Bolting and injecting quality evaluation method for underground engineering

A technology for underground engineering and quality evaluation, which is applied in the direction of earthwork drilling, installation of bolts, instruments, etc., can solve the problems of inability to take cores, broken surrounding rock, etc., to achieve comprehensive evaluation results, overcome inaccuracy, and evaluation methods more novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

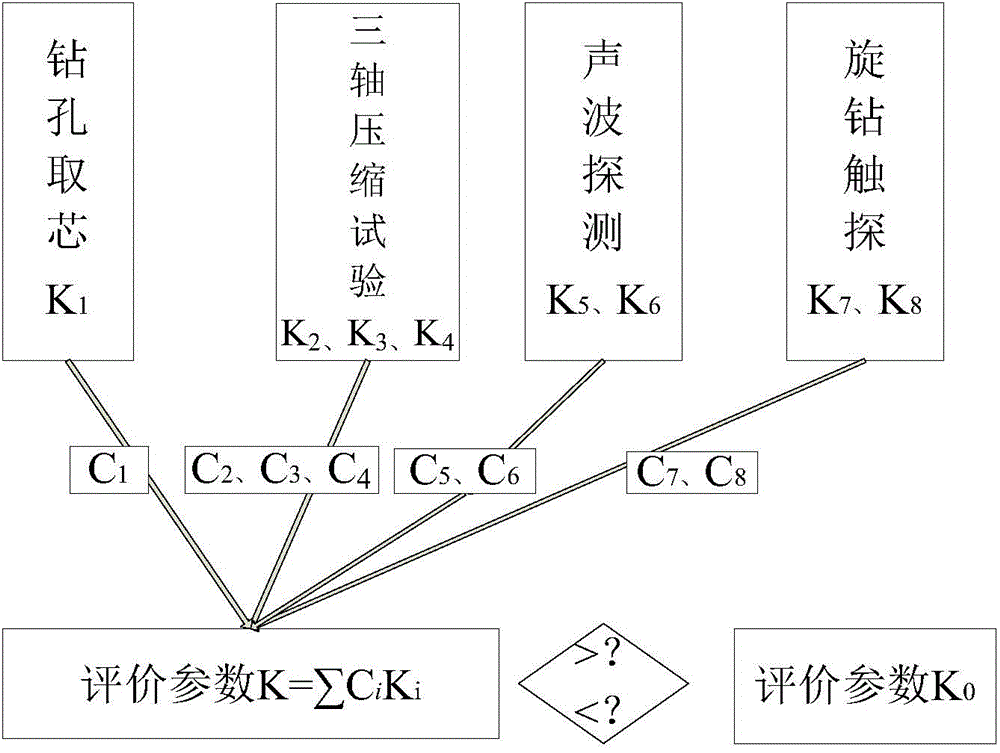

Method used

Image

Examples

Embodiment approach

[0055] Step 1: Surrounding rock detection scheme design before and after grouting;

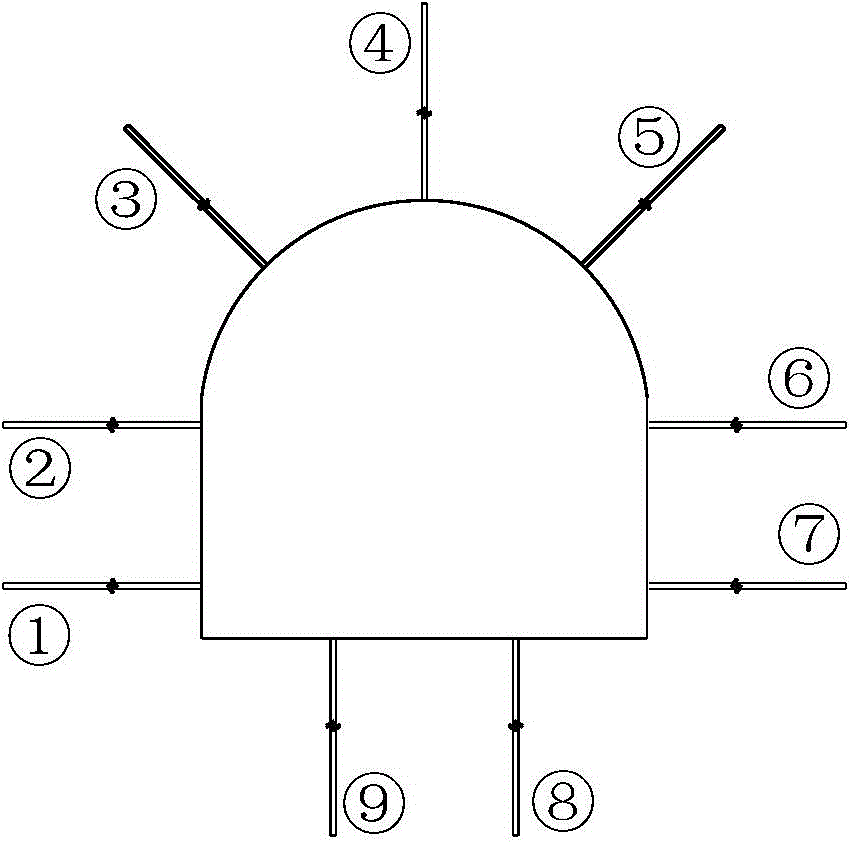

[0056] According to the geological conditions of the underground cavern site, section size and grouting parameters, design the surrounding rock detection plan before and after grouting, determine the number of drilling holes, orientation, diameter, depth, length of detection area, height and other parameters, and arrange n in different sections drill holes. Such as figure 2 As shown, ①~⑨ are the drilling numbers of the surrounding rock.

[0057] The second step: data collection before grouting;

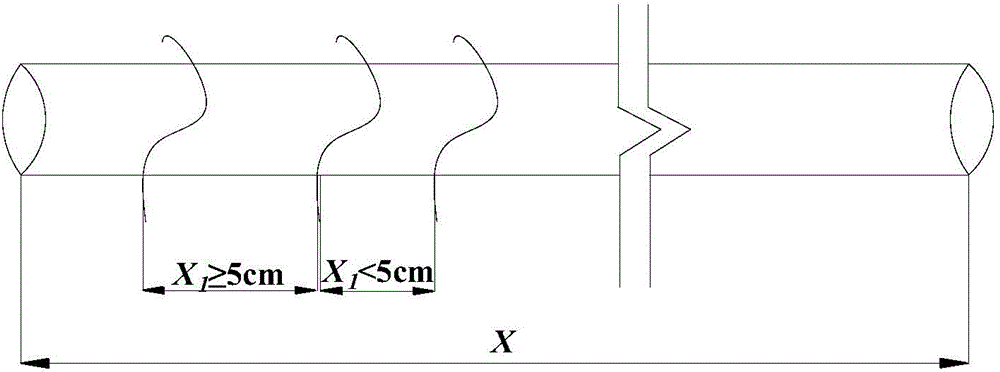

[0058] Diamond drill bits and double-layer core tubes are used to drill in the surrounding rock, and cores are taken continuously, the coring length is counted, and the coring rate QXL of the surrounding rock is calculated; the triaxial compression test of the surrounding rock specimen is carried out indoors, and the calculation test angle of internal friction Cohesion c and residual strength σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com