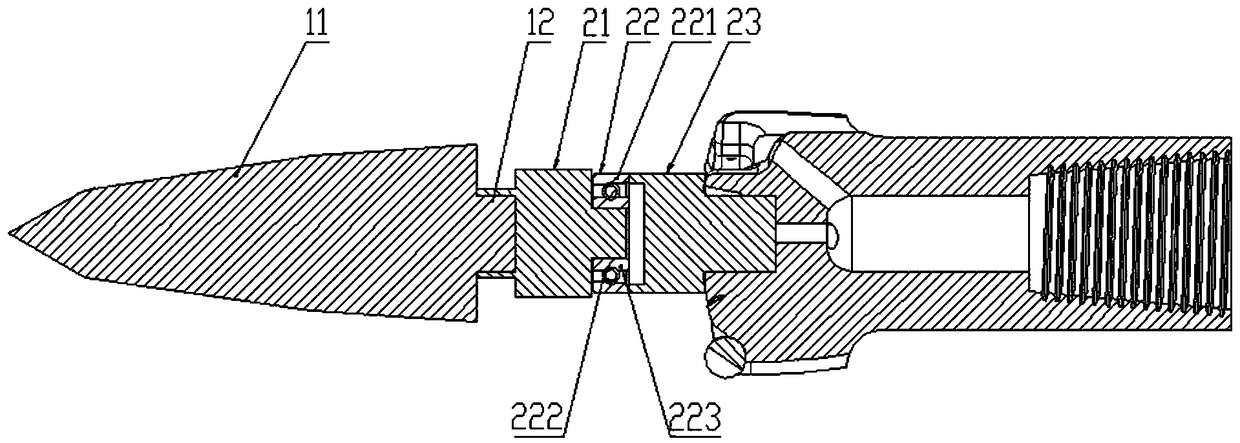

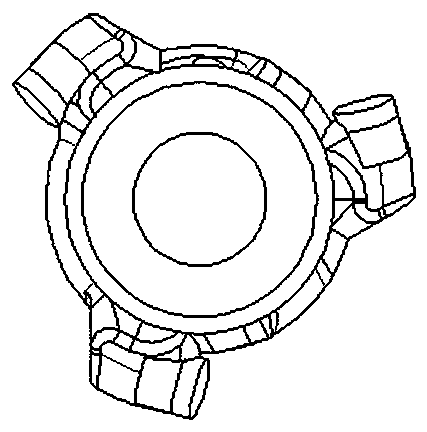

Embodiment 1

[0030] Embodiment one: step by step strengthening soft coal rock intensity drilling method, comprises the following steps:

[0031] ①. Take coal or rock samples at the site to be constructed, and determine the solidity coefficient of coal and rock through laboratory tests f ; Determination of coal seam gas pressure at the construction site p ;

[0032] ②. According to the solidity coefficient of coal and rock at the construction site f Determining the number of strengthening stages N of coal and rock mass and the length L of graded strengthening n , Grading Intensification Ratio d q-n ;Number of strengthened stages N is the number of segments of the coal-rock strengthened drill bit structure along the axial direction of the borehole, and the length of each segment is the graded strengthened length L n (n=1, 2, ..., n); graded strengthening ratio d q-n (n=1, 2,..., n) is the graded strengthening length L of the coal rock strengthening drill bit n The maximum diameter d...

Embodiment 2

[0042] Embodiment two: if Figure 7 ~ Figure 8 As shown, the difference from Example 1 is that the number of strengthening stages of coal and rock mass is 4, which is beneficial to improve the step-by-step strengthening effect.

Embodiment 3

[0043] Embodiment three: as Figure 9 ~ Figure 10 As shown, the difference from Example 1 is that the number of strengthening stages of the coal and rock mass is 5, and the middle section of the step-by-step strengthening body 11 is designed to be cylindrical, which is conducive to further stabilizing the strengthening effect of the front section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com