Large-scale complex surrounding rock condition bolt-grouting integrated coupling effect test system and method

An anchor-grouting integration and test system technology, which is applied to the installation of anchor rods, soil material testing, earth drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

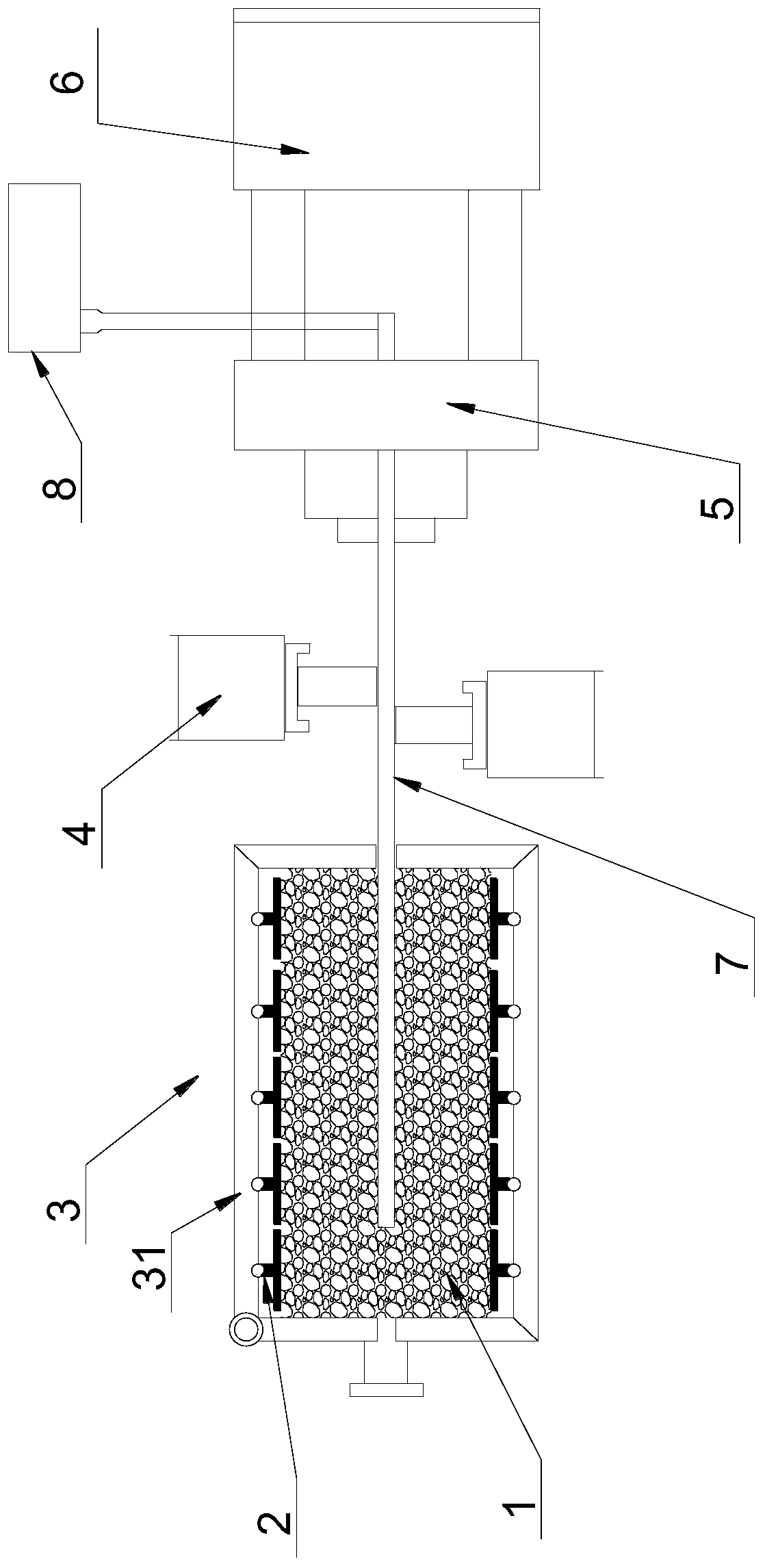

[0050] Such as figure 1 As shown, a large-scale and complex surrounding rock condition anchoring and grouting integrated coupling test system includes an underground simulation system 3; wherein the underground simulation system 3 includes: a sealed box 31, and several uniformly arranged on the inner wall of the box 31 The lateral pressure unit 2 that independently provides lateral extrusion force, wherein the lateral pressure unit 2 is uniformly arranged on the inner wall, facilitates pressure on the coal rock mass 1 in the sealed box 31 through the side wall, and the box 31 is filled with coal Rock mass 1; wherein, the lateral pressure unit 2 includes: several extrusion plates that are controlled by hydraulic cylinders and perform telescopic movement relative to the inner space of the box body 31 . Specifically, the specific struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com